Mineral water bottle crushing and disinfecting equipment

A technology for disinfection equipment and mineral water bottles, which is applied in the direction of disinfection, sanitary equipment for toilets, water supply devices, etc., can solve the problems of increasing labor intensity of staff, staff injuries, troubles, etc., and achieve the effect of disinfection work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

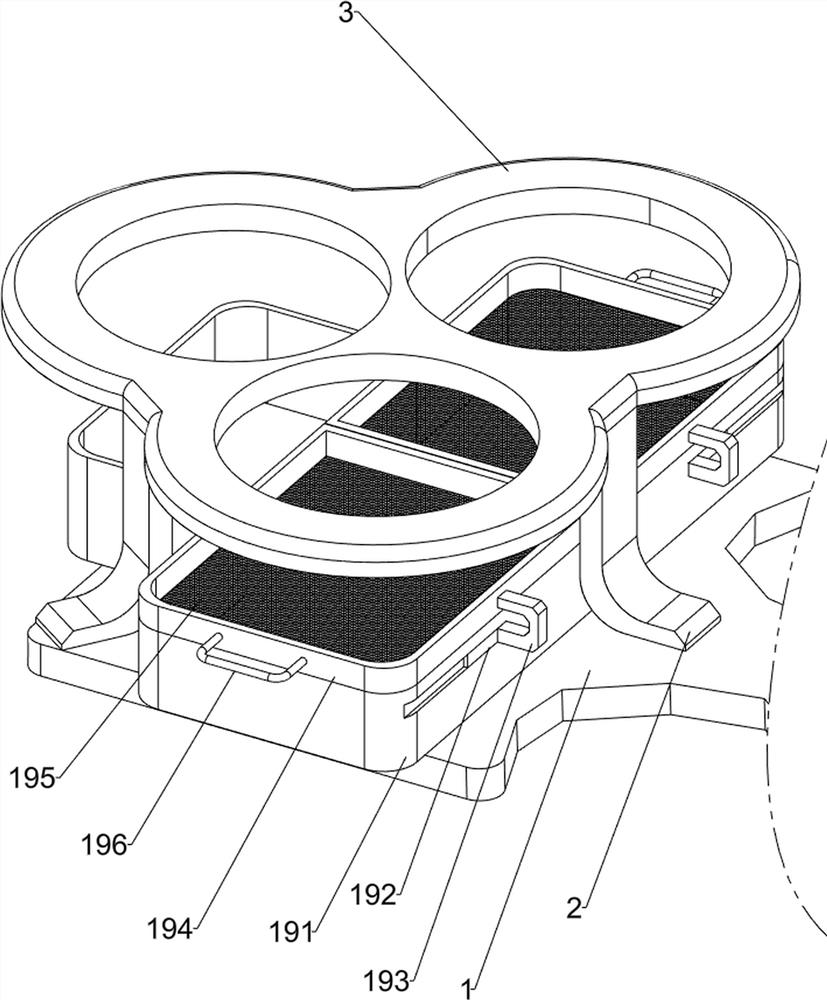

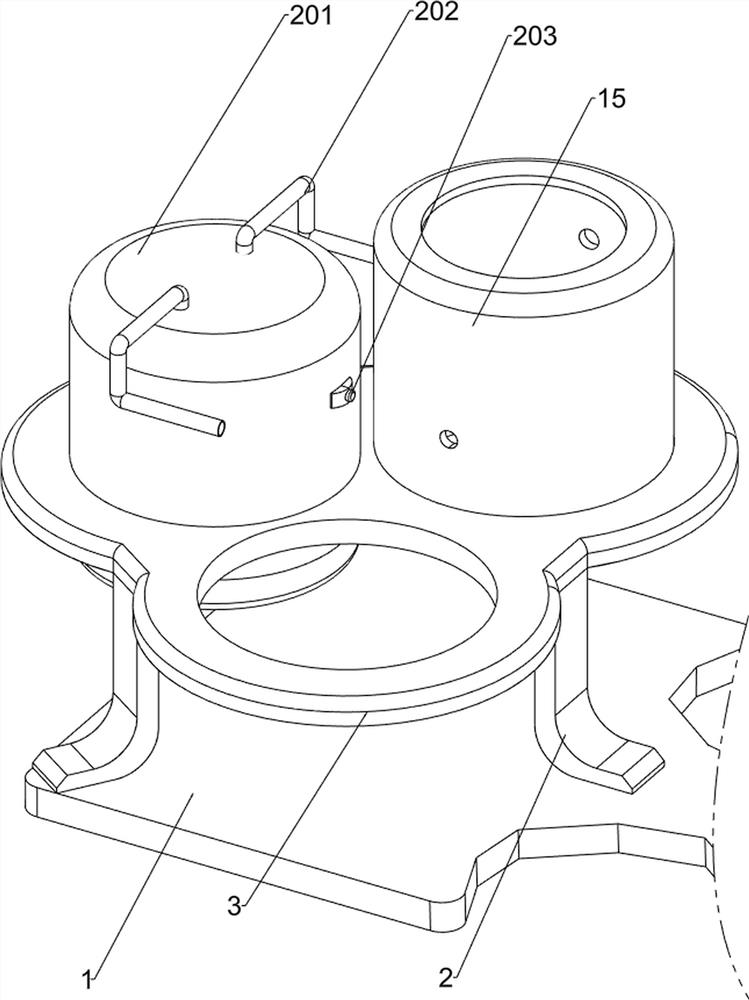

[0070] A kind of mineral water bottle crushing disinfection equipment, such as Figure 1-3 As shown, it includes a support plate 1, a first fixed column 2, a first support frame 3, a first fixed frame 4, a motor 5, a second fixed column 6, a first rotating shaft 7, a first transmission assembly 8, and a second rotating shaft 9. The third fixed column 10, the second support frame 11, the first rotating rod 12, the first bevel gear set 13, the circular plate 14, the first fixed plate 15, the blocking mechanism 16 and the blocking mechanism 17, the top of the supporting plate 1 The first fixed column 2 is provided, the number of the first fixed column 2 is three, the first support frame 3 is connected between the tops of the three first fixed columns 2, and the left and right sides