Comprehensive test device for pliers and nippers

A comprehensive test and bending test technology, applied in the direction of using a stable shear force to test the strength of materials, measuring devices, and using a stable torsion force to test the strength of materials, etc. and other problems, to achieve the effect of large output torque, fast and convenient assembly, and fast and accurate clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

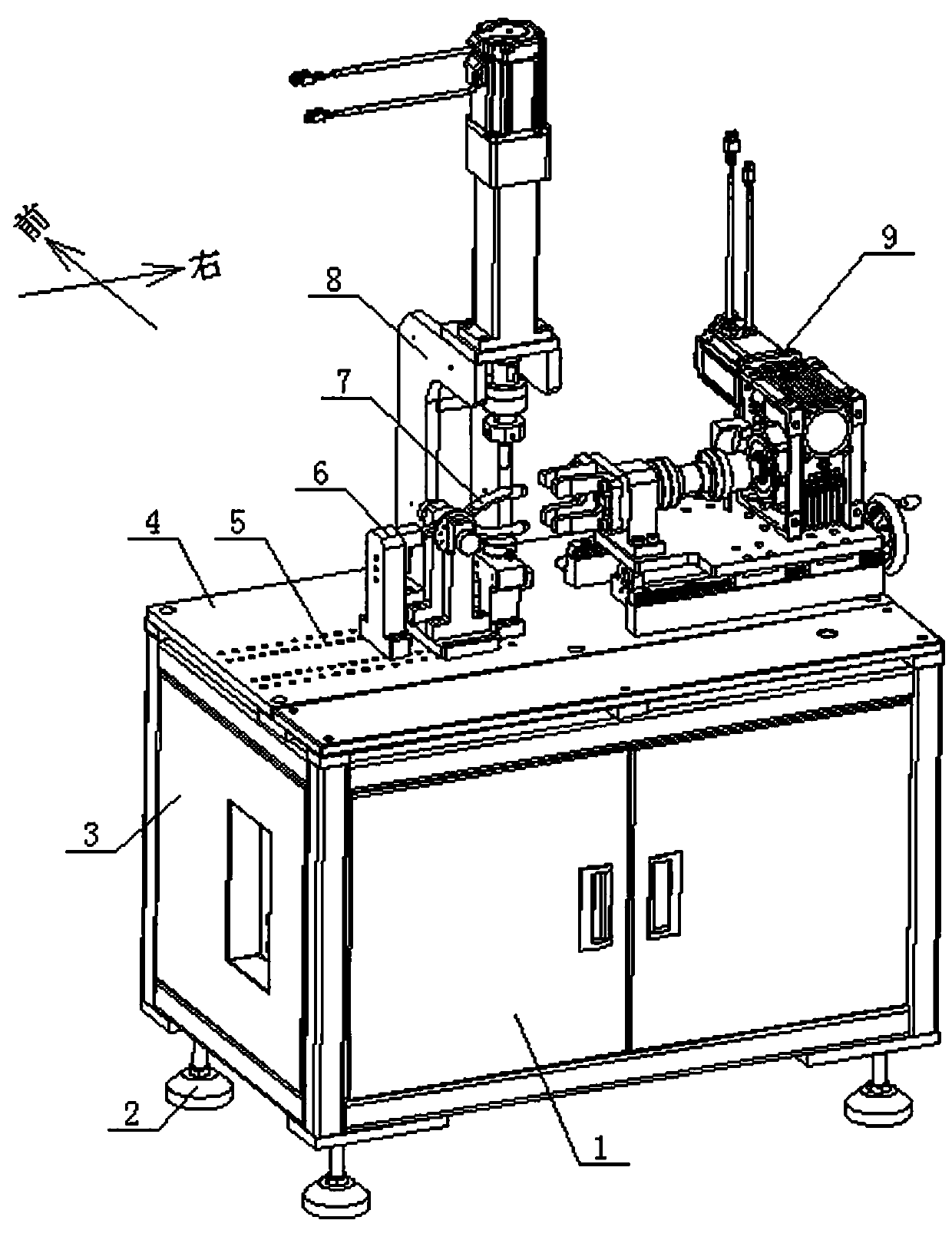

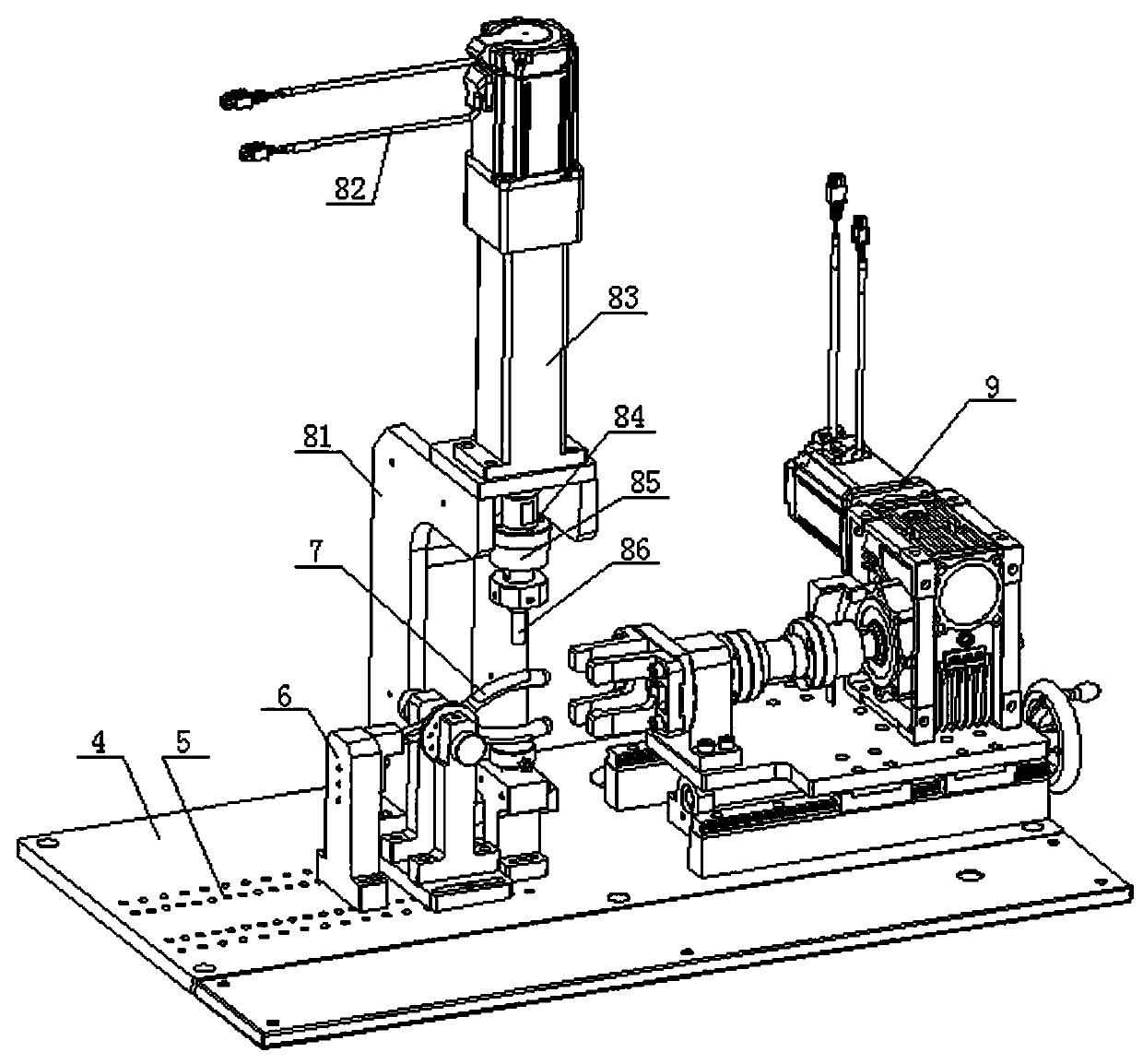

[0030] Such as figure 1 and figure 2 Shown, a kind of comprehensive test device for torsion pliers and shearing pliers comprises cabinet 3, and the top of described cabinet 3 is work platform 4, is equipped with pliers fixing mechanism 6, pliers pressure mechanism 8 and Pliers torque mechanism 9;

