Cutting debris crushing device, cutting debris crushing blade, and cutting debris crushing data collection method

The technology of a shredding device and a shredding knife is applied in the direction of grain processing, etc., which can solve the problems of difficult implementation of handling or recycling, and achieve the effects of improving the efficiency of shredding treatment, avoiding cost increase, and preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

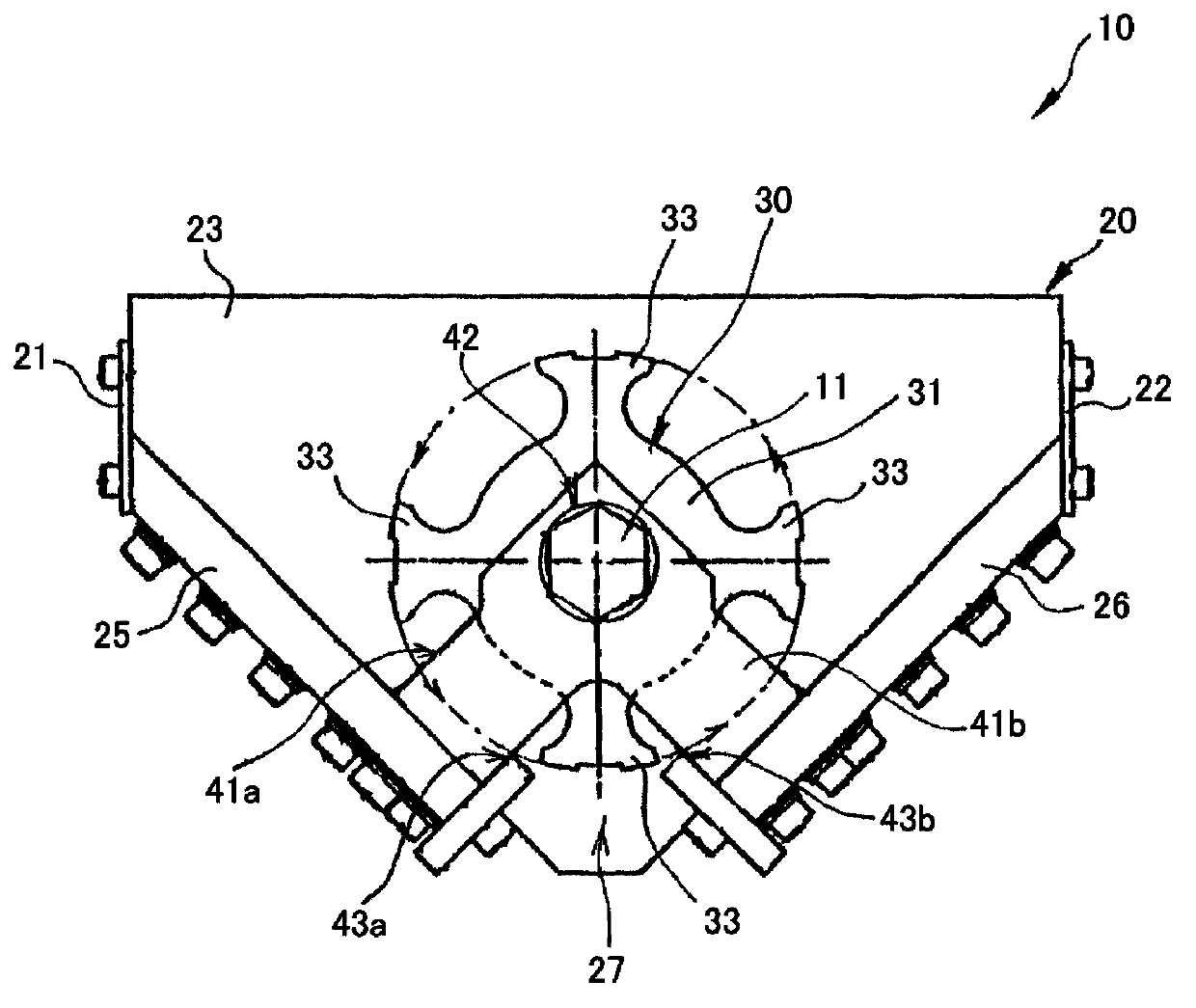

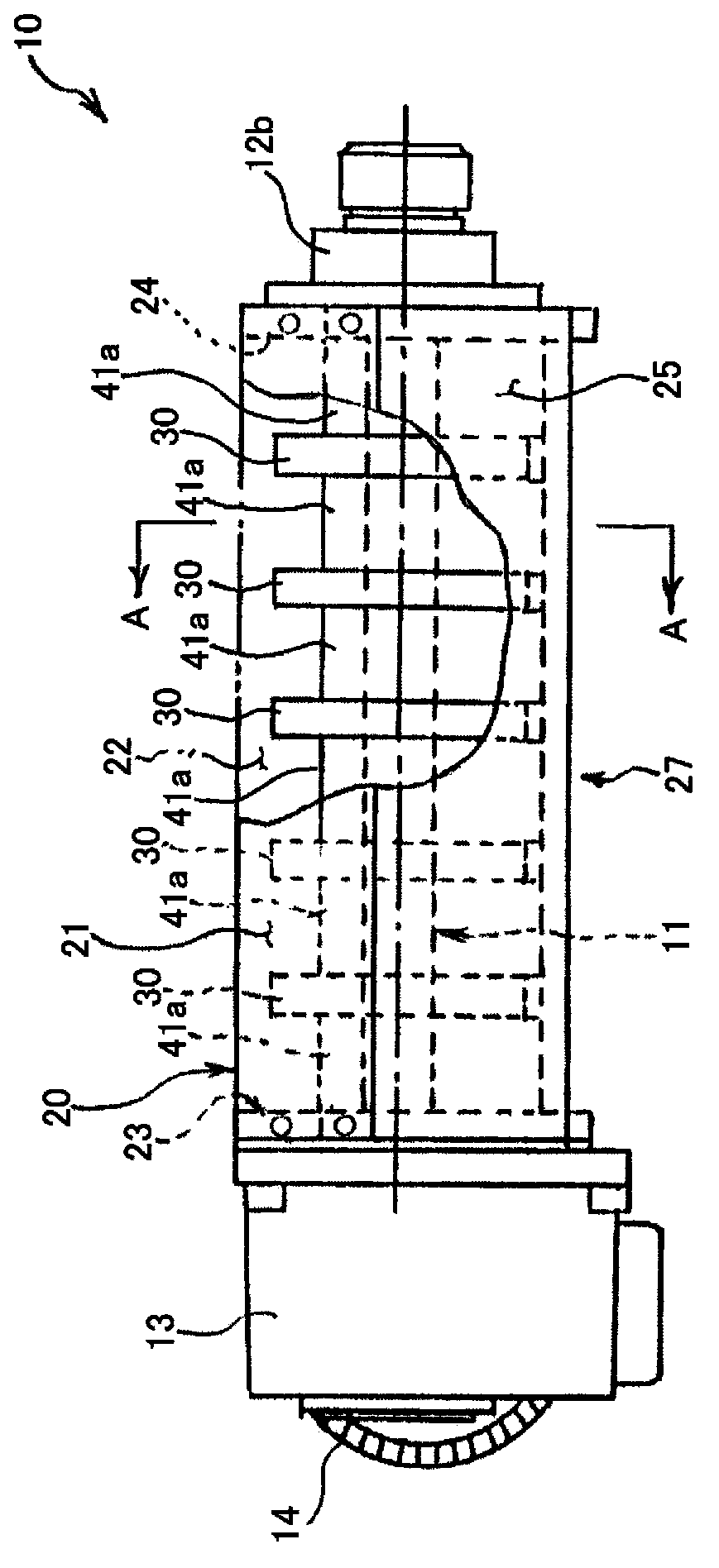

