Patents

Literature

40results about How to "Extend continuous operation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

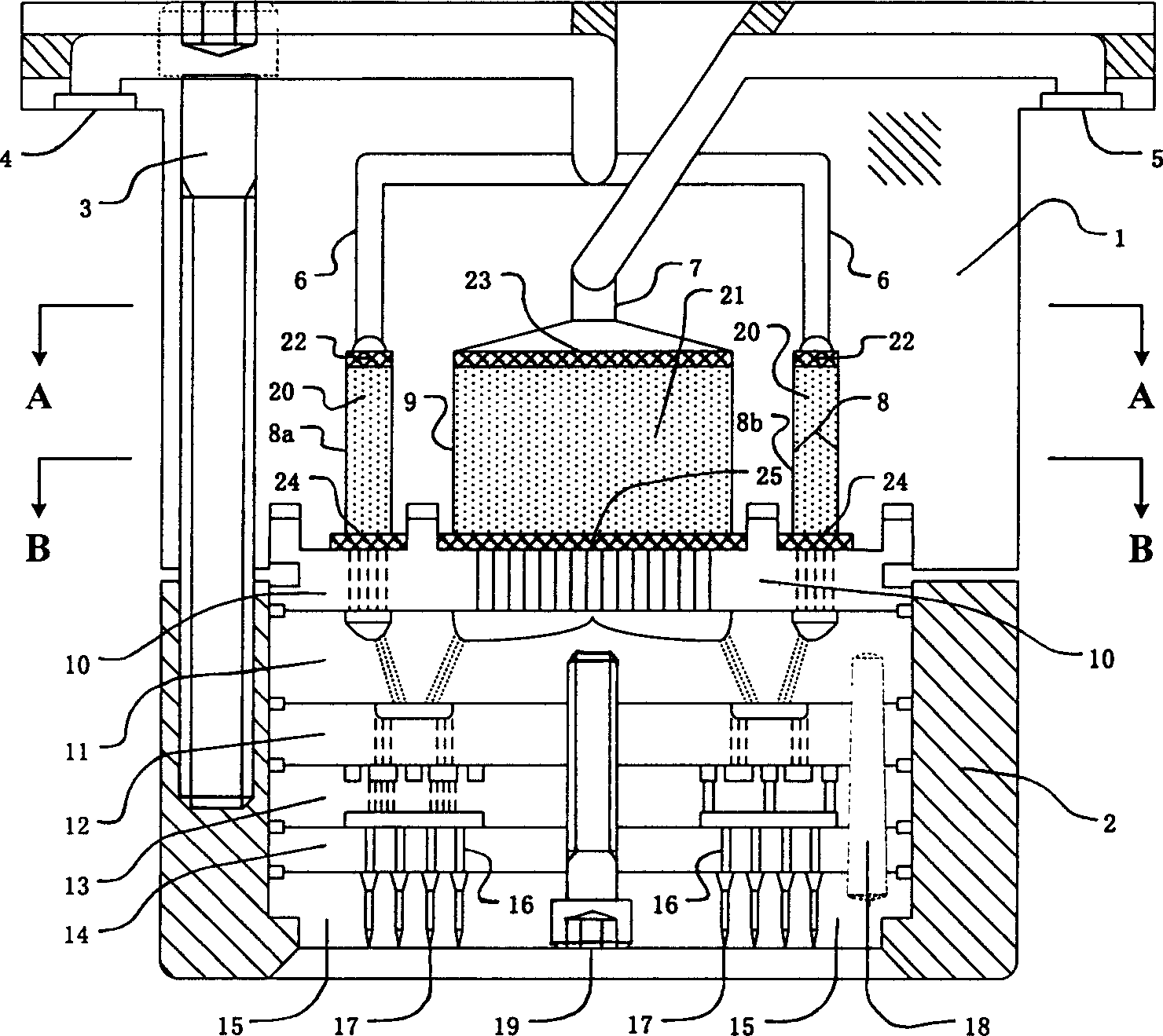

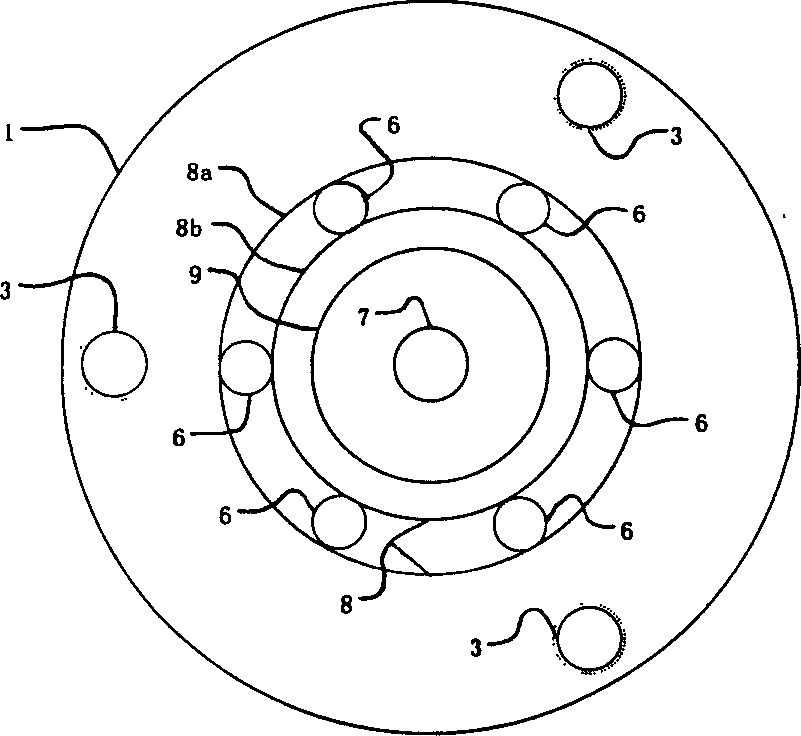

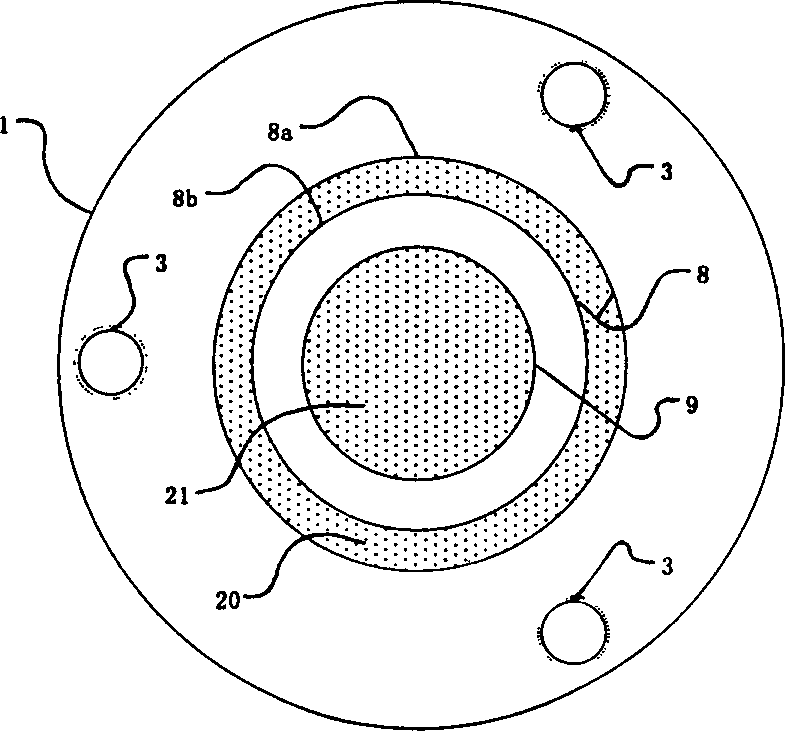

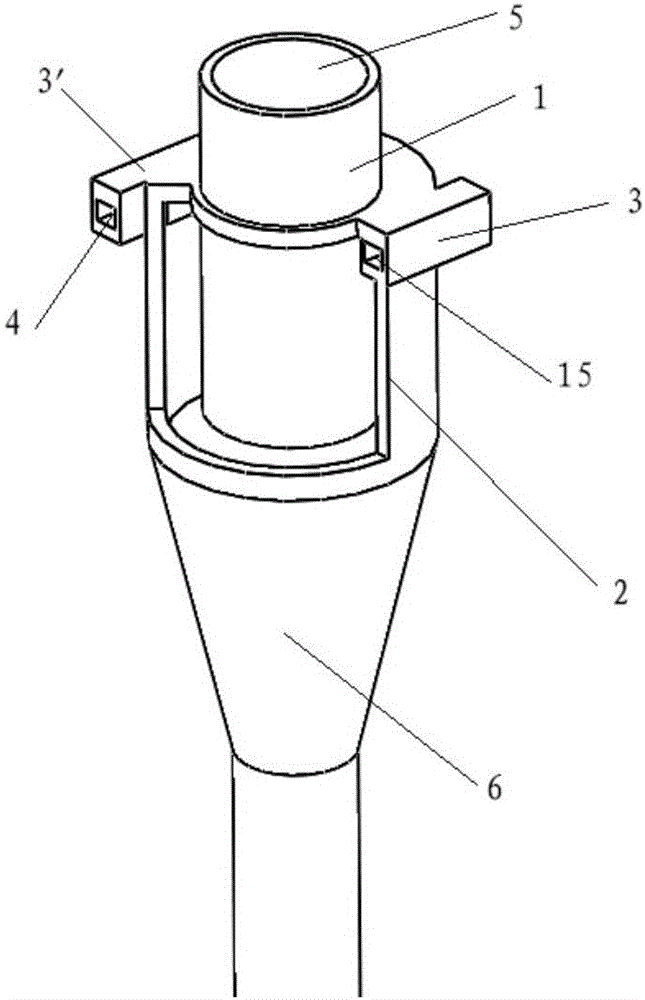

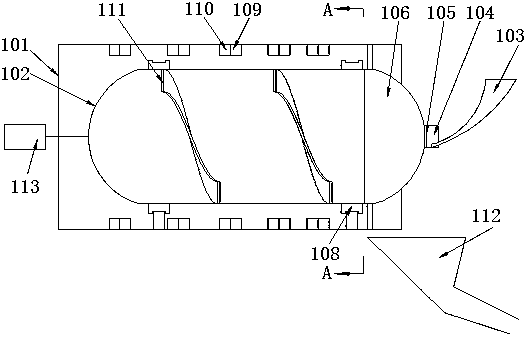

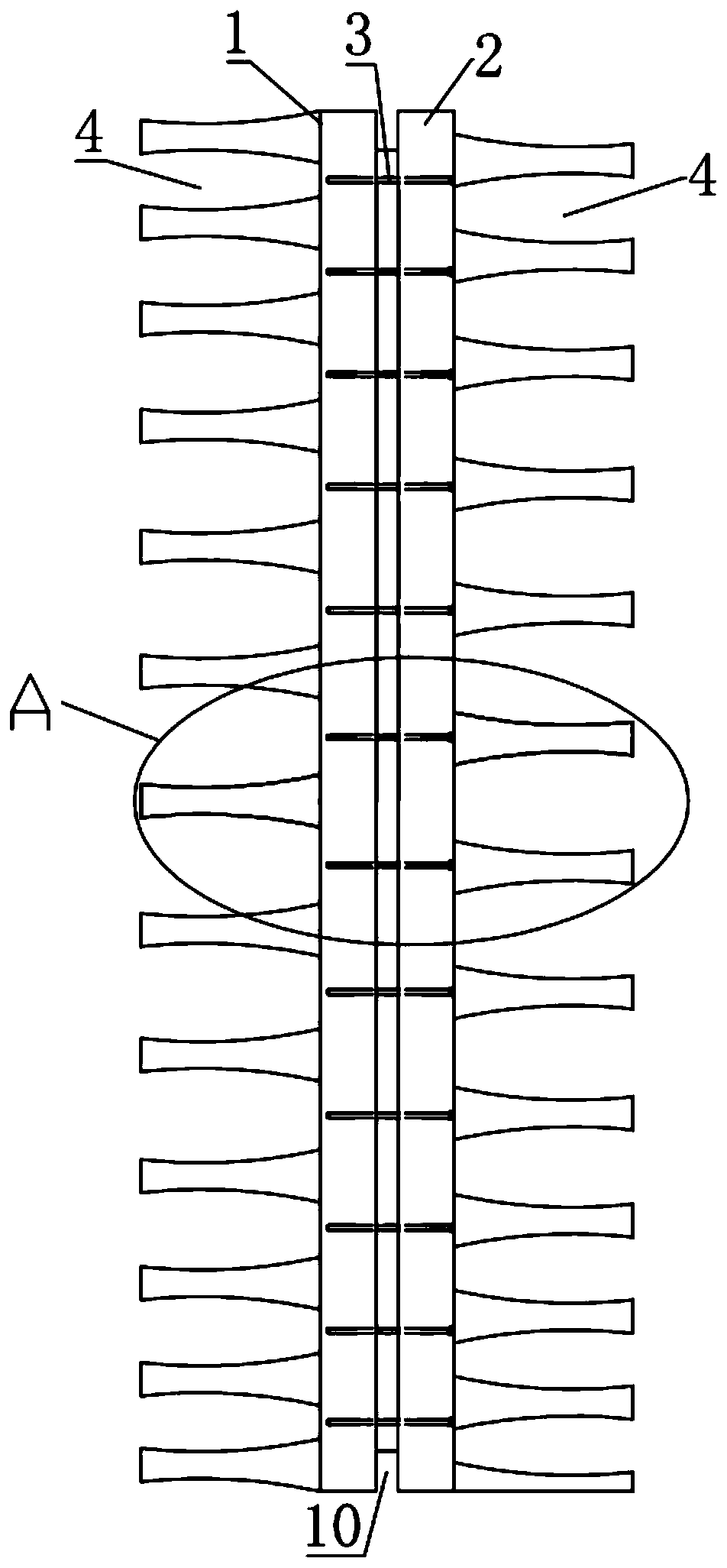

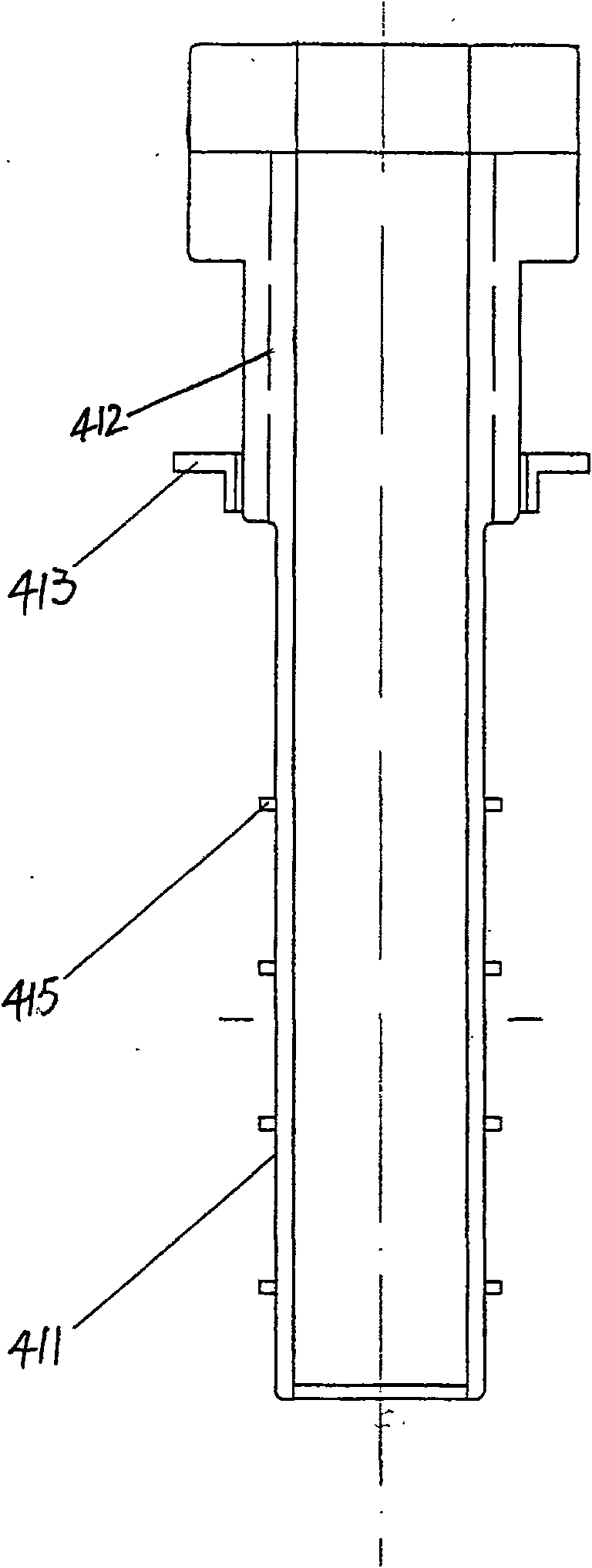

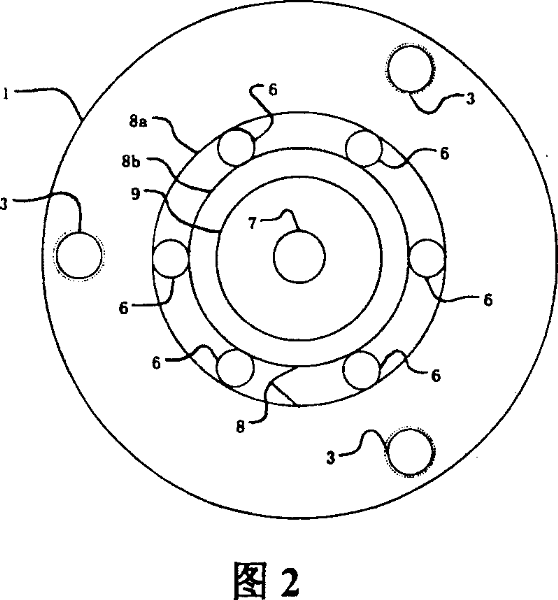

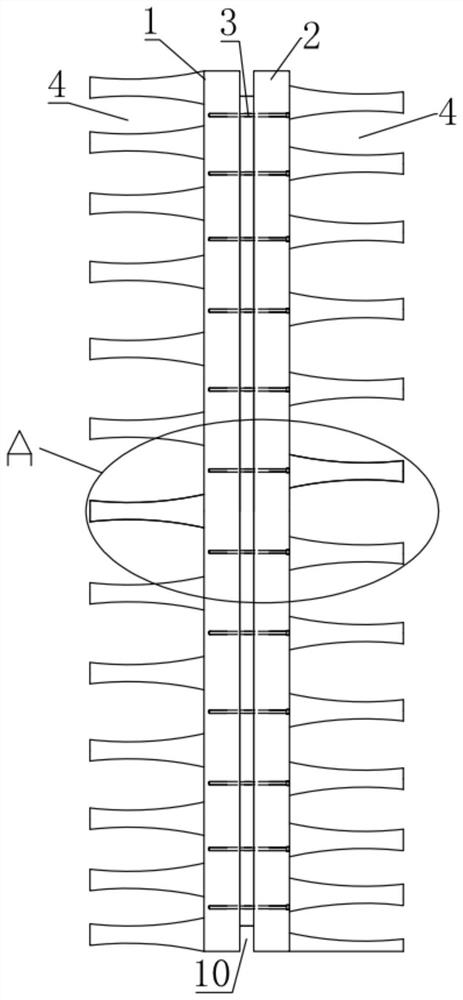

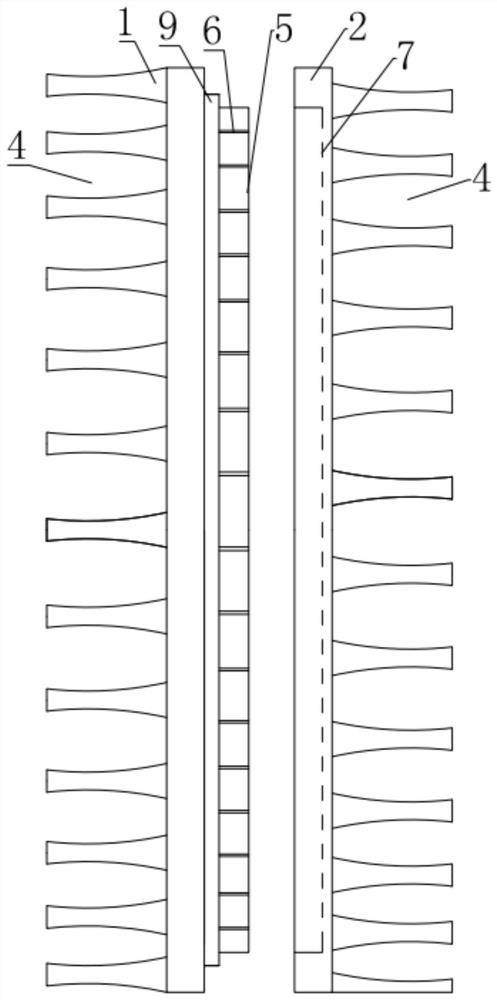

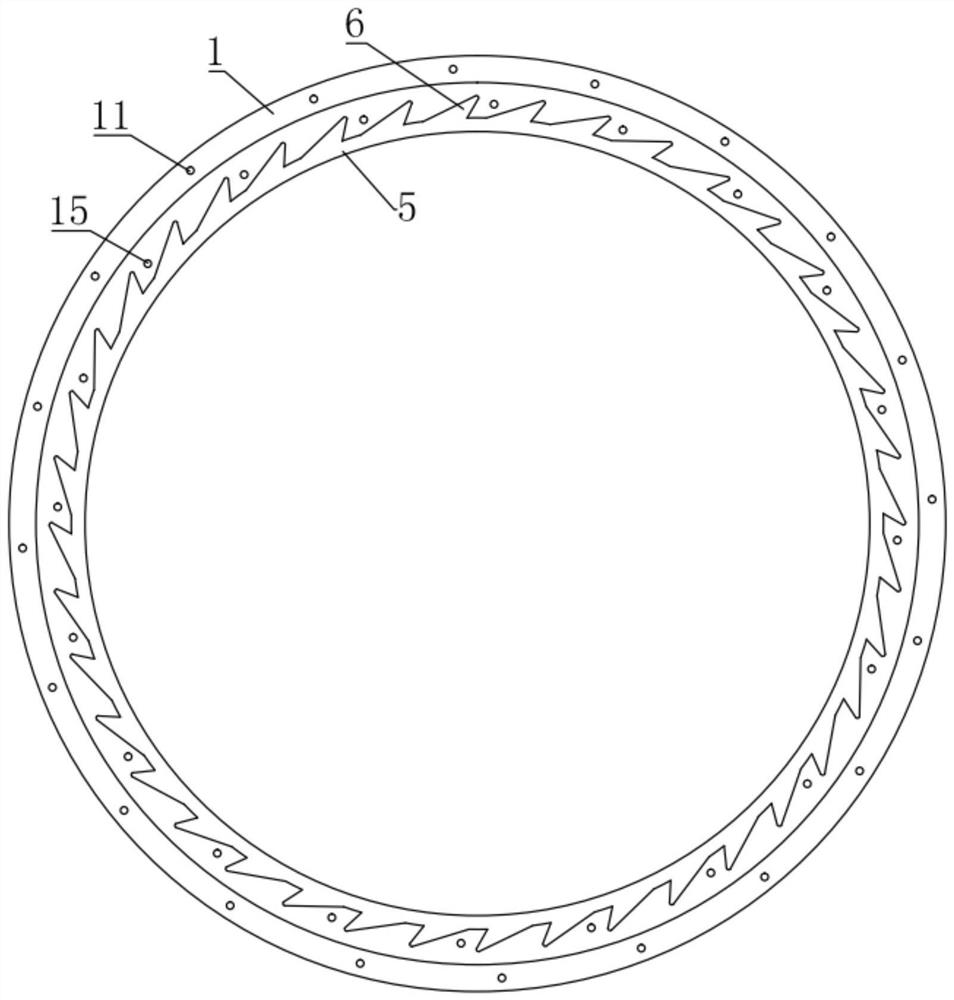

Composite spinning component entities including double constituents

ActiveCN1563523AExtend continuous operation timeReduce labor intensityFilament/thread formingFiltrationEngineering

This invention discloses a bi-component compound fiber spinning component including an up and down shell, a sand pool, a ring sand cavity, a bearing plate, a series distribution plate, a composite plate and a fiber spraying plate characterizing that the sand pool and the ring sand cavity are coaxial filtering melts of the bi-component separately and serial pin holes are designed on the third distributing plate in the lower shell, pin tubes are mounted in the holes, bottoms of the tubes are set in composite holes matched to duplate which are greatly increase filtration areas of the two melts.