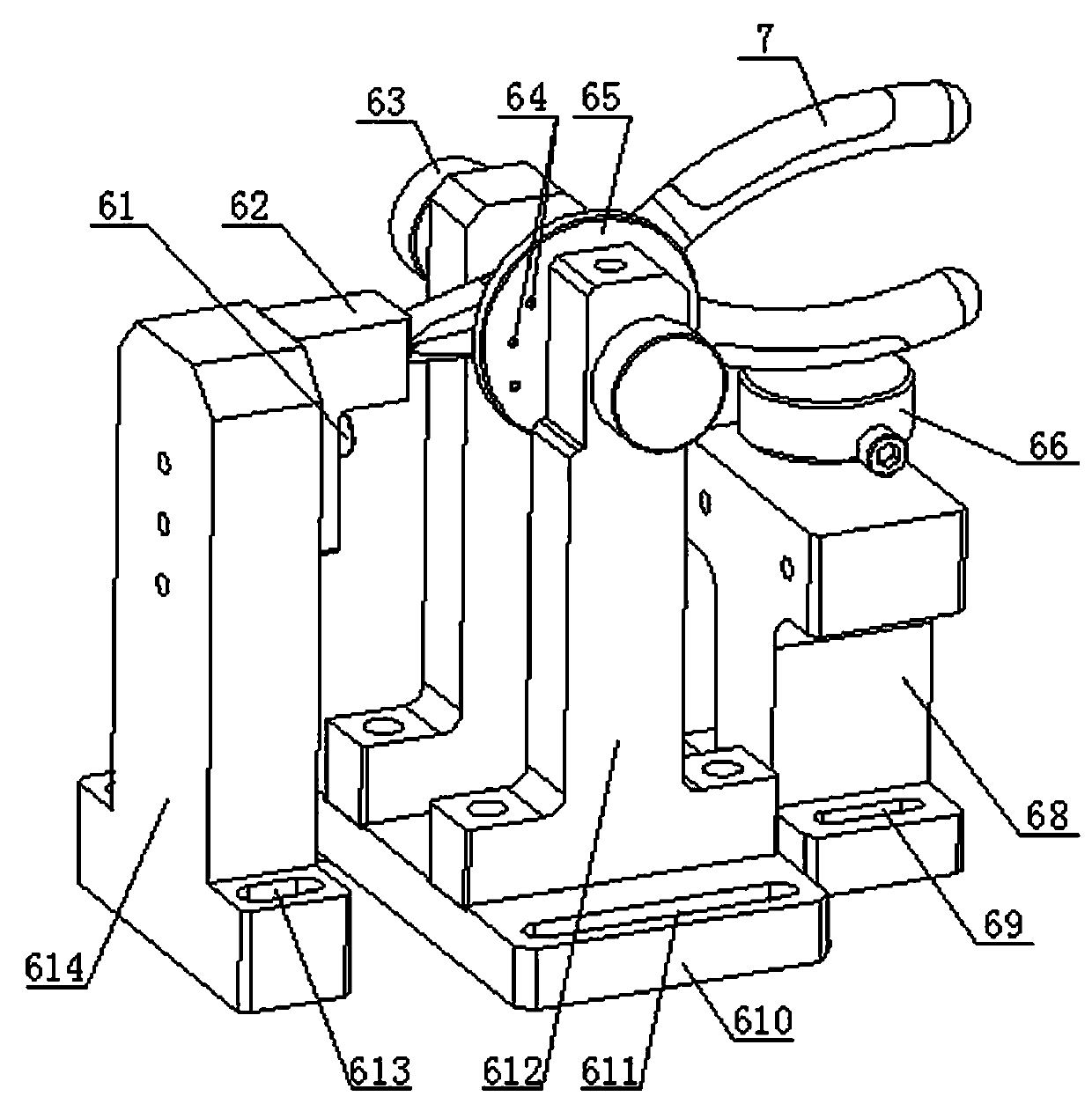

[0031] Such as image 3 As shown, the pliers fixing mechanism 6 sequentially includes a bending test piece clamping assembly, a pliers rotating shaft clamping assembly and a pliers handle support assembly from left to right. The clamping support arm 614 on the upper end of the clamping support arm 614 is fixed with a clamping seat 62 for clamping the bending test piece; the pliers rotating shaft clamping assembly includes a bottom plate 610 fixedly connected to the working platform 4, A front clamping arm and a rear clamping arm 612 are fixed side by side on the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com