Metal powder fuel supply device based on overpressure sealing

A fuel supply and metal powder technology, which is applied in the field of metal powder fuel supply devices, can solve the problems affecting the normal operation of the propulsion system, stable feed, permanent toxic storage, transportation, and retention, so as to increase the charge capacity and increase combustion. Effect of stability, long fluidization length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

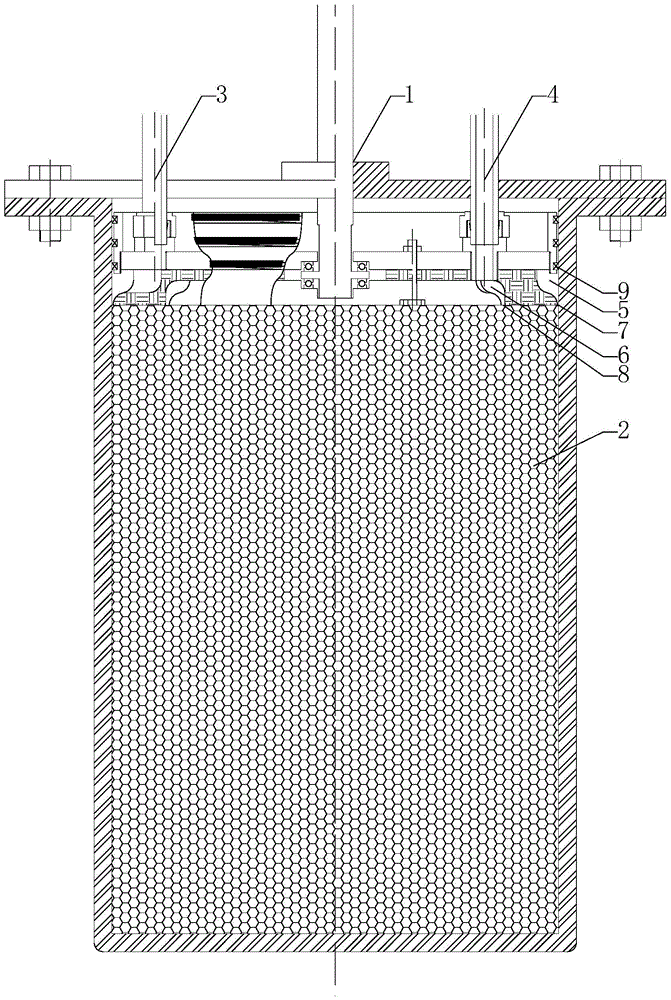

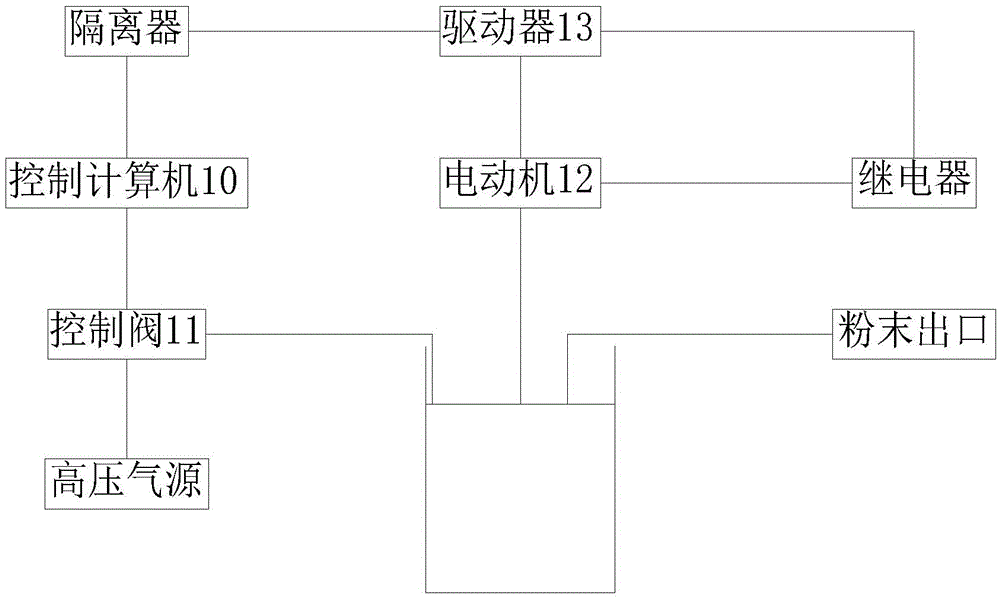

[0019] combine figure 1 , a metal powder fuel supply device based on overpressure sealing in the present invention, a piston and a transmission assembly 1 are arranged on the upper end of the nanometer metal powder grain 2, the piston and the transmission assembly 1 are driven by a motor, and the edge of the piston and the transmission assembly 1 is an annular nozzle 7 , There is an annular gas collection chamber 5 between the piston and the wall, and there are multiple sealing rings 9 between the annular gas collection chamber 5 and the outside world. There is an annular fluidization chamber 6 inside the piston, which is formed by connecting two upper and lower workpiece bolts.

[0020] The air pressure difference inside and outside the annular nozzle 7 forms an overpressure seal, so that the nanometer metal powder cannot penetrate upstream into the edge of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com