Owner:SINOPEC YIZHENG CHEM FIBER

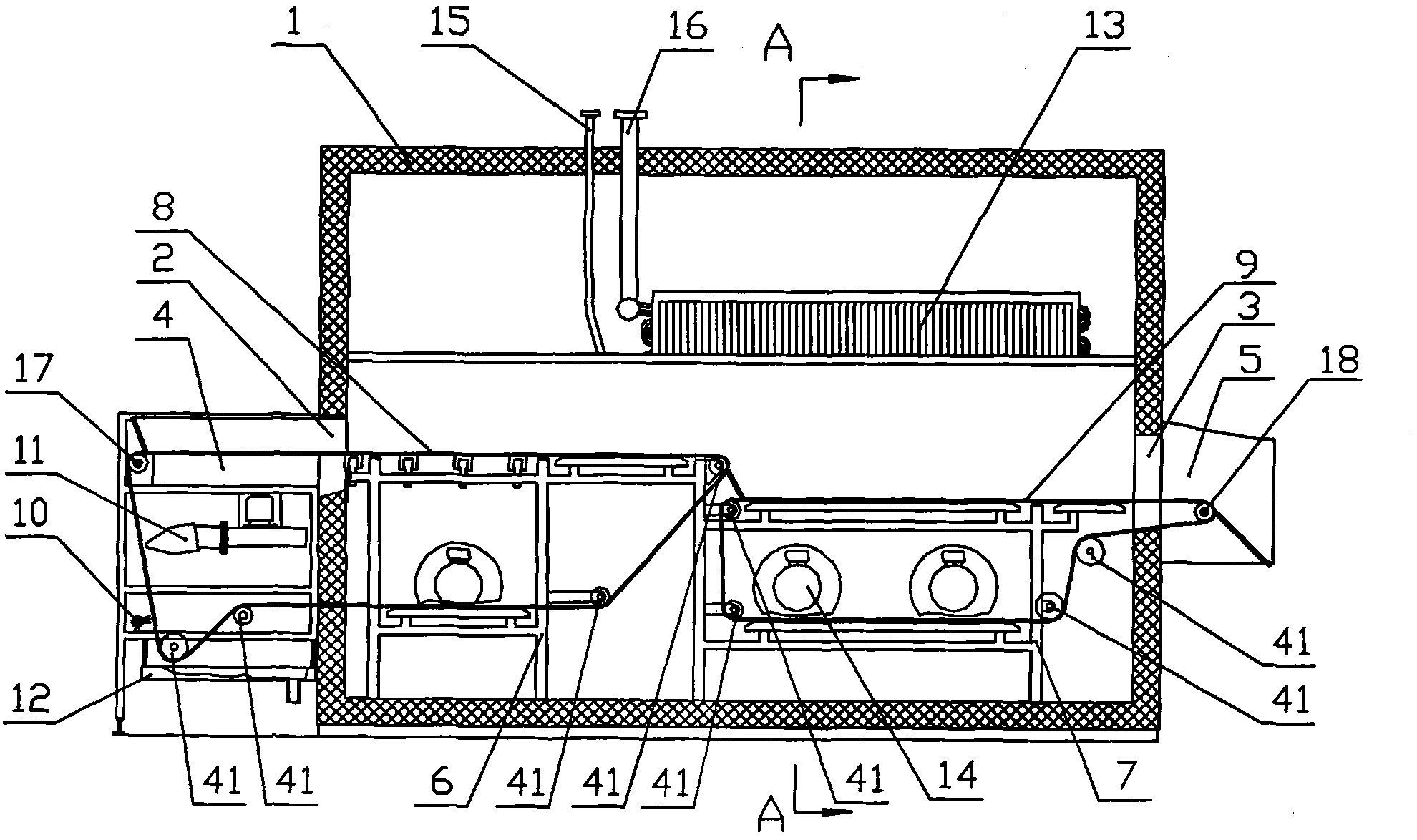

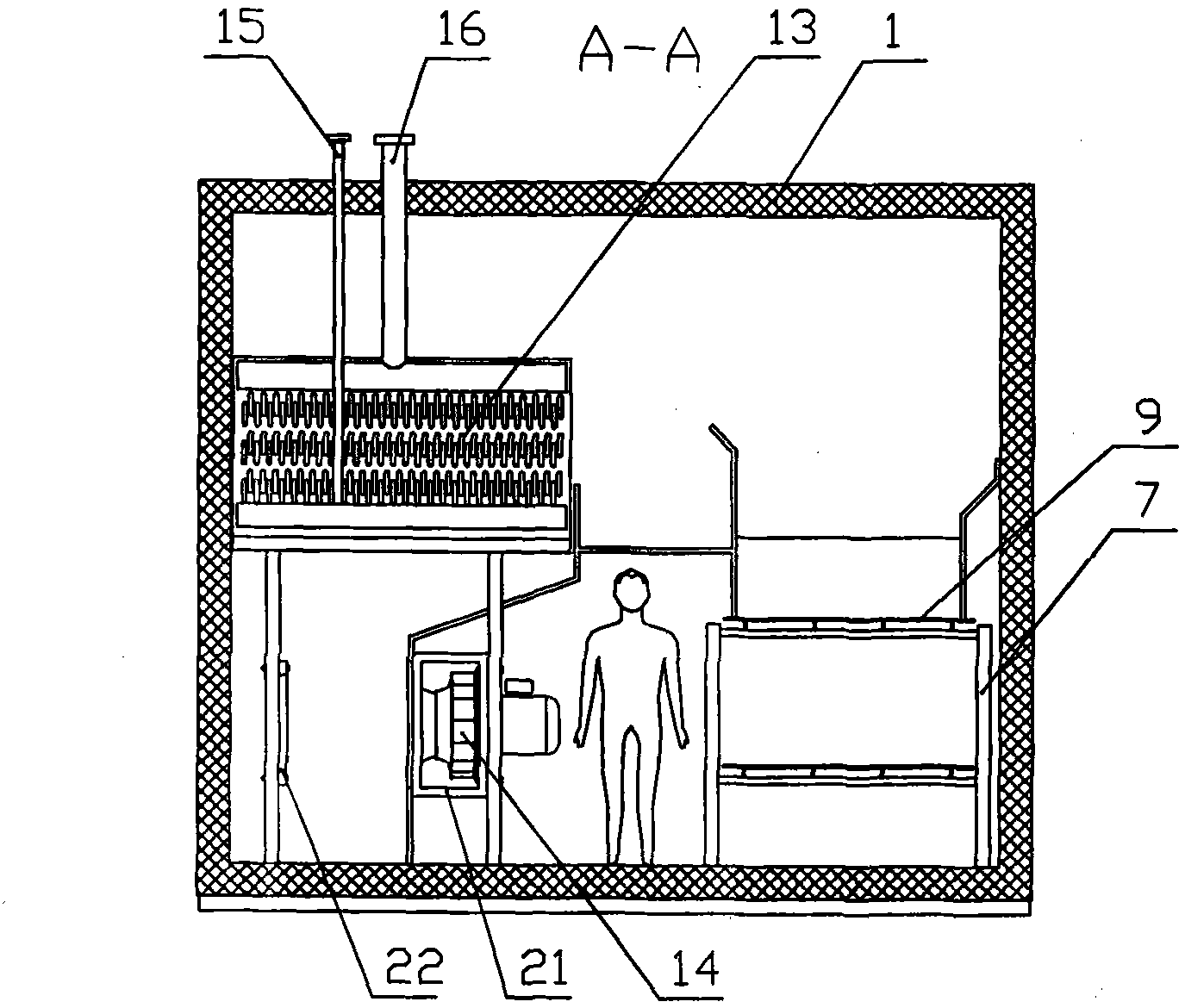

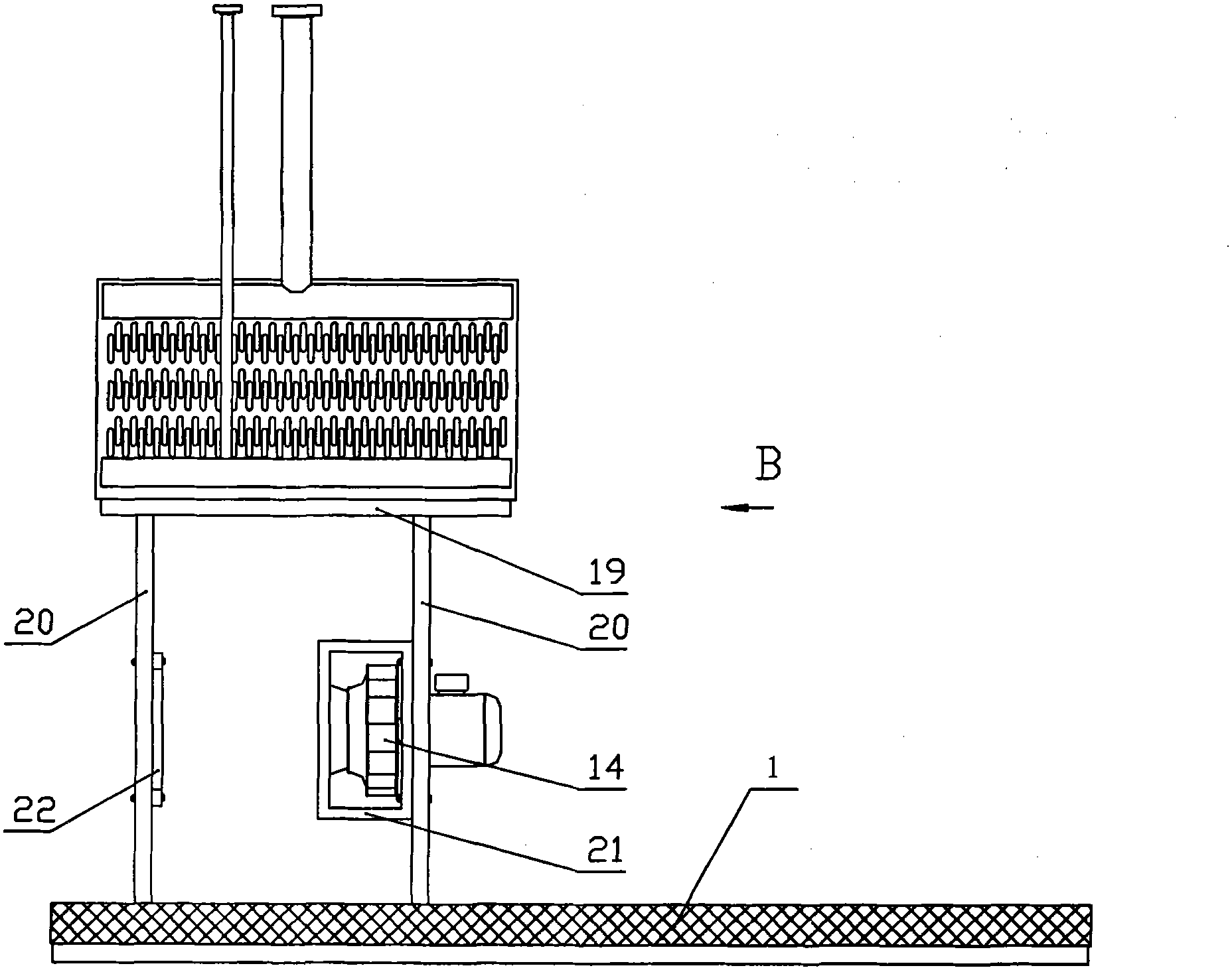

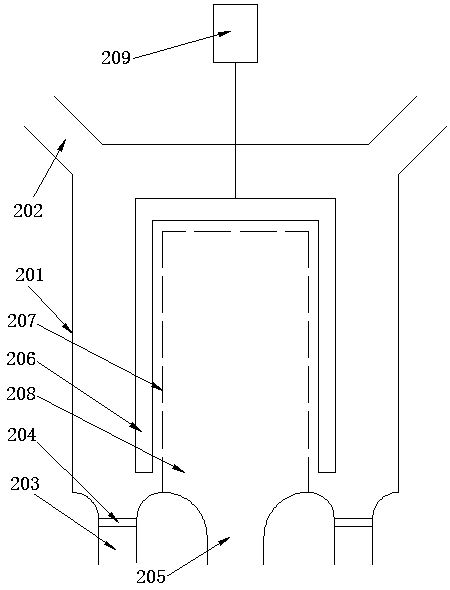

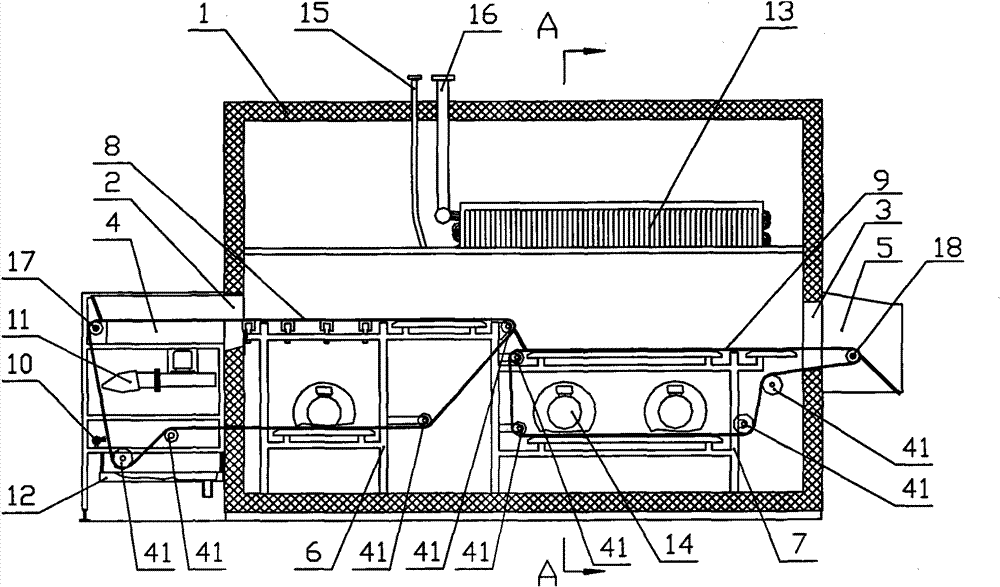

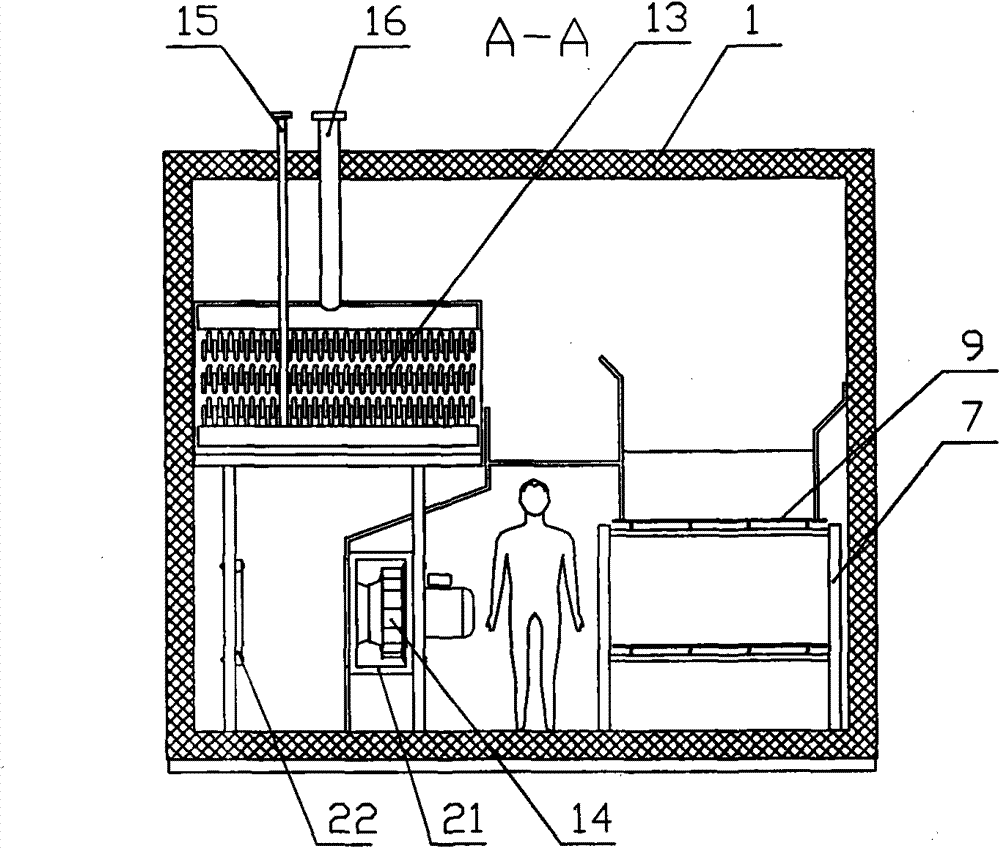

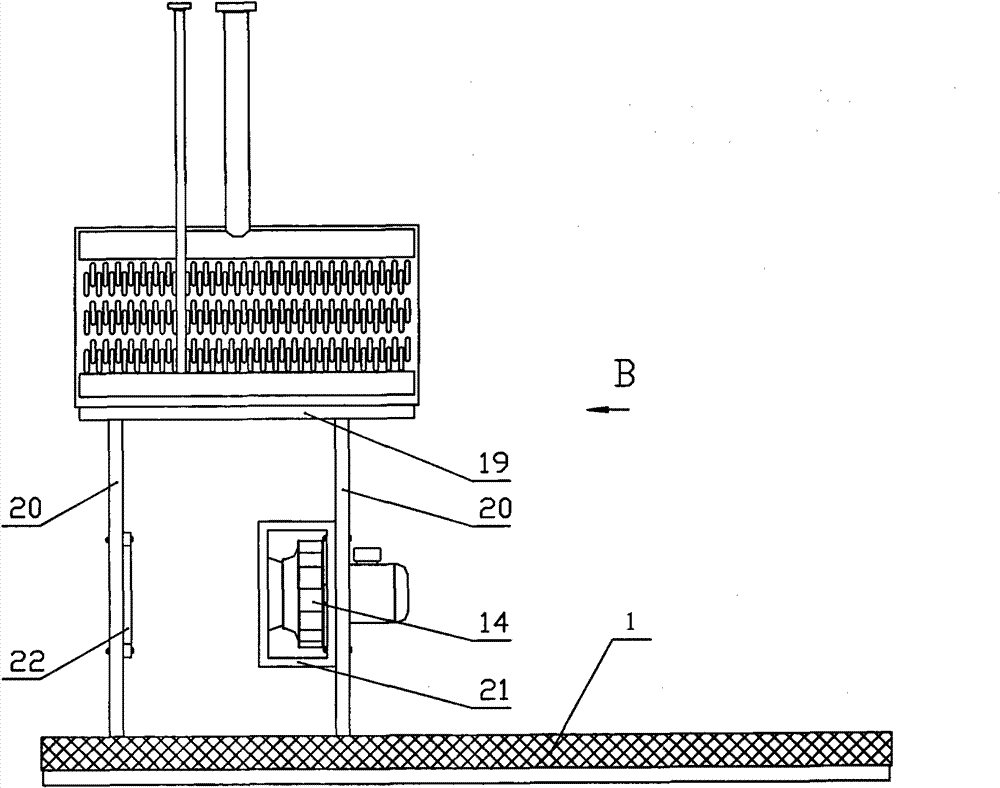

Freezing device

ActiveCN101881545AImprove securityStable structureLighting and heating apparatusStationary refrigeration devicesEngineeringRunning time

The invention discloses a freezing device comprising a heat insulating tank body, a feeding mechanism, a discharging mechanism, two conveying belts, a conveying belt stand, a top-blowing evaporator and a horizontal type centrifugal fan, wherein the feeding mechanism and a discharging mechanism are respectively arranged on a feed port and a discharge port of the heat insulating tank body, and the two conveying belts, the conveying belt stand, the top-blowing evaporator and the horizontal type centrifugal fan are arranged in the heat insulating tank body; a supporting rod is arranged below a cross beam of a support of the top-blowing evaporator, the supporting rod, the cross beam and the heat insulating tank body are fixedly connected to form a stressed member, and a frame-shaped fan stand is fixedly arranged on the supporting rod of the stressed member to form a stressed frame; an anti-icing bracket is arranged below the frozen conveying belt, a steam heating wind-shielding device is arranged below the conveying belt at the feeding port, the bottom of the feeding mechanism is provided with a conveying belt heating-up water tank, and a conveying belt tensioning shaft roll is arranged at the discharging mechanism. The invention has the advantages of stable structure, safe installation process of the evaporator and convenient use and also has the advantages of eliminating the phenomenon of icing under the conveying belts, prolonging the continuous running time of the freezing device and improving efficiency; and besides, because the low-temperature conveying belt is washed after immersed in the water tank and heated up, less water consumption and good cleaning effect are achieved.

