Feed and preparation process thereof

A preparation process and feed technology, applied in feed, animal feed, animal feed and other directions, can solve the problems of affecting feed fermentation, poor shredding effect, etc., and achieve the effect of facilitating feed fermentation and improving shredding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

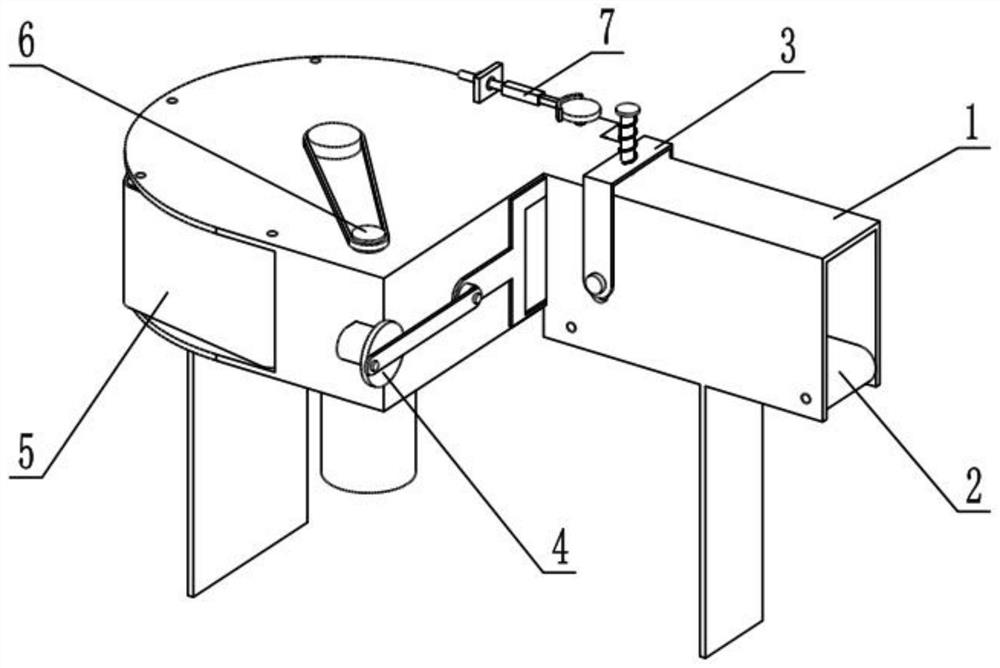

[0035] Such as Figure 1-12 Shown, a kind of feed preparation process comprises the following steps:

[0036] Step 1, take the straw and shred it, and mix it with other raw materials;

[0037] Step 2, preparing the strain mixture;

[0038] Step 3, mixing and fermenting the mixed material obtained in Step 1 and the strain mixture to obtain a finished feed;

[0039] The above-mentioned feed preparation process also involves a feed preparation device;

