Grinding device and combination method thereof

A grinding device and technology to be ground, applied in grinding machines, optical surface grinders, grinding/polishing equipment, etc., can solve problems such as reduced production capacity and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

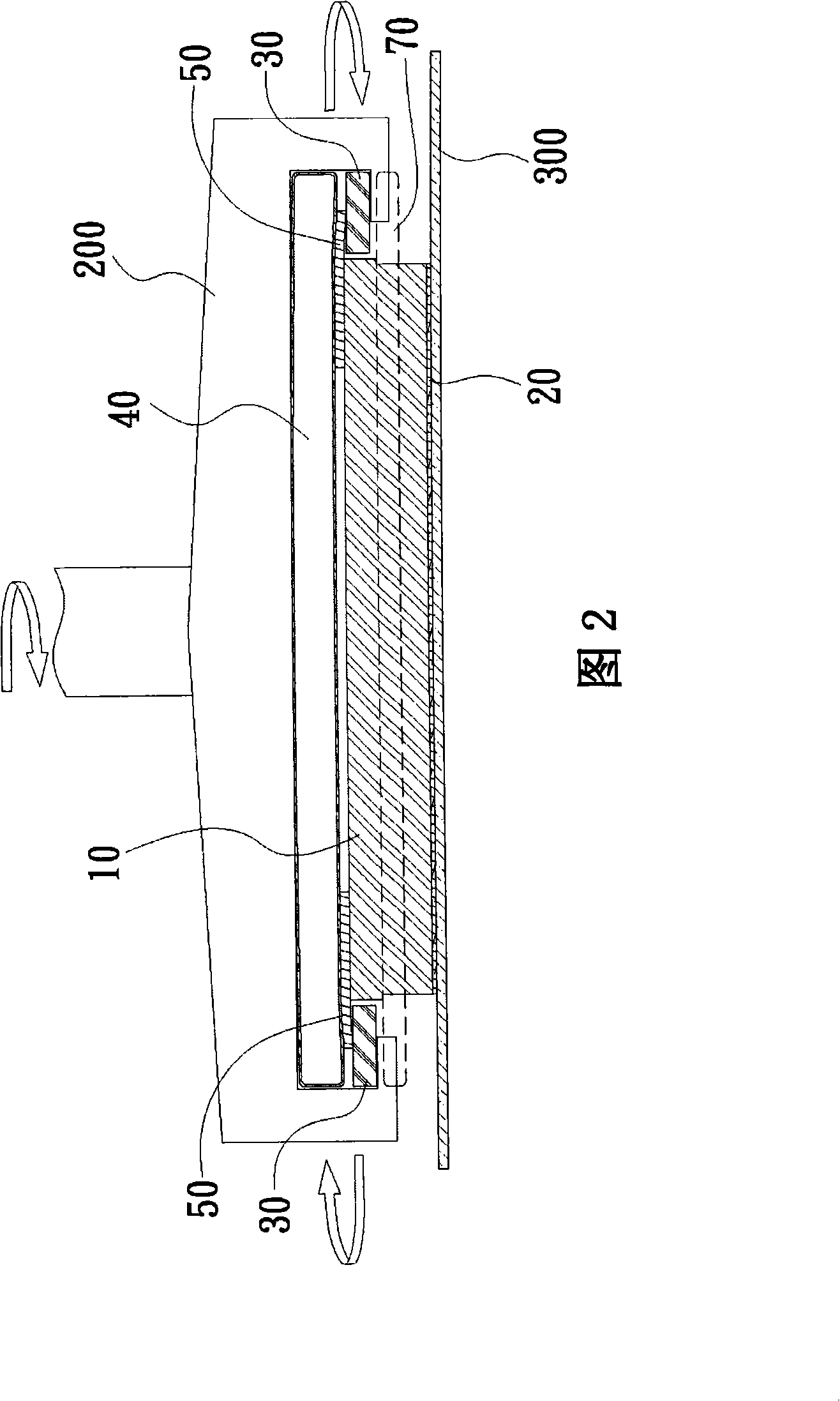

[0038] The preferred embodiments of the present invention and their effects are described below in conjunction with the accompanying drawings.

