Gunpowder ethyl alcohol blending unit

A technology of alcohol and unit, applied in mixers, mixers with rotating stirring devices, pyrotechnics, etc., can solve problems such as low efficiency, large alcohol consumption, and flying dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

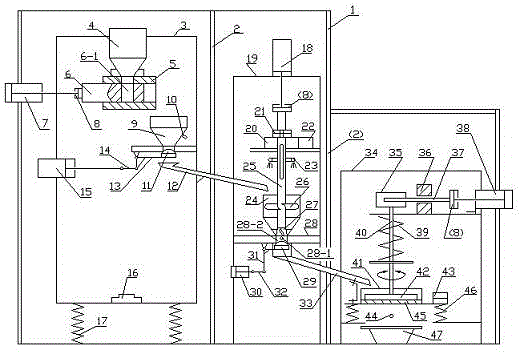

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0017] see figure 1 , figure 2 , the hood 1 is divided into three areas by two partitions 2, and the quantitative grouping frame 3 and the alcohol mixing frame 19 are respectively arranged, and the opening at the bottom is connected with the radial hole of the quantitative valve body 5 and the quantitative control of the quantitative shaft 6. The hole 6-1 is connected, one end of the metering shaft 6 is connected to the cylinder 7 through a T-shaped fork 8 and can slide in the valve body 5, the other end of the metering shaft 6 is provided with a receiving hopper 9, and the side wall of the receiving hopper 9 is provided with There is a sensor 10, the opening at the bottom of the receiving hopper 9 is flexibly connected with the first plug 11, and is closed or opened under the drive of the first lever 13, the first connecting rod 14 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com