Sealing device for spindle of disc mill used as density fiberboard production equipment

A technology for density fiberboard and production equipment, applied in fiber raw material processing, textiles and papermaking, pulp beating/refining methods, etc., can solve the problem of high initial investment cost and follow-up maintenance cost, and the machining accuracy of the main shaft and installation parts High requirements, high water quality requirements of the sealed cooling system, to achieve the effect of prolonging continuous operation time, shortening maintenance time, and small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

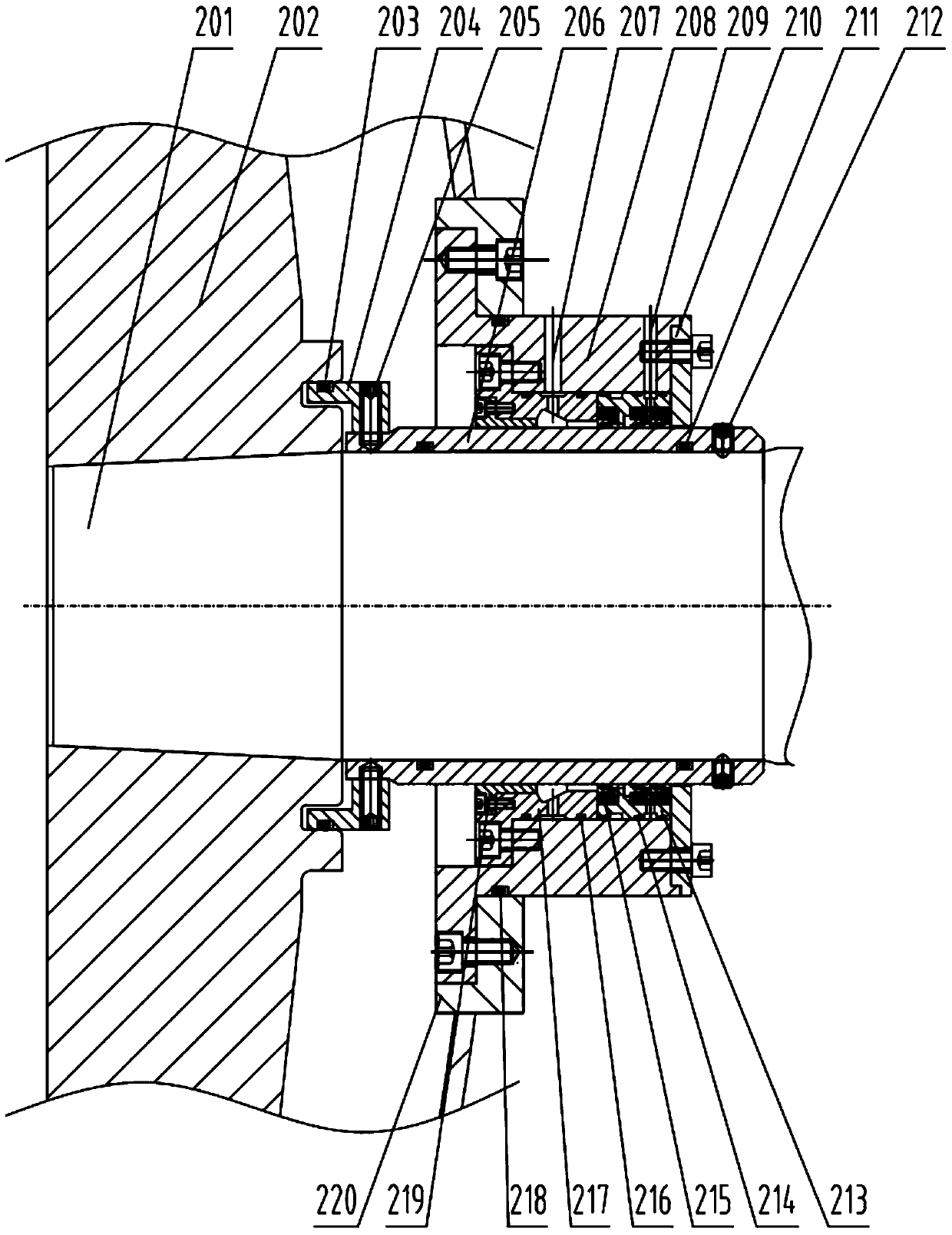

[0028] As shown in the figure, it is a sealing device for the main shaft of the disc refiner of density fiberboard production equipment. The main structure is a conventional disc refiner used in papermaking or medium-high density fiberboard pulping production line. The front end of the drive shaft 201 of the disc refiner fits It extends into the inside of the grinding chamber body cavity 220 of the disc refiner, and is fixedly connected to the movable grinding disc 202. When the system is running, the driving spindle 201 drives the moving grinding disc 202 to rotate, and cooperates with the grinding chamber body cavity 220 for refining; in this embodiment, the driving A shaft sleeve 206 is set on the main shaft 201, and a group of sealing components are installed on the outside of the shaft sleeve 206 to reduce the leakage of the sealing medium during operation and the impact of the slurry in the refining process on the shaft sleeve 206 and the seal assembly. Parts wear; the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com