Preparation method of high-quality olive kernel oil

A technology of olive kernel oil and olive kernel, which is applied in the directions of fat oil/fat refining, fat oil/fat production, and fat production, can solve problems such as spoilage of pomace oil products, difficulty in meeting usage requirements, etc., and achieve antioxidant activity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

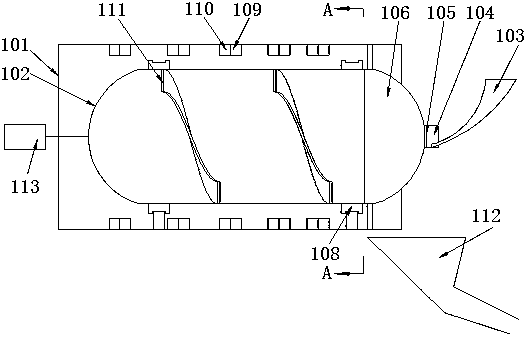

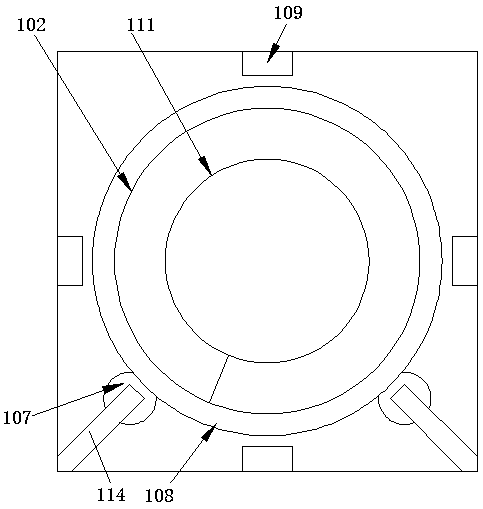

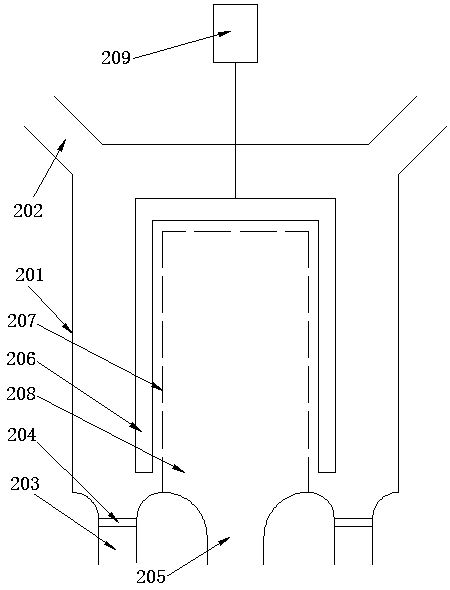

Image

Examples

Embodiment 1

[0034] A kind of high-quality olive kernel oil preparation method, comprises the following steps:

[0035] 1) Baking: Set the heat pump drying temperature to 60°C, the drying time to 20 hours, and the drying moisture to 5%. The purpose is to increase the brittleness and storability of olive stones for later crushing and storage.

[0036] 2) Crushing: Use a high-speed pulverizer to crush the olive core into 20-mesh particles.

[0037] 3) Vibrating sieving: Use a 45-mesh vibrating sieve to sieve and remove some fine-grained olive kernels. The separation of olive kernels and olive cores can reach 99%.

[0038] 4) The olive nuclei are first assisted by ultrasonic wave and then heated by microwave through the auxiliary processing equipment of ultrasonic and microwave heating: the frequency of ultrasonic wave is 120w, and the time is 4min. The purpose is to use the ultrasonic "empty drum effect" to accelerate the separation of grease; after stopping the ultrasonic wave, select micr...

Embodiment 2

[0052] A kind of high-quality olive kernel oil preparation method, comprises the following steps:

[0053] 1) Baking: Set the heat pump drying temperature to 55°C, the drying time to 22 hours, and the drying moisture to 6%. The purpose is to increase the brittleness and storage of olive stones for later crushing and storage.

[0054] 2) Crushing: Use a high-speed pulverizer to crush the olive core into 30-mesh particles.

[0055] 3) Vibrating sieving: Use a 40-mesh vibrating sieve to sieve and remove some fine-grained olive kernels. The separation of olive kernels and olive cores can reach 99%.

[0056] 4) The olive nuclei are ultrasonically assisted by the combined auxiliary treatment equipment of ultrasonic and microwave heating, and then heated by microwave: the frequency of the ultrasonic wave is 130w, and the time is 4.5min. The material turning device in the combined auxiliary treatment equipment of ultrasonic and microwave heating is forward , the purpose is to use the...

Embodiment 3

[0070] A kind of high-quality olive kernel oil preparation method, comprises the following steps:

[0071] 1) Baking: Set the heat pump drying temperature to 65°C, the drying time to 30 hours, and the drying moisture to 7%. The purpose is to increase the brittleness and storability of the olive stones for later crushing and storage.

[0072] 2) Crushing: Use a high-speed grinder to crush the olive core into 40-mesh particles.

[0073] 3) Vibrating sieving: 50-mesh vibrating sieve is used to sieve, and some fine-grained olive kernels are removed, and the separation of olive kernels and olive cores can reach 99%.

[0074]4) The olive nuclei are first assisted by ultrasonic wave and then heated by microwave through the auxiliary processing equipment combined with ultrasonic and microwave heating: the frequency of ultrasonic wave is 160w, and the time is 6min. Its purpose is to use the ultrasonic "hollow drum effect" to accelerate the separation of grease; after stopping the ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com