Freezing device

A freezing device and anti-icing technology, applied to household refrigeration devices, coolers, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

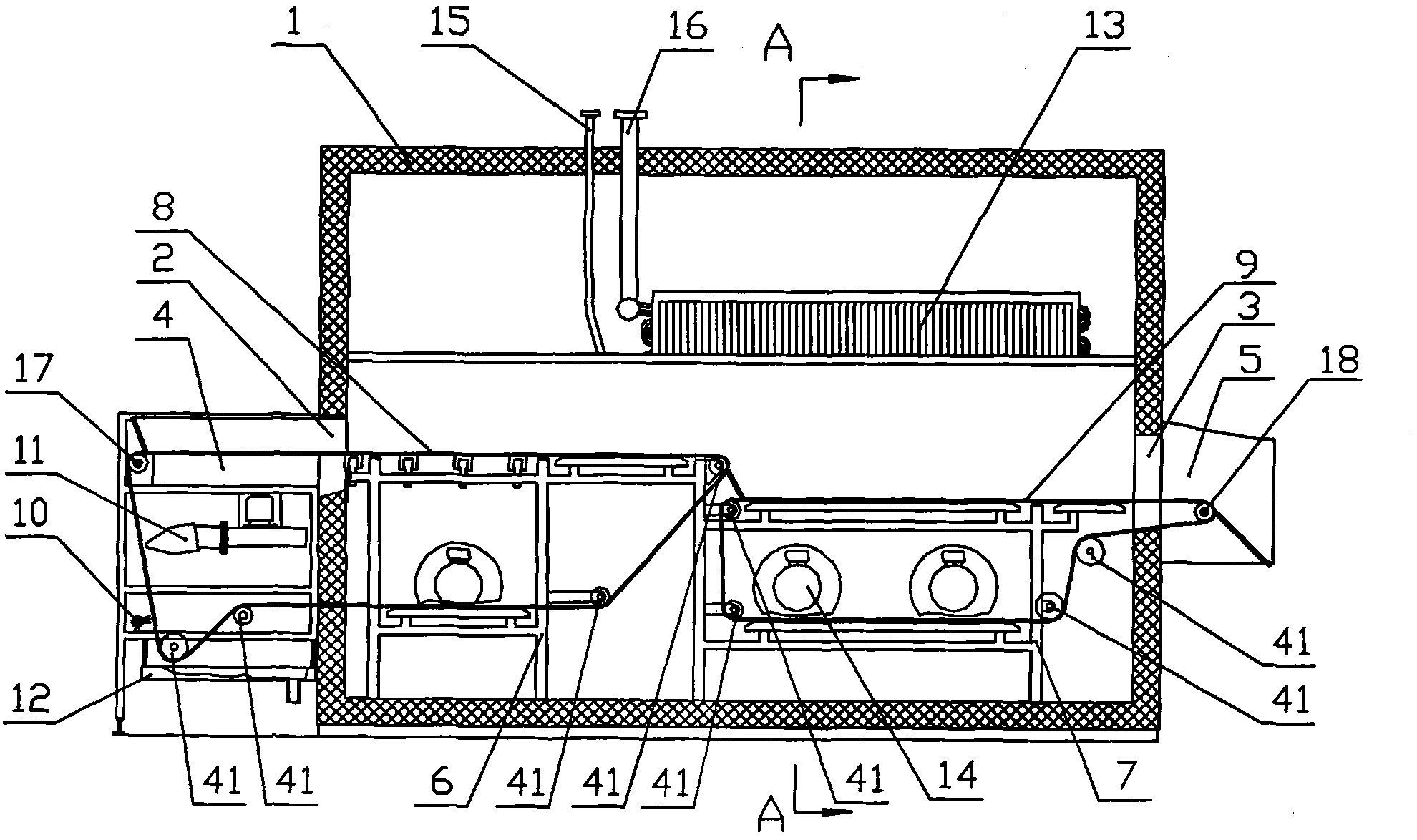

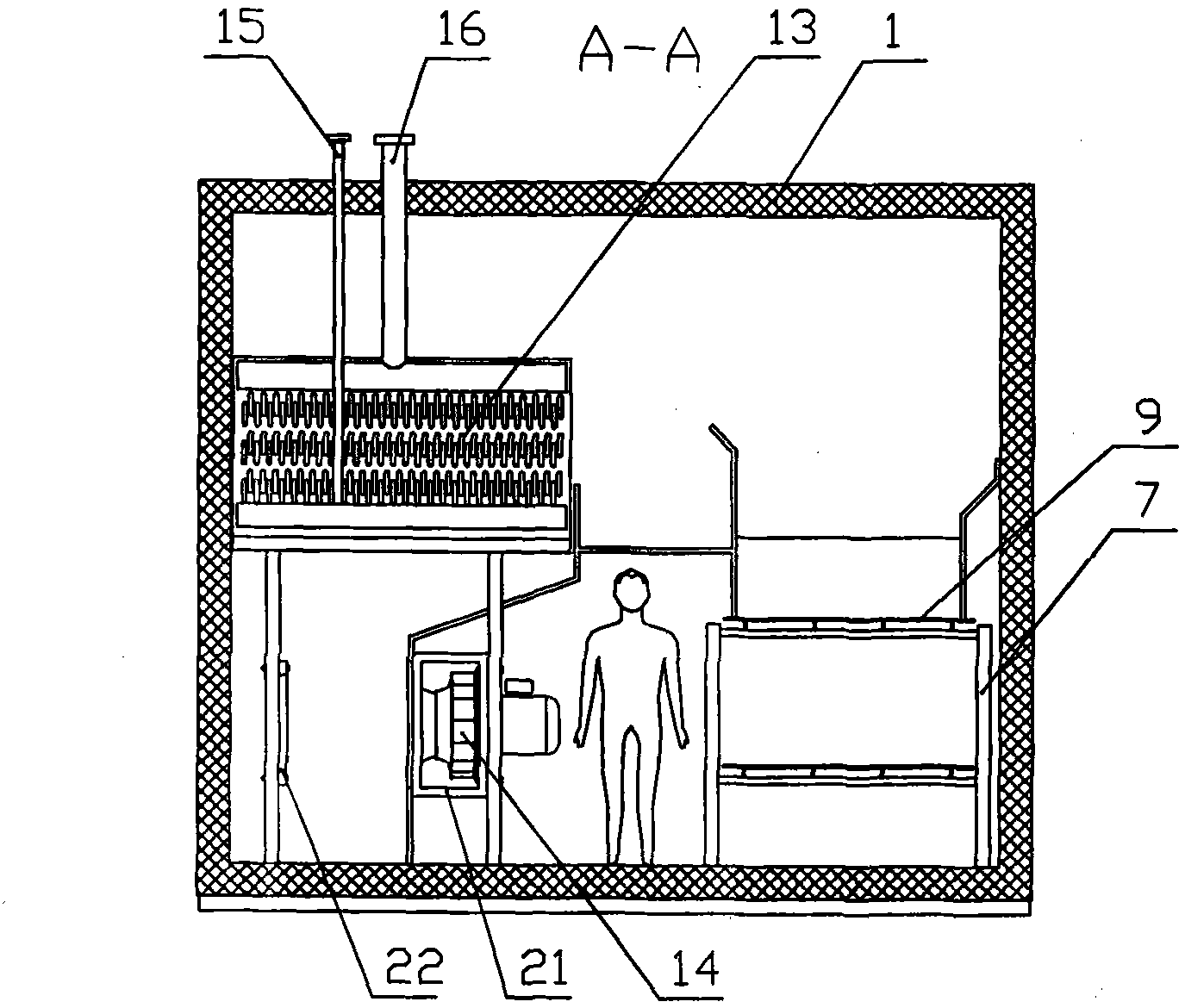

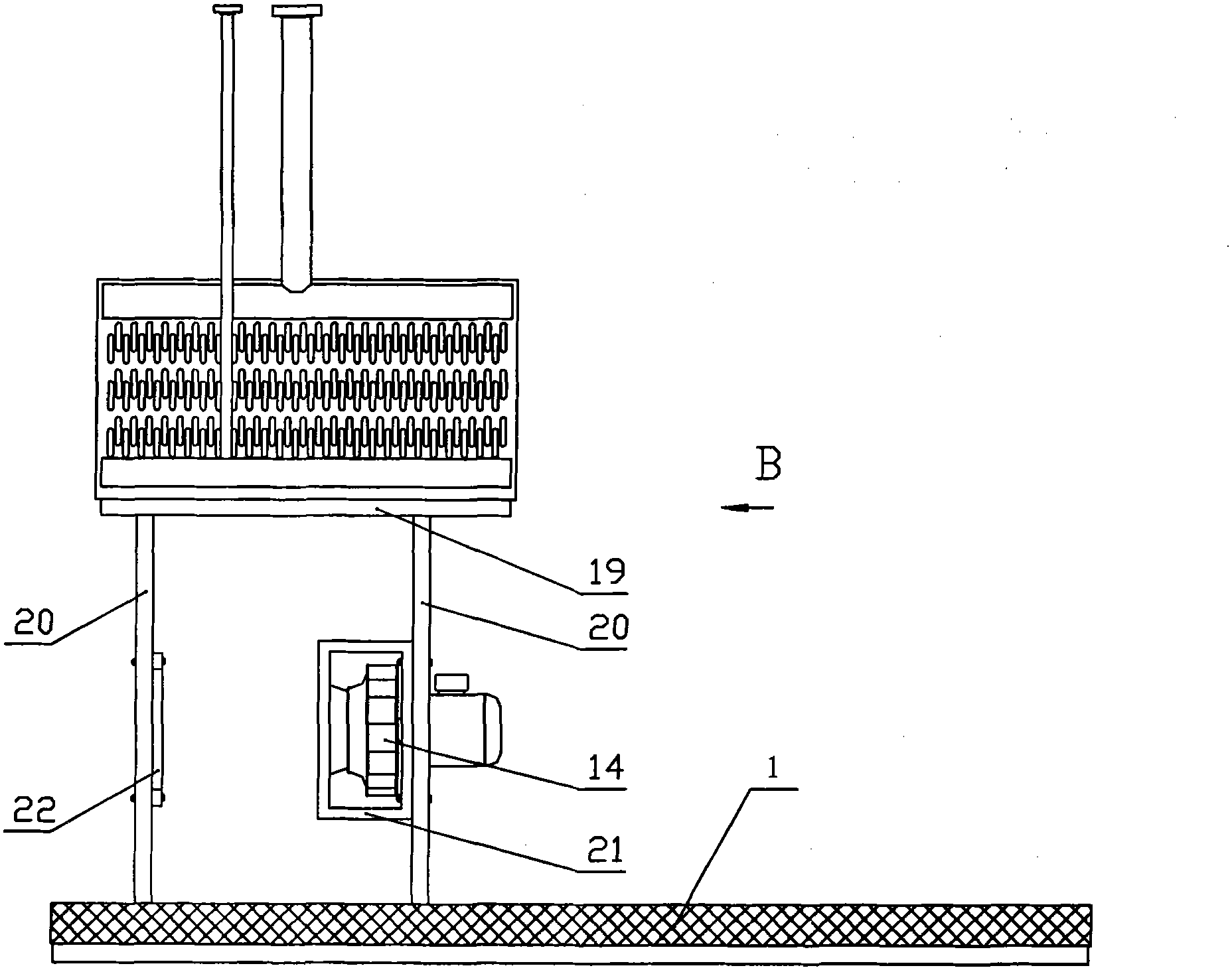

[0035] freezer (see figure 1 , figure 2 ) includes a heat insulating box body 1, a feeding mechanism 4 and a material discharging mechanism 5 respectively placed in the material inlet 2 and the material outlet 3 of the heat insulating box body 1, and the feeding conveyor belt frame 6 installed in the heat insulating box body 1 And the discharge conveyor belt frame 7, the first section of the loop conveyor belt 8 and the second section of the loop conveyor belt 9 installed on the feed conveyor belt frame 6 and the discharge conveyor belt frame 7 respectively, are located at the feed mechanism 4 The flushing device 10 below, the blowing device 11 , the water collecting tray 12 , the air cooler that is positioned at the air blowing evaporator 13 and the horizontal centrifugal fan 14 in the heat