Owner:SIFANG TECH GRP CO LTD

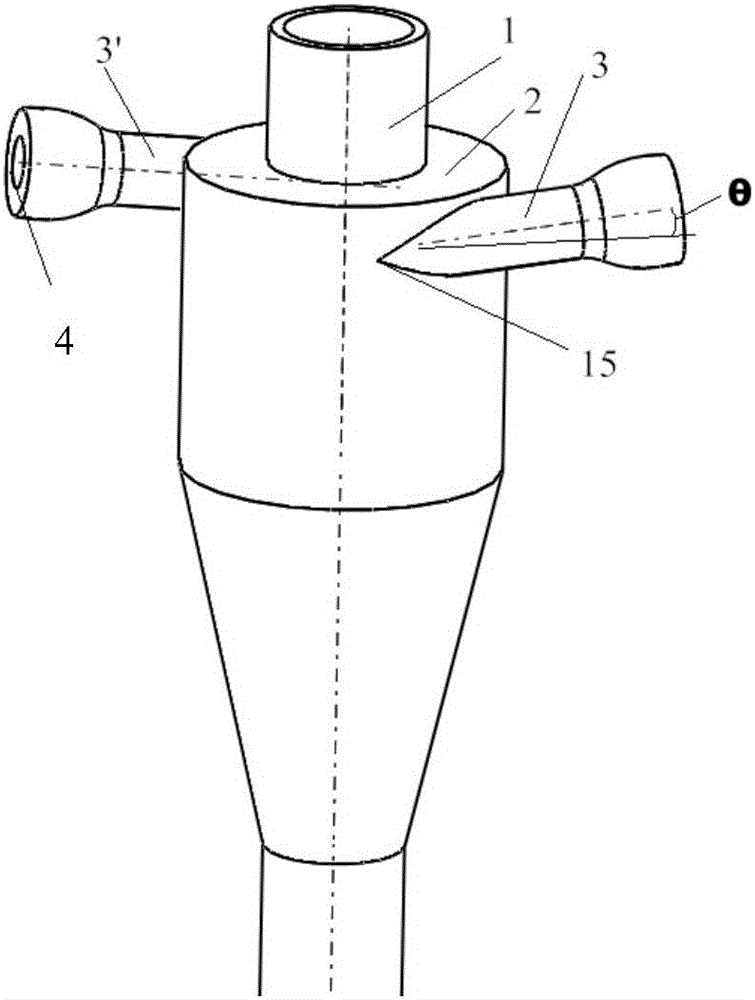

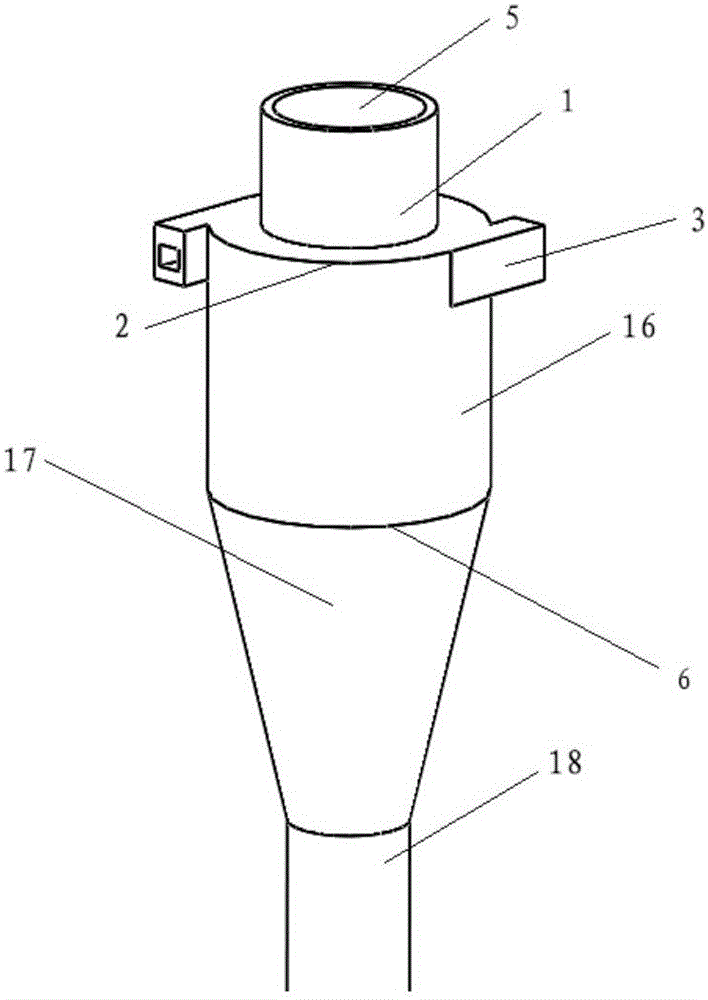

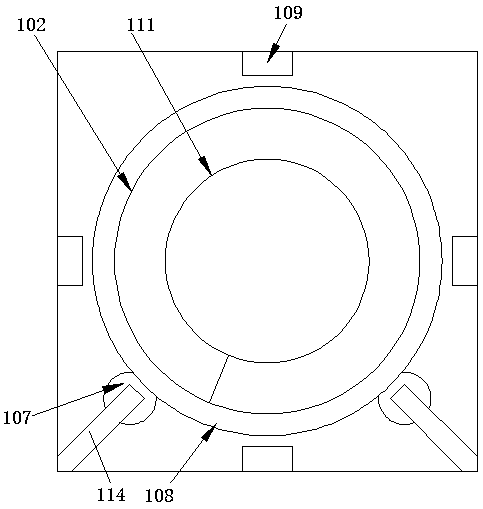

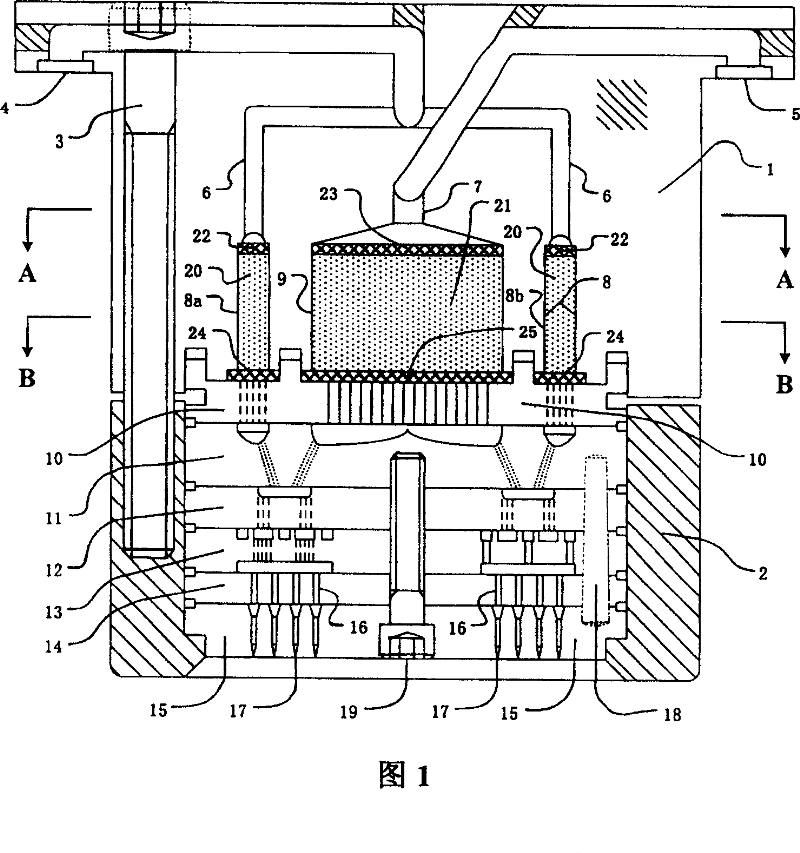

Micro cyclone separator with double-side air inlet function and high-pressure separation device adopting separator

InactiveCN105903580AIncrease media handling capacityHigh speedReversed direction vortexCycloneEngineering

The invention provides a micro cyclone separator with a double-side air inlet function and a high-pressure separation device adopting the separator. The micro cyclone separator with the double-side air inlet function comprises an inner pipe and an outer pipe. An air outlet of the cyclone separator is formed in the top of the inner pipe. Part of the lower portion of the inner pipe enters the upper portion of the outer pipe. The top of the outer pipe is connected with the outer wall of the inner pipe in a sealing mode. The micro cyclone separator is characterized in that two air inlets communicating with the interior of the outer pipe are formed in the top of the outer wall of the outer pipe, and the two air inlets extend in the tangential direction of the outer wall of the outer pipe correspondingly and are distributed in a central symmetry mode. By means of the double-side air inlets which are distributed in the tangential direction in the central symmetry mode, the air inlet area is effectively increased, the air inlet efficiency is improved, the medium treating capacity is improved, the pressure drop is reduced, and the separation efficiency is improved.

Owner:BEIJING YUANCHENG IND SAFETY TECH CO LTD

Piston rod steel

The invention discloses a piston rod steel. The piston rod steel comprises 0.37-0.45wt% of C, 0.17-0.37wt% of Si, 0.50-0.80wt% of Mn, 0.035wt% or less of S, 0.035wt% or less of P, 0.25wt% or less of Cr, 0.25wt% or less of Ni, 0.25wt% or less of Cu, below 0.1% of other inevitable impurities, and the balance Fe. The piston rod steel has the advantages of good strength, strong cutability, good cold plasticity, improvement of the quality of a piston rod, prolongation of the service life of the piston rod, and reduction of the processing difficulty and the processing production cost of the piston rod.

Owner:宁波艾尔迪机械有限公司

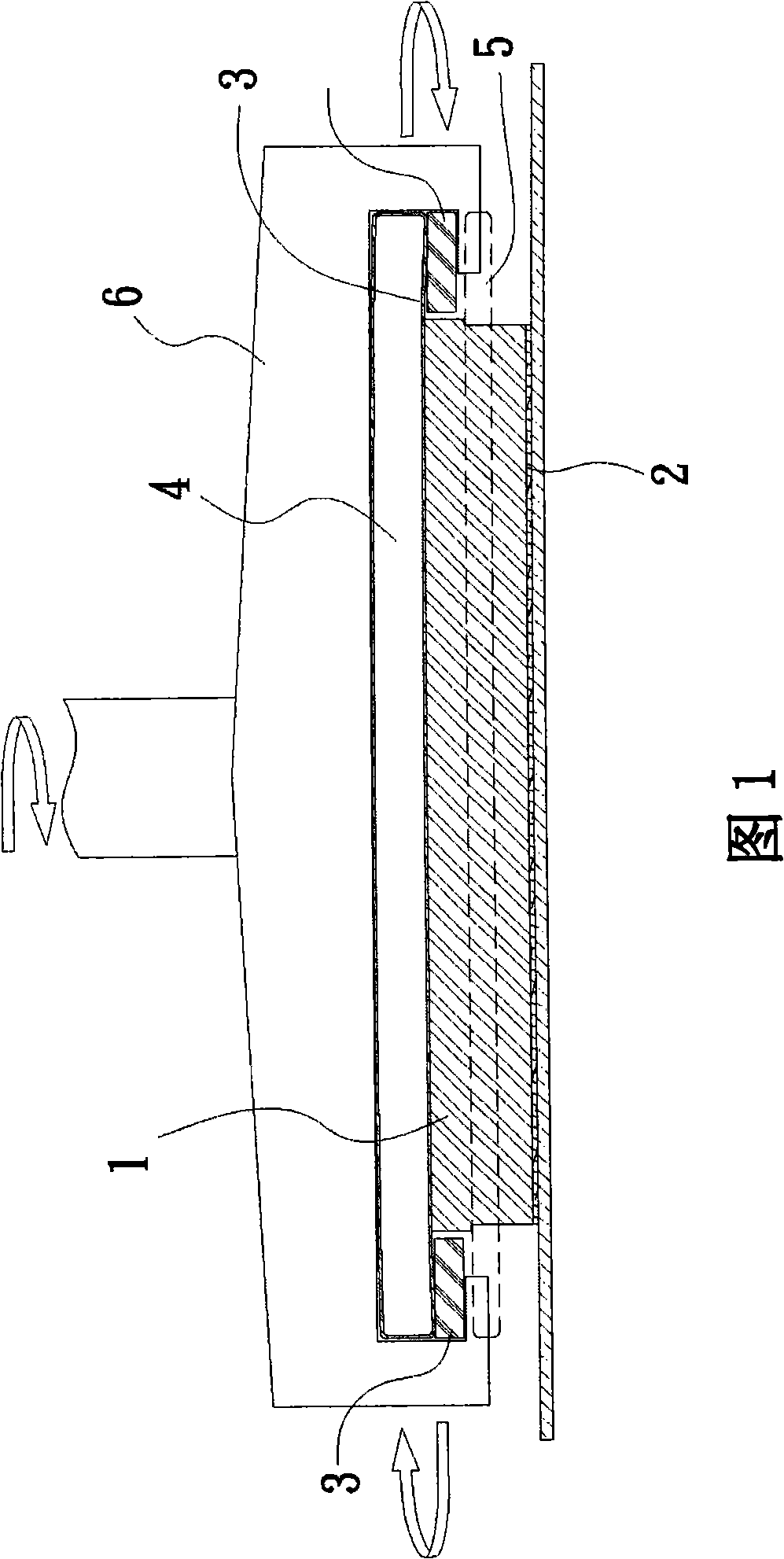

Grinding device and combination method thereof

InactiveCN101342672AReduce the chance of breakageExtend continuous operation timeOptical surface grinding machinesPositive pressureEngineering

The invention relates to a grinding device and a combination method used for grinding a grinding piece. The grinding device comprises a fixing disk, at least one baffle, a positive pressure air cushion and a gasket. The fixing disk has a compression face and a load bearing face. The grinding gasket is fixed on the load bearing face. The baffle is arranged on the lateral side of the edge of the fixing disk. The positive pressure air cushion is arranged on the compression face and on the upper part of the baffle block, in order to press the compression face and drive the fixing disk and grinding gasket moving to the direction of the grinding piece. The gasket is arranged between the compression face and the positive pressure air cushion, and extends and covers to the baffle block part. The gasket is used for separating part of the positive pressure air cushion that extends outside the edge of the fixing disk, and therefore the situation that the edge of the fixing disk embedding to the positive pressure air cushion is avoided, and the damage probability of the positive pressure air cushion is reduced.

Owner:AU OPTRONICS CORP

Preparation method of high-quality olive kernel oil

PendingCN110982611AImproves antioxidant activityYellowish colorFatty-oils/fats refiningFatty-oils/fats productionUltrasonic assistedPhysical chemistry

The invention relates to a preparation method of high-quality olive kernel oil. The preparation method comprises the following steps: setting the drying temperature of a heat pump to be 55-65 DEG C, setting the drying time of the heat pump to be 20-30 hours, and setting drying moisture to be 5-7%; crushing olive kernels into 20-40-mesh particles by using a high-speed crusher; carrying out screening by using a 40-50-mesh vibrating screen, and taking lower-portion fine-particle olive kernels; performing ultrasonic-assisted treatment on the fine-particle olive kernels through ultrasonic and microwave heating combined auxiliary equipment, and performing microwave heating after ultrasonic treatment is stopped; discharging the olive kernels into a barrel of a presser, and carrying out pulse direct pressure pressing with pressing pressure set to be 100 t to 150 t and pressing time set to be 0.5 h to 1 h; pumping squeezed olive kernel oil into a storage tank, then pumping the oil into a filtering device through a high-pressure pump, and carrying out filtering; and taking a sample, and determining the oxidation resistance and the olive polyphenol content of the olive kernel oil.

Owner:FUZHOU DASHIJIE OLIVE

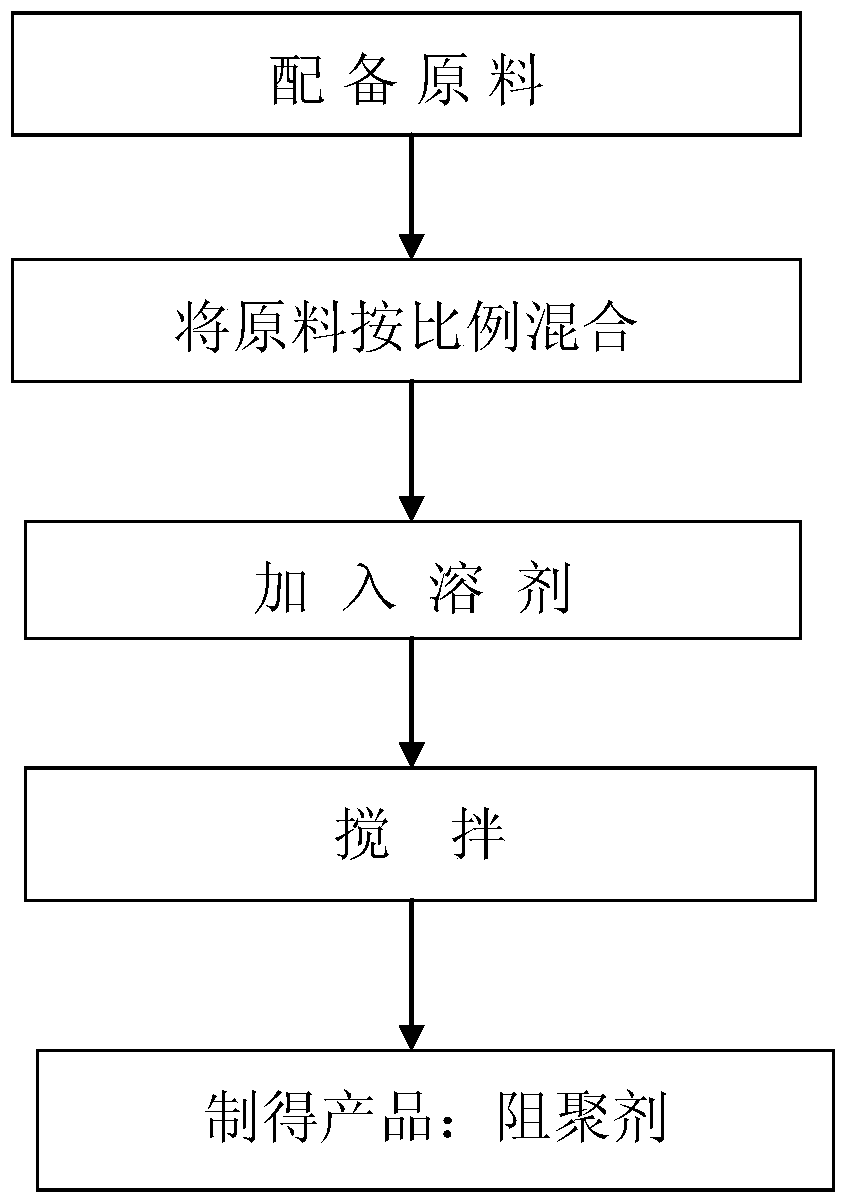

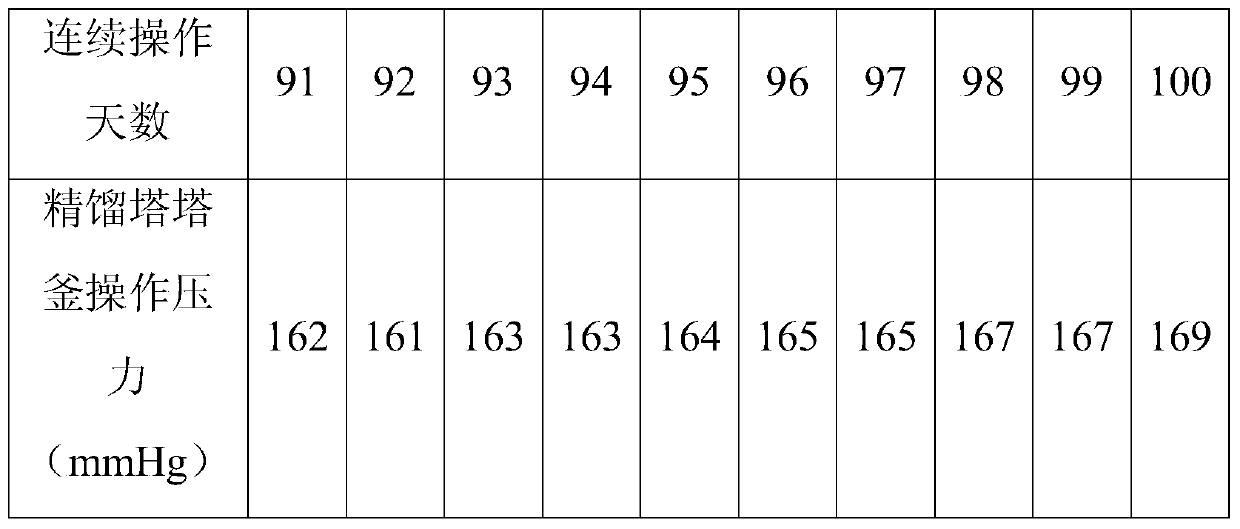

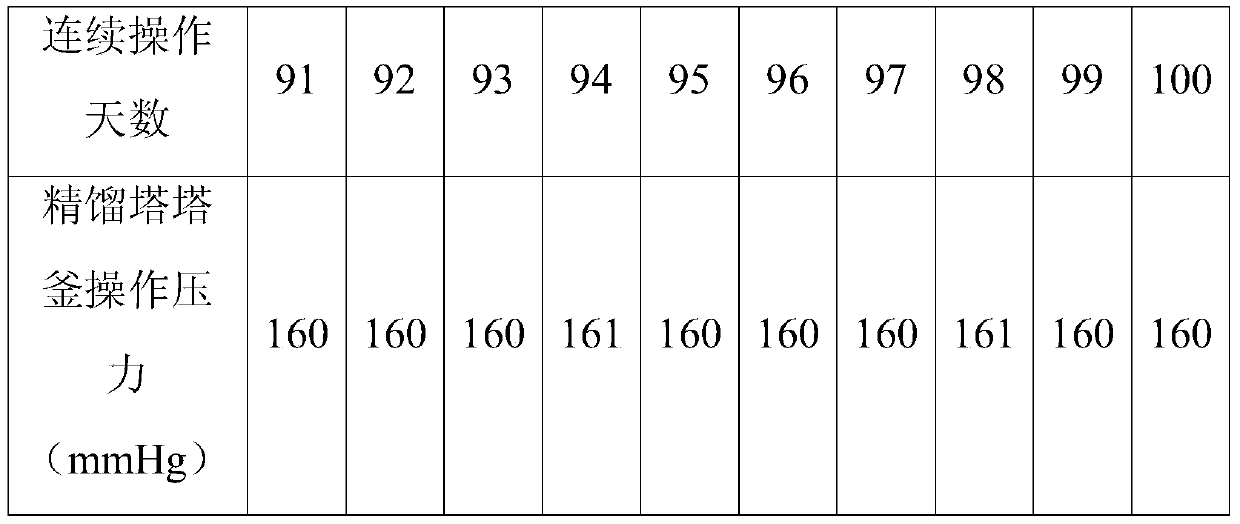

A kind of polymerization inhibitor used for refining acrylic acid monomer

ActiveCN105732360BImprove continuous production cycleExtend continuous operation timeCarboxylic compound separation/purificationPolymer scienceOrganic synthesis

The invention belongs to the technical field of organic synthesis and provides a polymerization inhibitor for acrylic acid monomer refining. The polymerization inhibitor comprises, by mass, 94-95% of hydroquinone, 4.0-5.0% of chlorpromazine and 1.0-2.0% of promethazine. Through use of two common chemical products in the original polymerization inhibitor, the modified polymerization inhibitor does not need change of original reaction conditions of the production device. The novel polymerization inhibitor can be prepared through simple and easy processes. The modified polymerization inhibitor can substantially prolong a rectifying tower continuous production period to 200 days in acrylic acid monomer production.

