Method for manufacturing retort rice, and retort rice

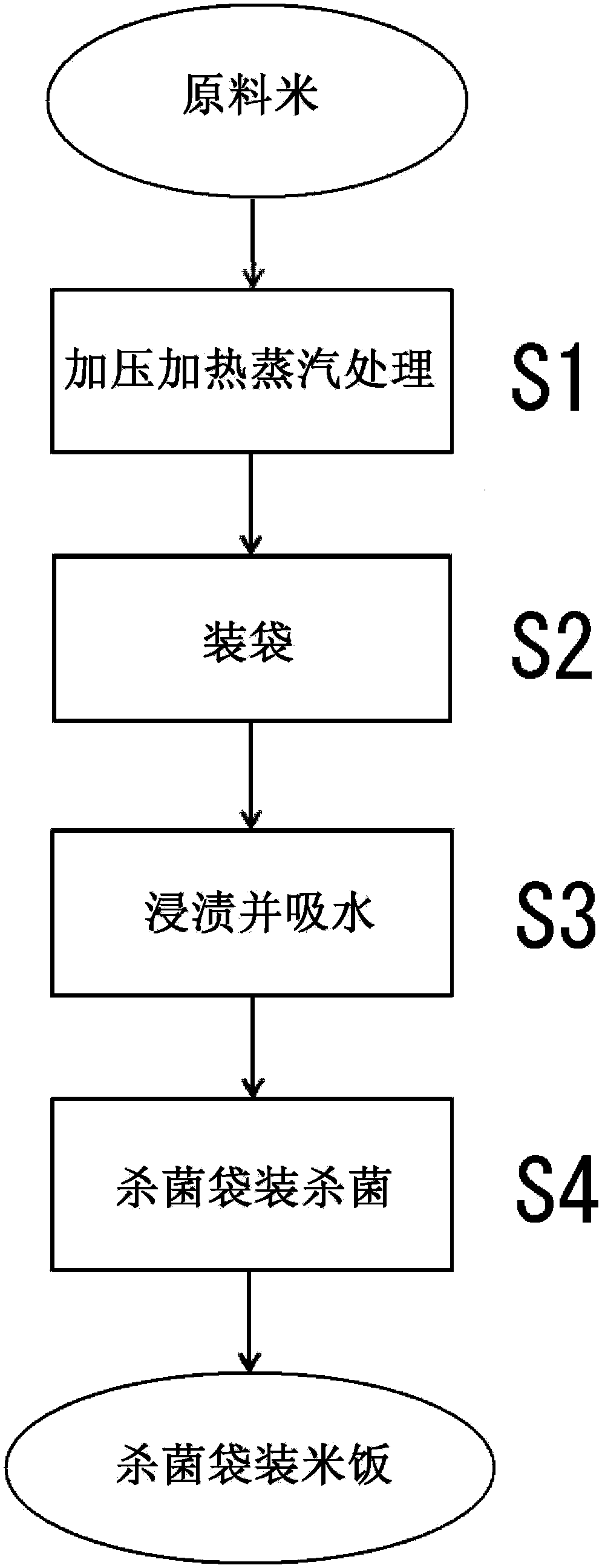

一种制造方法、杀菌袋的技术,应用在食品制备、食品保存、食物科学等方向,能够解决米易粘结、生产效率存在问题、计量不稳定等问题,达到容易计量、提高生产效率、缩短预处理时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] In order to obtain 500g of paella-style retort rice (rice with a core) with an inner content of 55% moisture, 178g of long-grain rice (Puntal rice produced in Spain) with a moisture content of 12% was used. The non-washed rice was placed in a retort (manufactured by Japan Biocon Co., Ltd., steam circulation cooking and sterilizing device 100-1B), and processed under pressurized heating steam at a pressure of 0.14 MPa and a temperature of 125°C for 2 minutes.

[0092] Then, the processed non-washed rice and 96g of warm water at 60°C and 226g of seasoning liquid at 60°C containing 68g of solids such as cuttlefish and shrimp were filled and sealed in a retort bag, and a 60% headspace was ensured.

[0093] Then, in order to make the water and the seasoning liquid absorb water and infiltrate the non-washed rice and the solid matter, slow souring was carried out for 25 minutes, and inversion was performed 5 times during that time.

[0094] Finally, as in the conventional meth...

Embodiment 2

[0097] To obtain 500g of retort-packed white rice (sticky rice) with a moisture content of 62% (sticky rice), 218g of long-grain rice (Puntal rice produced in Spain) with a moisture content of 13% was used, and the non-washed rice was Put it in a retort (manufactured by Nippon Biocon Co., Ltd., steam circulation cooking and sterilizing device 100-1B), and process it for 3 minutes under pressurized heating steam at a pressure of 0.18 MPa and a temperature of 130°C.

[0098] Then, 282 g of the treated non-washed rice and 80° C. of warm water were filled and sealed in a sterilization bag, and a head space of 60% was ensured.

[0099] Then, in order to absorb and infiltrate water into the non-washed rice, it was slowly soaked for 35 minutes, during which time it was reversed 5 times.

[0100] Finally, as usual, retort sterilization was carried out in which the temperature was raised for 22 minutes, the center of the product was heated at 115°C for 35 minutes, and then the temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com