Electronic component transfer loading device and method

A technology of electronic components and transfer devices, which is applied in the direction of measuring devices, electronic circuit testing, measuring electricity, etc., can solve the problems of increasing production costs, affecting test quality, poor level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

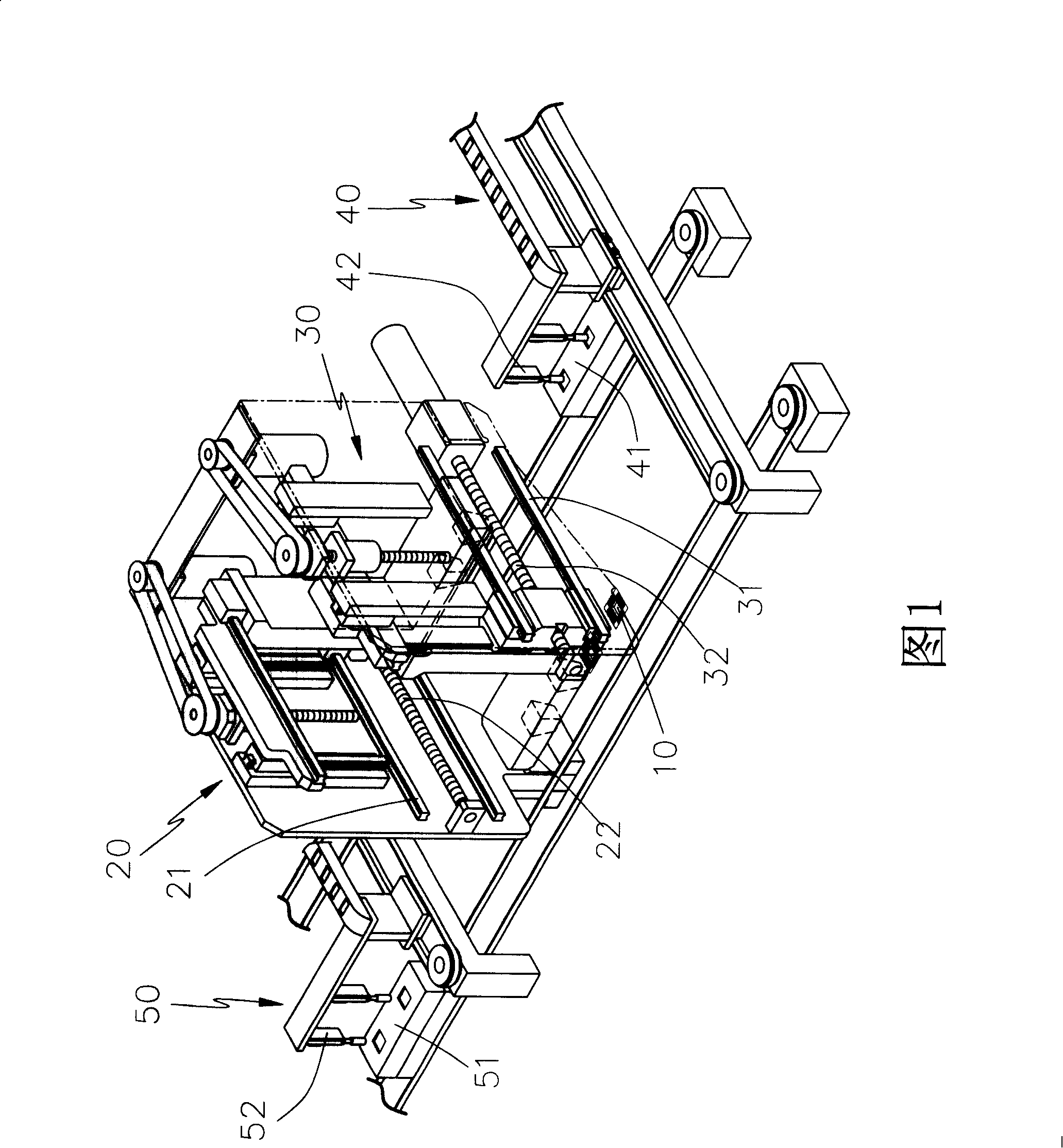

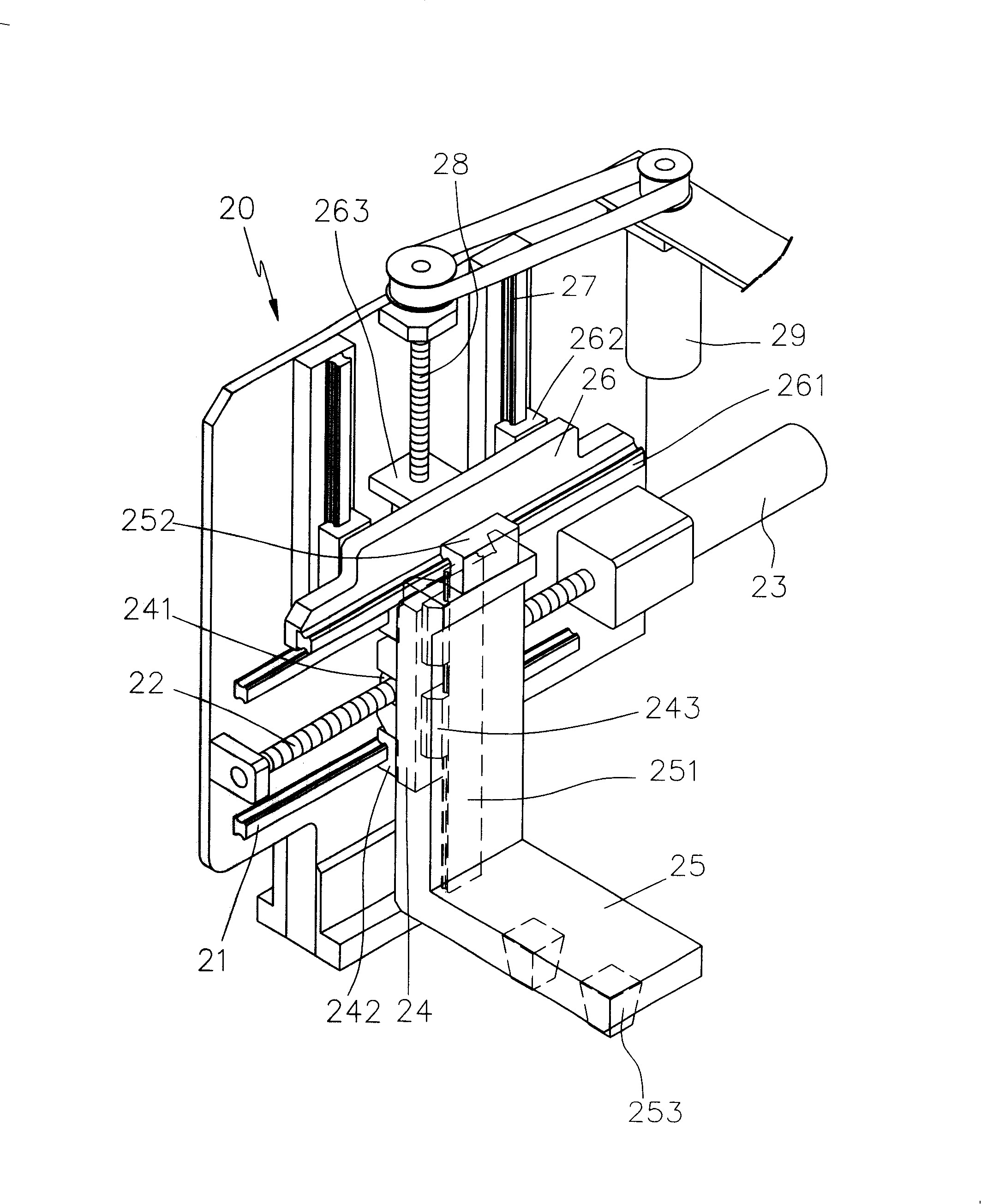

