Preparation method of high-strength isostatic pressing graphite

An isostatic pressing and high-strength technology, which is applied in the field of static pressure graphite preparation, can solve the problem of inability to ensure the mixing of pitch mesocarbon microspheres and paste powder in a fixed ratio, and achieve the effect of prolonging the laying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

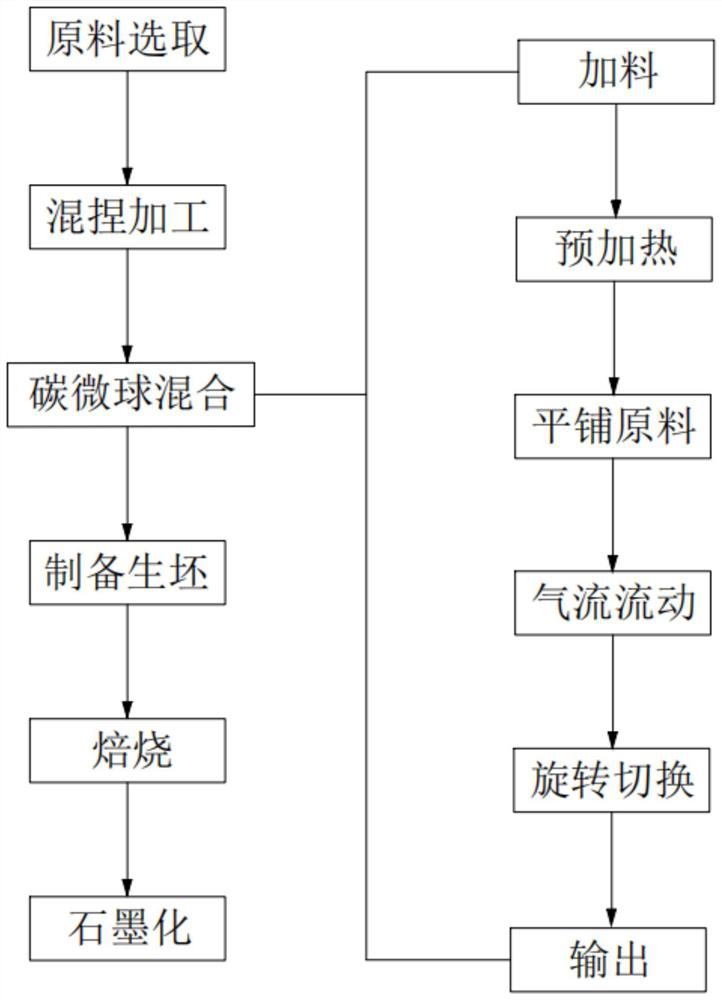

[0077] like figure 1 Shown, a kind of preparation method of high strength isostatic graphite, comprises the following steps:

[0078] Step 1, raw material selection, crushing the calcined petroleum coke or pitch coke raw material and then pulverizing to obtain raw material powder with a median particle size D50 in the range of 8-15um;

[0079] Step 2, kneading process, mix the raw material powder prepared in step 1 evenly in the kneading pot and preheat to 150°C, add high-temperature coal tar pitch with a softening point of 110-120°C as a binder for kneading, and knead at 190-200°C After kneading at ℃ for 60 minutes, take it out of the pot, and after the paste is cooled, carry out secondary grinding to obtain paste powder with a median particle size D50 range of 25-50um;

[0080] Step 3, carbon microspheres are mixed, and the paste powder prepared in step 2 is mixed with pitch mesophase carbon microspheres with a median particle size D50 range of 2-5um and a volatile content ...

