Compound organic matter for vanadium slag reduction crude titanium tetrachloride vanadium removal process and preparation method thereof

A crude titanium tetrachloride and reduction technology, applied in the direction of titanium halide, etc., can solve the problems of increasing the cost of vanadium slag treatment and maintenance equipment, affecting the continuity of titanium tetrachloride refining process, and incomplete carbon generation by pyrolysis. Achieve the effect of increasing continuous operation time, reducing the amount of vanadium slag, and promoting dispersion

Active Publication Date: 2019-06-25

BOHAI UNIV

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The reason for this problem is that the pyrolysis of organic matter is not complete, and a large amount of viscous polymers are produced, which leads to equipment sticking, blockage, etc., which affects the continuity of the titanium tetrachloride refining process and increases the processing capacity of vanadium. Slag and cost of maintaining equipment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

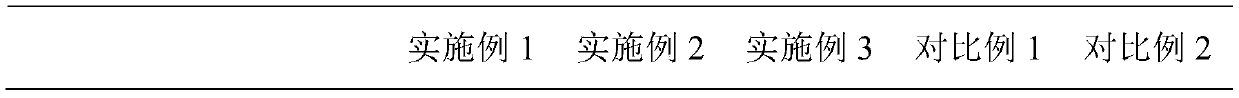

[0036] In Example 1, Example 2 and Example 3, except that there are multiple choices of raw materials and their contents, other reaction conditions and parameters are completely consistent.

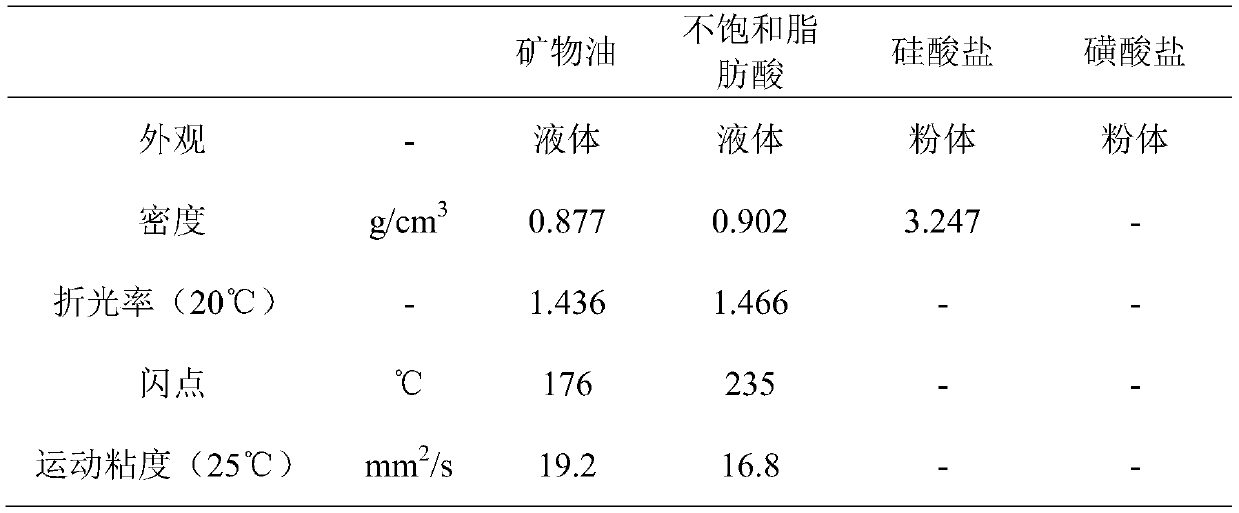

[0037] Table 2 shows the composition, physical properties and effect evaluation of the compounded organic matter. The evaluation methods in Table 2 are as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the field of organic matter refined titanium tetrachloride, in particular to a compound organic matter for a vanadium slag reduction crude titanium tetrachloride vanadium removal process. The compound organic matter is prepared from mineral oil, unsaturated fatty acid, silicate and sulfonate in a mass ratio of (40 to 55) to (35 to 50) to (2 to 8) to (2 to 8), wherein the mineral oil is industrial white oil; the industrial white oil is industrial-grade 26# white oil; the unsaturated fatty acid is linoleic acid; the silicate is aluminum silicate; the sulfonate is sodiumalpha-olefin sulfonate. The compound organic matter has the advantages of high vanadium removing efficiency, high adsorption capacity, and capability of ensuring stable vanadium removing effect on thepremise of the reduction of vanadium slag.

Description

technical field [0001] The invention belongs to the field of refining titanium tetrachloride with organic matter, and in particular relates to a complex organic matter for vanadium removal process of vanadium slag reduction crude titanium tetrachloride and a preparation method thereof. Background technique [0002] Titanium dioxide, also known as titanium dioxide, is considered to be a white pigment with the best performance in the world. Titanium tetrachloride is an intermediate product for preparing titanium dioxide, and the purity of titanium tetrachloride directly affects the chroma of titanium dioxide. The existing titanium tetrachloride refining process is mainly based on organic matter refining. This vanadium removal process will cause problems such as equipment sticking and blockage after running for a period of time. The reason for this problem is mainly because a large amount of high molecular polymer by-products are produced in the process of cracking organic ma...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01G23/02

Inventor 鄂涛邢振强杨姝宜刘琳钱建华马增英程颖肖鑫宇

Owner BOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com