Longitudinal cutting type kelp cutting machine

A technology of shredding machine and kelp, which is applied in metal processing and other directions, can solve the problems of high production cost, complex structure, and low overall shredding efficiency, and achieve the effect of low production cost, simple structure, and fast shredding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

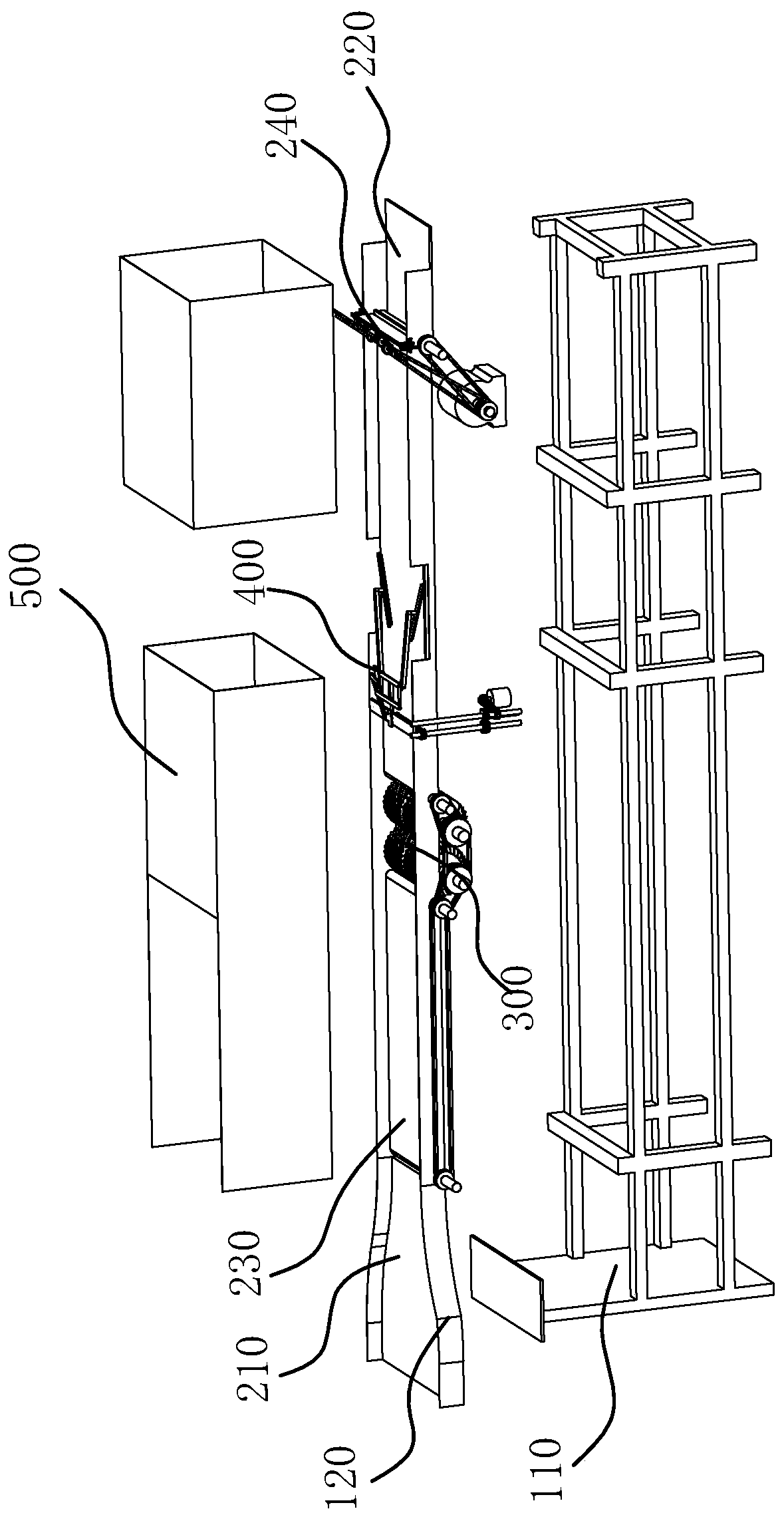

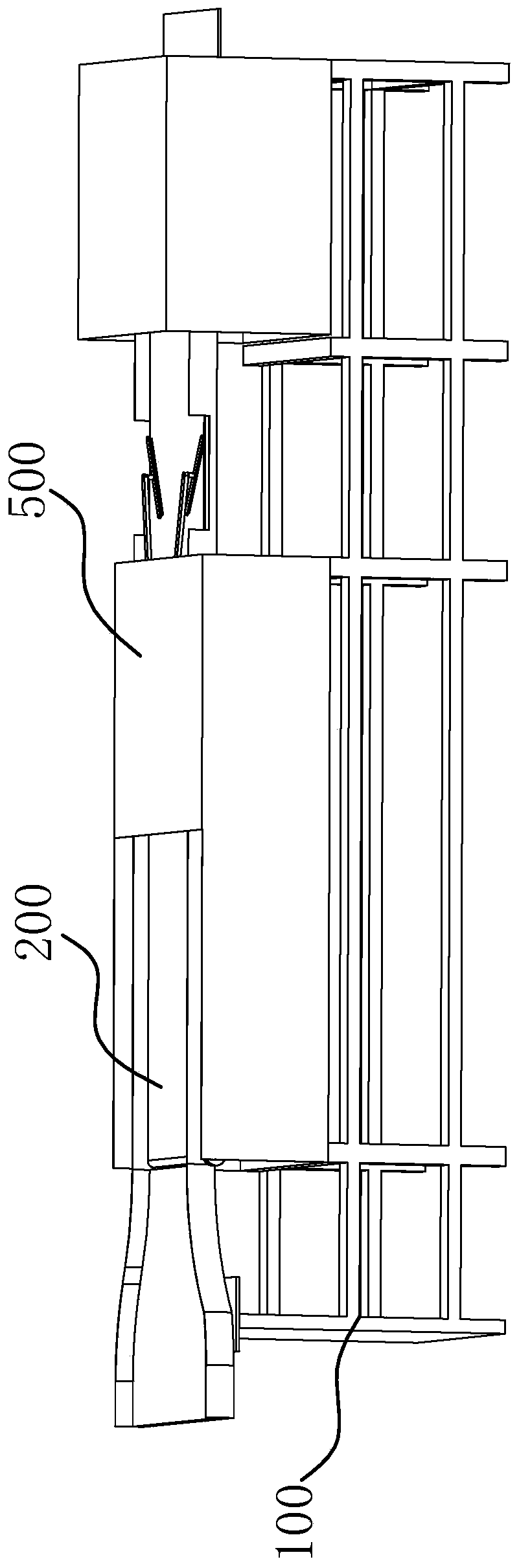

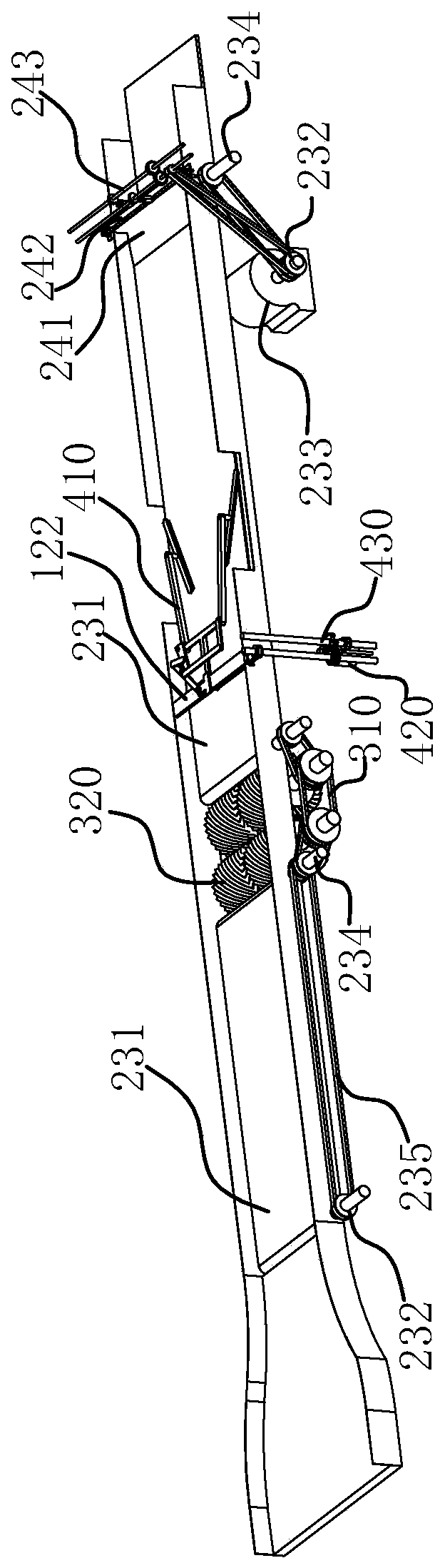

[0035] Present embodiment provides a kind of slitting type kelp shredding machine, as Figure 1-5 shown, including:

[0036] Seat body 100, described seat body 100 comprises fixed base 110, and described fixed base 110 is provided with fixed platform 120, and described fixed platform 120 is equipped with kelp shred assembly 200;

[0037] The kelp shredding assembly 200 includes a material inlet 210, a material outlet 220, a conveying device 230 and a shredding device 240. The material inlet 210 is arranged on the left end of the fixed table 120, along the The conveying device 230 is provided to the right, and the conveying device 230 includes a conveying belt 231, a transmission wheel 232 and a first motor 233, and a shredding device 240 is arranged on the fixed table 120 to the right along the conveying belt 231, so that The outlet 220 is disposed behind the shredding device 240 .

[0038] In order to solve the problems of the existing kelp shredding machine with complex st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com