of the top of the first support frame 3 are provided with the second A fixed frame 4, a motor 5 is installed on the top front side of the first fixed frame 4 on the left side, and a second fixed column...

Embodiment 2

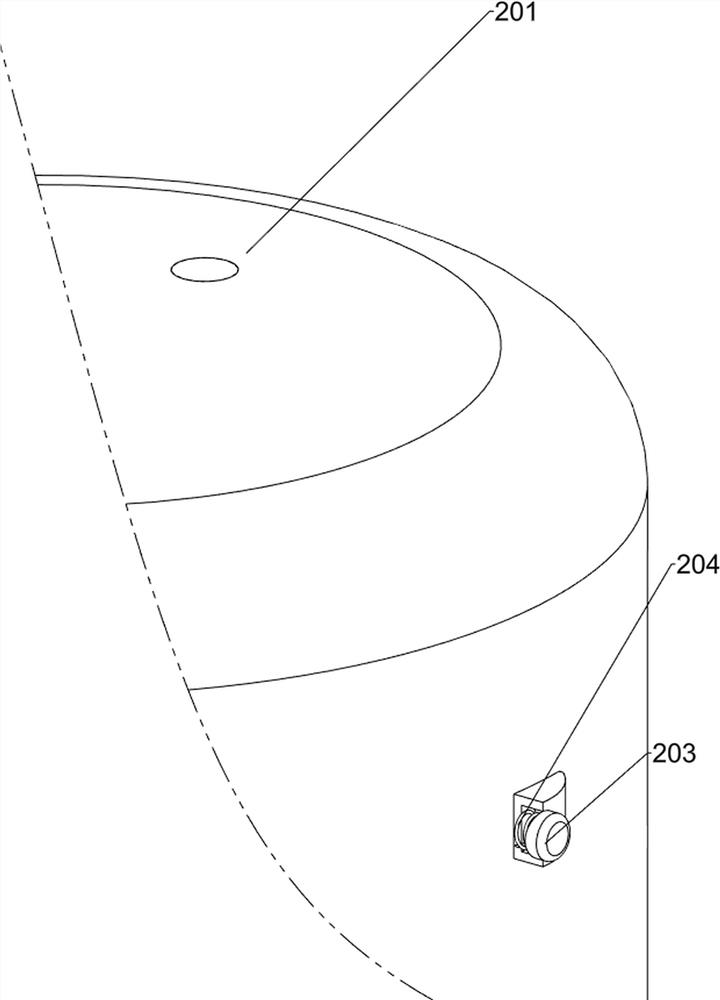

[0077] On the basis of Example 1, such as Figure 4-8 As shown, a moving mechanism 18 is also included, and the moving mechanism 18 includes a limit rod 181, a first spring 182, a first support column 183, a rack 184, a second support column 185 and a third baffle plate 186, and the second fixed frame 161 top rear side is provided with limit rod 181, and the limit rod 181 is provided with the first support column 183 slidingly, is wound with the first spring 182 on the limit rod 181, and the first spring 182 is connected on the second fixed mount 161 and the second Between one supporting column 183, the top of the first supporting column 183 is provided with a rack 184, and the three one-way gears 172 are all in contact with the rack 184, and the middle rear side of the top of the rack 184 is provided with a second supporting column 185. A third baffle 186 is disposed on the top of the support column 185 , and the third baffle 186 cooperates with the push rod 163 .

[0078] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com