Filter

A technology of filter and filter area, which is applied in the direction of gravity filter, filter separation, loose filter material filter, etc., can solve the problems of stable control of anhydrous, waste of filter area, and influence of filter efficiency, etc., to prevent short circuit and Bias current phenomenon, easy installation and replacement, guaranteed treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

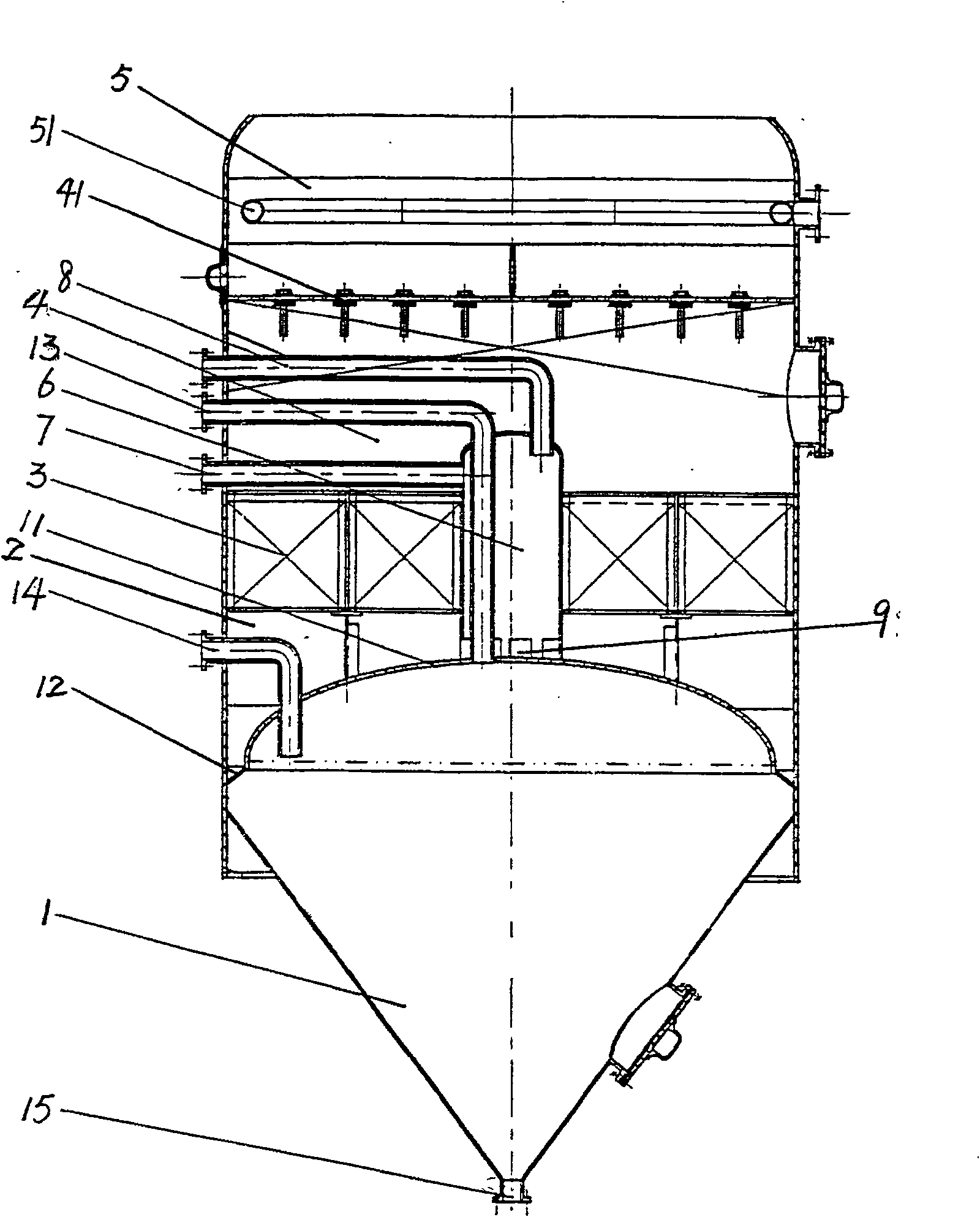

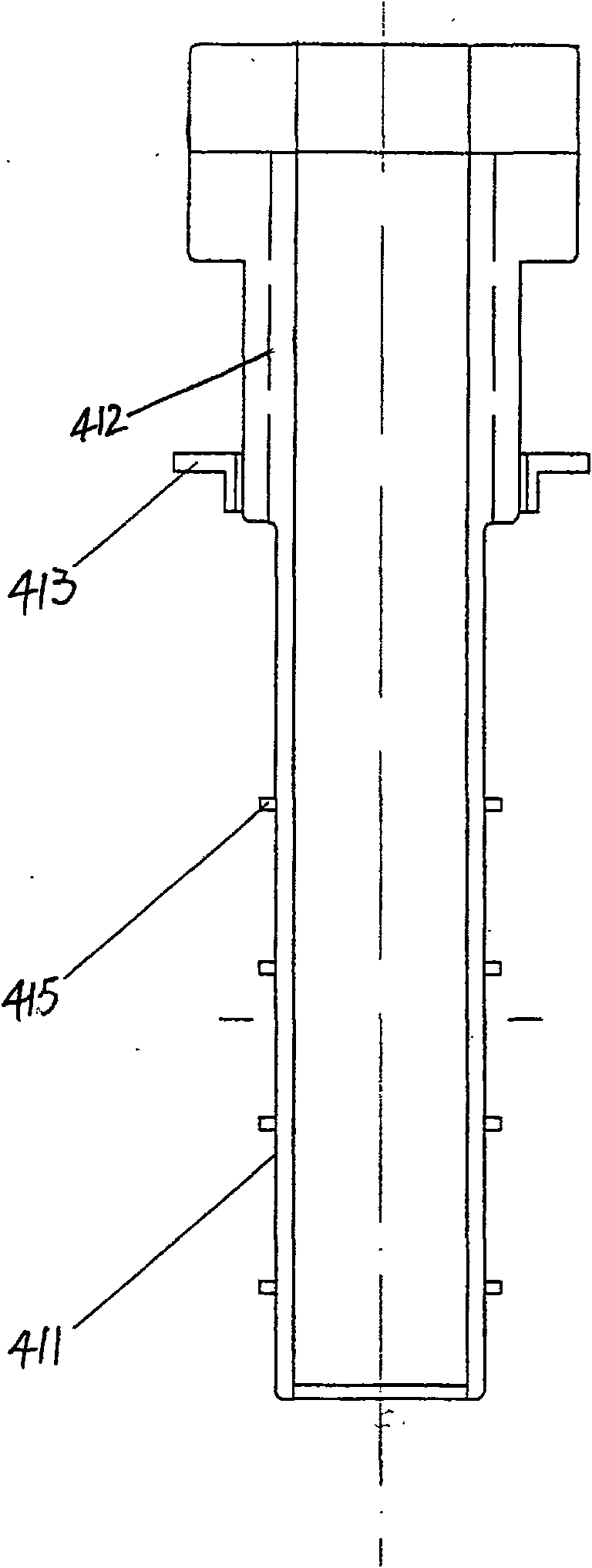

[0013] A filter, comprising a shell with an open top, and the shell is composed of a mud collecting area 1, a flocculation area 2, a sedimentation area 3, a filtering area 4, and a clean water area 5 in order from bottom to top.

[0014] The mud collecting area 1 is a conical mud collecting bucket. The top of the conical mud collecting bucket is provided with a flange cap 11. The bottom of the conical mud collecting bucket is equipped with a regular slurry discharge system 15. The conical mud collecting buckets on both sides of the flange cap 11 There is a mud water inlet 12 connected to the flocculation zone at the bucket port, an inlet pipe 13 is connected to the top of the flange cap 11, and a return pipe 14 is also arranged in the space of the conical mud collecting bucket flange cap;

[0015] The upper part of a central liquid inlet tank 6 is connected to the water inlet pipe 7, the top is connected to the exhaust pipe 8, and the bottom is fixed in the center of the flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com