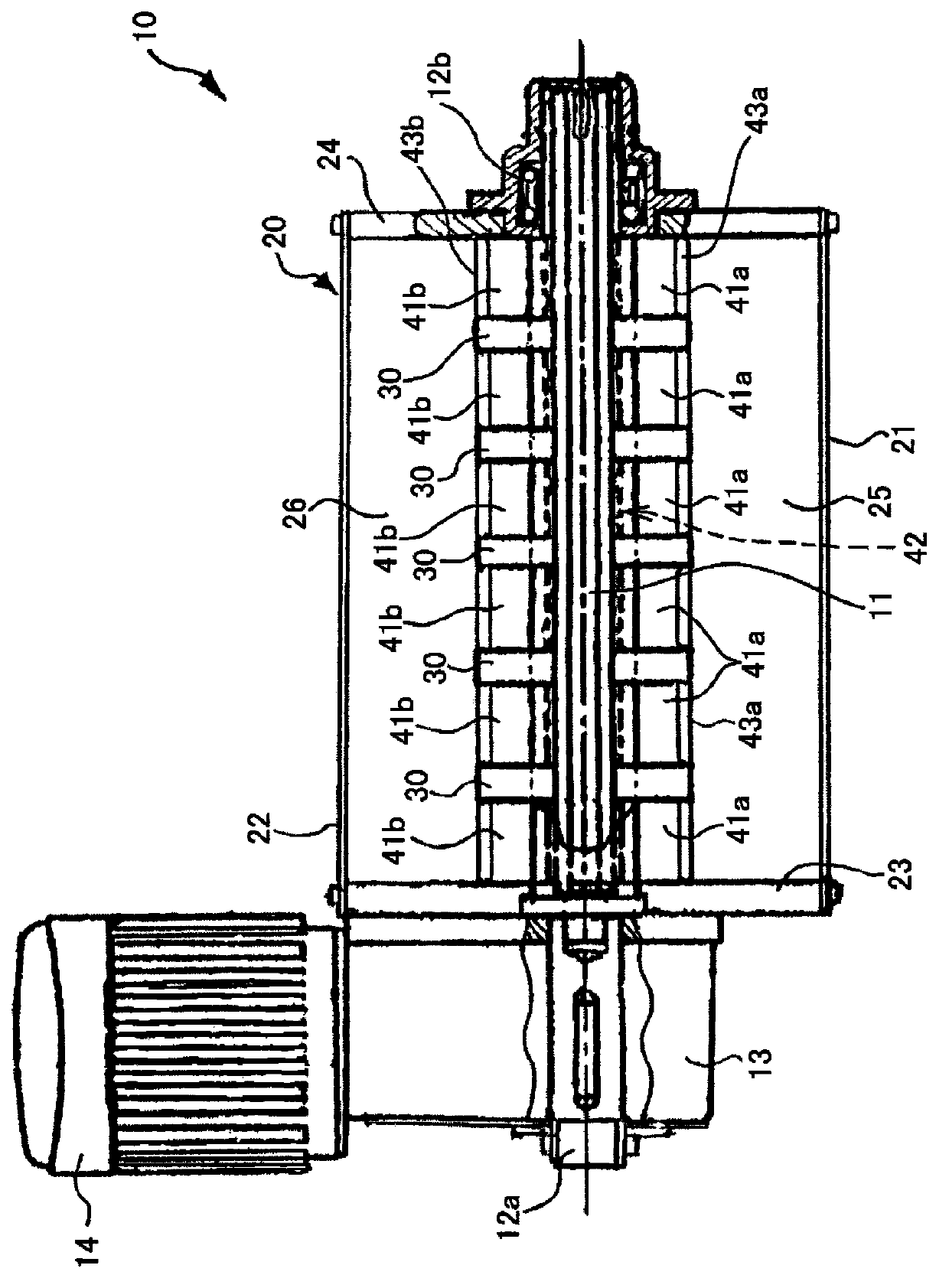

[0053] Hereinafter, the chip shredding device of the present invention will be further described in detail according to the embodiments shown in the drawings. Figure 1 ~ Figure 3 It is a schematic diagram showing a chip crushing device according to an embodiment of the present invention. figure 1 Yes figure 2 The A-A direction of the sectional view. figure 2 is the front view of the chip shredding device, image 3 It is a plan view of the chip shredding device.

[0054] The chip crushing device 10 of the present embodiment rotatably supports a rotary drive shaft 11 by bearing portions 12 a and 12 b in a case 20 opened on the upper surface.

[0055] Housing 20 is made of front side plate 21, rear side plate 22, left side plate 23, right side plate 24, front base plate 25, rear base plate 26, as figure 2 and image 3 As shown, it is formed longer in the left-right direction.

[0056] like figure 1 As shown, the front base plate 25 and the rear base plate 26 are inclin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com