Shredder blade

A paper shredder and blade technology, applied in grain processing and other directions, can solve the problems of poor assembly precision of paper shredder tools, cumbersome processing procedures of paper shredder blades, and high cost of energy strip steel, and achieves good shredding effect, enhanced strength, The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

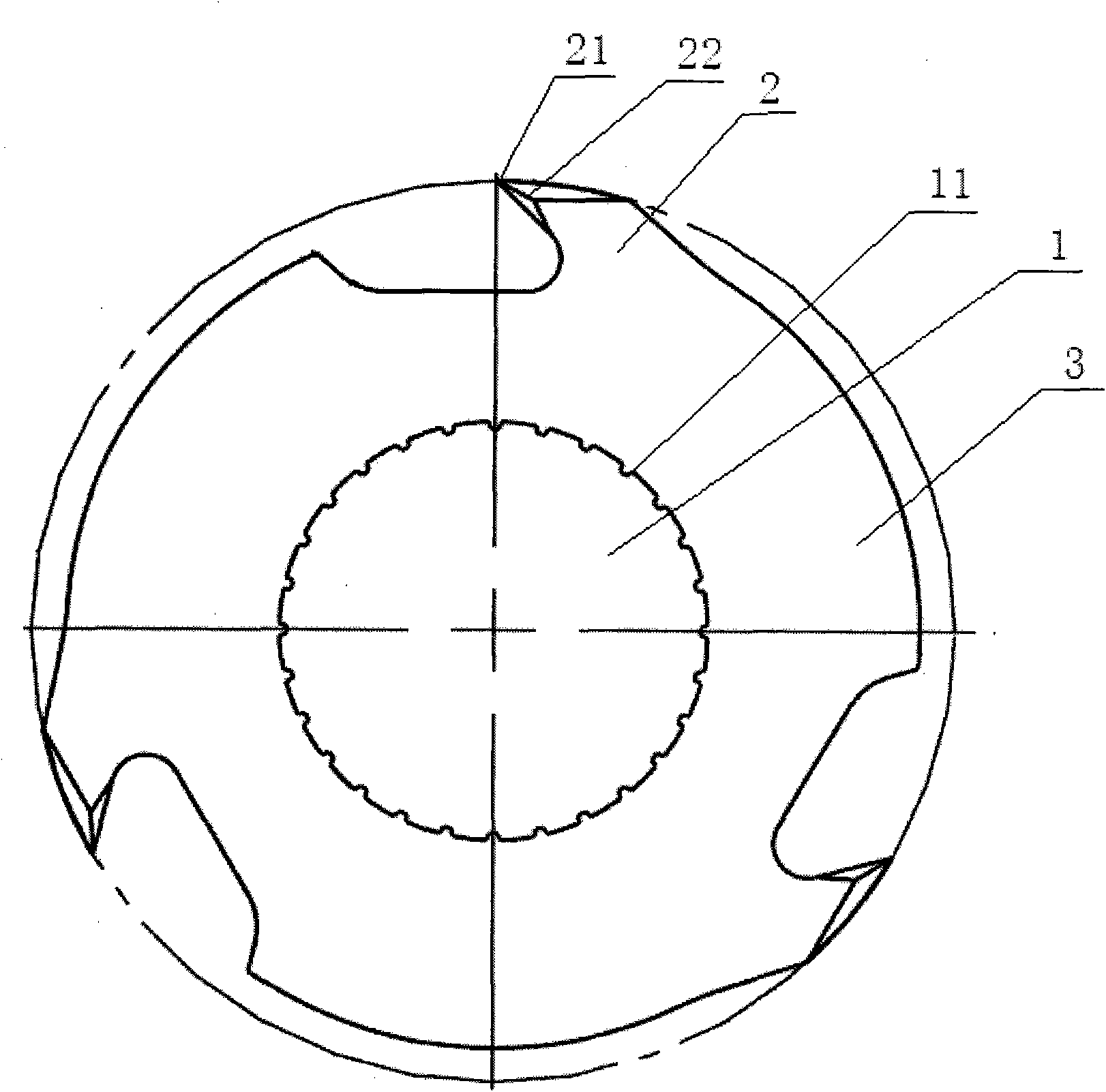

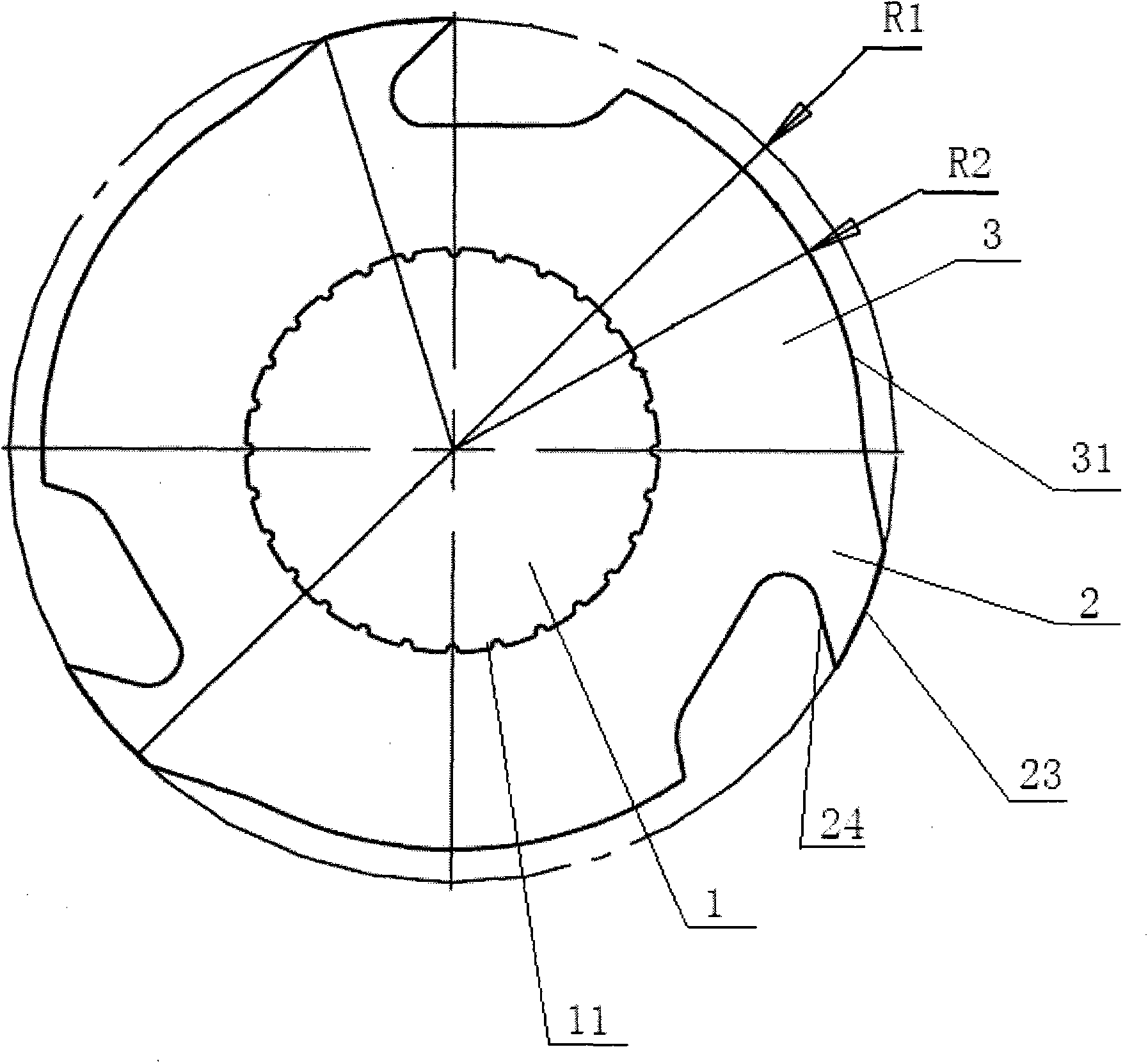

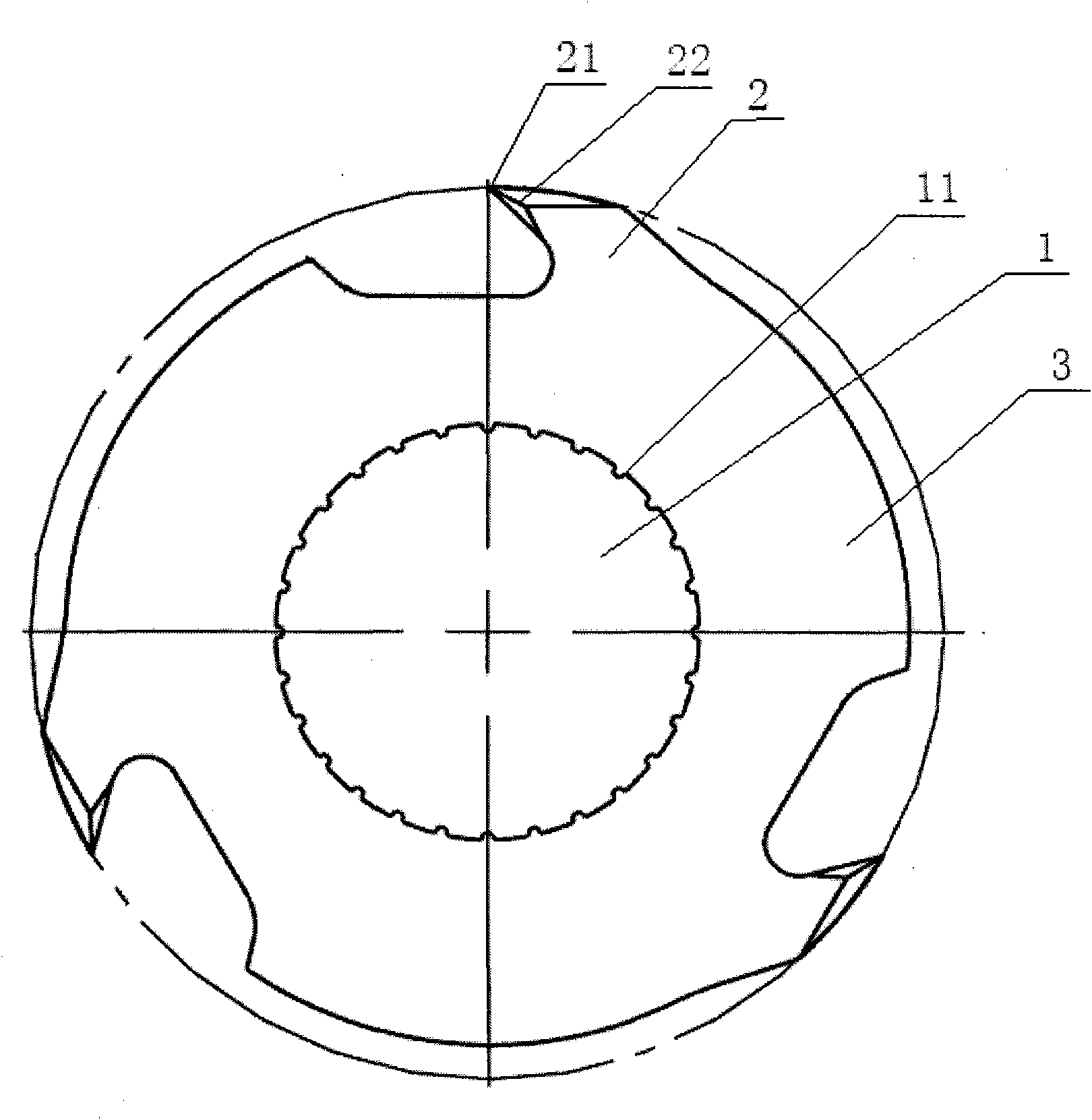

[0021] Such as figure 1 combine figure 2 As shown, the paper shredder blade of this embodiment includes a circular sheet blade body with a mounting hole 1 in the middle of the sheet blade body, and three cutter heads 2 on the outer circle, and the cutter head includes a knife tip 21 and consists of two The cutting edge 22 formed by the inclined surface, the wall of the installation hole 1 is a ring of tooth-like structure 11; the upper surface 23 of the cutter head 2 is a circular arc with the same center as the installation hole, and the lower surface 24 cuts into the blade body to form a knife tip twenty one. A cutter head seat 3 extends fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com