Owner:PETROCHINA CO LTD

Alloy steel for manufacturing bearings

The invention relates to an alloy steel for manufacturing bearings. The alloy steel is characterized by comprising the following components in parts by weight: 0.22-0.29 part of molybdenum, 0.36-0.45 part of carbon, 0.44-0.80 part of manganese, less than 0.33 part of copper, 0.16-0.23 part of silicon, less than 0.05 part of sulfur, less than 0.03 part of phosphorus, less than 0.25 part of chromium, less than 0.25 part of nickel, less than 0.3 parts of unavoidable impurities and the balance of iron. The alloy steel provided by the invention has higher strength, is good in wear resistance, excellent in cold deformation shaping and good in surface wear resistance, and improves the whole quality and service life of the bearing product, thereby effectively improving the continuous operation time of equipment, lengthening the maintenance period of the equipment, and reducing the use cost of the equipment.

Owner:新昌县南明街道锦泰机械厂

Freezing device

ActiveCN101881545BImprove securityStable structureLighting and heating apparatusStationary refrigeration devicesEngineeringRunning time

Owner:SIFANG TECH GRP CO LTD

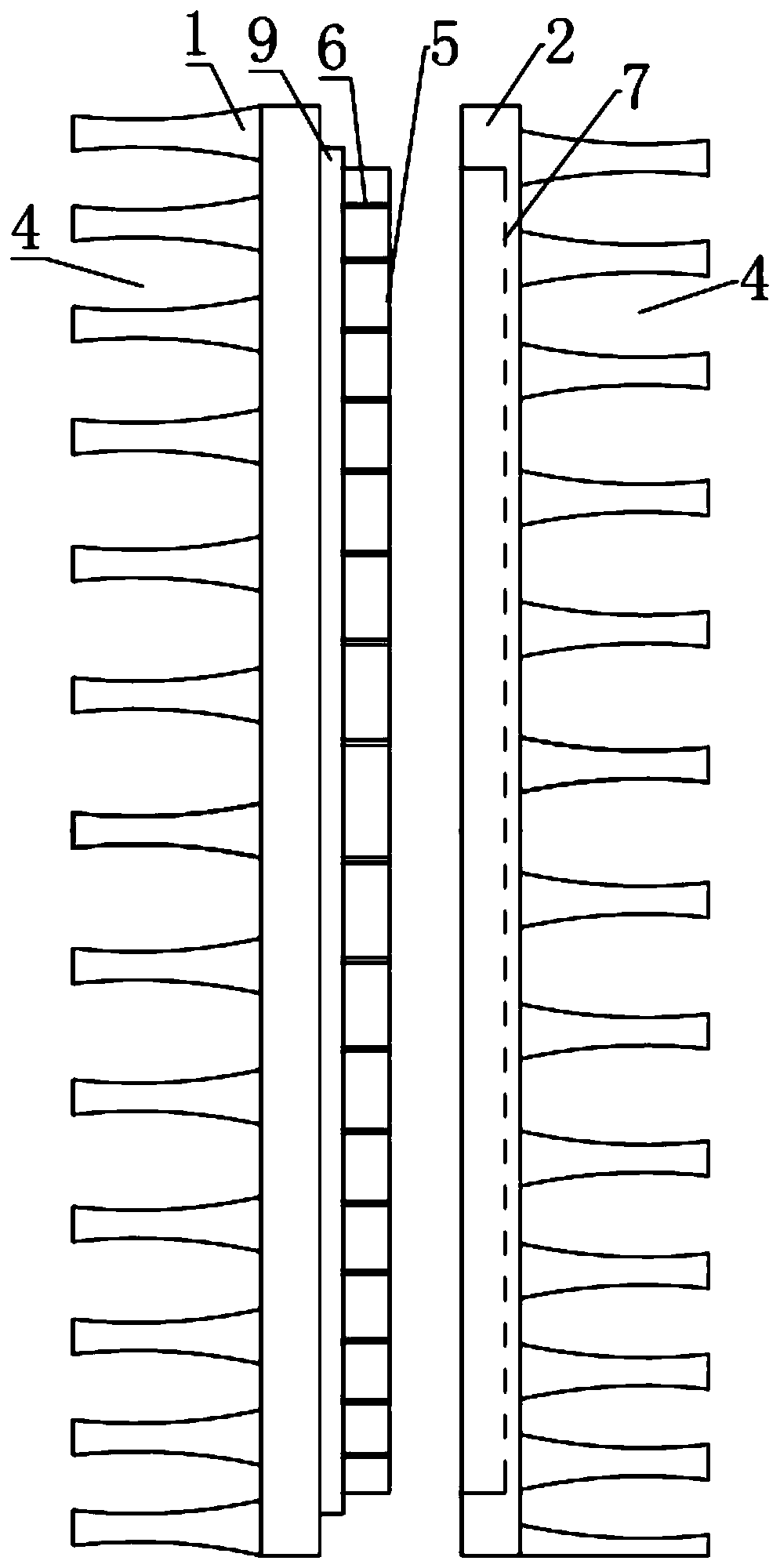

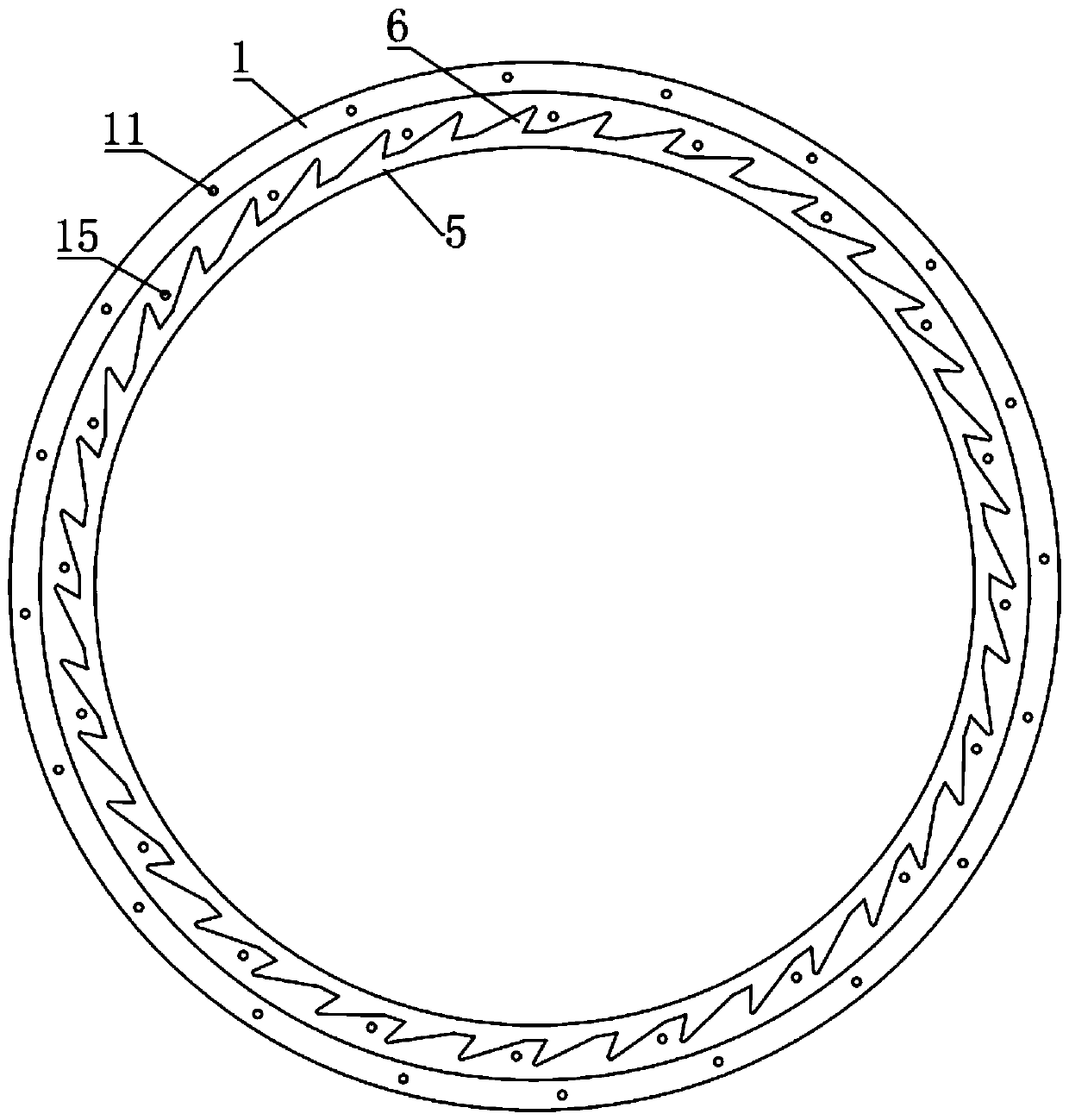

Preparation method of bearing retainer with cooling and wear-resistant structure for robot

ActiveCN110848264AWith self-lubricating functionImprove cooling effectMetallic material coating processesBearing coolingStructural engineeringIndustrial engineering

The invention relates to a preparation method of a bearing retainer with a cooling and wear-resistant structure for a robot, and belongs to the technical field of mechanical basic parts and manufacture. A first retainer body, a second retainer body and a group of inner hexagon countersunk head screws are included, the first retainer body and the second retainer body are each provided with a groupof roller pockets, the end face, close to the first retainer body, of the second retainer body is provided with a first boss, the outer wall of the first boss is provided with a group of pawls, one end, close to the first retainer body, of the second retainer body is provided with a first groove, the inner wall of the first groove is provided with a group of wedge-shaped grooves, the first boss isarranged in the first groove, and the group of pawls are clamped in the group of wedge-shaped grooves. According to the preparation method, the design of a split structure is adopted, so that the replacement of the retainer part is facilitated, the pawls and the wedge-shaped grooves are arranged for radial rotation, the first retainer body and the second retainer body form a structurally stable whole through the group of inner hexagon countersunk head screws, and the service life of a bearing is prolonged.

Owner:苏州圣典企业管理咨询有限公司 +1

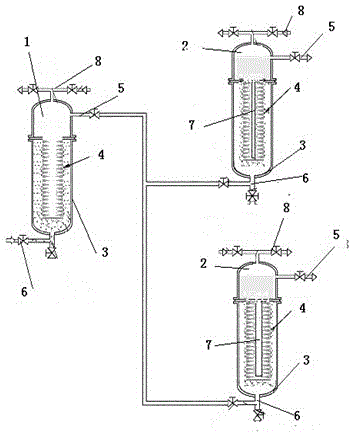

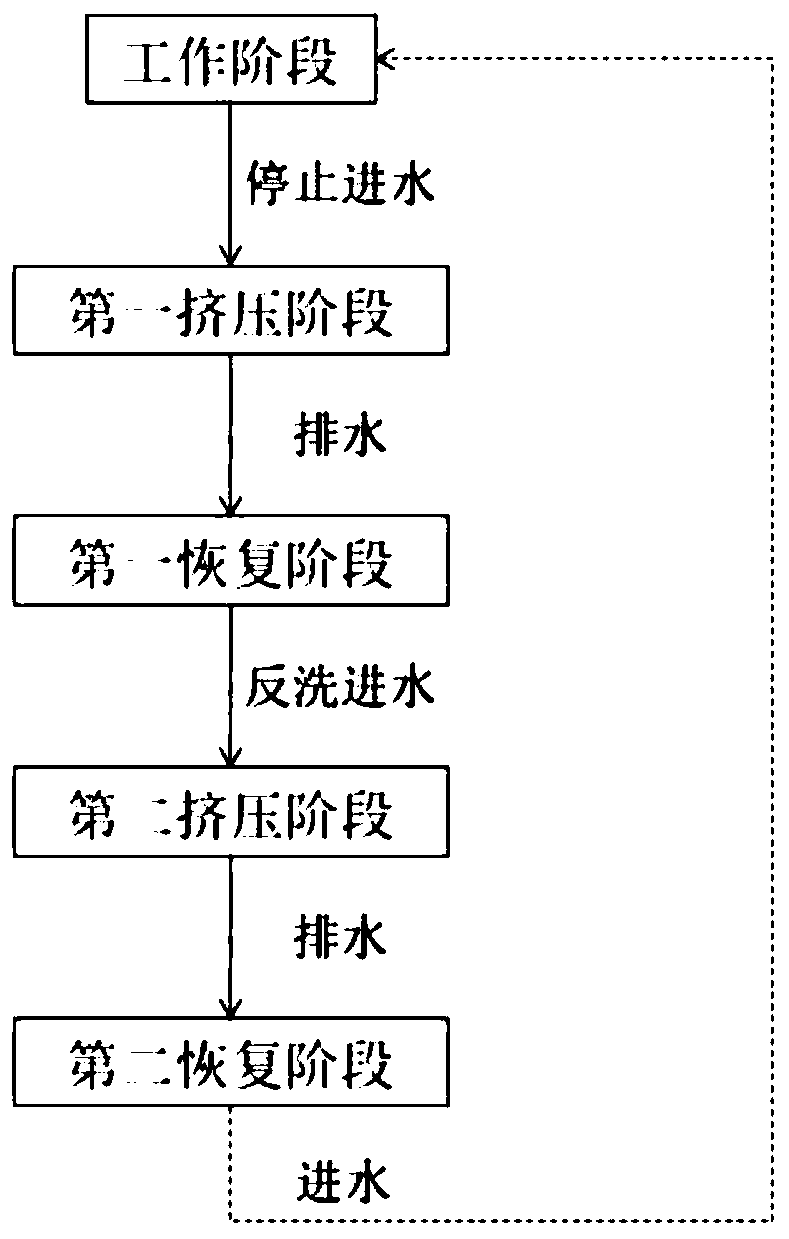

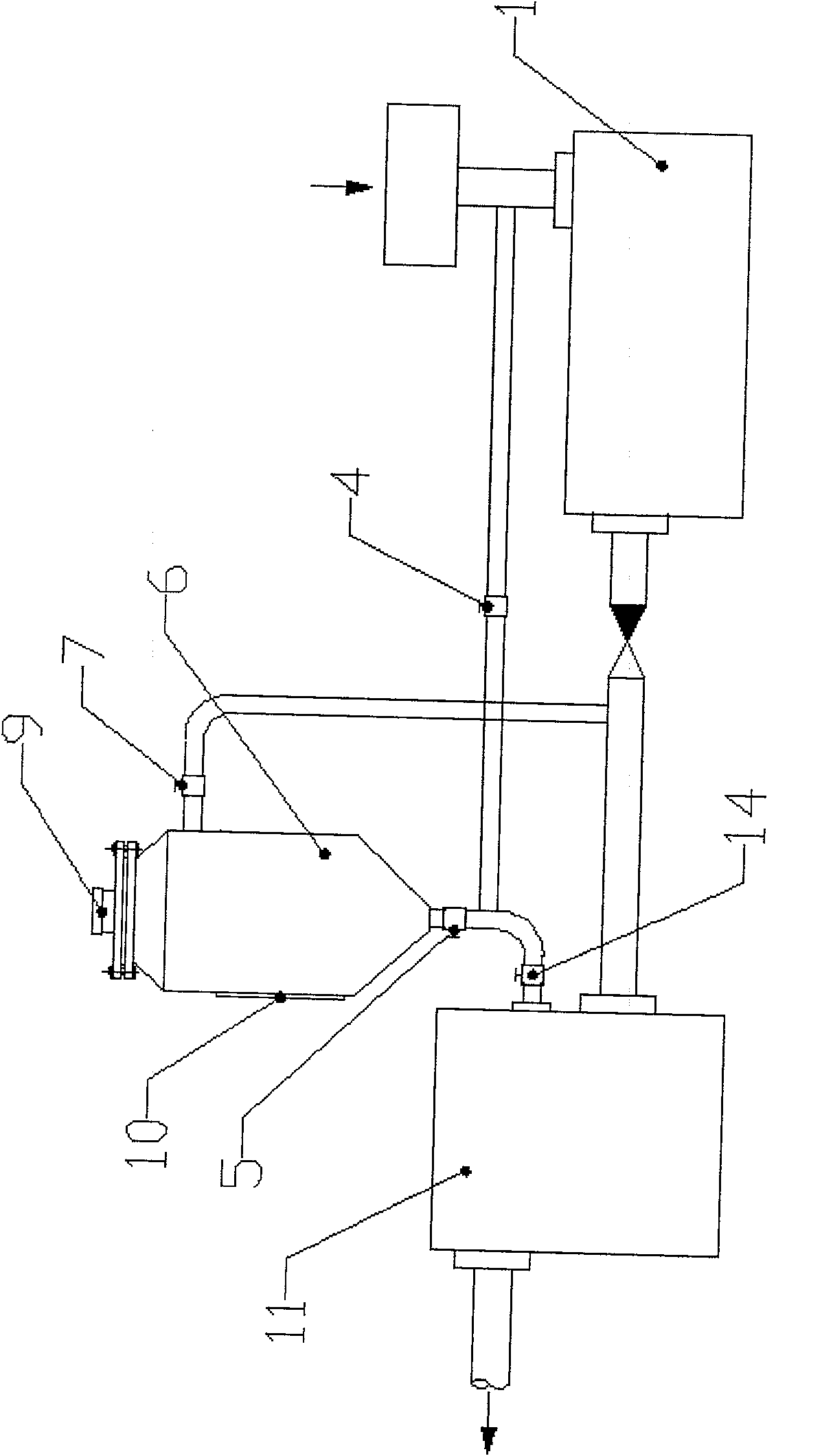

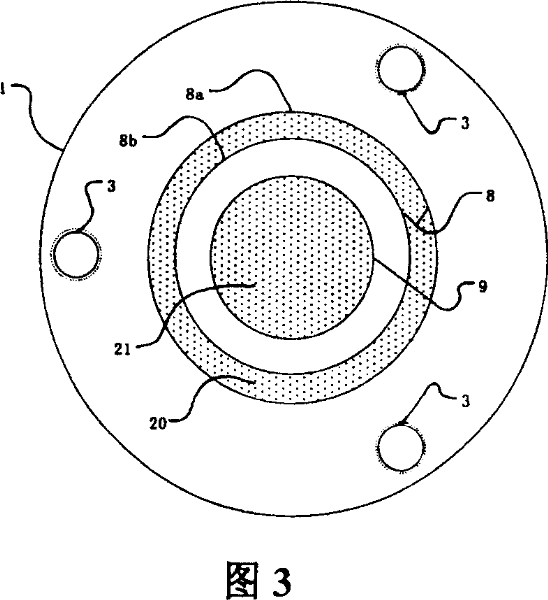

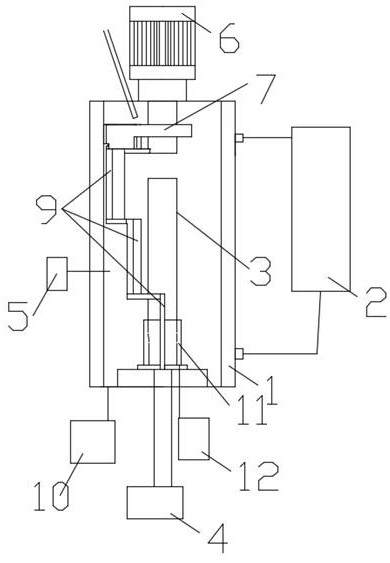

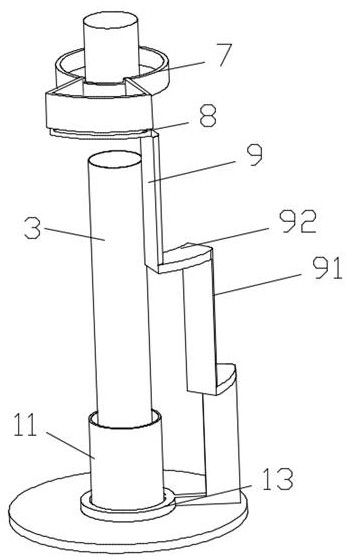

Anti-blocking drip irrigation filtering system

InactiveCN104941309AGuaranteed differential pressureNormal dischargeWatering devicesCultivating equipmentsDrip irrigationFilter system

The invention relates to a filtering device for farmland irrigation, and discloses an anti-blocking drip irrigation filtering system. The anti-blocking drip irrigation filtering system comprises a first-stage filter and a second-stage filter which are connected in series; each filter comprises a tank body and a filtering screen; the upper end of the tank body of each filter is provided with a water outlet, and the lower end of the tank body of each filter is provided with a water inlet. The anti-blocking drip irrigation filtering system is characterized in that the first-stage filter comprises at least one filter, and is internally provided with filter screens; the second-stage filter comprises at least two filters and is internally provided with filter screens and filter elements, and the filter elements are installed in the filtering screens, and are quartz sand filter elements; the filter screens and the water outlets of the tank bodies are connected. The anti-blocking drip irrigation filtering system can effectively prevent sediment in water from blocking a valve and a drip irrigation belt, and can be widely applied to irrigation of crops.

