A kind of preparation method of high-strength isostatic pressing graphite

An isostatic pressing, high-strength technology, applied in the field of static pressing graphite, can solve the problem of not being able to guarantee the mixing of pitch mesocarbon microspheres and paste powder in a certain ratio, and achieve the effect of prolonging the tiling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

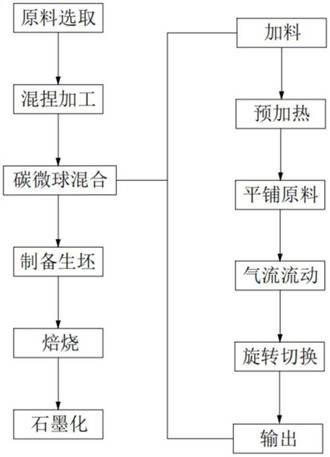

[0077] like figure 1 As shown, a preparation method of high-strength isostatic graphite includes the following steps:

[0078] Step 1, raw material selection, crushing the calcined petroleum coke or pitch coke raw material and grinding to obtain raw material powder with a median particle size D50 of 8-15um;

[0079] Step 2, kneading process, mix the raw material powder prepared in step 1 uniformly in the kneading pot and preheat to 150 ℃, add high temperature coal pitch with a softening point of 110-120 ℃ as a binder for kneading, at 190-200 ℃ After kneading at a temperature of ℃ for 60 minutes, the pot is taken out, and the paste is cooled and then ground for a second time to obtain a paste powder with a median particle size D50 range of 25-50um;

[0080] Step 3, carbon microspheres are mixed, and the paste powder prepared in step 2 is mixed with pitch mesocarbon microspheres with a median diameter of D50 ranging from 2-5um and a volatile content of 6-10% in a ratio of 10:1-...

Embodiment 2

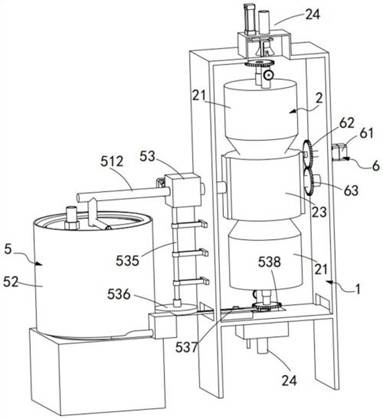

[0127] like Figure 2 to Figure 5 As shown, a raw material mixing equipment for the production of high-strength isostatic graphite includes:

[0128] Mounting rack 1, the mounting rack 1 is arranged in a frame;

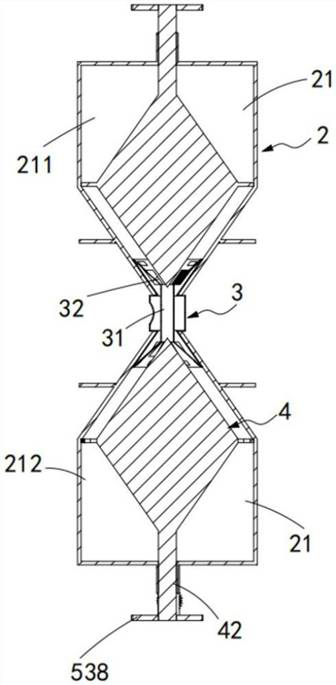

[0129] Reaction tank 2, the reaction tank 2 is set in an hourglass shape, and includes two tank bodies 21 in a funnel shape and facing each other. The tank body 21 located above is provided with a storage cavity 211. The storage cavity Raw material powder is stored in 211, and a receiving cavity 212 is arranged in the tank body 21 located below. A material pipe 213 is arranged on the flat side wall;

[0130] Feeding head 3, the feeding head 3 is arranged between the tanks 21, it includes an inner pipe 31 communicating with the tank 21 and a feeder 32 arranged around the inner pipe 31, the feeding The inner wall of the container 32 cooperates with the outer wall of the inner tube 31 to form a material cavity 33 for accommodating carbon microspheres, and a feeding po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com