insulation box 1 constitutes. The liquid supply pipe 15 and the air return pipe 16 of the top blowing evaporator 13 are respectively connected with the refrigerating unit, and the drivin...

Embodiment 2

[0037] The difference with Embodiment 1 is: there is an anti-icing bracket 23 below the first section of circulating conveyor belt 8 that enters freezing in the heat-insulating box 1 (see Figure 5 , Figure 6 , Figure 7 ), the two ends of the anti-icing bracket 23 have mounting plate 24 and feed conveyor belt frame 6 to be fixedly connected. The upper plane 25 and the two side faces 26 of the anti-icing bracket 23 basically all adopt polytetrafluoroethylene material to form a polytetrafluoroethylene support surface, and there is a gap between the upper plane 25 and the two side faces 26 of the polytetrafluoroethylene material Wear-resistant strip 27 of ultra-high molecular polyethylene material. 28 is a mounting screw, 29 is a mounting screw, 30 is a mounting nut, and the polytetrafluoroethylene sleeve 31 is connected to the mounting screw 29 with a cotter pin 32 . There is at least one anti-icing bracket 23 below the first section of endless conveyor belt 8 , and multiple...

Embodiment 3

[0039] The difference with Embodiment 1 or 2 is that there is a steam heating windshield device 33 below the first section of the circulating conveyor belt 8 at the inlet 2 of the heat-insulating box body 1 (see Figure 8 , Figure 9 , Figure 10 ), the windshield 34 of the steam heating windshield 33 is fixedly connected with the heat insulation box body 1, and the upper plane 35 of the steam heating windshield 33 and the side 26 lower edge of the polytetrafluoroethylene of the anti-icing bracket 23 are connected And the outside of the heat insulation box 1 is inclined downward. The windshield 34 and the upper plane 35 are fixed on the heating pipe 37 with the heat conduction plate 36, and the steam pipe 38 is inserted in the heating pipe 37, and there is a return steam pipe 39 at the bottom of the heating pipe 37, and the steam enters the steam pipe 38 and enters the heating pipe 37, Flow out through return pipe 39 again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com