Machine core of paper pulverizer

A shredder and machine core technology, applied in grain processing and other directions, can solve the problems of reducing the life of the shredder, paper jams, paper carrying, etc., and achieve the effect of ideal shredding effect, large number of shredded papers, and less failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

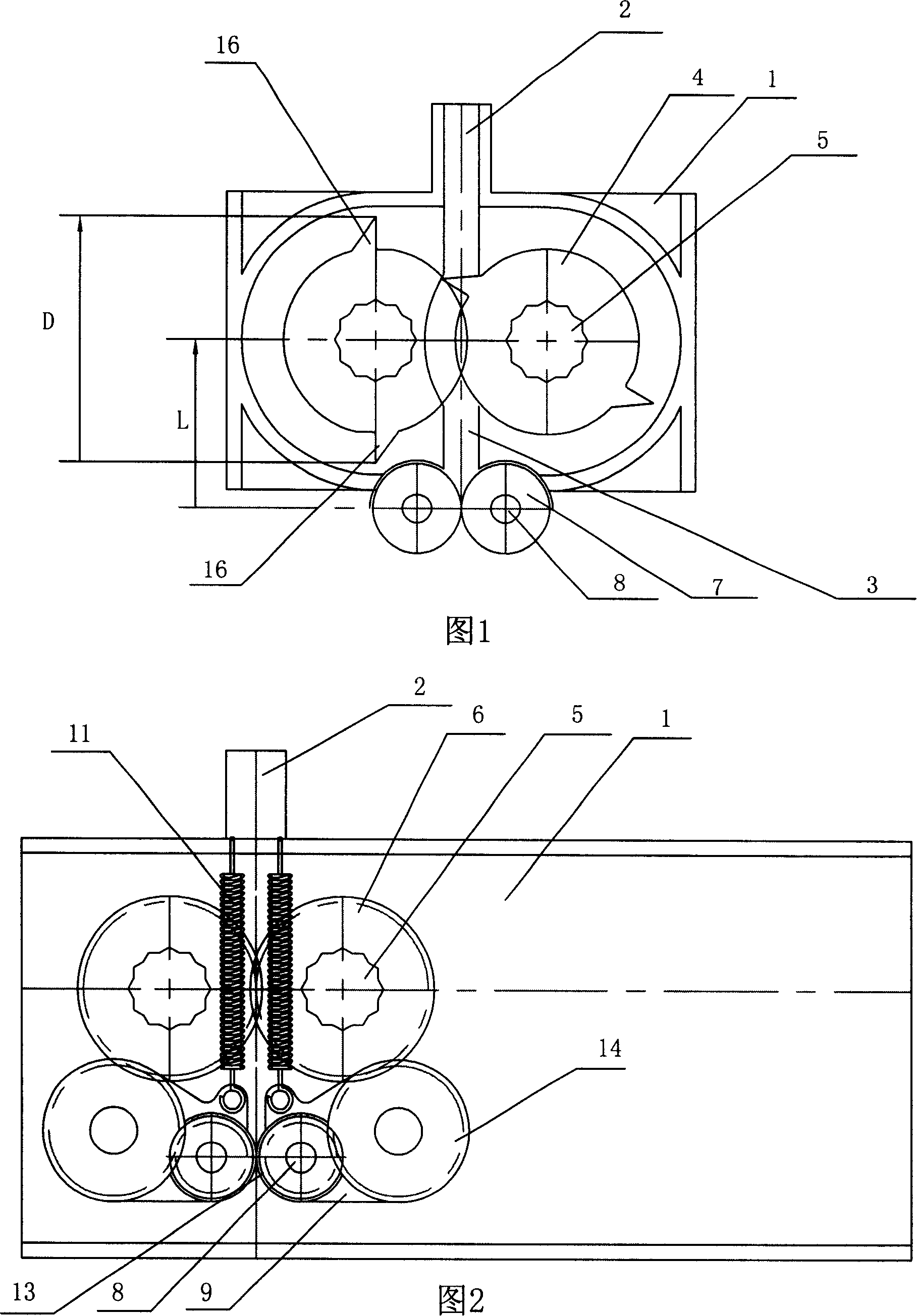

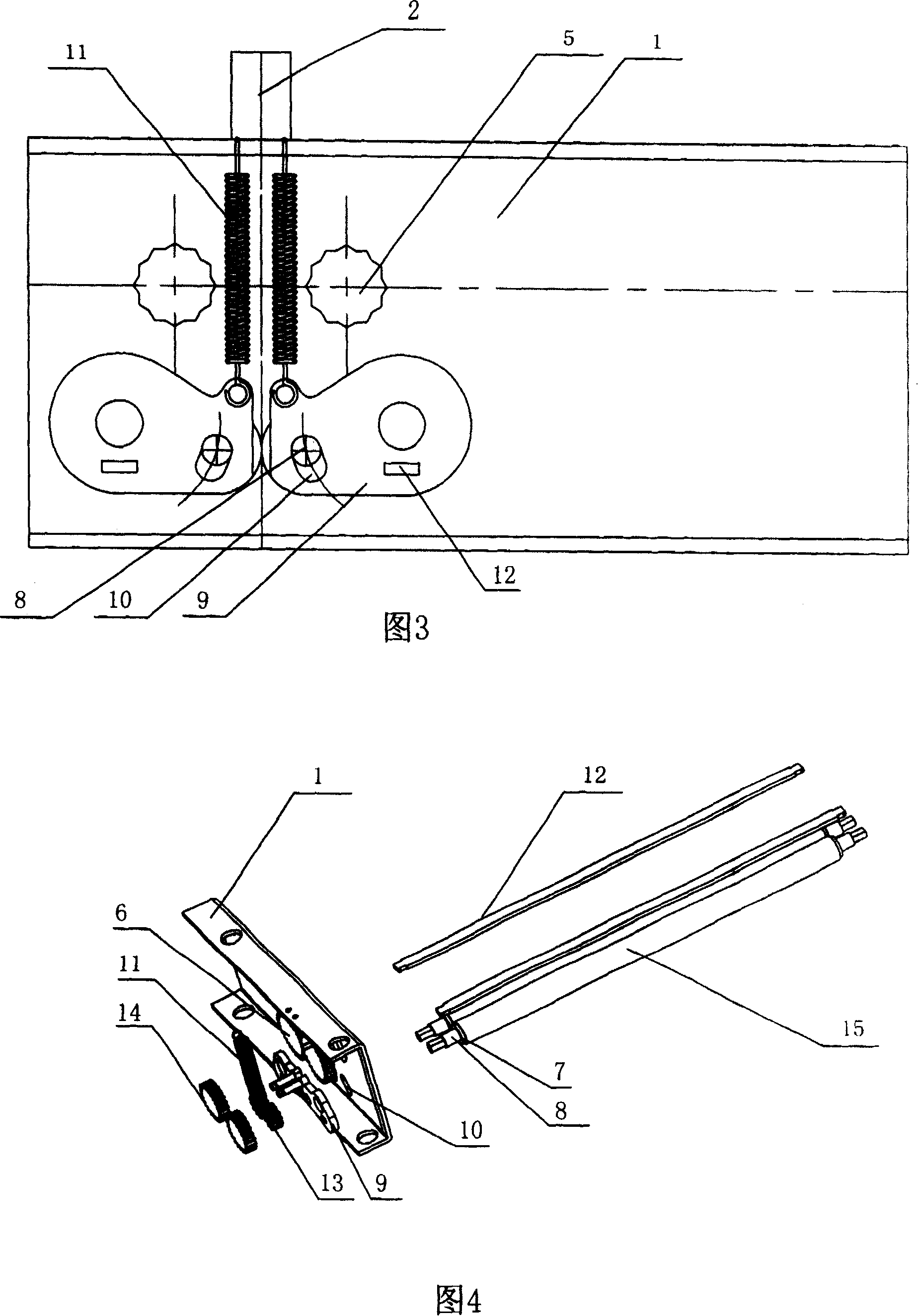

[0015] As shown in the figure, a core of a paper shredder includes a core body 1, on which a paper inlet 2 and a paper outlet 3 are arranged, and a roller is arranged between the paper inlet 2 and the paper outlet 3. The cutter shredding mechanism comprises two hob shafts 5 provided with hobs 4, one side of the hob shaft 5 is coaxially provided with a hob gear 6, and the other end of the hob shaft 5 is connected with a drive mechanism (not shown in the figure). display), two paper threading rollers 7 are arranged behind the paper outlet 3, the paper threading rollers 7 are coaxially arranged on the paper threading roller shaft 8, two swing arms 9 are arranged at both ends of the paper threading roller 7, and the core body 1 An arc-shaped groove 10 is arranged on the top, and the paper threading roller shaft 8 passes through the arc-shaped groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com