Garbage disposal plant

A waste disposal device and drive device technology, which is applied in the direction of grain processing, etc., can solve the problems of low crushing efficiency and complex structure design, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

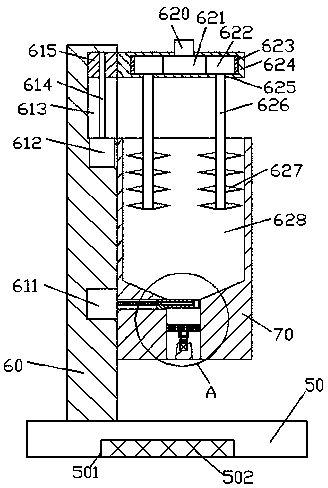

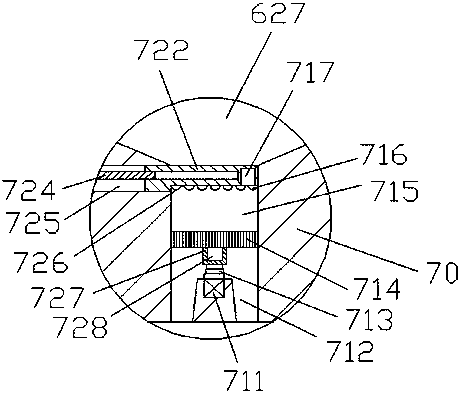

[0013] Combine below Figure 1-3 The present invention will be described in detail.

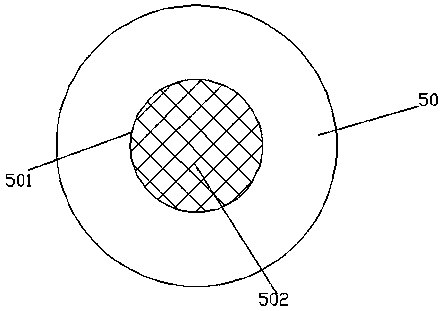

[0014] refer to Figure 1-3 , a garbage disposal device according to an embodiment of the present invention, comprising a counterweight base 50 fixedly installed on the bottom end surface of the vertical pole 60 and a container 70 fixedly installed on the right end surface of the vertical pole 60, the counterweight base The inner bottom of the 50 is provided with a counterweight groove 501, and a counterweight 502 is fixed in the counterweight trough 501, and the bottom weight of the counterweight seat 50 can be increased through the counterweight 502, thereby improving the support stability A driving device is provided in the right side end surface of the vertical rod 60 on the upper side of the container 70, a cavity 628 is provided in the top end surface of the container 70, and a pusher is provided on the inner bottom wall of the cavity 628. cavity 715, a first sliding cavity 725 penetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com