Tableware stamping and automatic feeding device

A technology of automatic feeding and stamping devices, applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems of workers prone to danger, labor consumption, limited output, etc., to shorten production time, improve production efficiency, and production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

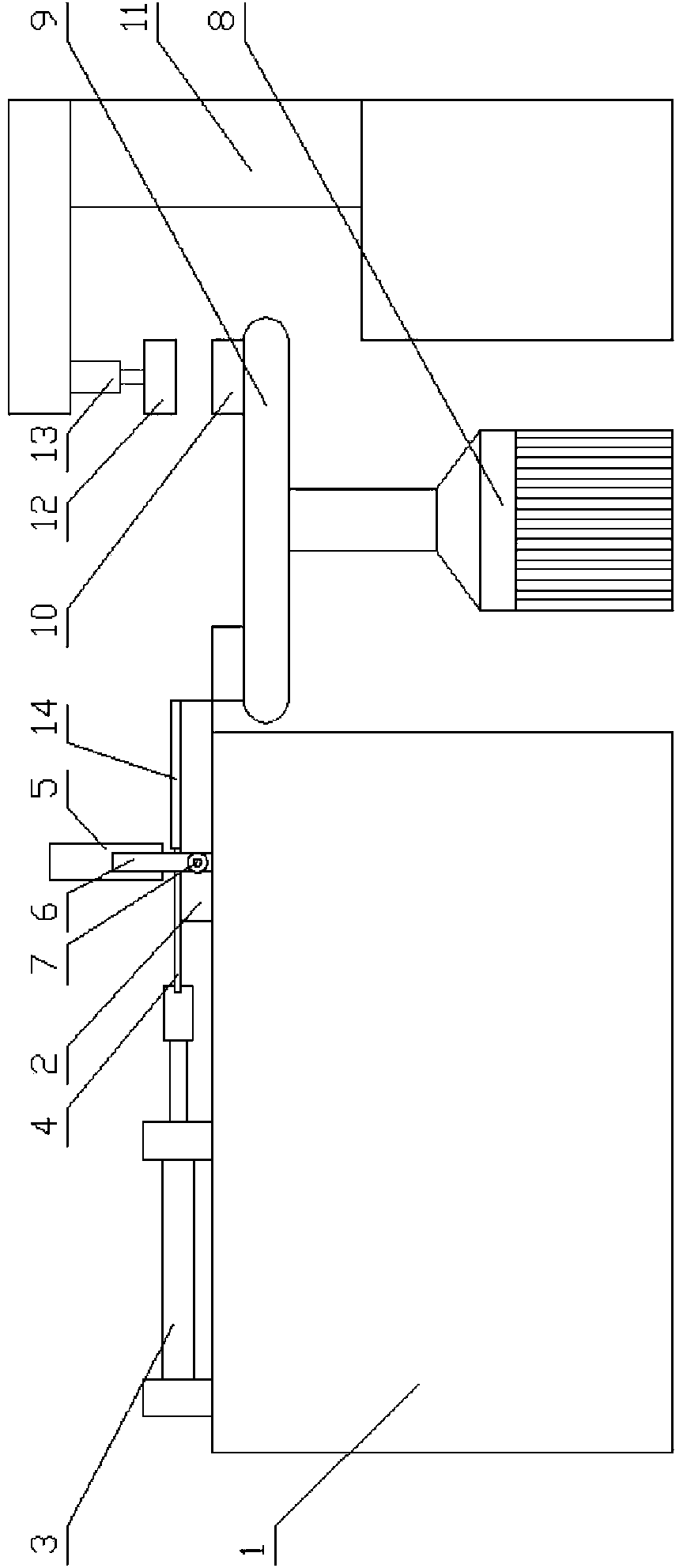

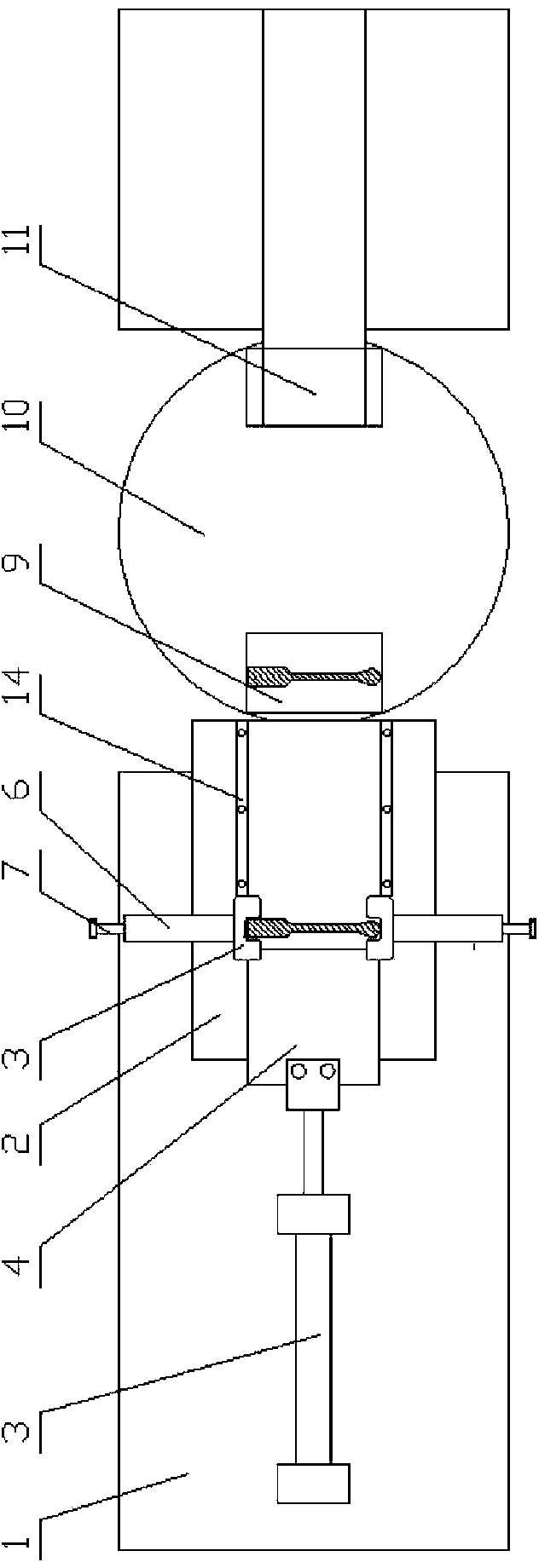

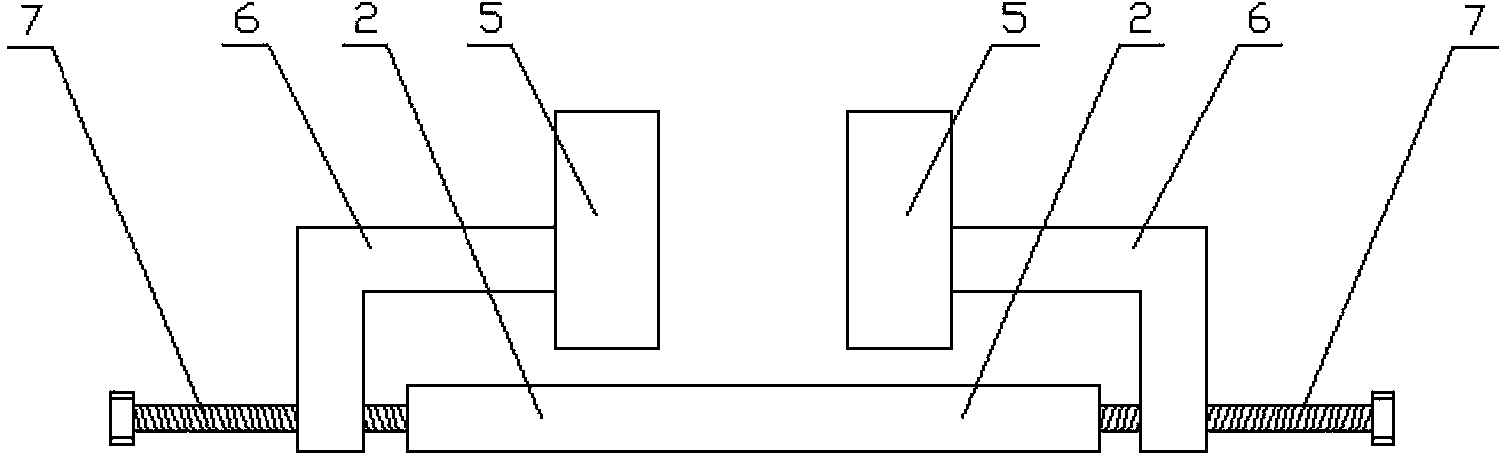

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] like Figure 1-Figure 3 As shown in the structural diagram of the present invention, the present invention provides a tableware stamping automatic feeding device, comprising a pushing device, a rotary feeding device, a storage device and a stamping device, the pushing device, a storage device, a rotary feeding device and a stamping device The device is set up in order, and the pushing device includes a base 1, a feeding plate 2 and a pushing cylinder 3, and the pushing cylinder 3 is installed on the upper surface of the base 1 side, and the front end of the pushing cylinder 3 is equipped with The horizontal push plate 4, the feeding plate 2 is horizontally arranged on the upper surface of the other side of the base 1, and the upper surface of the feeding plate 2 is oppositely provided with a guide rod 14. The material storage device includes a material storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com