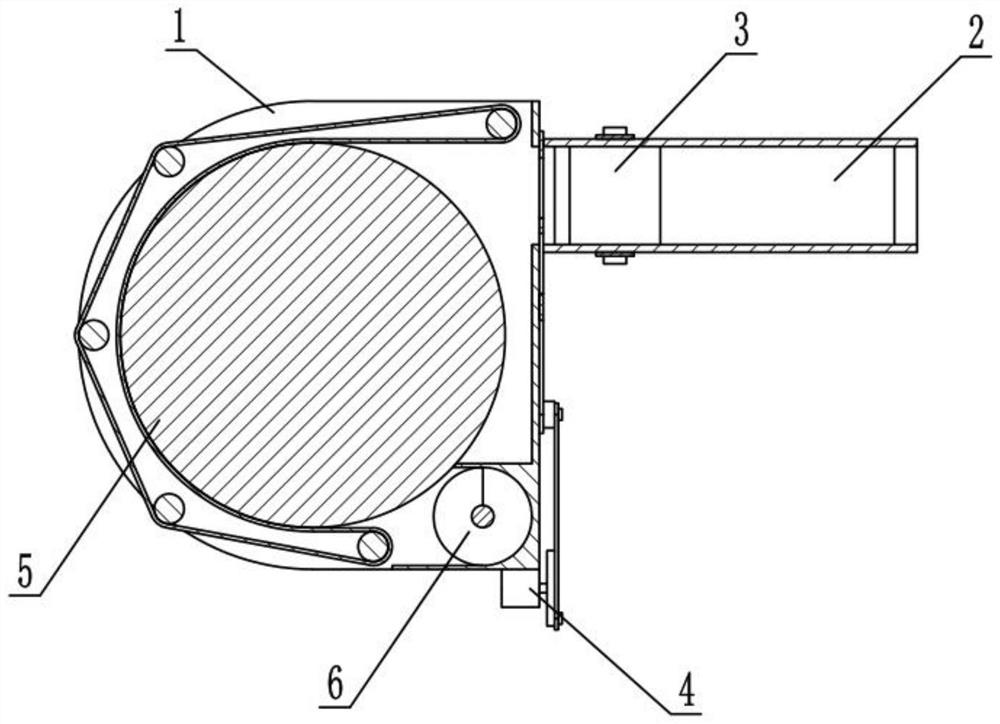

[0040] The described feed preparation device comprises an outer frame 1, a feeding conveying mechanism 2, a clamping mechanism 3, a cutter mechanism 4, a kneading mechanism 5, a discharging mechanism 6 and a deceleration mechanism 7, and the described feeding conveying mechanism 2 is connected to the front end of the outer frame 1, the material clamping mechanism 3 is slidably connected to the front end of the outer frame 1 and is located at the upper end of the feeding conveying mechanism 2, the described cutter mechanism 4 is...

specific Embodiment approach 2

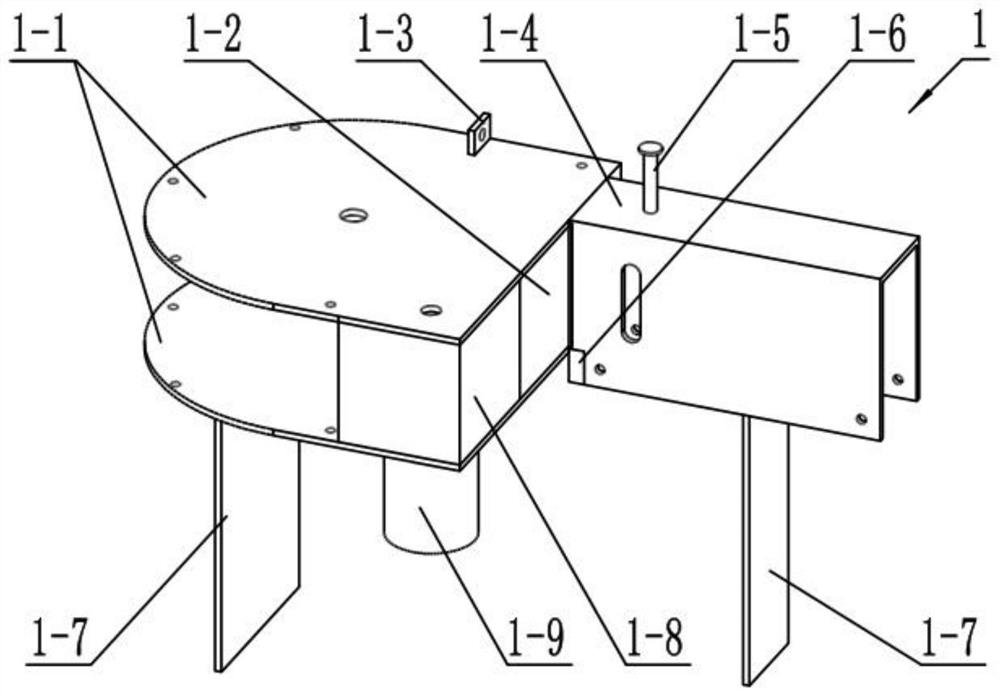

[0043] Such as Figure 1-12As shown, the outer frame 1 includes a side plate 1-1, a support plate 1-2, an upper fixed plate 1-3, a feed pipe 1-4, an upper fixed column 1-5, a cutter seat 1-6, Outrigger plate 1-7, discharge seat 1-8 and discharge pipe 1-9, two side plates 1-1 are provided, and the front ends of the two side plates 1-1 are all fixedly connected on the support plate 1-2 , the rear end of the feed pipe 1-4 is fixedly connected to the support plate 1-2, the upper fixed plate 1-3 is fixedly connected to the side plate 1-1 located at the upper end, and the upper fixed column 1-5 is fixedly connected to the feeding On the pipe 1-4, the cutter seat 1-6 is fixedly connected to the lower end between the support plate 1-2 and the feed pipe 1-4, and there are two leg plates 1-7, two leg plates 1- 7 are respectively fixedly connected to the lower end of the side plate 1-1 at the lower end and the lower end of the feed pipe 1-4, and the discharge seat 1-8 is fixedly connect...

specific Embodiment approach 3

[0046] Such as Figure 1-12 As shown, the feed conveying mechanism 2 includes a feed roller 2-1 and a feed conveyor belt 2-2, the feed roller 2-1 is provided with two, and the two feed rollers 2-1 are rotatably connected to In the feed pipe 1-4, two feed rollers 2-1 are connected through a feed conveyor belt 2-2, and one of the feed rollers 2-1 is provided with a feed conveyor motor.

[0047] The feed roller 2-1 is driven by the feed conveying motor to rotate the feed conveyor belt 2-2, so that the stalks thrown in the feed pipe 1-4 are delivered to the cutter mechanism 4 places for shredding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com