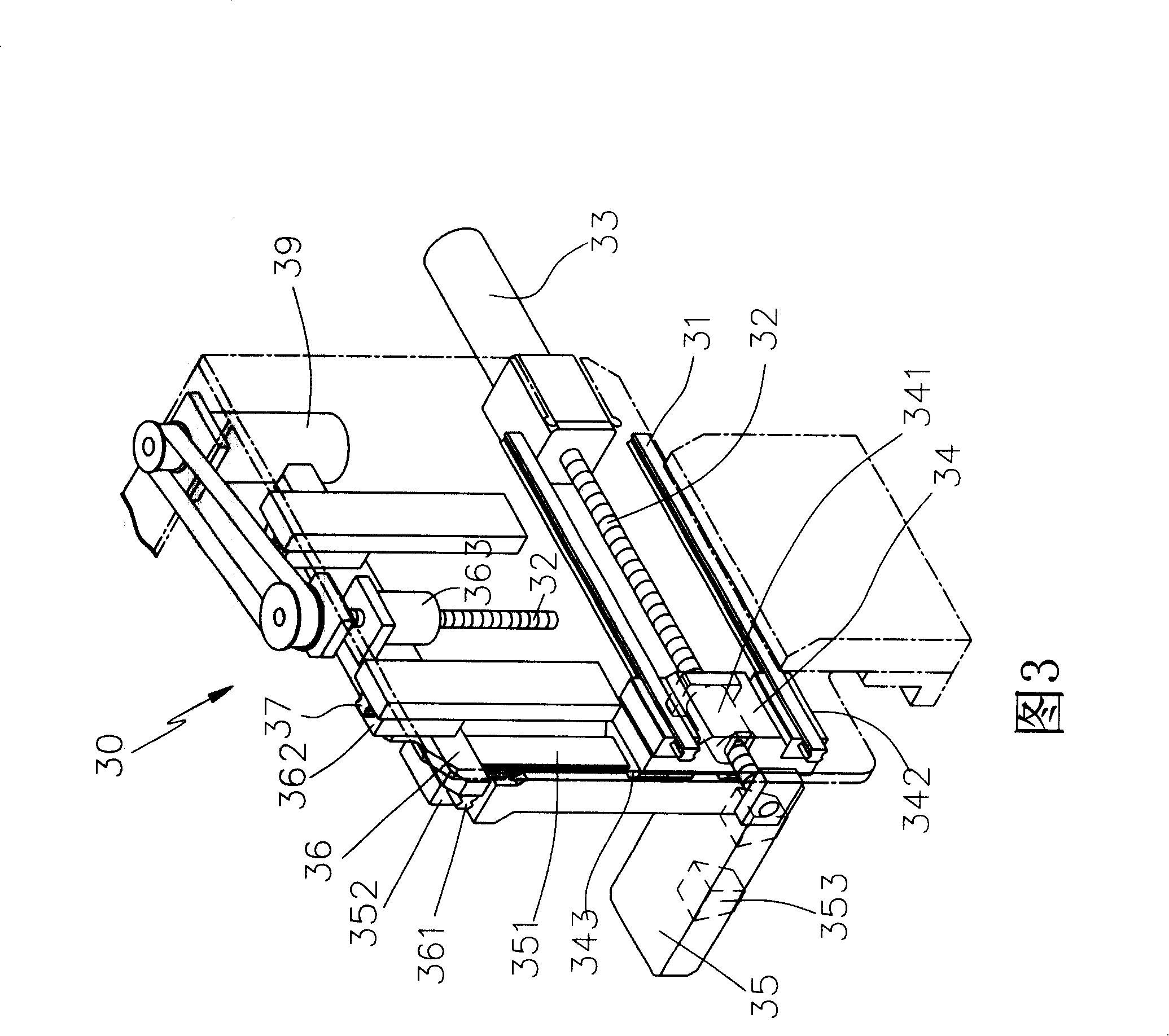

[0026] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0027] Please refer to Fig. 4, when the present invention is configured in a test classifier, the test classifier includes a feeding mechanism 60, an input conveying mechanism 70, a work station area 80, an output conveying mechanism 90 and a receiving mechanism 100 The input end conveying mechanism 70 is to transport the electronic components to be detected on the feeding mechanism 60 to the first and second feeding carriers 81, 82 in the operation area 80 respectively, and the first and second receiving carriers in the operation area 80 The tested electronic components on the material carriers 83 and 84 are transported by the output conveying mechanism 90 to the receiving mechanism 100 for sorting and placing according to the test results.

[0028]Referring to Fig. 5 and Fig. 6, the operation area 80 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com