Embodiment 2

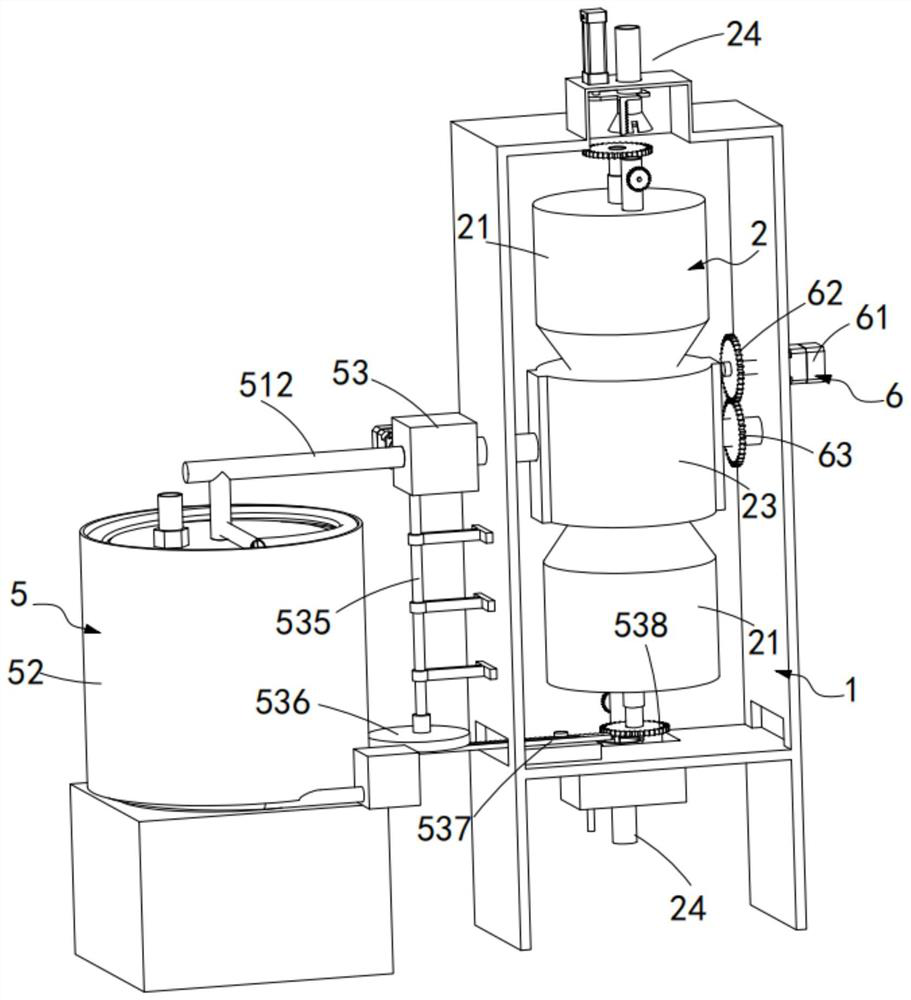

[0127] like Figure 2 to Figure 5 Shown, a kind of raw material mixing equipment for the production of high-strength isostatic graphite, comprising:

[0128] A mounting frame 1, the mounting frame 1 is arranged in a frame;

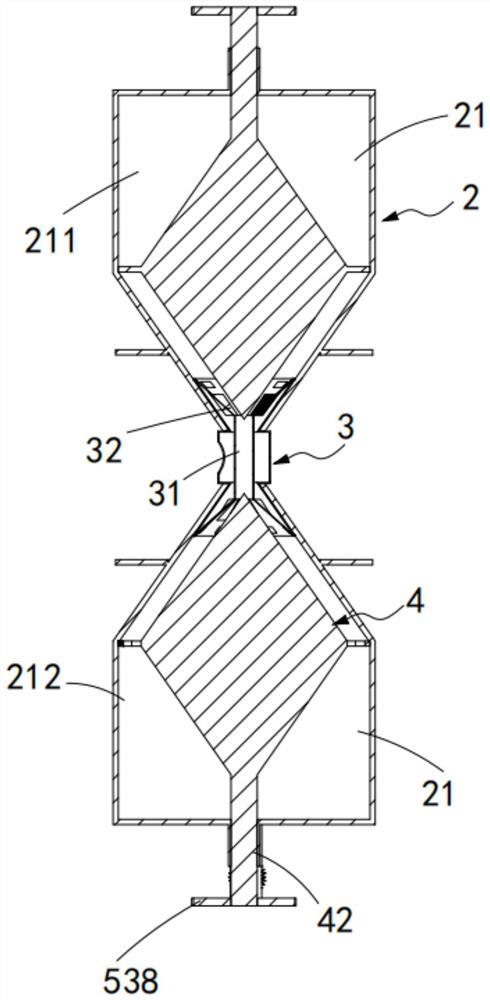

[0129] Reaction tank 2, the reaction tank 2 is arranged in an hourglass shape, and it includes two funnel-shaped and facing tank bodies 21, and a storage chamber 211 is arranged in the tank body 21 above, and the storage chamber Raw material powder is stored in 211, and a material receiving cavity 212 is arranged in the tank body 21 located below, and the tank body 21 is rotatably installed on the installation frame 1 through the connecting shell 23, and the tank body 21 A material tube 213 is arranged on the flat side wall;

[0130] Feed head 3, described feed head 3 is arranged between described tank body 21, and it comprises the inner tube 31 that communicates with described tank body 21 and the feeder 32 that is arranged around this inner tube 31, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com