Casting product having alumina barrier layer

A technology of aluminum oxide and barrier layer, which is applied in coating, manufacturing tools, solid-state diffusion coating, etc., can solve the problems of reduced wood ductility, achieve the effects of inhibiting coking, improving operating efficiency, and reducing the number of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] The molten metal was smelted by atmospheric melting in a high-frequency induction heating melting furnace, centrifugally cast through a mold, and a pipe body with the chemical composition of the alloy shown in Table 1 below was cast. The tube body has an inner diameter of 80mm, an outer diameter of 100mm, and a length of 250mm.

[0094] [Table 1]

[0095] .

[0096] The obtained Examples 1 to 8 and Comparative Examples 1 to 6, which are examples of the invention, were subjected to two-step heat treatment in an oxidative atmosphere with different heating temperatures. Heat treatment is performed first at low temperature and then at high temperature. The low temperature heat treatment is 5 hours, and the high temperature heat treatment is 5 hours.

[0097] [Table 2]

[0098] .

[0099] For the test tubes of Examples 1 to 8 and Comparative Examples 1 to 6 subjected to heat treatment, the elements contained in the aluminum oxide barrier layer formed on the surface ...

Embodiment 2

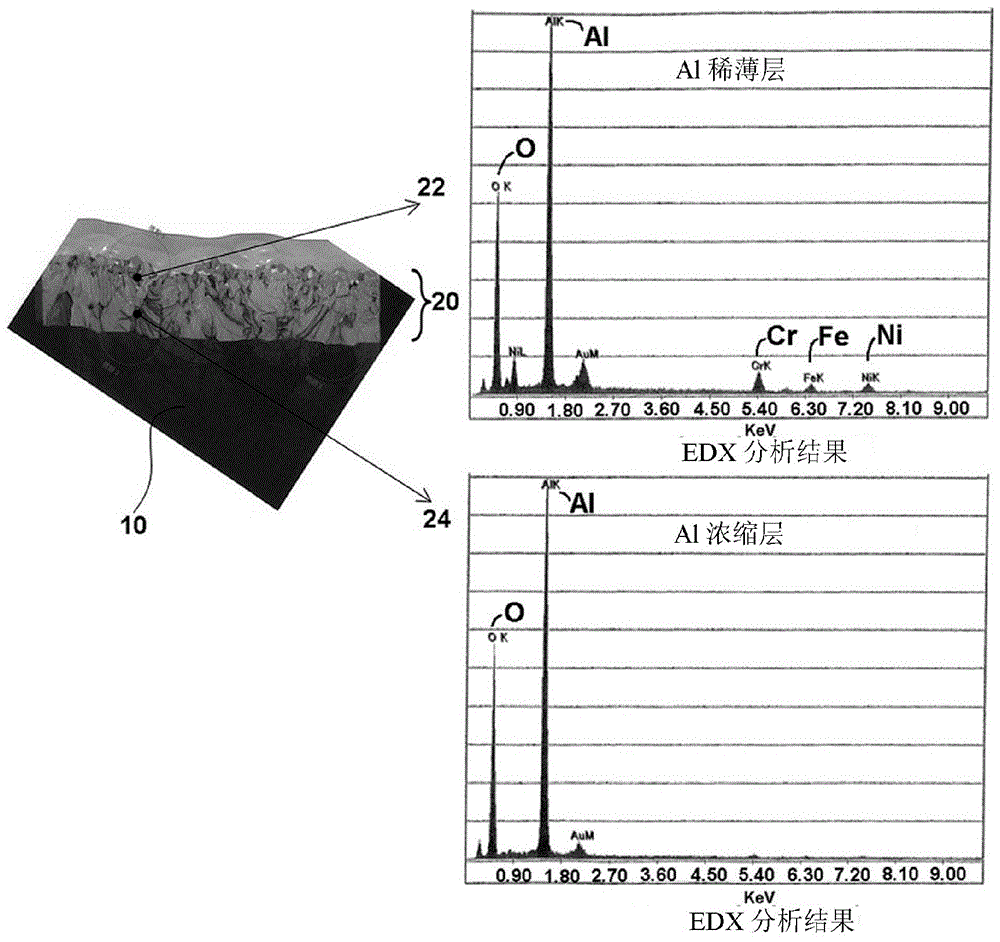

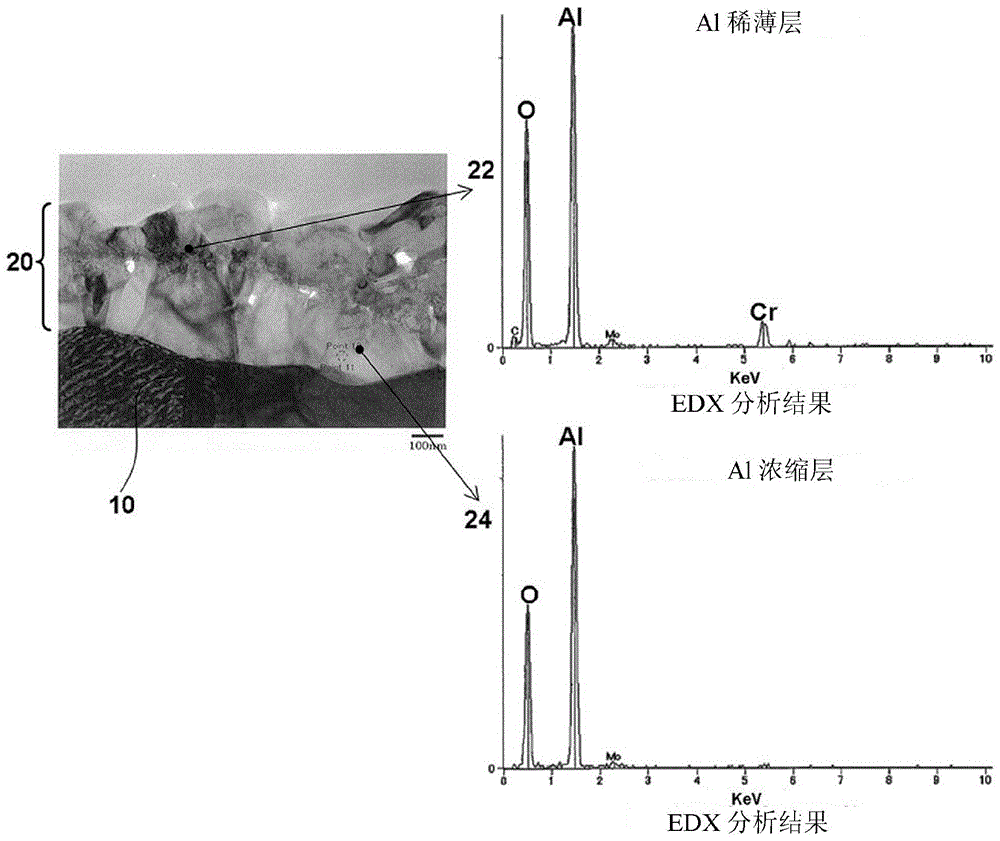

[0119] In Invention Example 2 and Invention Example 7, TEM observation of the film of the alumina barrier layer was performed using a transmission microscope (TEM). In addition, EDX analysis was performed on the Al thin layer and the Al concentrated layer, respectively. The result of Invention Example 2 is shown in Figure 4 , the results of Invention Example 7 are shown in Figure 5 .

[0120] refer to Figure 4 It can be seen that the thin Al layer 22 formed on the surface side in Invention Example 2 is mainly Al oxides, but small amounts of Cr, Fe, and Ni were observed. On the other hand, Cr, Fe, Ni, etc. other than Al were not observed in the Al concentrated layer 24 . From this, it can be seen that the Al concentrated layer 24 is formed of extremely high-purity aluminum oxide.

[0121] refer to Figure 5 It can be seen that the thin Al layer 22 formed on the surface in Inventive Example 7 is mainly Al oxide, but a small amount of Cr was observed. On the other hand,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com