Proportional layering fertilizer applying device

A layered fertilization and proportional technology, applied in fertilization devices, fertilizer distributors, agricultural gas emission reduction, etc., can solve the problems that crops cannot fully absorb nutrients, increase food production costs, and volatilize and lose chemical fertilizers. Easy adjustment and control, high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

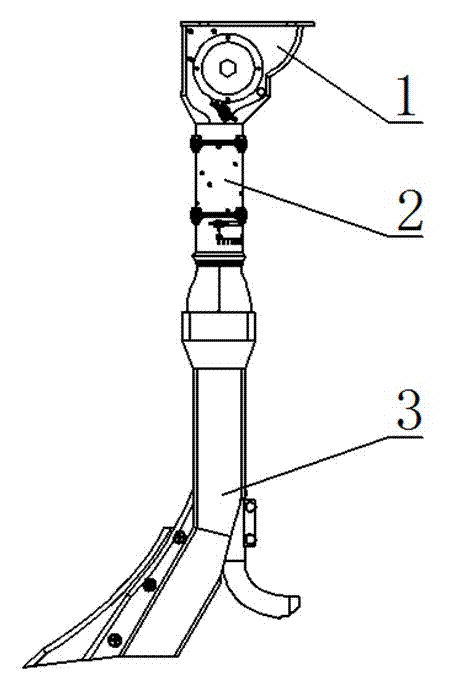

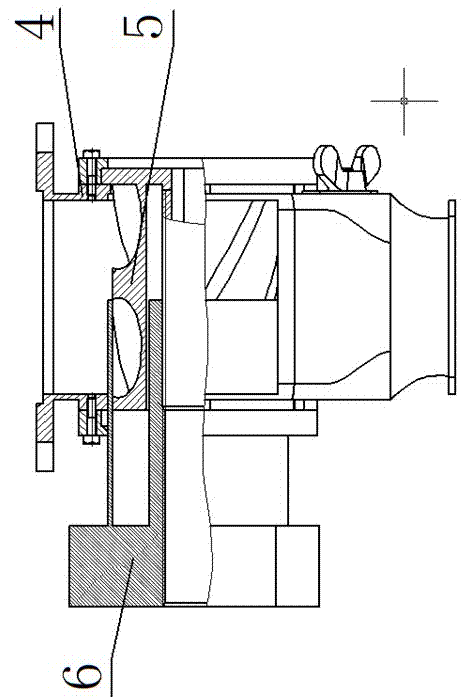

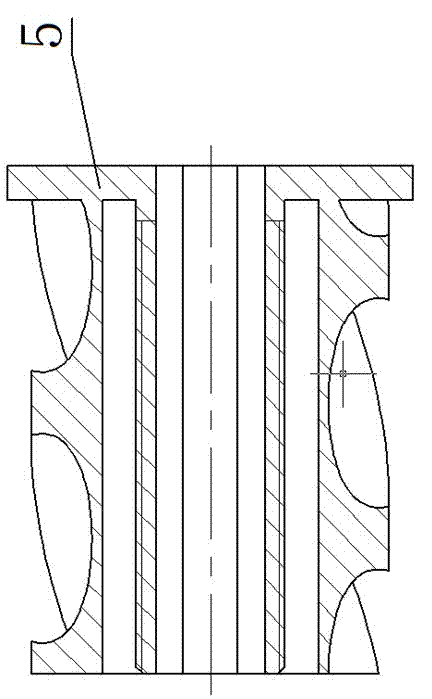

[0012] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. The proportional layered fertilization device includes an outer grooved wheel fertilizer discharger 1, a fertilizer volume control and distribution assembly 2 and a layered fertilizer applicator 3, which are sequentially connected and assembled from top to bottom. The outer grooved wheel type fertilizer discharger 1 consists of a shell 4. The helical outer sheave 5 and the fertilization amount control sleeve 6 are composed. The helical outer sheave 5 is installed in the housing 4, and the inner thread on the fertilization amount control sleeve 6 and the helical outer groove The outer thread connection on the wheel 5 is matched to axially move the fertilization amount control sleeve 6 on the side of the helical outer sheave 5, and the cylindrical barrel-shaped outer wall of the fertilization amount control sleeve 6 is connected to the helical outer sheave....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com