Owner:TIANJIN GREEN VISION ENERGY SAVING ENG EQUIP

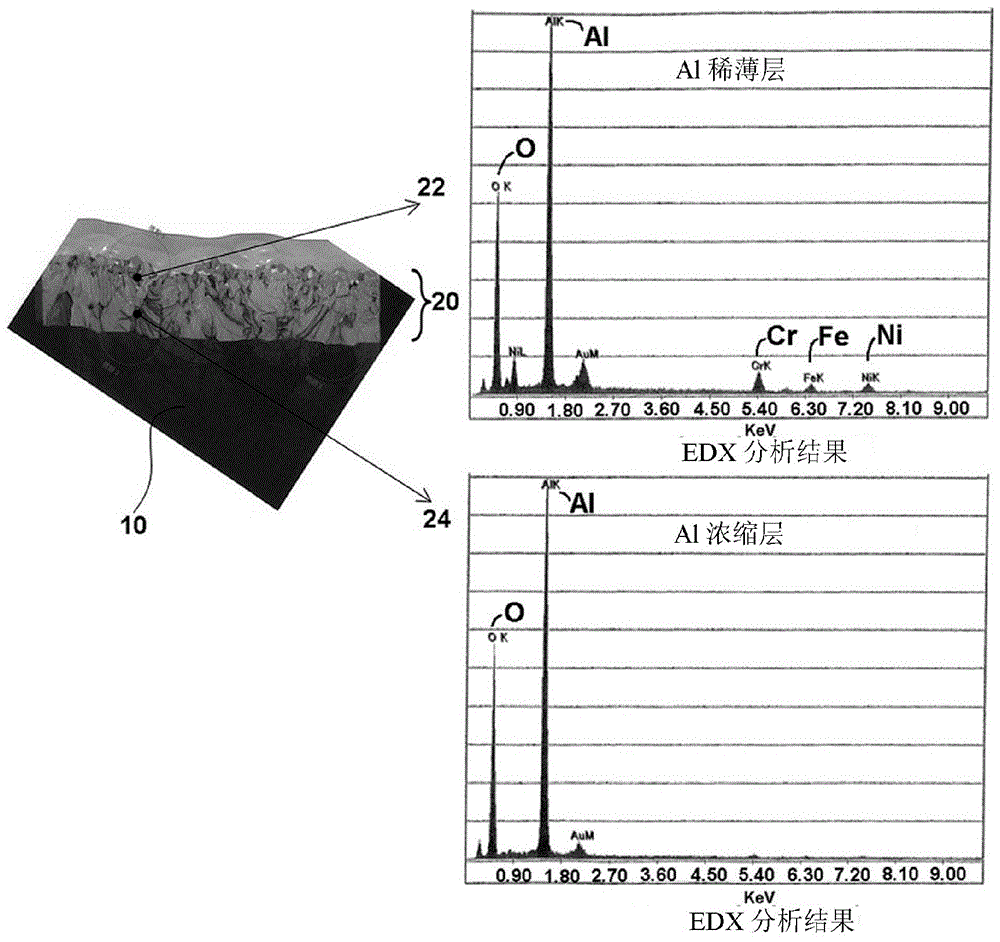

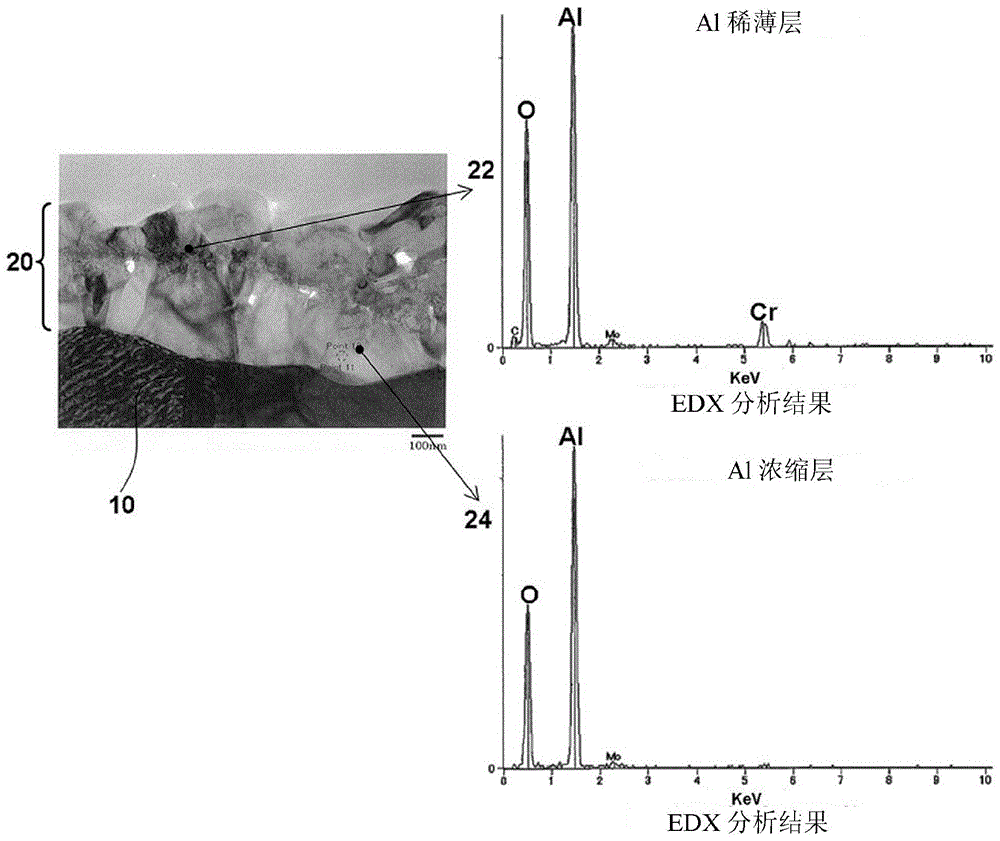

Casting product having alumina barrier layer

ActiveCN106460144AInhibition formationStable structureSolid state diffusion coatingFurnace typesSolid solutionAtmosphere

The present invention provides a casting product which has an alumina barrier layer having further improved stability, and can exhibit superior oxidation resistance, carburization resistance, nitridation resistance, corrosion resistance and the like when used under high-temperature atmospheres. The casting product according to the present invention is one having an alumina barrier layer which is formed on the surface of a base and contains an aluminum oxide, wherein the aluminum oxide is represented by the formula: (Al(1-x)M(x))2O3 wherein M represents at least one element selected from Cr, Ni, Si and Fe and 0 < x < 0.5. The casting product according to the present invention is also one having an alumina barrier layer which is formed on the surface of a base and contains an aluminum oxide, wherein the aluminum oxide contains at least one element selected from Cr, Ni, Si and Fe which is dissolved in the form of a solid solution, and wherein the content ratio, in at.%, of at least one element selected from Cr, Ni, Si and Fe which is dissolved together with Al in the form of a solid solution satisfies the formula: Al / (Cr+Ni+Si+Fe) >= 2.0.

Owner:KUBOTA LTD

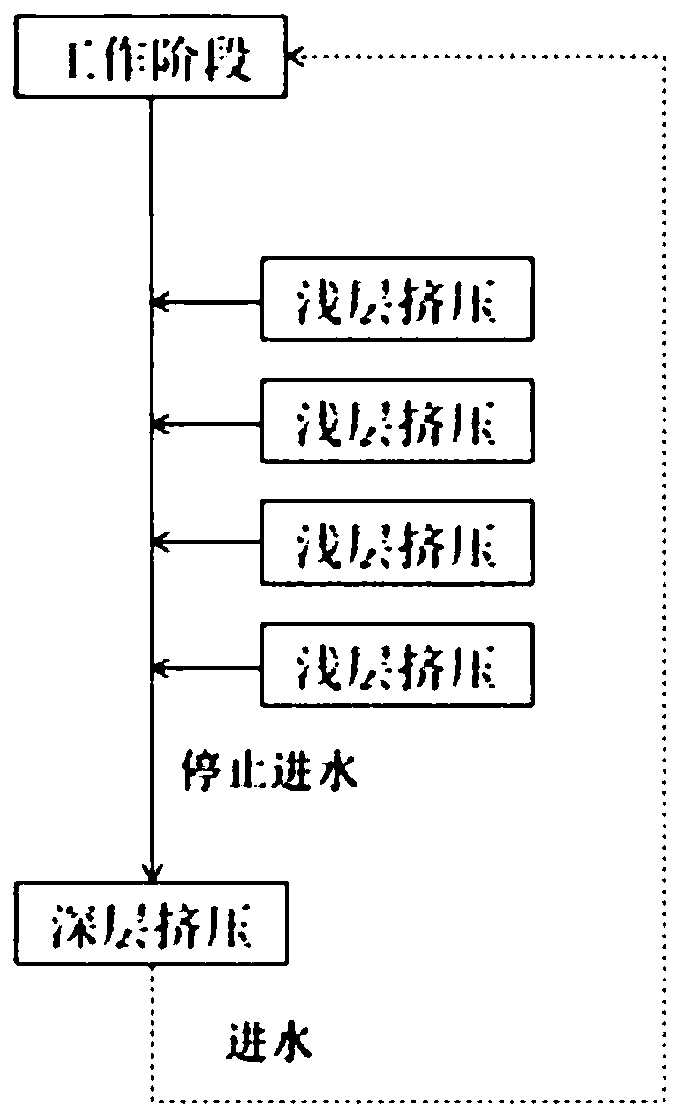

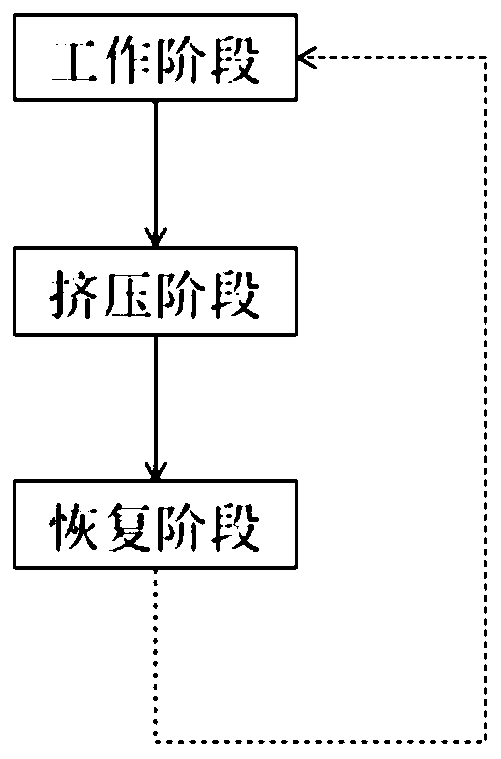

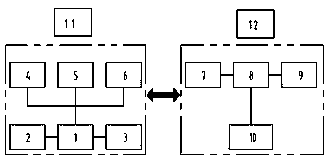

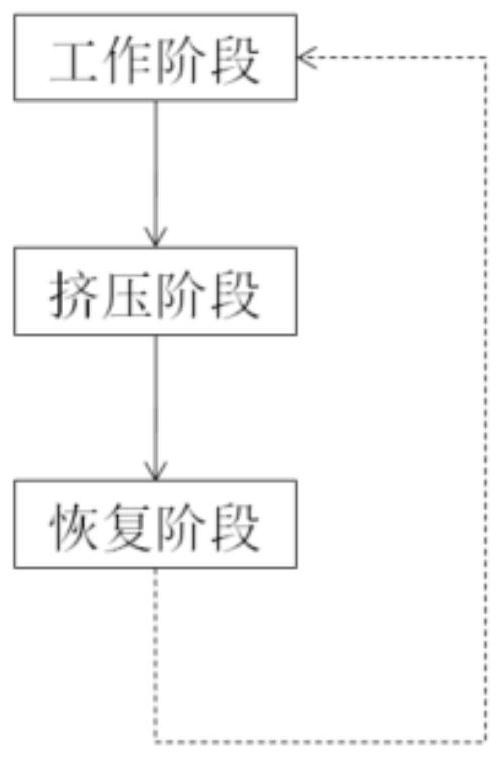

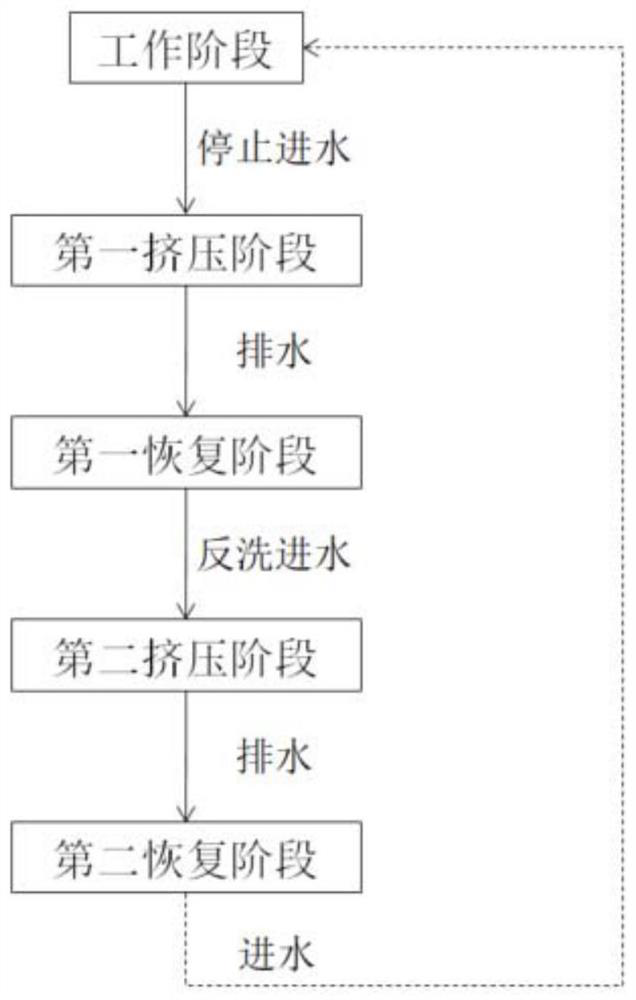

Enhanced nitrification process based on coupled demolding

ActiveCN111362408AAvoid cloggingStable and uniform dissolved oxygen distributionWater contaminantsTreatment with aerobic and anaerobic processesSewageSewage treatment

The invention discloses an enhanced nitrification process based on coupled demolding, and belongs to the technical field of sewage treatment. In the sewage nitrification process, under a condition ofkeeping a certain content of dissolved oxygen in a system, extrusion treatments are carried out on an elastic filler so as to generate different deformation degrees, in each extrusion treatment, deepextrusion and shallow extrusion are coupled; deep extrusion is carried out when the system load decreases, the effluent quality is close to an index value, or the system resistance exceeds a designedinflow water distribution pressure; and shallow extrusion is carried out when the system load is stable. Through the combination of deep extrusion and shallow extrusion, on one hand, demolding and redistribution of a bio-membrane filler can be realized, the mass transfer efficiency is improved, on the other hand, dissolved oxygen inside and outside the bio-membrane filler can be distributed more uniformly, through the synergistic effect of deep extrusion and shallow extrusion, the nitrification reaction is enhanced, the sewage treatment efficiency is improved, and the effluent quality is recovered.

Owner:ANHUI PUSHI ECOLOGICAL ENVIRONMENT ENG

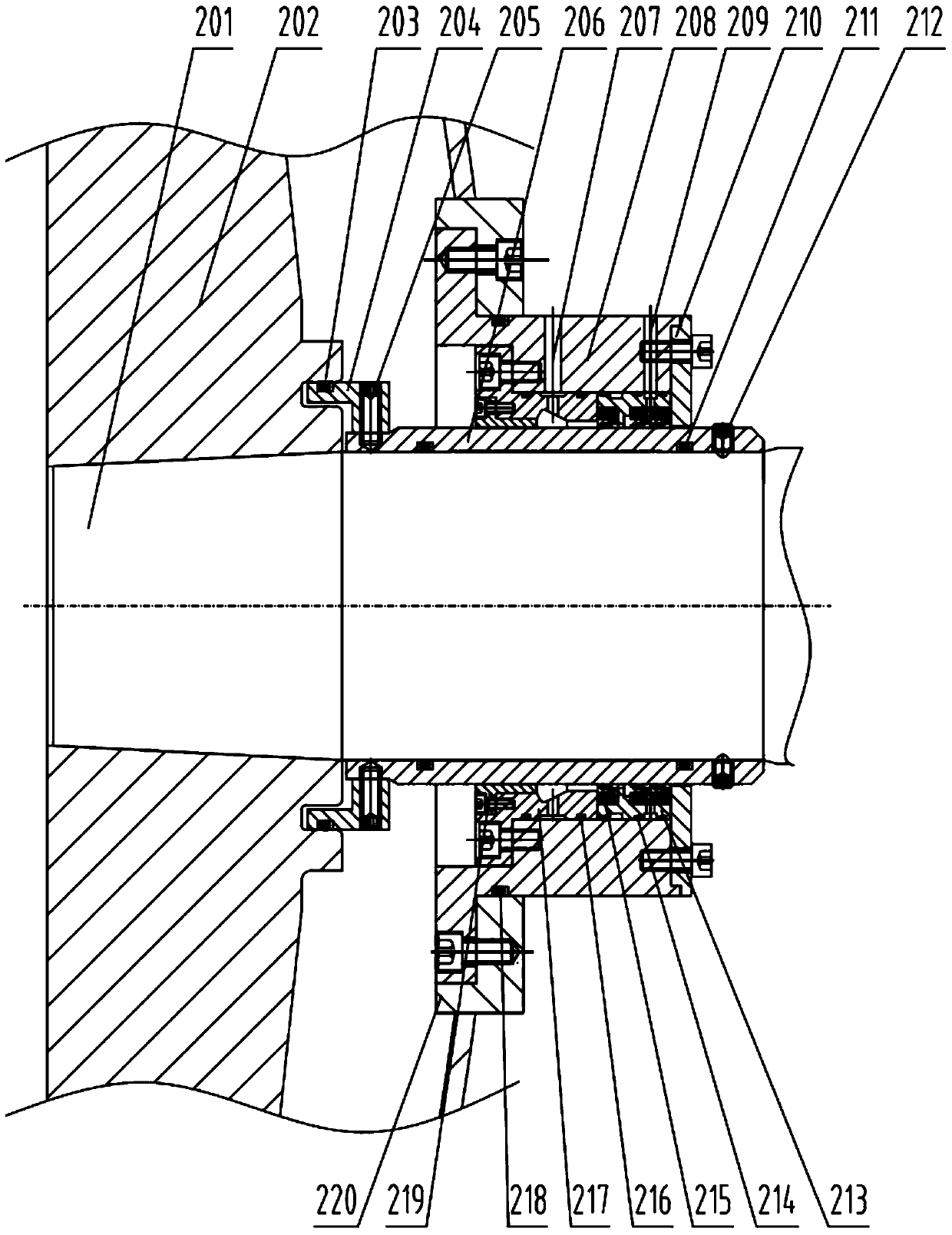

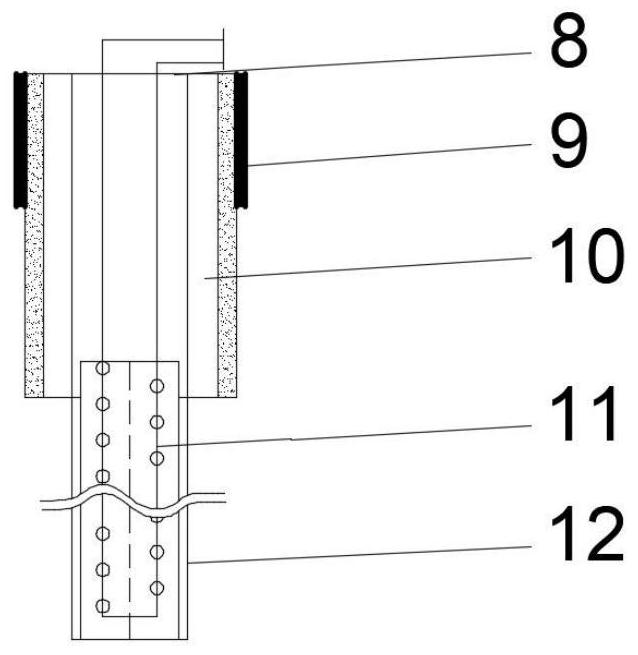

Sealing device for spindle of disc mill used as density fiberboard production equipment

PendingCN110565428APrevent leakageAvoid wear and tearPulp beating/refining methodsFiberboardMillstone

The invention discloses a sealing device for a spindle of a disc mill used as density fiberboard production equipment. According to the invention, an oil seal chamber, a flushing ring, an embedded part and a sealing ring are simultaneously mounted outside a shaft sleeve on the driving spindle in a matched manner through a sealing seat; a packing is arranged in the oil seal chamber; the flushing ring is connected with a compressed air source through an air inlet; and the front end of the sealing ring is inserted into a limiting groove in the back of a movable millstone. Slurry and steam in a pulping area of the disc mill are sealed through a plurality of groups of seal loops so as to prevent a sealing medium from leakage; compressed air is introduced through the air inlet in the system operation process; so leakage of the sealing medium in the operation process and damage of pulp to the shaft sleeve and the seal loop group in the oil seal chamber in the pulp grinding process are reduced, the leakage of the sealing medium can be prevented, and abrasion to a sealing assembly and the spindle is reduced. The sealing device has the advantages of good sealing effect, reliable performance,simple structure, convenient operation, small maintenance workload, and low cost.

Owner:SUZHOU SUFOMA MACHINERY

Alloy steel formula for bearing

InactiveCN103805881AIncreased strength and wear resistanceCold deformation shape is goodChromiumAlloy steel

The invention discloses an alloy steel formula for a bearing. The alloy steel formula comprises the following components in percentage by weight: 0.37-0.45 percent of carbon, 0.24-0.29 percent of molybdenum, 0.33-0.39 percent of zirconium, 0.17-0.37 percent of silicon, 0.50-0.80 percent of manganese, less than 0.4 percent of sulfur, less than 0.05 percent of phosphorus, less than or equal to 0.25 percent of chromium, less than 0.25 percent of nickel, less than 0.25 percent of copper, less than 0.1 percent of other inevitable impurities and the balance of iron. The alloy steel has high strength and wear resistance, high cold deformation shaping and high surface abrasion resistance, the overall quality of the bearing product is improved, and the service life is prolonged, so that the continuous operating time of equipment is effectively improved, the maintenance period of the equipment is prolonged, and the use cost of the equipment is saved.

