Method for manufacturing retort rice, and retort rice

A manufacturing method and technology of sterilizing bags, which are applied in food preparation, food preservation, food science, etc., can solve the problems of unstable measurement, problems of production efficiency, and easy sticking of rice, so as to shorten the pretreatment time and improve production efficiency , easily measurable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

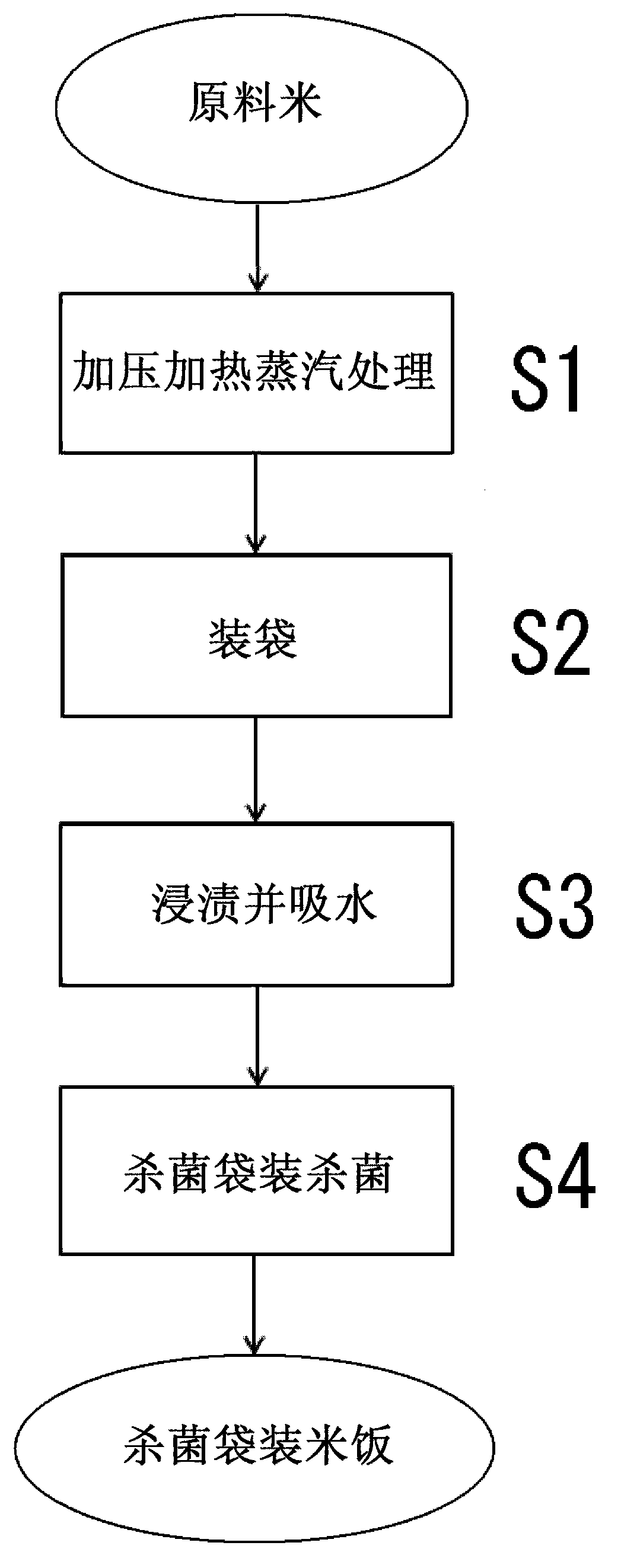

Method used

Image

Examples

Embodiment 1

[0091] In order to obtain 500g of paella-style retort rice (rice with a core) with an inner content of 55% moisture, 178g of long-grain rice (Puntal rice produced in Spain) with a moisture content of 12% was used. The non-washed rice was placed in a retort (manufactured by Japan Biocon Co., Ltd., steam circulation cooking and sterilizing device 100-1B), and processed under pressurized heating steam at a pressure of 0.14 MPa and a temperature of 125°C for 2 minutes.

