Corrosion resistance testing system for wind power cooler core

A technology of cooler core and test system, applied in the direction of weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc. The fan can not work normally, pollute the natural environment around the fan, etc., to achieve the effect of prolonging the continuous operation time, convenient installation and operation, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

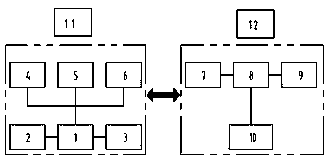

[0019] Such as figure 1 As shown, the present invention includes a test device 11 and a control system 12, and the test device 11 includes a cooler core 1, a pressurizing device 2, a monitoring device 3, a corrosive gas generating device 4, a temperature and humidity generator 5 and Solar UV Simulator6.

[0020] The pressurizing device 2 is connected to the cooler core 1 through a pipeline, and the pressurizing device 2 includes a tank, a booster pump, a check valve, a pressure sensor, a liquid level thermometer and an electric ball valve, wherein the booster pump , the check valve and the pressure sensor are installed on the inlet pipeline of the cooler core 1, the electric ball valve is installed on the outlet pipeline of the cooler core 1, and the liquid level and temperature gauge is installed on the box to monitor the inside of the box. The liquid level and temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com