Owner:俞政

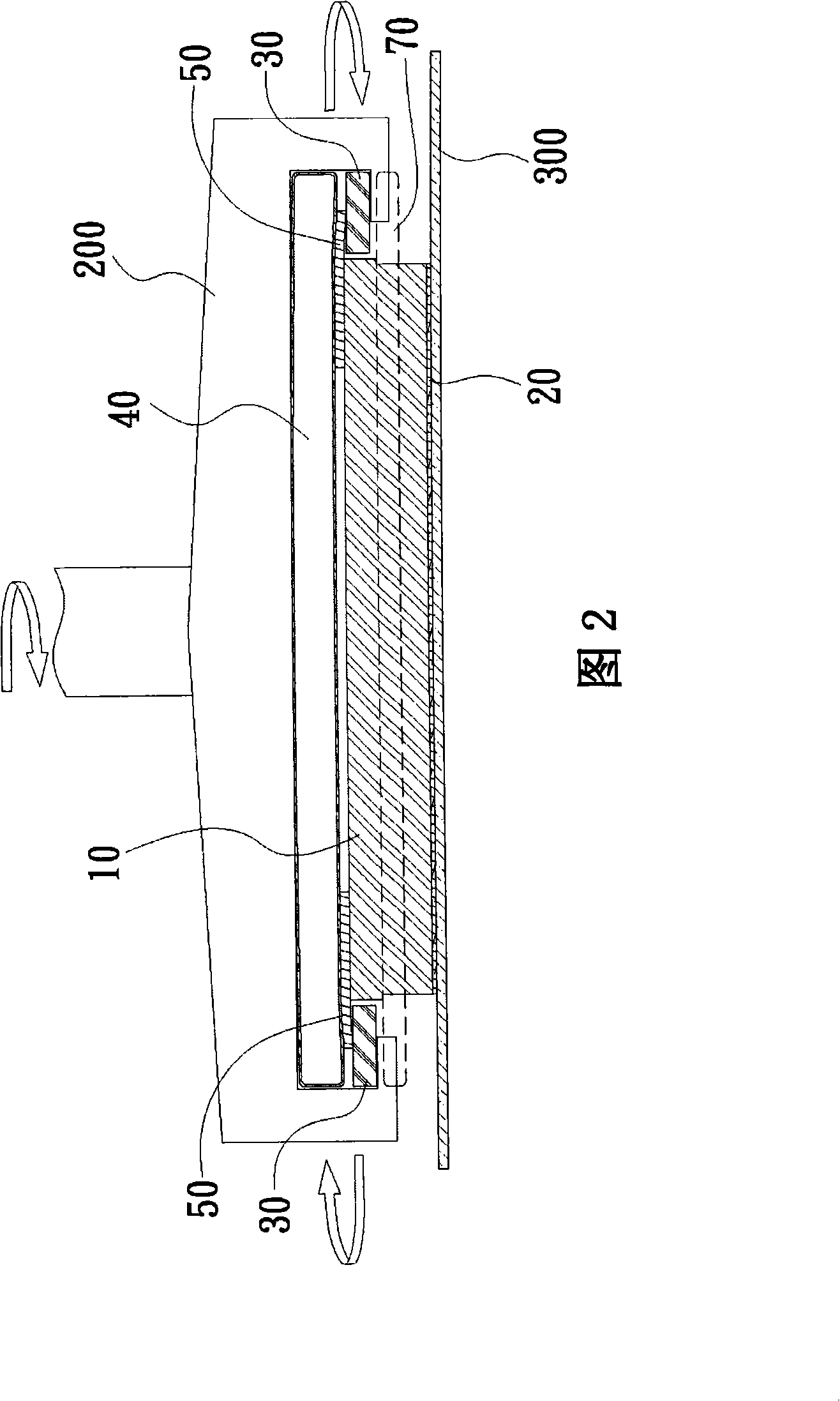

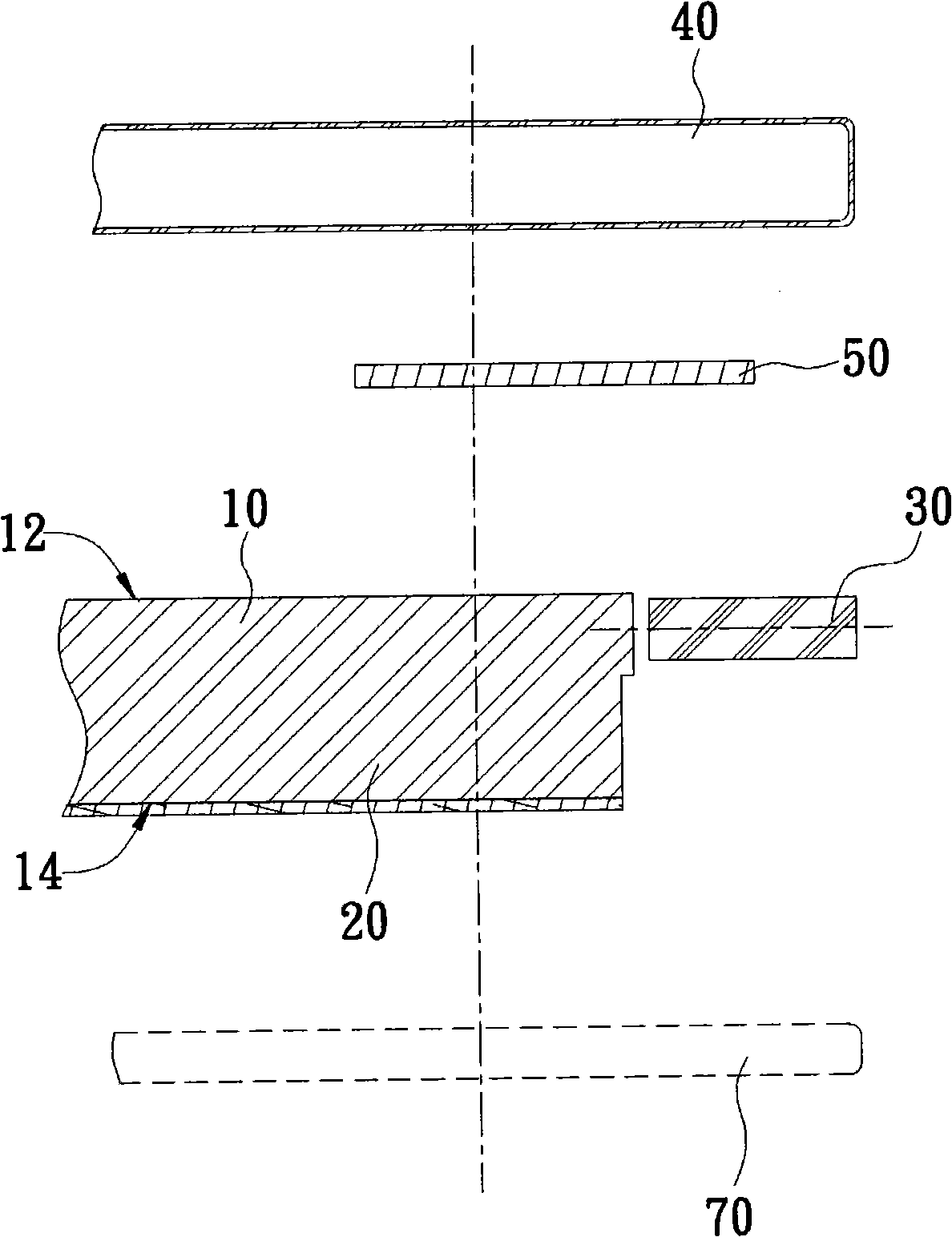

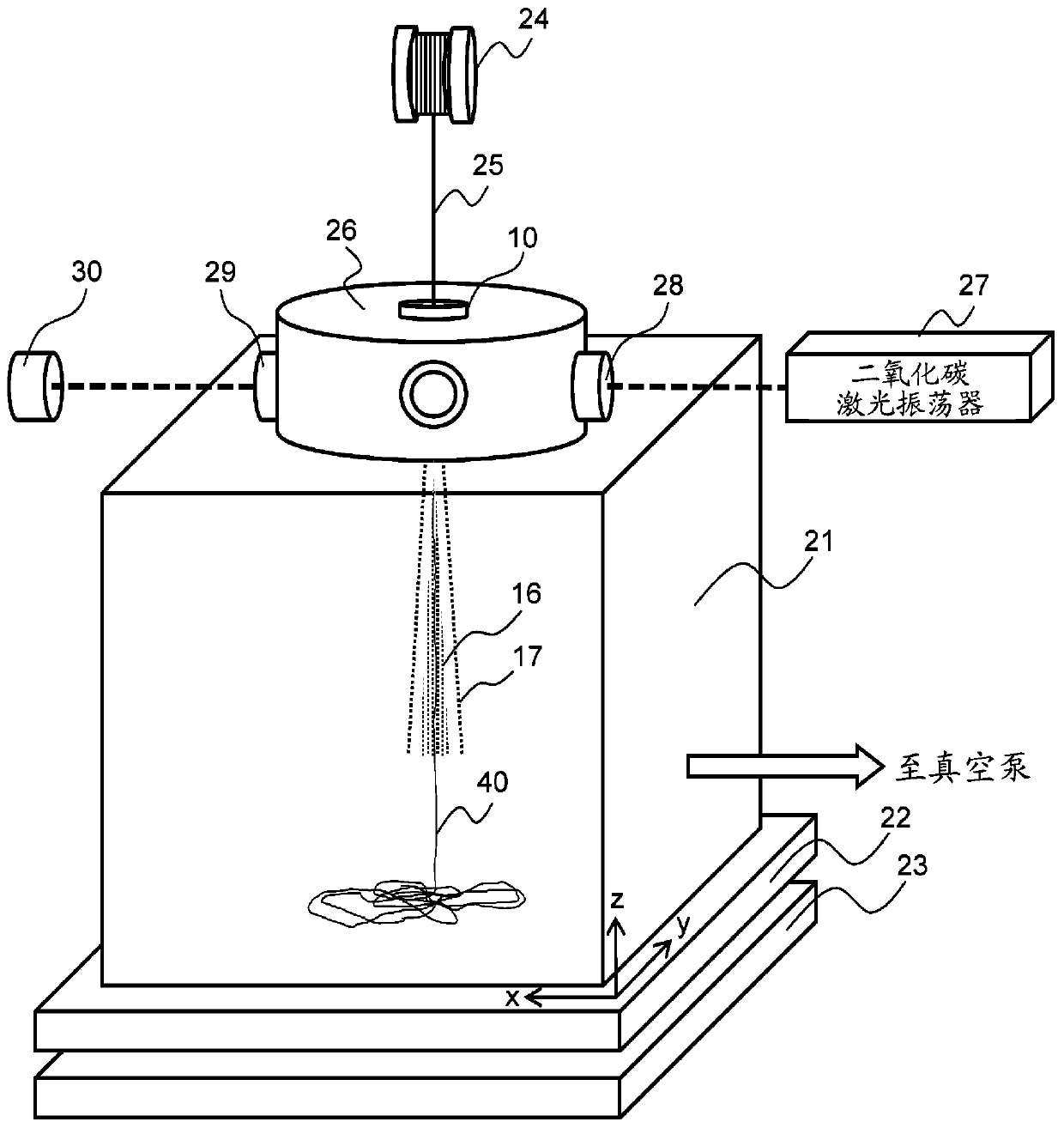

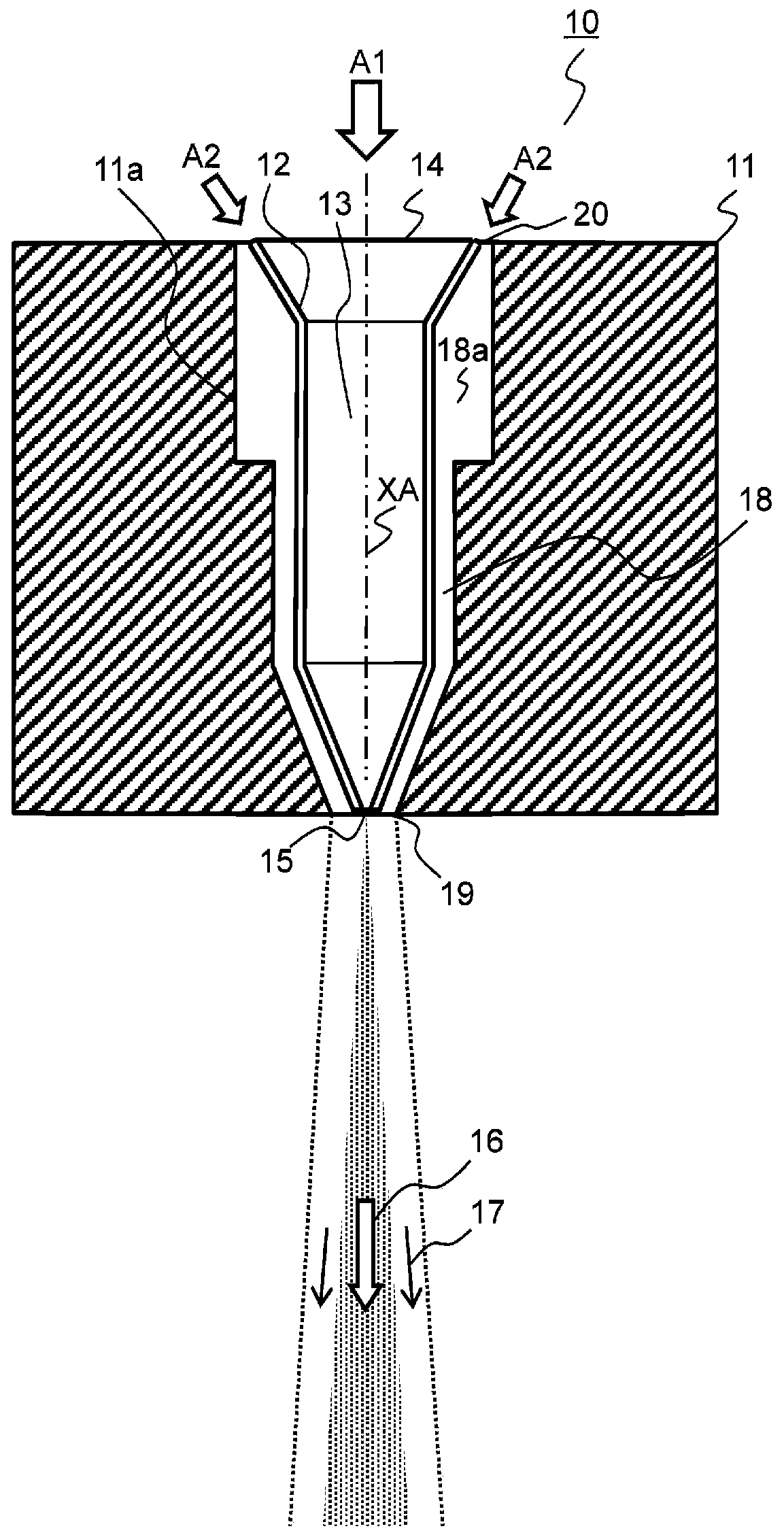

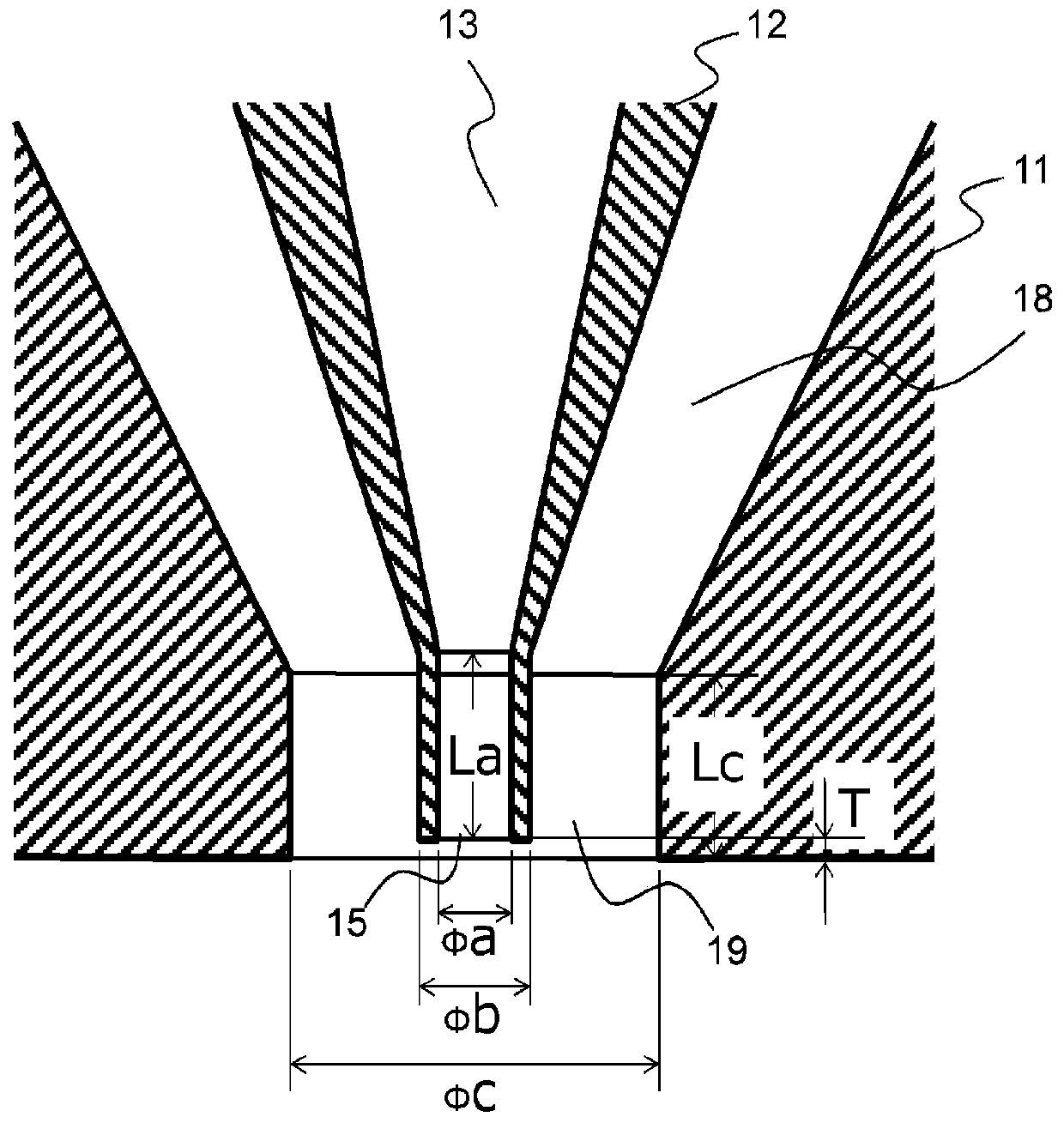

Apparatus for manufacturing ultrafine fiber and method for manufacturing ultrafine fiber

InactiveCN110785518AStable manufacturingSuppress swingFilament forming substance formingMelt spinning methodsSpray nozzleMicrofiber

This apparatus for manufacturing ultrafine fiber comprises a nozzle (10), a laser irradiation unit (26), and a drawing chamber (21). The nozzle (10) comprises an inlet for supplying raw fibers (25), afirst spray outlet, communicating with the inlet, for delivering the raw fibers and spraying a first drawing gas stream (16) for drawing the raw fibers, and second spray outlets, disposed around thefirst spray outlet, for spraying a second drawing gas stream (17). The nozzle (10) is installed on the laser irradiation unit (26), and the raw fibers (25) delivered from the first spray nozzle are irradiated and melted by a laser. In the drawing chamber (21), the molten raw fibers (25) are drawn using the first drawing gas stream (16) and the second drawing gas stream (17) sprayed from the nozzle(10).

Owner:JXTJ NIPPON OIL & ENERGY CORP

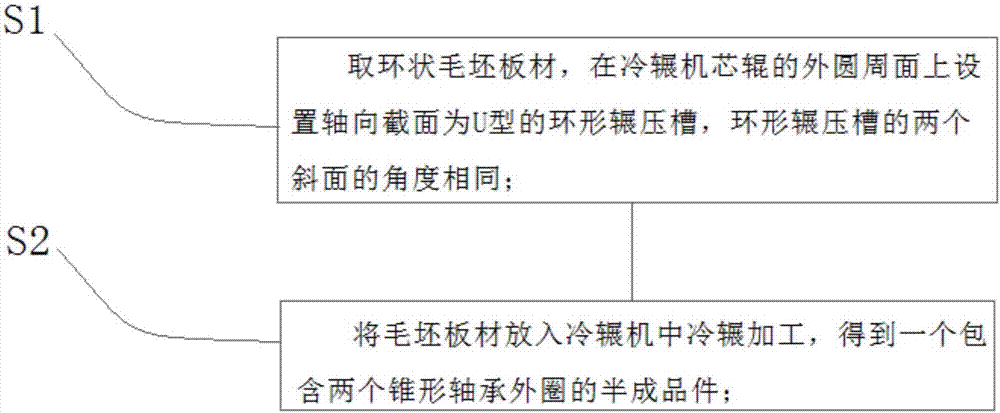

Machining method for bearing outer rings

InactiveCN107971437AQuality improvementExtended service lifeBearing componentsUltimate tensile strengthWear resistance

The invention relates to the field of bearing machining, in particular to a machining method for bearing outer rings. The machining method for bearing outer rings comprises the following steps that anannular blank plate is fetched, an annular rolling groove with a U-shaped axial section is formed in the outer circumferential surface of a core roller of a cold rolling machine, and two inclined surfaces of the annular rolling groove have the same angle; and the blank plate is placed in the cold rolling machine and subjected to cold rolling machining, and a semi-finished product comprising two conical bearing outer rings is obtained. Strength and abrasion resistance are high, cold deformation molding is good, surface abrasion resistance is good, the overall quality of bearing products is improved, and the service life of bearing products is prolonged, so that the continuous operating time of equipment is effectively prolonged, the maintenance period of the equipment is prolonged, and theusing cost of the equipment is saved.

Owner:方晓超

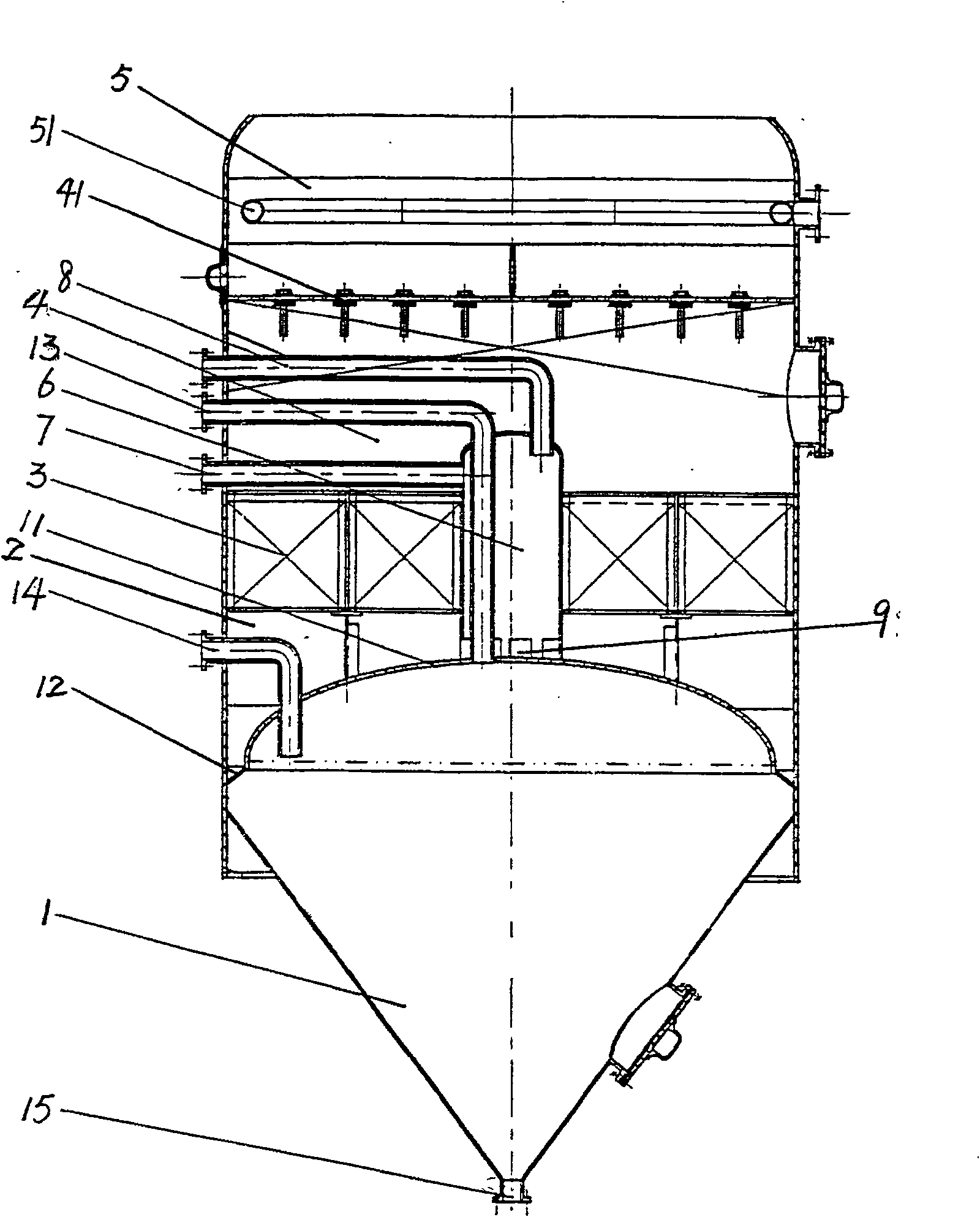

Filter

InactiveCN100548429CEasy to install and replaceConstant water flowMultistage water/sewage treatmentLoose filtering material filtersFiltrationSludge

A filter, which belongs to a water purification and recovery device, includes a shell, and the shell is composed of a mud collection area, a flocculation area, a sedimentation area, a filtration area, and a clear water area in order from bottom to top. The mud collection area is a conical collection area. Mud hopper, a flange cap is placed on the top of the conical mud collecting hopper. The port of the conical mud collecting hopper on both sides of the flange cap has a mud water inlet connected to the flocculation area, and the opening on the top of the flange cap is connected to an air inlet pipe. The upper part of a central liquid inlet tank is connected to the water inlet pipe, the top is connected to the exhaust pipe, the bottom is fixed in the center of the flange cap, and there is a water outlet hole on the side wall where it connects with the flange cap. It is a multi-functional solid-liquid separation device that integrates, discharges, and cleans. It has good mud collection during operation, stable water outlet, high filter efficiency, long service life, long continuous operation time, small investment, good treatment effect, and low operating cost. It can operate continuously at low pressure, discharge the concentrated liquid regularly, and the operation and management are very convenient.

