Ground water pumping hole pumping drainage method for working face roof separation water damage

A roof separation layer and working face technology, which is applied in drainage, earthwork drilling, safety devices, etc., can solve problems such as endangering national property and people's life safety, well flooding, etc., and achieves long continuous operation time, convenient installation, and easy to use Maintain Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

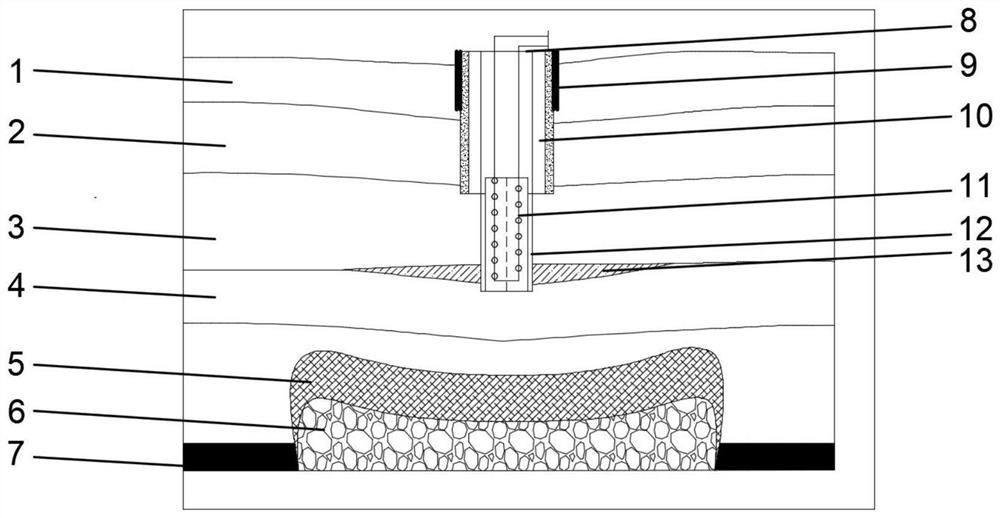

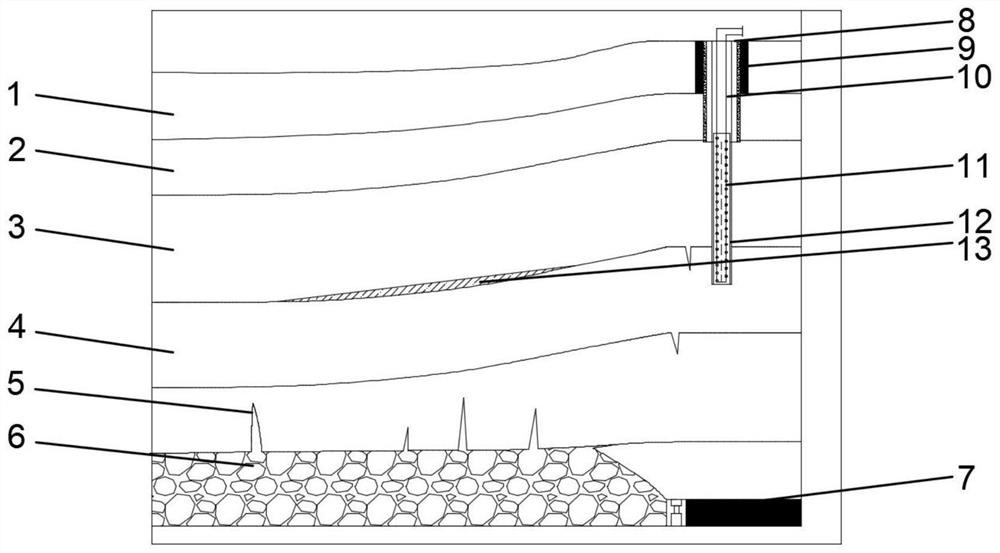

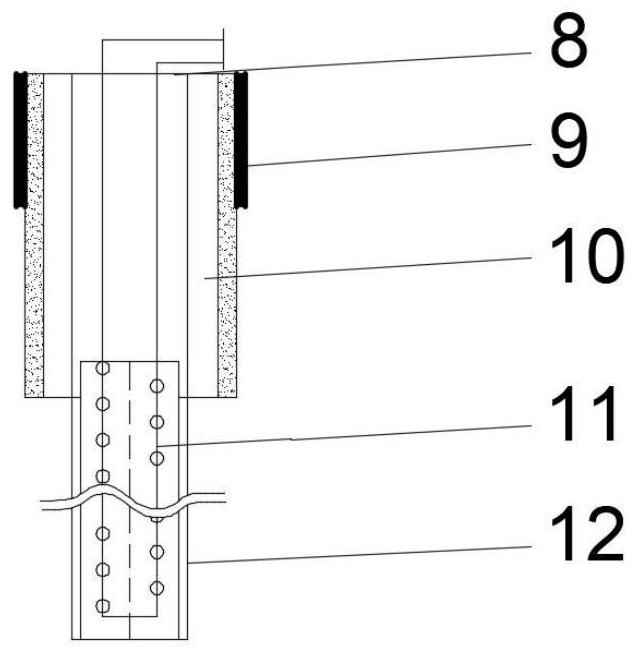

[0022] Such as Figure 1-3 The shown technical scheme provided by the present invention is as follows, a method for pumping and draining water holes on the ground for roof detachment water damage on the working face, comprising the following steps:

[0023] Step 1: Reasonably determine the parameters of the coal mining face, master the data of the working face engineering, hydrogeological conditions and mining conditions, calculate the development height of the water-conducting fracture zone after the mining of the working face, judge the development position of the separation layer, and analyze the impact of water filling on the separation layer the layers of the aquifer;

[0024] Step 2: Along the advancing direction of the working face, arrange the drilling rig at the center of the working face and perpendicular to the ground surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com