Instant New-year-cake processing method and its extruding-formation apparatus

A processing method and extrusion molding technology, which are applied in baking, baked food, food science and other directions, can solve the problems of poor eating effect of rice cake, difficult to rehydrate, no convenient eating effect, etc., and achieve a simple structure and high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Material:

[0039] Mixture 1: Mix 100 parts of glutinous rice flour and 40 parts of water evenly;

[0040] Mixture 2: Mix 100 parts of glutinous rice flour, 1.0 parts of sodium alginate, and 40 parts of water;

[0041] Ripening: cook and ripen material 1 and material 2 respectively;

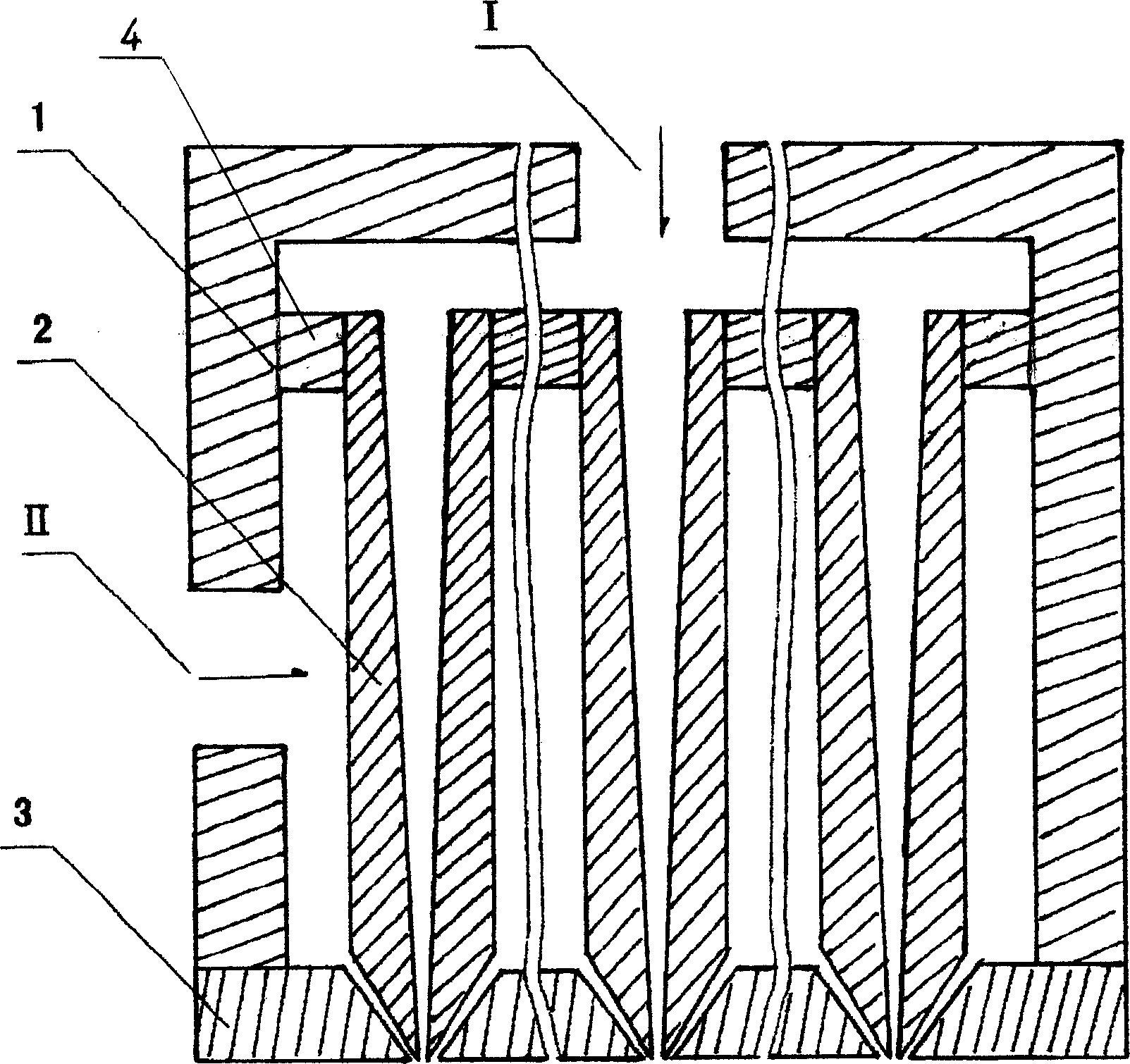

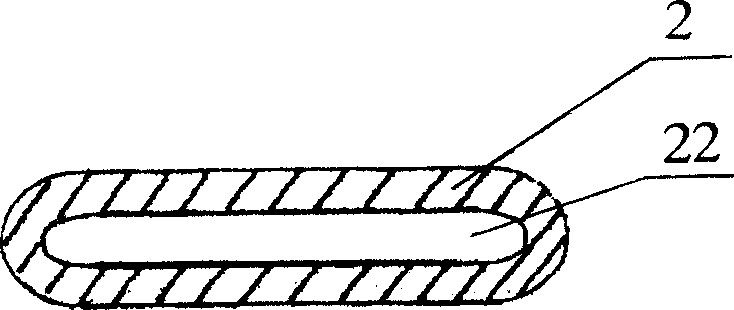

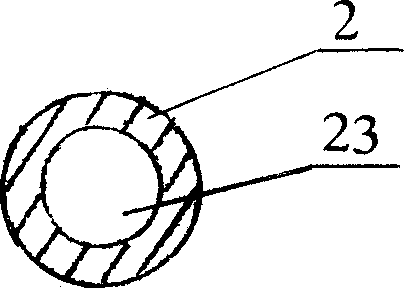

[0042] Extrusion molding: Input the matured material 1 and material 2 respectively into two extruders or extrude in two separated extrusion cavities of the same extruder, and pass through the extrusion molding device of the present invention Extruded, extruded into 1-5mm thick strip-shaped rice cakes or columnar rice cakes;

[0043] Film formation: The rice cakes extruded into strips or columns are passed through 12% calcium chloride solution, so that the sodium alginate gel on the outer layer forms a film, and a thin layer can be formed on the surface that can prevent the rice cakes from sticking to each other. layer;

[0044] Cleaning: cleaning the processed rice cake in clear water;...

Embodiment 2

[0049] Ingredients: 100 parts of glutinous rice flour, 3 parts of potassium alginate, and 45 parts of water are mixed evenly by weight;

[0050] Extrusion molding: Extrude the mixture directly from the rice cake machine to form a 1-5mm thick strip or columnar rice cake;

[0051] Film formation: pass the rice cakes extruded into strips or columns in 5% calcium chloride solution to form a film of potassium alginate, and form a thin layer on the surface that can prevent the mutual bonding between rice cakes;

[0052] All the other are the same as embodiment one.

Embodiment 3

[0054] Material:

[0055] Ingredients: 85 parts of waxy corn flour, 15 parts of glutinous rice flour, 8 parts of sodium alginate, and 40 parts of water are mixed evenly by weight;

[0056] Extrusion molding: Extrude the mixture directly from the rice cake machine to form a 1-5mm thick strip or columnar rice cake;

[0057] Film formation: pass the rice cakes extruded into strips or columns in 5% calcium chloride solution to make sodium alginate gel into a film, and form a thin layer on the surface that can prevent the rice cakes from sticking to each other;

[0058] All the other are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com