Owner:宜兴市亿达工业成套设备有限公司

Fuel injection helical lobe compressor lubricant oil ancillary equipment

InactiveCN100564883CExtend continuous operation timeLight in massRotary piston pumpsRotary piston liquid enginesGas compressorLubricant

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Composite spinning component entities including double constituents

ActiveCN100338271CExtend continuous operation timeReduce labor intensityFilament/thread formingFiltrationEngineering

Owner:SINOPEC YIZHENG CHEM FIBER

Corrosion resistance testing system for wind power cooler core

InactiveCN110608994AExtend continuous operation timeMultiple benefitsWeather/light/corrosion resistanceCorrosion resistantFrequency conversion

The invention discloses a corrosion resistance testing system for a wind power cooler core. The testing system comprises a testing device and a control system. The testing device includes a cooler core body, a pressurizing device, a monitoring device, a corrosive gas generating device, a temperature and humidity generator and a sunlight ultraviolet simulator. The corrosive gas generating device, the temperature and humidity generator and the sunlight ultraviolet simulator are connected with the control system through circuits. The control system includes a signal converter, a PLC controller, ahuman-computer interface and a frequency conversion control device; the signal converter is connected with the PLC through a circuit; and the PLC controller is connected with the human-computer interface and the frequency conversion control device through circuits. Therefore, the corrosion-resistant performances of various cooler cores in different environments can be efficiently and quickly tested; and the medium leakage and replacement and shutdown losses of the fan after corrosion can be reduced and the time of continuous operation time of the fan is greatly prolonged.

Owner:SOLINER NANJING INTELLIGENT TECH CO LTD

A process based on coupled stripping and enhanced nitrification

ActiveCN111362408BAvoid cloggingStable and uniform dissolved oxygen distributionWater contaminantsTreatment with aerobic and anaerobic processesBiofilmSewage

The invention discloses a process for strengthening nitrification treatment based on coupled type stripping and belongs to the technical field of sewage treatment. During the nitrification treatment process of sewage, under the condition of maintaining a certain content of dissolved oxygen in the system, the elastic filler is subjected to extrusion treatment with different degrees of deformation. The extrusion treatment includes the coupling of deep extrusion and shallow extrusion. , the deep extrusion is carried out when the system load drops, the outlet water quality is close to the target value or the system resistance exceeds the design inlet water distribution pressure, and the shallow extrusion is carried out when the system load is stable. The present invention combines deep extrusion and shallow extrusion, on the one hand, it can realize the release and redistribution of the biofilm filler, improve the mass transfer efficiency, and on the other hand, it can promote a more uniform distribution of dissolved oxygen inside and outside the biofilm filler. The synergistic effect of the two can strengthen the nitrification reaction, improve the efficiency of sewage treatment, and restore the quality of effluent water.

Owner:ANHUI PUSHI ECOLOGICAL ENVIRONMENT ENG

Method for removing odor substances in zanthoxylum bungeanum seed oil and wiped film type molecular distillation device used by method

PendingCN113198199AReduce speedReduce wearFatty-oils/fats refiningMolecular distillationBiotechnologyZanthoxylum bungeanum

The invention discloses a method for removing odor substances in zanthoxylum bungeanum seed oil and a wiped film type molecular distillation device used by the method, the pretreated zanthoxylum bungeanum seed oil is distilled by molecular distillation equipment, the odor substances are removed from a light phase, and the finished zanthoxylum bungeanum seed oil is obtained from a heavy phase. According to the method, the molecular distillation device is used for distilling the pretreated zanthoxylum bungeanum seed oil, the odor substances are removed from the light phase, and the finished zanthoxylum bungeanum seed oil is obtained from the heavy phase so that the temperature can be well controlled, and the total beneficial substances of the zanthoxylum bungeanum seed oil are well prevented from being oxidized. For the wiped film type molecular distillation device, in the using process, a great factor influencing the separation effect is that the effective separation rate is low due to the fact that entrainment caused by rotation of the scraper plate directly contacts with the condensation pipe, and the technology cannot be popularized to large-scale production, for the problem, the applicant makes the following improvements on the wiped film type molecular distillation device, and the defects of the existing wiped film type molecular distillation device are overcome.

Owner:贵州玄德生物科技股份有限公司

Reverse feed high-aromatic-hydrocarbon hydro-upgrading method

InactiveCN105694968ALess investmentReduce energy consumptionTreatment with hydrotreatment processesChemistrySeparation process

A reverse feed high-aromatic-hydrocarbon hydro-upgrading method includes the steps that high-aromatic-hydrocarbon BF such as low-temperature coal tar serves as quenching oil for recovering reaction heat to make direct contact with high-temperature gas-phase-contained material flow R10PVX based on first hydrogenation reaction outflow matter R10P in the high-pressure separation process, at least one time of contact is completed so that part of light components in the raw material hydrocarbon BF can be gasified and separated into gas S1V and liquid material flow S1L possibly containing solid, the material flow S1L or material flow S1LPX obtained after high-carbon-residue components are removed from the material flow S1L enters the first hydrogenation reaction process R10 to be subjected to hydrogenation thermal cracking reaction to be converted into R10P, R10P can enter the previous separation step BS first to be separated into gas BSV and liquid material flow BSL possibly containing solid, at least part of the material flow BSL can return to the step R10 so that circulation conversion and catalyst circulation can be achieved, and the material flow containing solid in the step R10 or the step BS is used for discharging waste catalysts.

Owner:何巨堂 +1

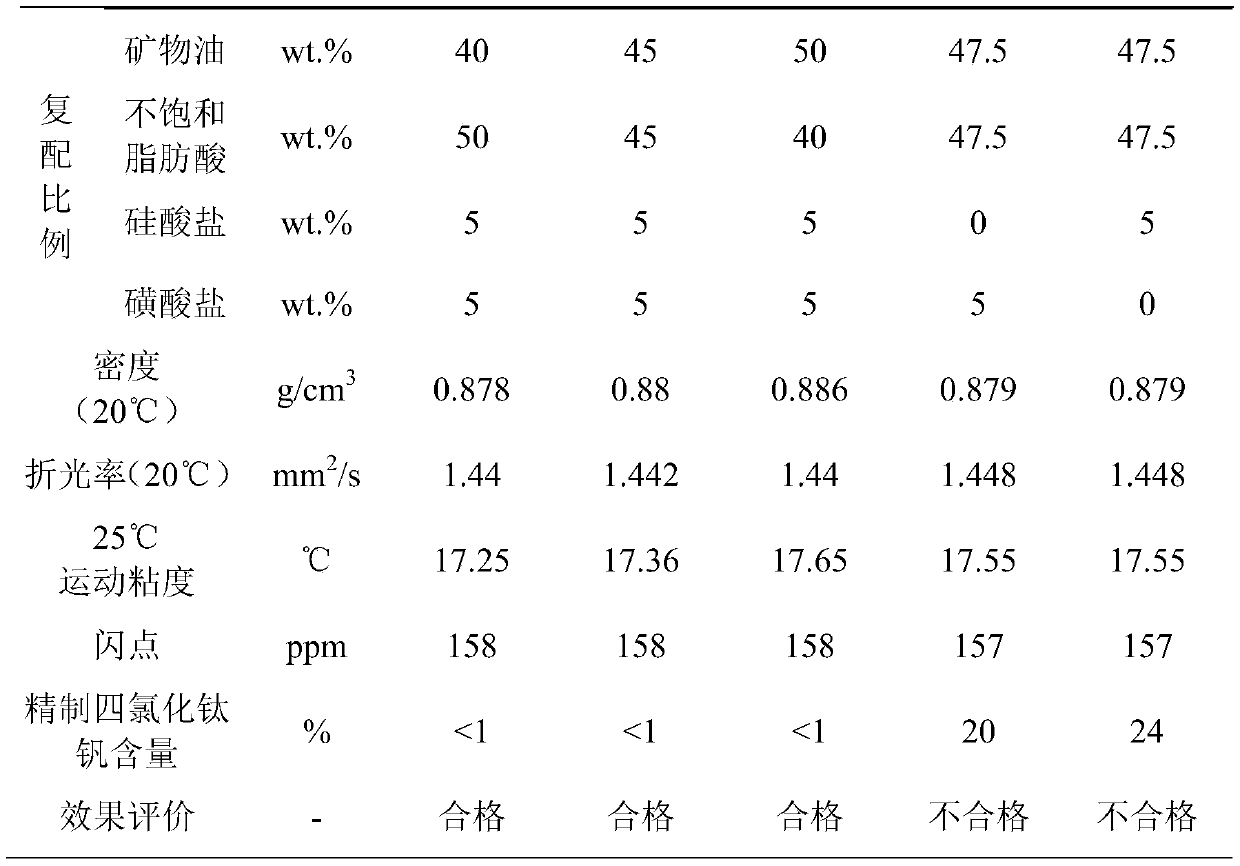

Compound organic matter for vanadium slag reduction crude titanium tetrachloride vanadium removal process and preparation method thereof

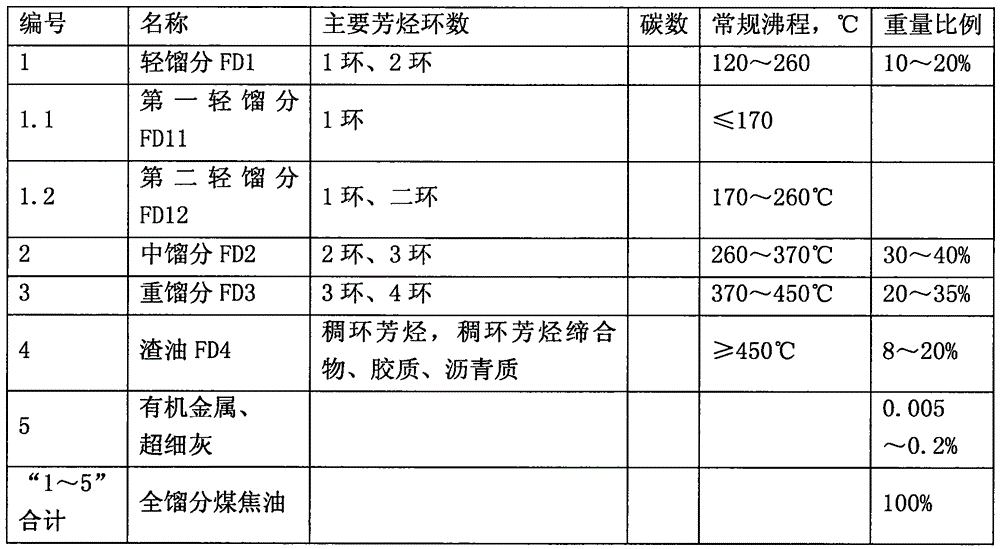

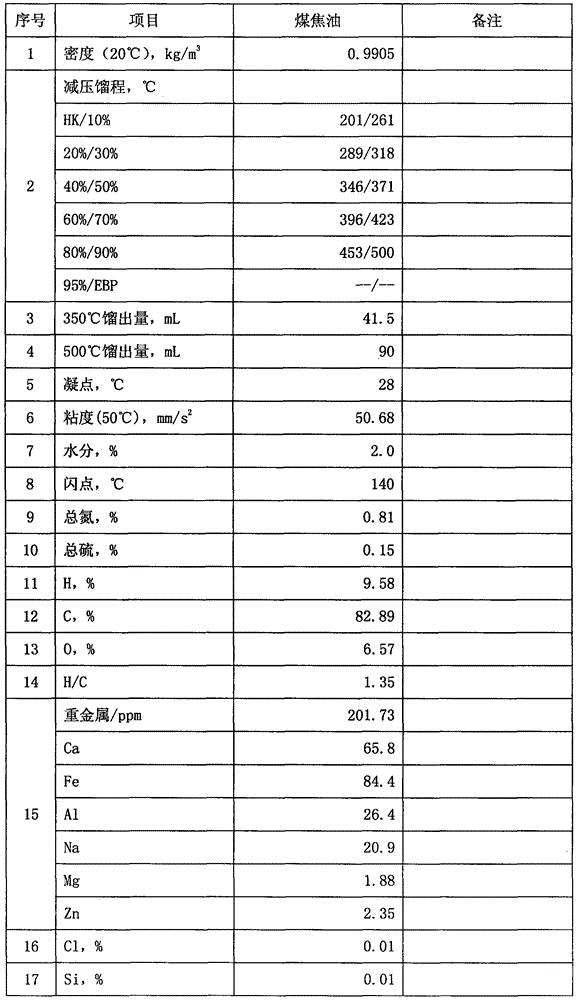

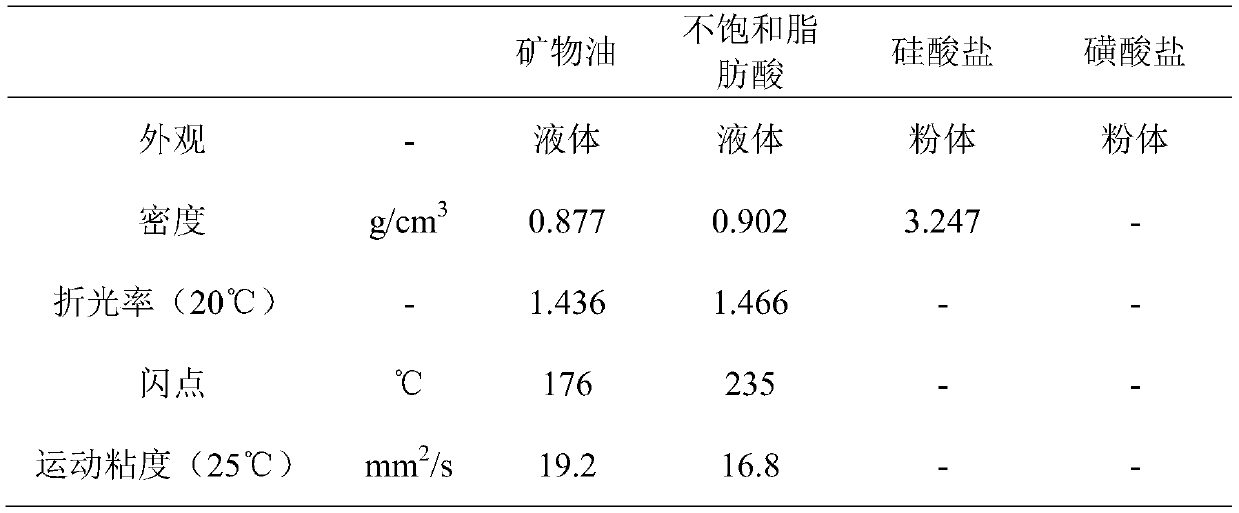

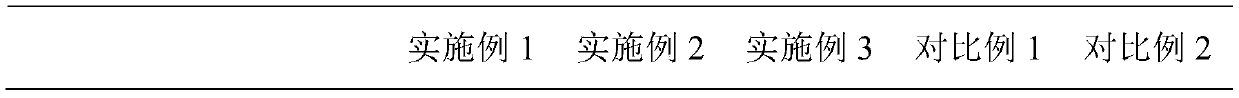

ActiveCN109928424AExtend continuous operation timeReduced service lifeTitanium halidesCompound organicTitanium chloride

The invention belongs to the field of organic matter refined titanium tetrachloride, in particular to a compound organic matter for a vanadium slag reduction crude titanium tetrachloride vanadium removal process. The compound organic matter is prepared from mineral oil, unsaturated fatty acid, silicate and sulfonate in a mass ratio of (40 to 55) to (35 to 50) to (2 to 8) to (2 to 8), wherein the mineral oil is industrial white oil; the industrial white oil is industrial-grade 26# white oil; the unsaturated fatty acid is linoleic acid; the silicate is aluminum silicate; the sulfonate is sodiumalpha-olefin sulfonate. The compound organic matter has the advantages of high vanadium removing efficiency, high adsorption capacity, and capability of ensuring stable vanadium removing effect on thepremise of the reduction of vanadium slag.

Owner:BOHAI UNIV

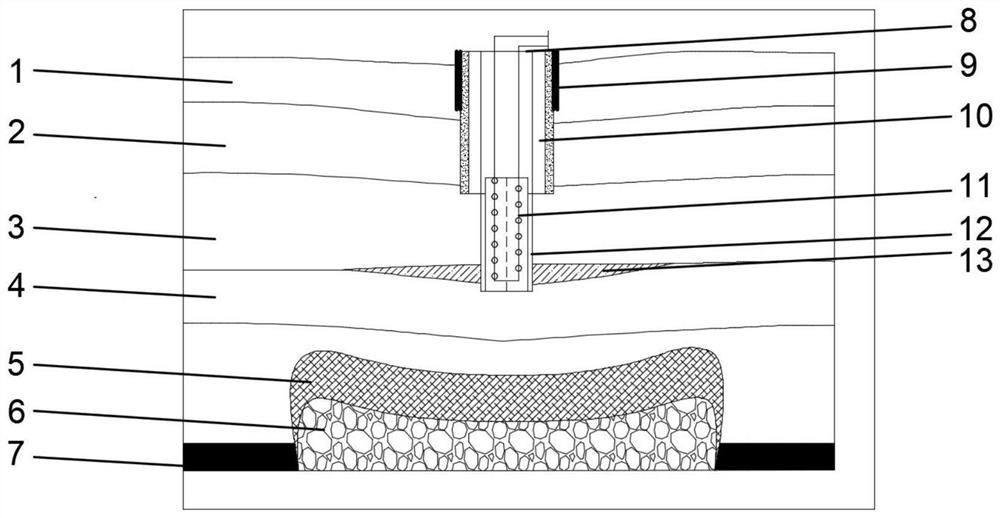

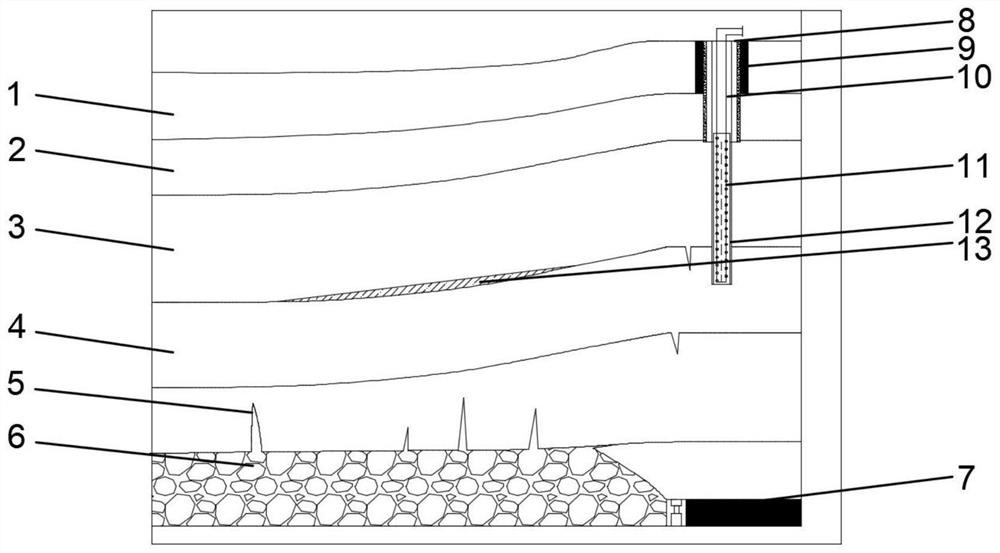

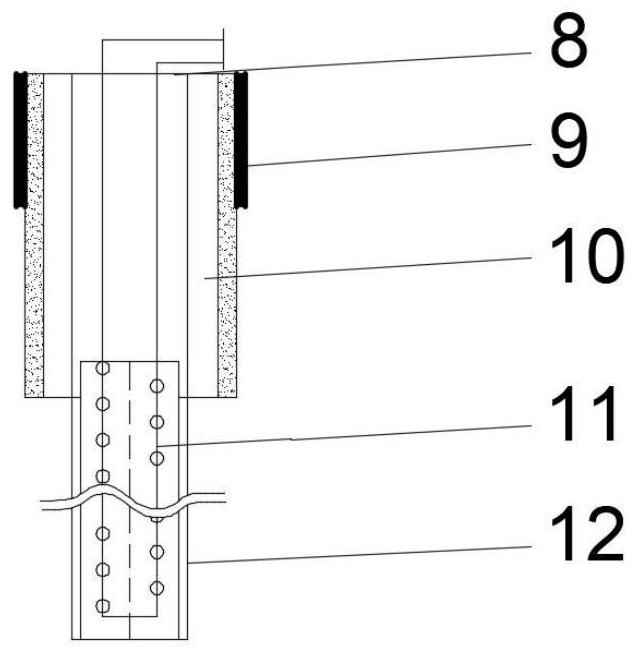

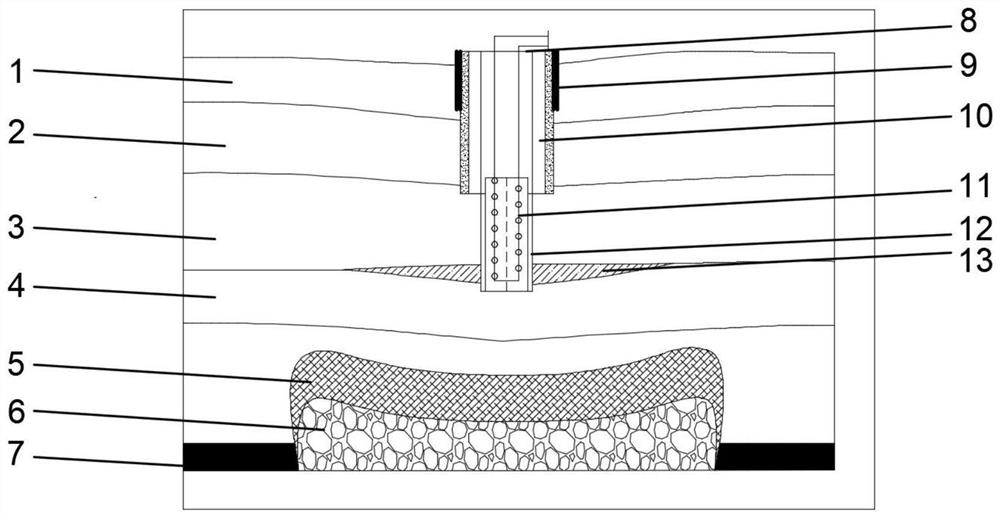

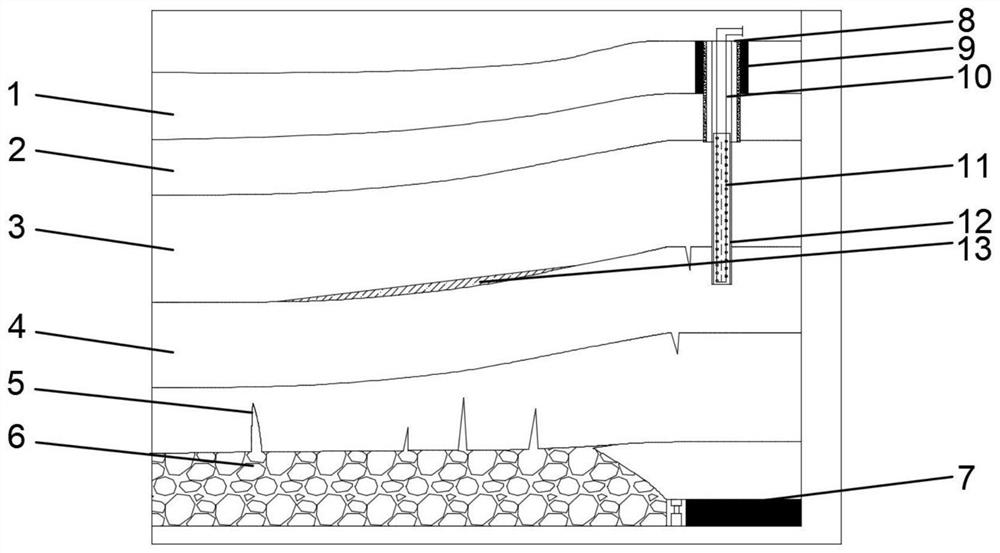

Ground water pumping hole pumping drainage method for working face roof separation water damage

ActiveCN111894671AExtend continuous operation timeEasy to installDrainageEnvironmental engineeringWater diversion

The invention discloses a ground water pumping hole pumping drainage method for working face roof separation water damage. The method is mainly designed for the conditions that ultra-thick mudstone upward-pitching water draining hole construction cannot be achieved underground, and the ground through hole difficulty is too large. The method comprises the following steps of firstly, mastering the stratum condition, judging the development position of a separation layer and the development height of a water diversion fissure zone, forming a plurality of water pumping drill holes corresponding tothe ground from the central position of a working surface, vertically constructing the drill holes from top to bottom by virtue of a ground drilling machine every 200-300 meters, enabling a first-stage drill hole to penetrate through a perforated section loose bed, and beating to 10-20m below the bottom boundary of a bedrock layer; and drilling a thick-wall floral tube in the second level to thebottom of a stratum where a separation layer may develop by 10-20 meters, carrying out pumping drainage work of a pumping hole before the working face is pushed to be 100 meters away from the workingface, absorbing water in an aquifer and the separation layer through the thick-wall floral tube, and arranging a mining deep well submersible pump to drain the water, so that pumping drainage and closure of the separation layer space are achieved, and the problem of accumulated water of the separation layer of the working face roof is solved.

