A process based on coupled stripping and enhanced nitrification

A treatment process, coupled technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of reduced utilization rate of dissolved oxygen and easy congestion and agglomeration of biofilm , Nitrification load decline and other issues, to achieve the effect of promoting dissolved oxygen distribution, maintaining stable nitrification treatment effect, and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

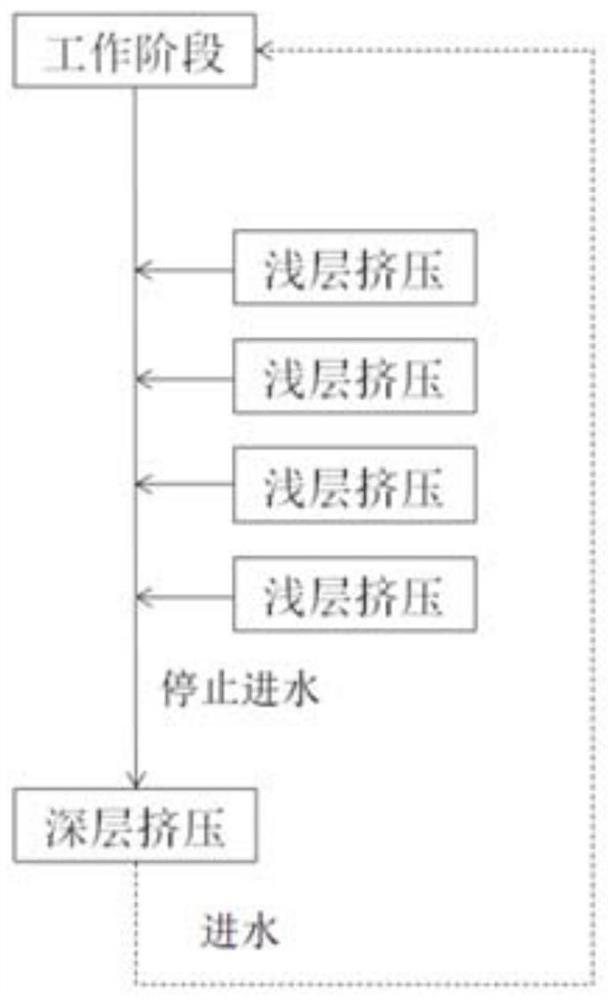

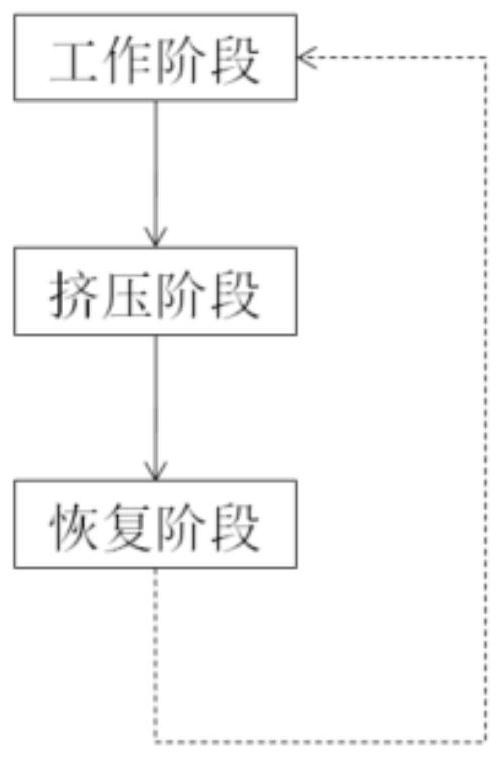

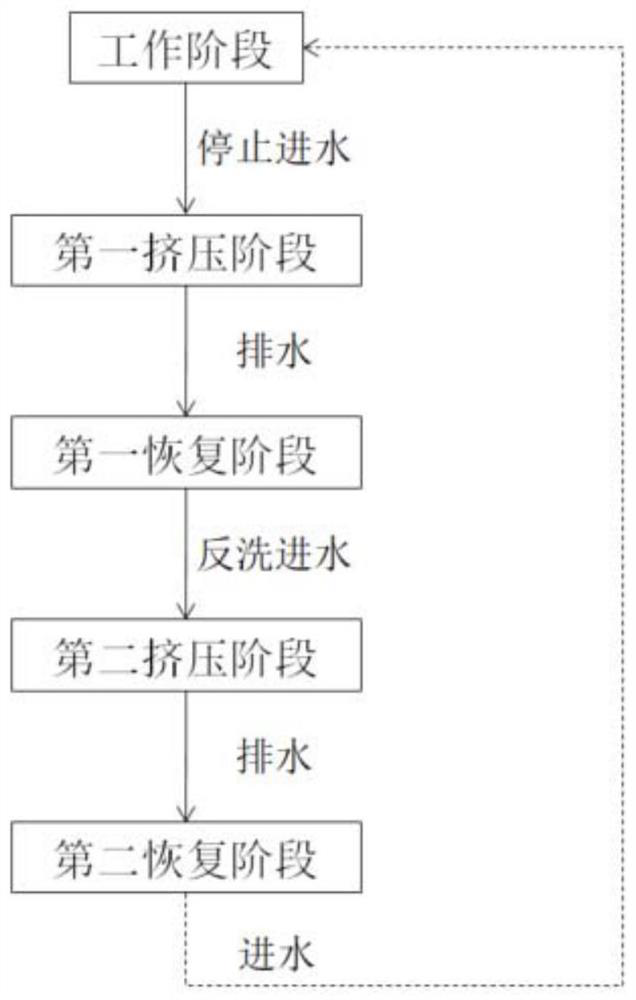

[0078] figure 1 In order to be applied to the technological process of sewage nitrification treatment; in the normal working stage, the interception and accumulation of suspended solids in the filler or the growth and aging of biofilm will lead to a gradual decrease in effluent water quality and a gradual increase in system resistance. When the water quality is lower than the design After the water outlet requirement or the water inlet head exceeds the set resistance, stop the water inlet and perform deep extrusion. In the coupling-type film-removing enhanced nitrification treatment process of the present invention, several shallow layer extrusions are carried out before the deep layer extrusion.

[0079] In this embodiment, the type of sewage to be treated is river sewage, and the influent water quality parameters mainly include COD, ammonia nitrogen, total phosphorus, etc., and the influent volume of the river sewage is 1000m 3 / d, influent ammonia nitrogen<10mg / L, COD<50mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com