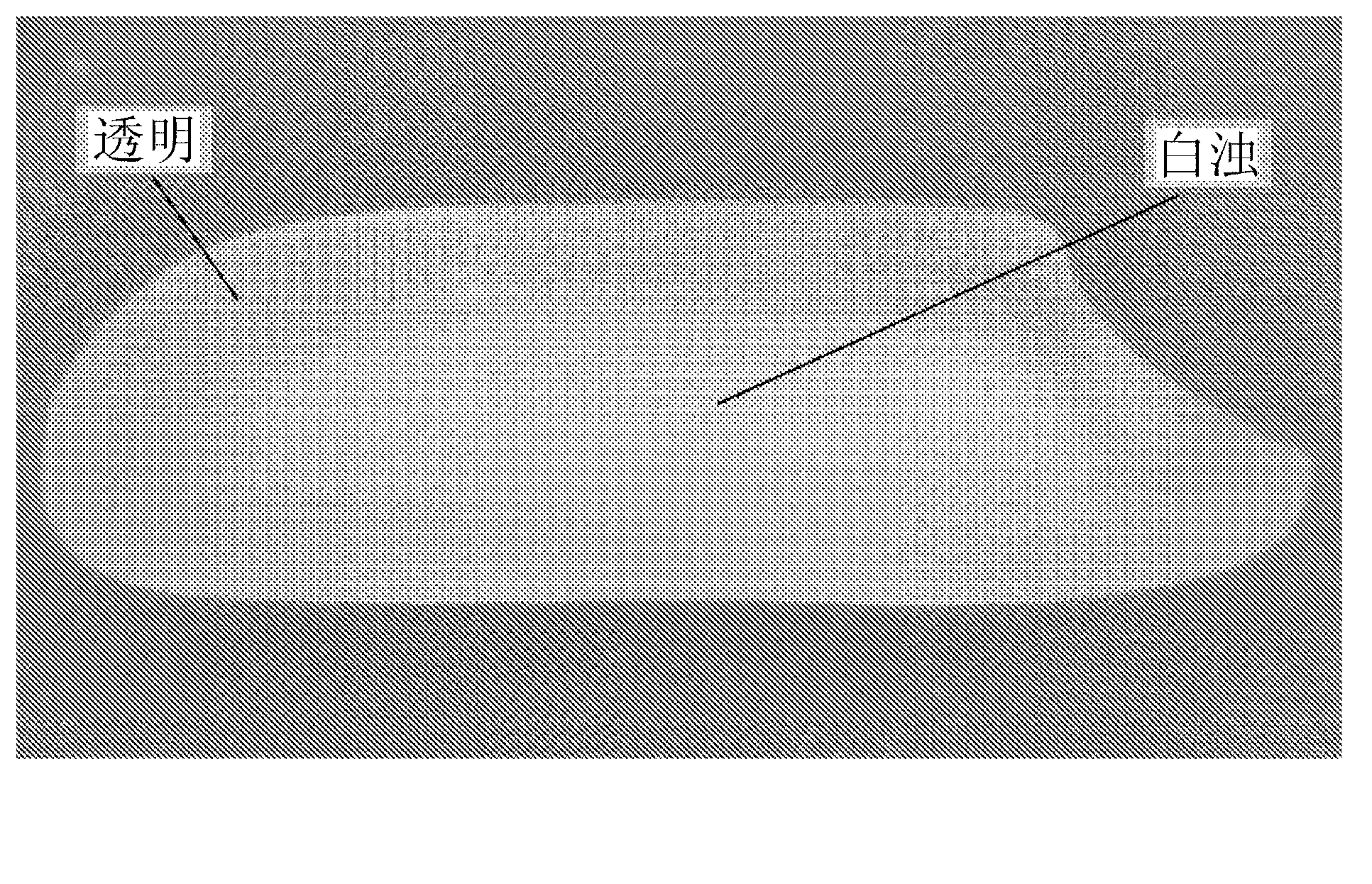

[0092] Then, the processed non-washed rice and 96g of warm water at 60°C and 226g of seasoning liquid at 60°C containing 68g of solids such as cuttlefish and shrimp were filled and sealed in a retort bag, and a 60% headspace was ensured.

[0093] Then, in order to make the water and the seasoning liquid absorb water and infiltrate the non-washed rice and the solid matter, slow souring was carried out for 25 minutes, and inversion was performed 5 times during that time.

[0094] Finally, as in the conventional meth...

Embodiment 2

[0097] To obtain 500g of retort-packed white rice (sticky rice) with a moisture content of 62% (sticky rice), 218g of long-grain rice (Puntal rice produced in Spain) with a moisture content of 13% was used, and the non-washed rice was Put it in a retort (manufactured by Nippon Biocon Co., Ltd., steam circulation cooking and sterilizing device 100-1B), and process it for 3 minutes under pressurized heating steam at a pressure of 0.18 MPa and a temperature of 130°C.

[0098] Then, 282 g of the treated non-washed rice and 80° C. of warm water were filled and sealed in a sterilization bag, and a head space of 60% was ensured.

[0099] Then, in order to absorb and infiltrate water into the non-washed rice, it was slowly soaked for 35 minutes, during which time it was reversed 5 times.

[0100] Finally, as usual, retort sterilization was carried out in which the temperature was raised for 22 minutes, the center of the product was heated at 115°C for 35 minutes, and then the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com