Owner:SHANDONG UNIV OF SCI & TECH

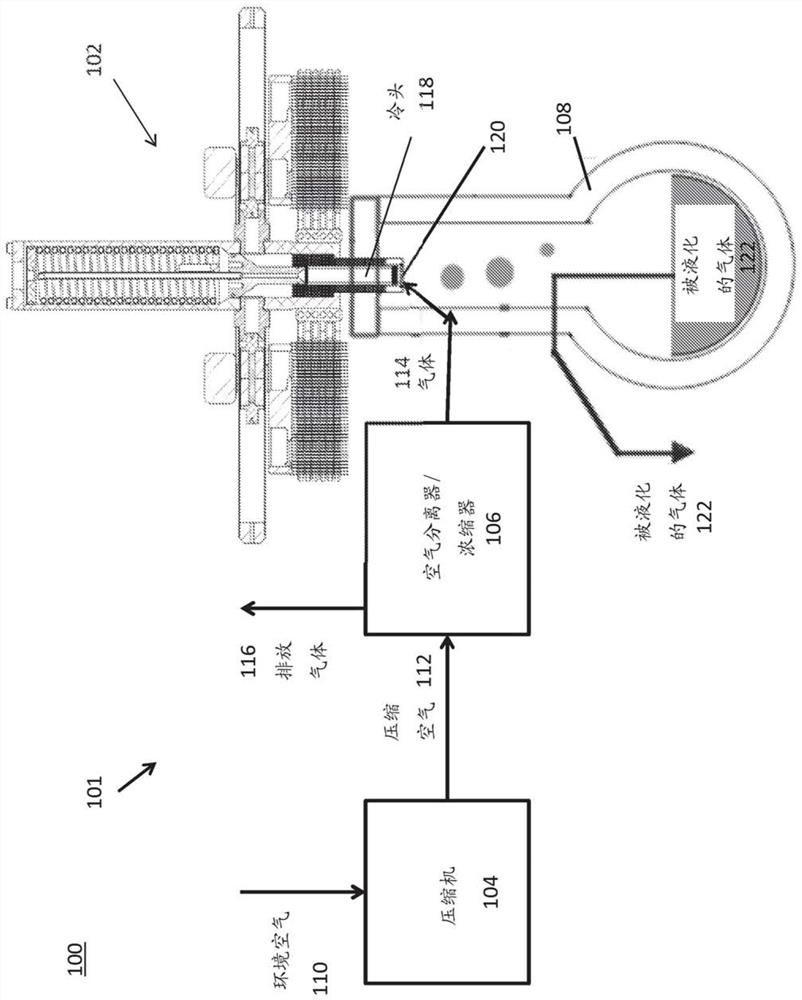

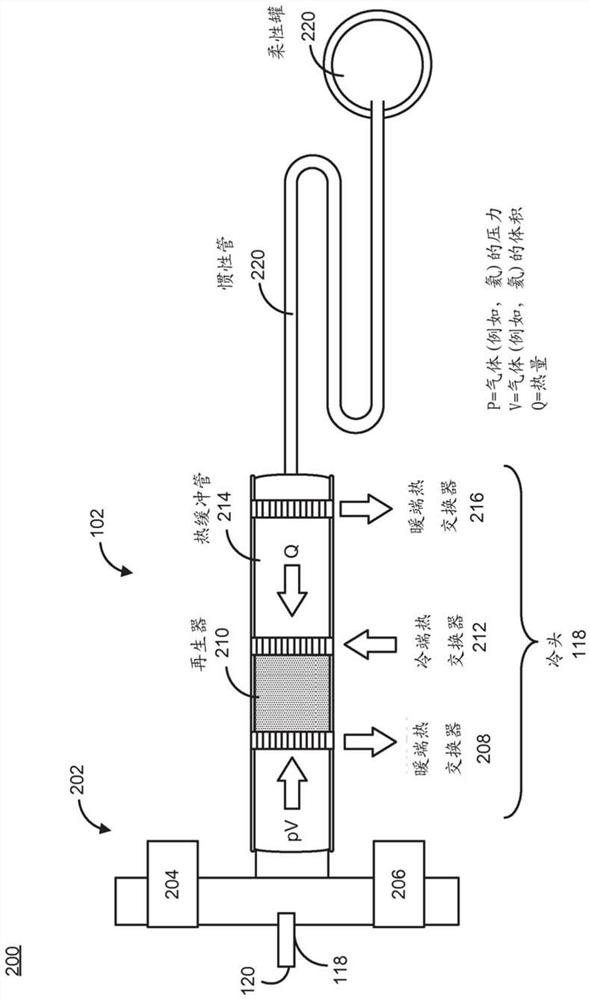

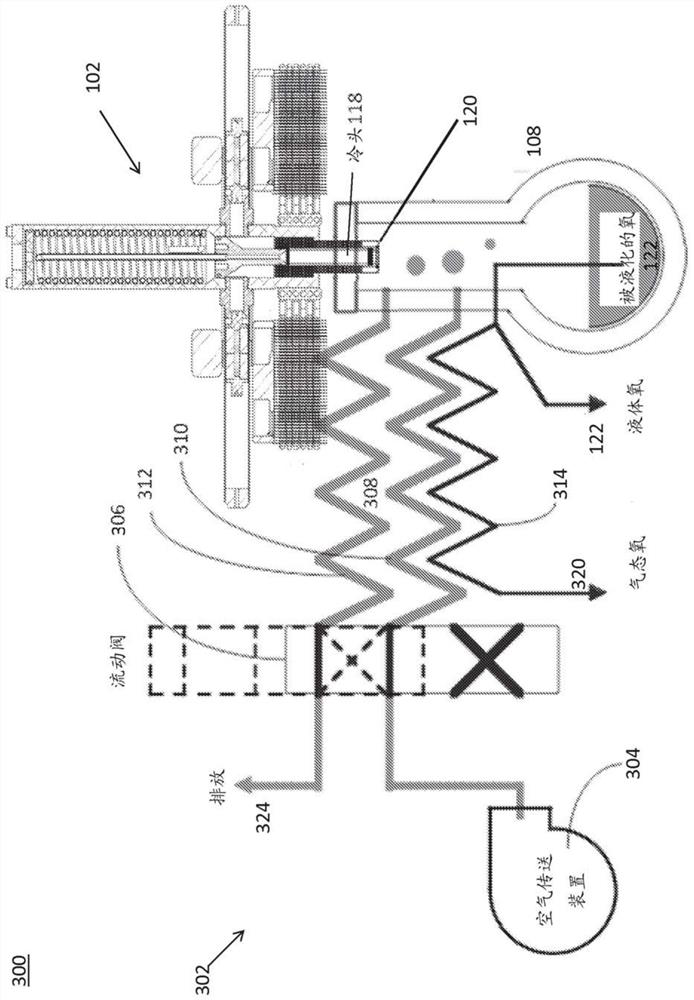

Cryocooler with magnetic reciprocating piston

ActiveCN111765664AExtend continuous operation timeLow costCompression machinesPiston pumpsReciprocating motionElectrical polarity

A cryocooler is described that can include a pressure wave generator, and a refrigeration device (for example, a coldhead), which can be used to liquefy a gas when the gas is exposed to a surface of the refrigeration device. The pressure wave generator can include one or more motors. Each motor can include a stator, and at least one electrical coil wound around a portion of the stator. The electrical coil can generate a reversing magnetic field when alternating electric current is passed through the electrical coil. The motor can further include a pressurized container that can be placed within the space enclosed by the stator, and a piston that can be placed inside the pressurized container. The stators can be placed external to the pressurized container. The piston is made by combining magnets that have opposite and transverse polarities, and are combined adjacently on a common reciprocating axis.

Owner:엠브이이바이오로지컬솔루션스유에스엘엘씨

A method for preparing a bearing cage for a robot with a cooling and wear-resistant structure

ActiveCN110848264BWith self-lubricating functionImprove cooling effectMetallic material coating processesBearing coolingManufacturing technologyBearing (mechanical)

A method for preparing a bearing cage for a robot with a cooling and wear-resistant structure, which belongs to the field of mechanical basic parts and manufacturing technology, and includes a cage body 1, a cage body 2, and a set of hexagon socket head screws. The cage body A group of roller pockets are arranged on the first and the cage body two, the end surface of the cage body one close to the cage body two is provided with a first boss, and a group of spines are arranged on the outer wall of the first boss Claw, the end of the cage body two close to the cage body one is provided with a first groove, the inner wall of the first groove is provided with a set of wedge-shaped grooves, and the first boss is arranged on the first groove Inside, the set of pawls is engaged in a set of wedge-shaped grooves. The present invention adopts the design of the split structure, which is convenient for the replacement of the cage part. The ratchet and the wedge-shaped groove are placed to rotate radially, and the cage body 1 and the cage body 2 are formed by a set of hexagonal countersunk head screws to form a stable structure. The whole, prolonging the service life of the bearing.

Owner:苏州圣典企业管理咨询有限公司 +1

A method of pumping and draining ground water holes for roof detachment water damage on working face

The invention discloses a ground water hole pumping method aimed at the water damage of the roof separation layer of the working face. The invention is mainly designed for the situation that it is impossible to realize the upward drainage hole construction of huge thick mudstone underground and the ground penetration hole is too difficult. This method should first grasp the stratum conditions, determine the development position of the separation layer and the development height of the water-conducting fissure zone, and open a number of pumping boreholes from the central position of the working face corresponding to the ground, and rely on the ground drilling rig to construct vertically from top to bottom every 200-300m Drilling, the first-level drilling passes through the loose layer of the opening section, and drills to 10-20m below the bottom boundary of the bedrock layer; the second-level drilling drills the thick-walled flower tube to the bottom of the stratum where separation layers may develop 10-20m, and drills in the working face Advance to 100m away from the working face to carry out the pumping and drainage work of the pumping hole, absorb the water in the aquifer and the separation layer through the thick-walled flower tube, and set up the mine deep well submersible pump to drain it, so as to realize the pumping and drainage of the separation layer space With the interception, the problem of water accumulation on the top plate of the working face is solved.

Owner:SHANDONG UNIV OF SCI & TECH

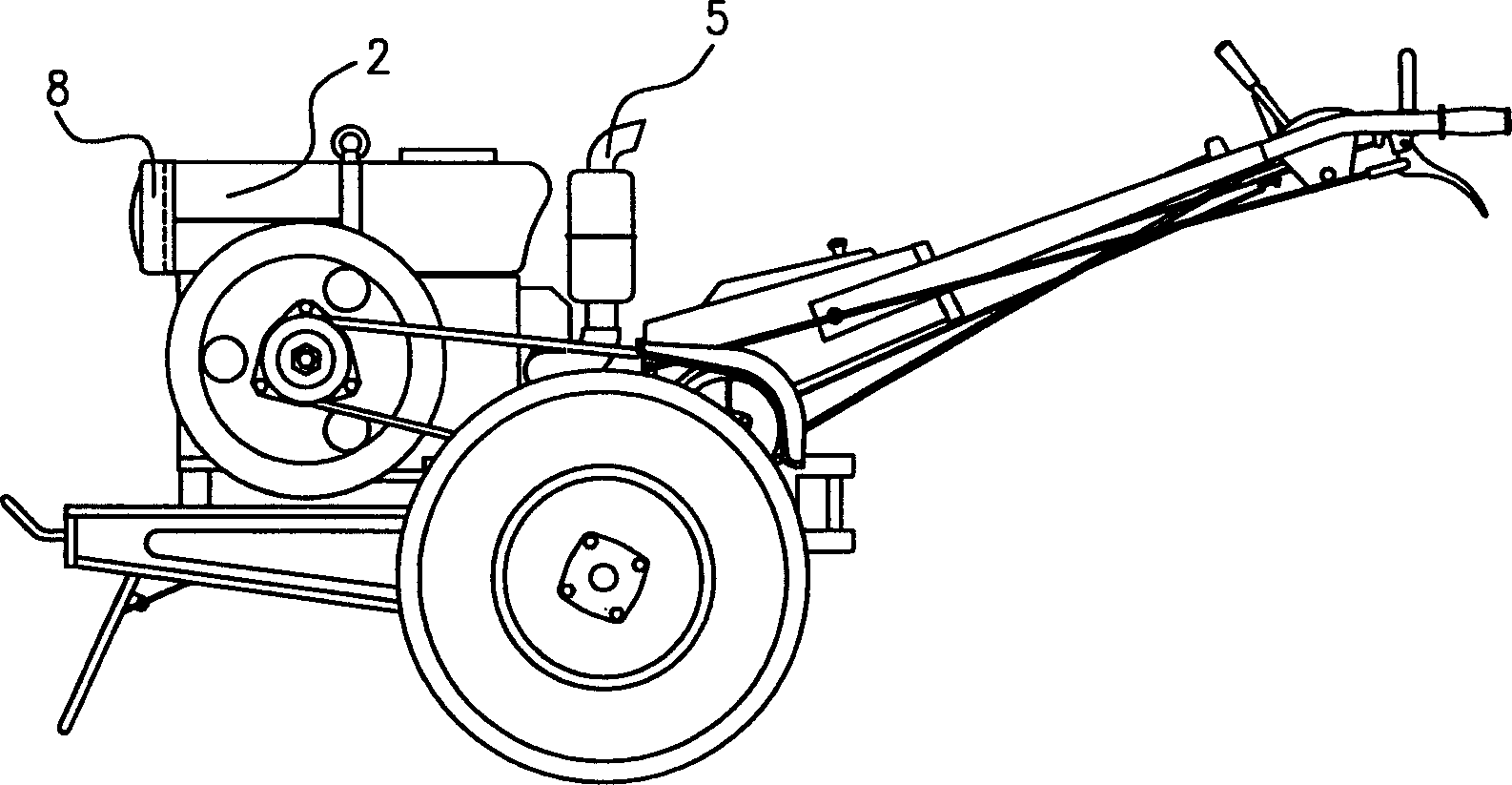

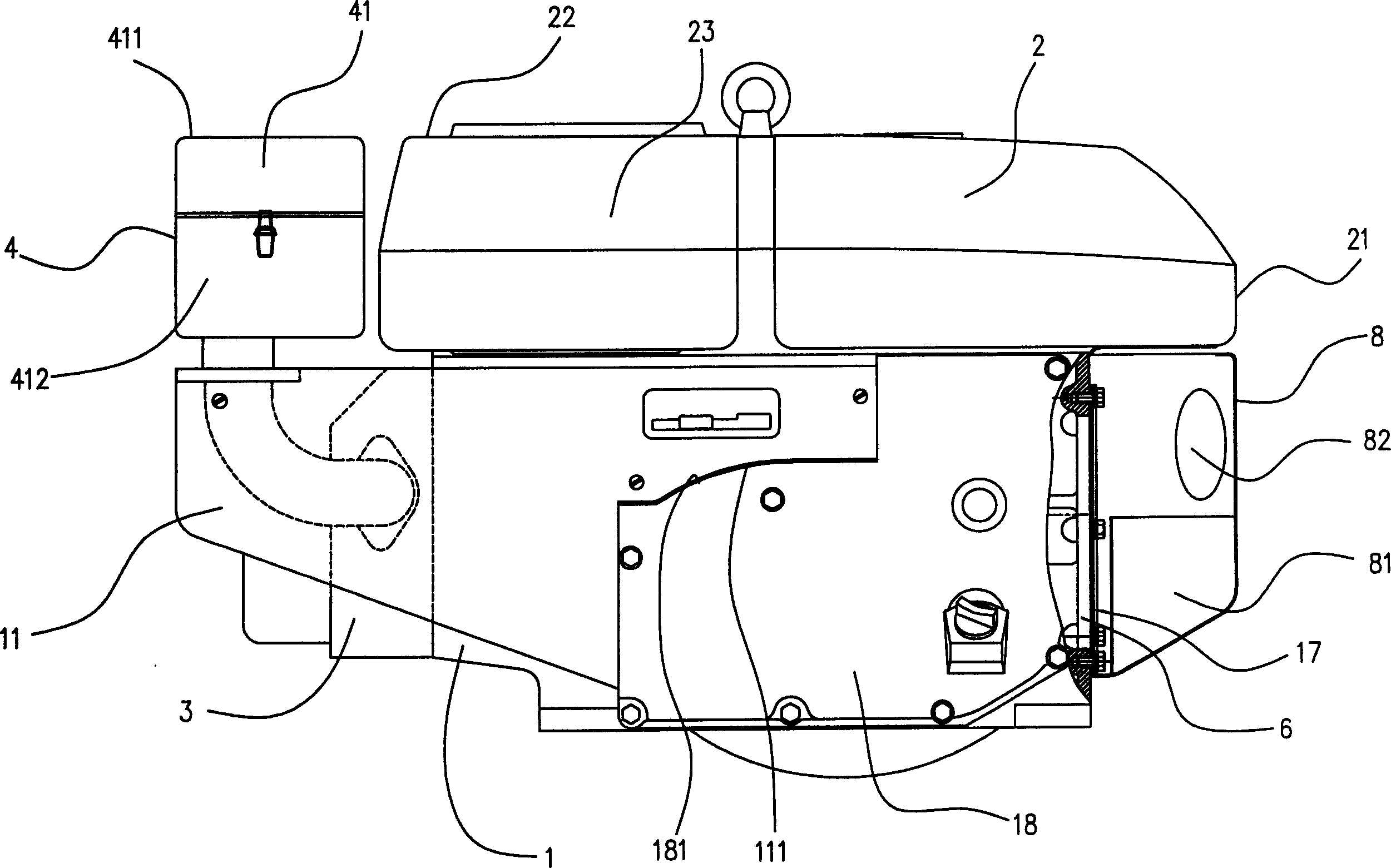

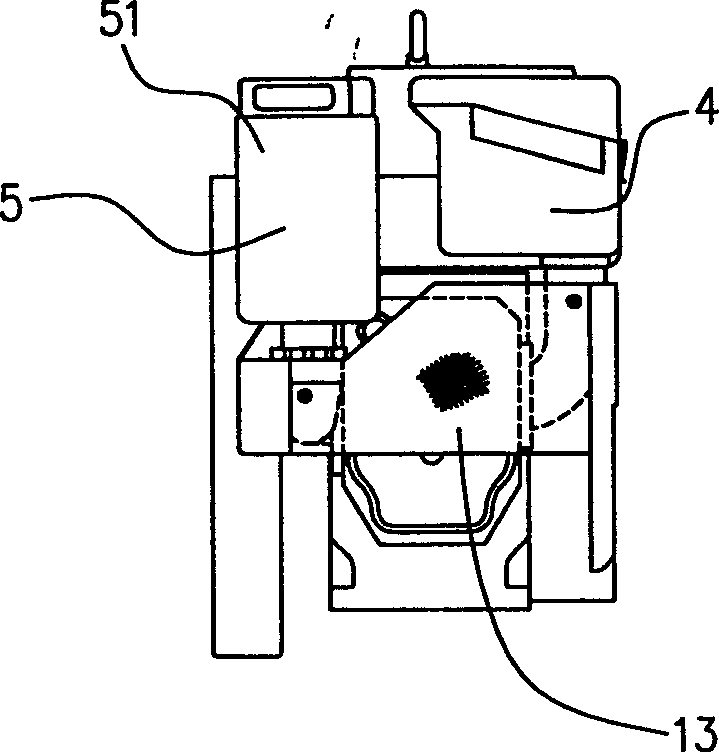

Single cylinder horizontal water cooling diesel engine hand tractor installed with said diesel engine

InactiveCN1176825CIncrease volumeExtended working hoursMachine framesSuperstructure subunitsAir cleanersFlywheel

The tractor includes the main body of diesel engine. The oil box or the water tank or their combination, including the upper wall and the perisporium, is installed on the body. The cylinder cover is installed on the one end of the body. The air cleaner and the muffler are installed on the cylinder cover. There is an opening and the cover on the other end of the body. The flywheel is on one side of the body, and the cover of the gearbox in on the other side. The length and the volume of the oil box or the water tank or their combination can be increased under certain length of the entire diesel engine. The lighting blind zone appeared on the front and below part of the tractor can be removed so as to be favorable to field operation.

Owner:CHANGZHOU CHANGFA POWER MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com