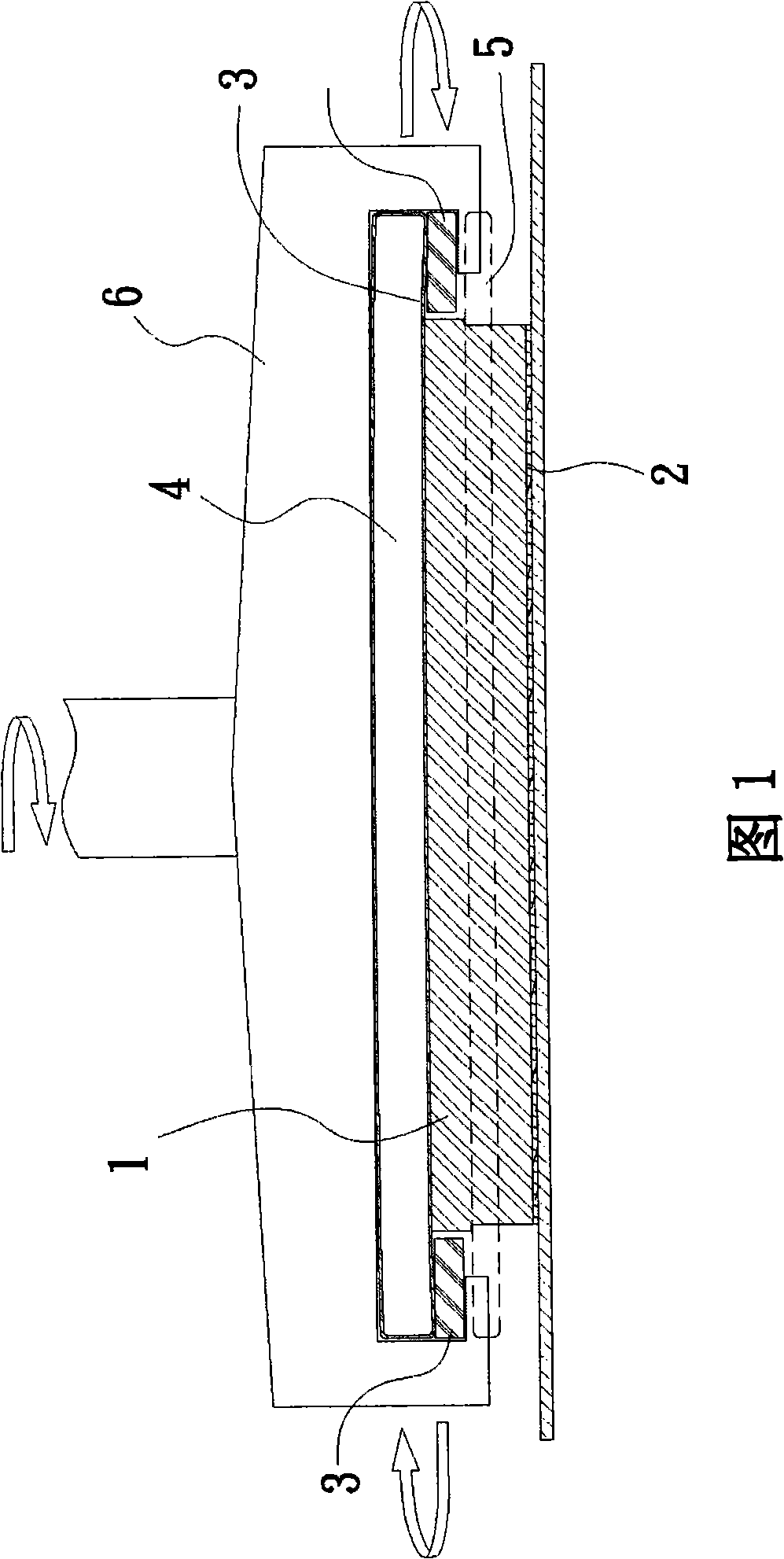

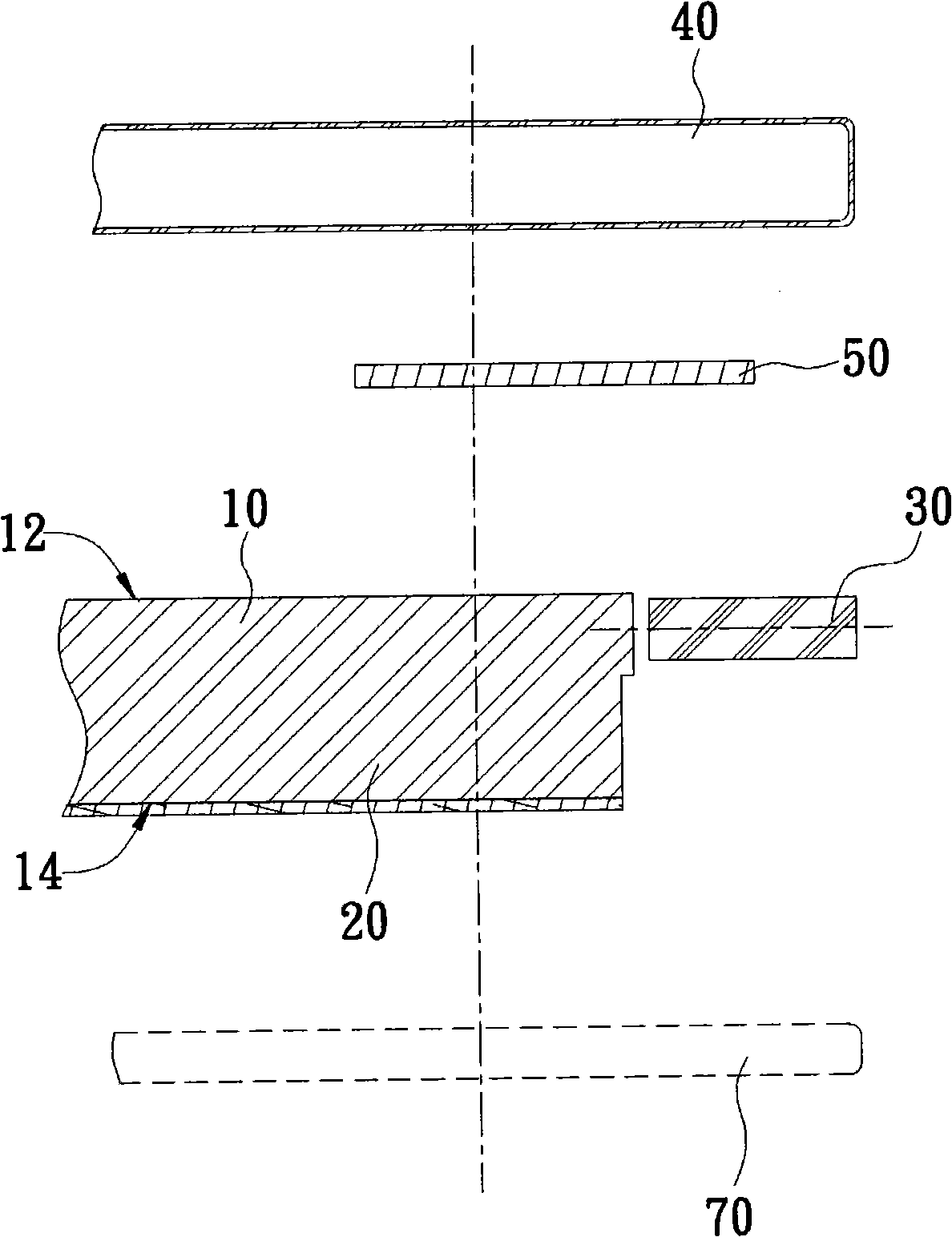

[0039] Please refer to FIG. 2 , which is a grinding device disclosed in the first embodiment of the present invention, which is used to grind a workpiece 300 to be ground so that the surface of the workpiece 300 to be ground is smooth. For example, the workpiece 300 to be polished is a color filter coated with a color photoresist. After the grinding device grinds the surface of the color filter, the angular difference of the color photoresist is reduced and the photoresist residue is removed at the same time, so that the surface of the color filter is smooth. And maintain good filter characteristics. The grinding device includes a fixed plate 10 , a grinding pad 20 , a block 30 , a positive pressure air pad 40 and a gasket 50 . The grinding device is pressed by a chuck 200, and the chuck 200 drives the grinding device to rotate toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com