Energy source forest harvester

A harvester and energy technology, applied in forestry, application, agriculture, etc., can solve the problems of high harvesting cost, reduced machine productivity, low efficiency, etc., and achieve the effect of good comprehensive economic benefits and improved operation quality and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

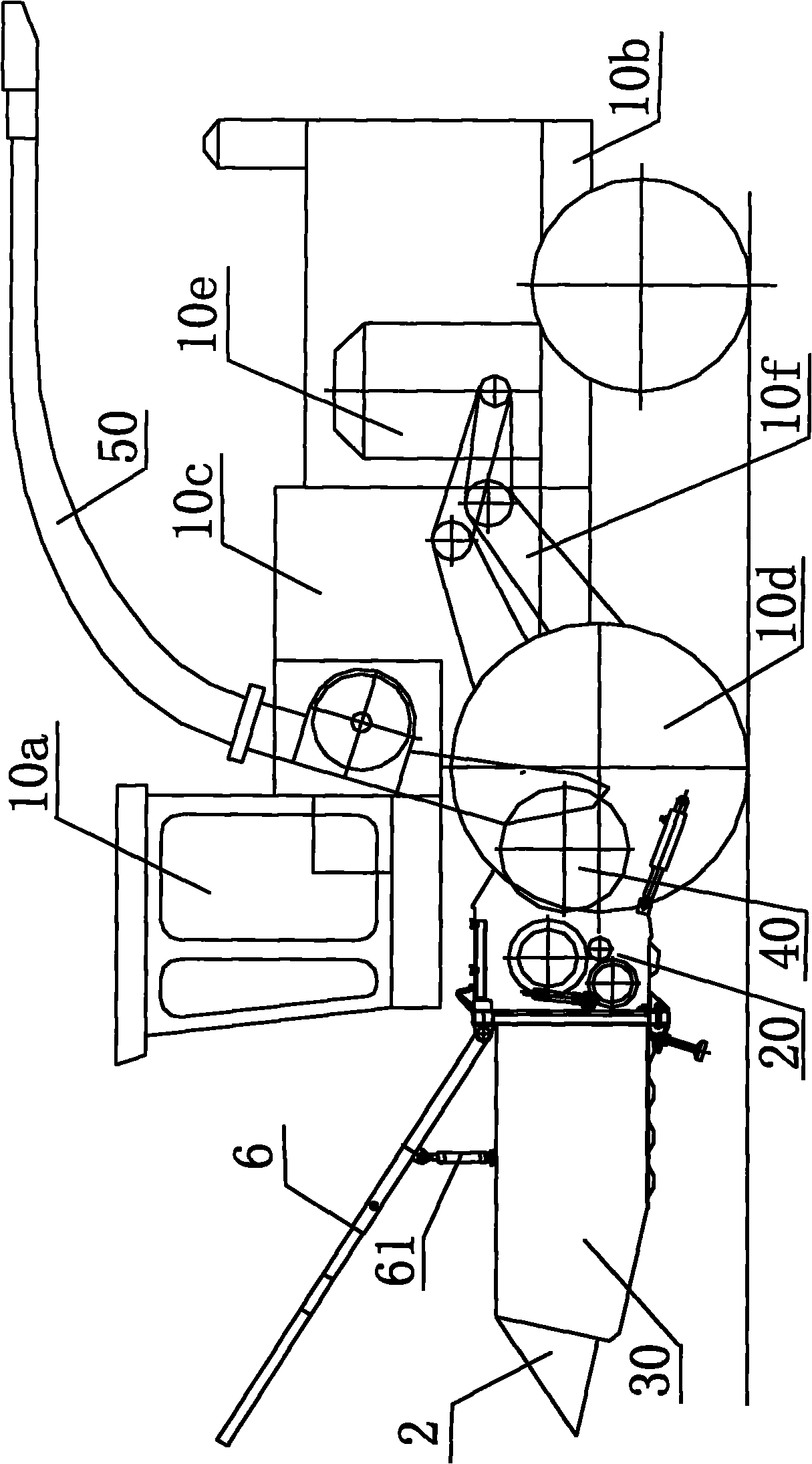

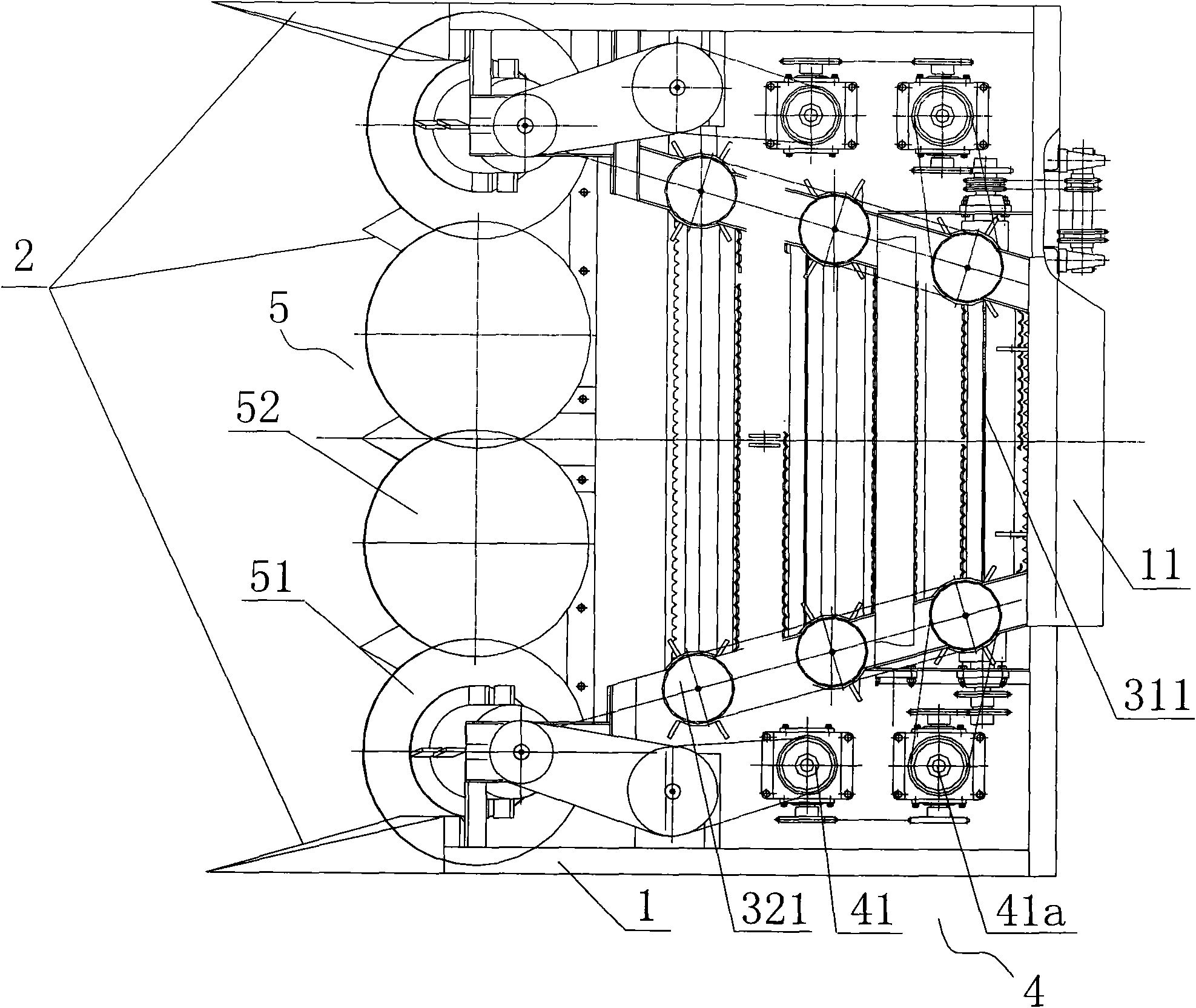

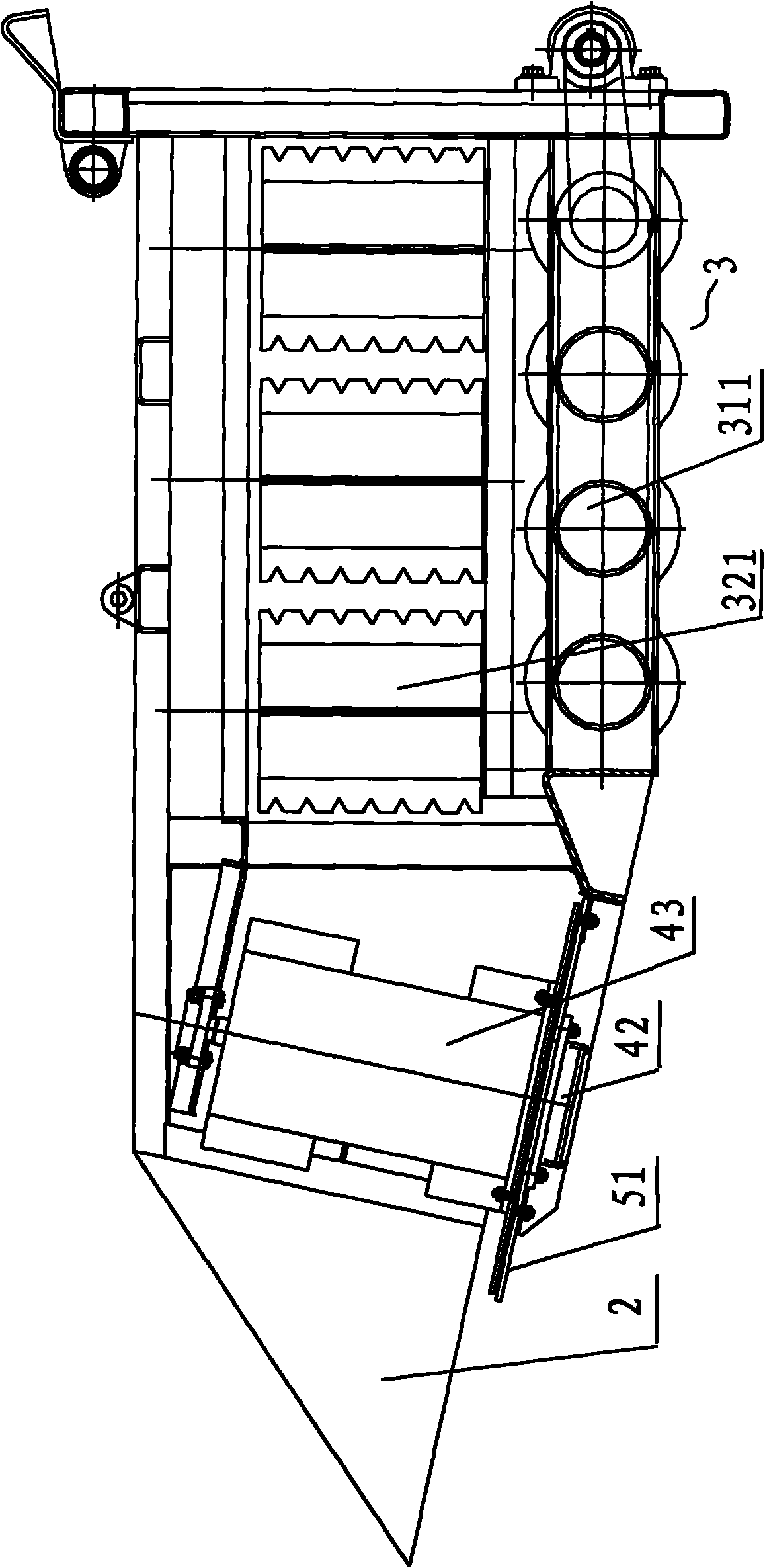

[0067] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0068] The energy forest harvester of the present invention comprises a chassis 10b, a driver's platform 10a installed on the chassis 10b, a frame 10c, a running part 10d, an engine 10e, a power transmission device 10f and a forced feeding device 20, a harvesting platform 30, The shredding device 40 and the throwing device 50, the forced feeding device 20 is located under the driving platform 10a, and the rear part of the forced feeding device 20 is sequentially connected to the shredding device 40 and the throwing device 50, The front end of the forced feeding device 20 is hooked to the harvesting platform 30, and the power transmission device 10f is respectively connected to the engine 10e and the harvesting platform 30, the forced feeding device 20, the chopping device 40 and The throwing device 50, the harvesting platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com