PET (Polyethylene Terephthalate) slice production system and production process thereof

A production system and slicing technology, applied in the production process field of the PET slicing production system, can solve the problems of high energy consumption and low technical efficiency, and achieve the effects of low temperature, long residence time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

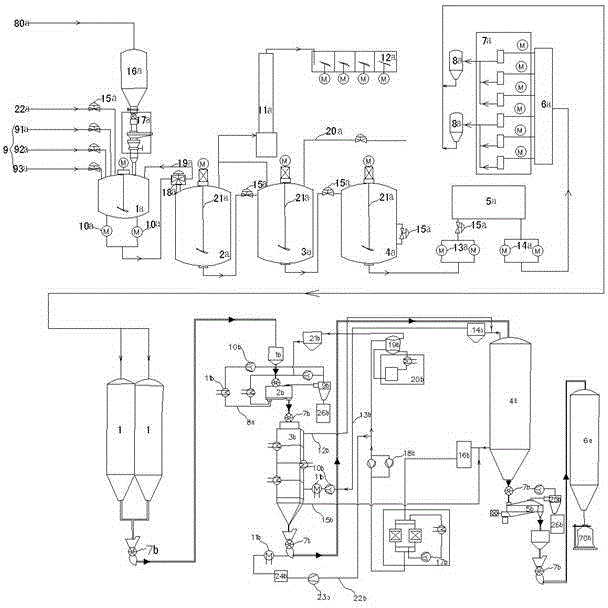

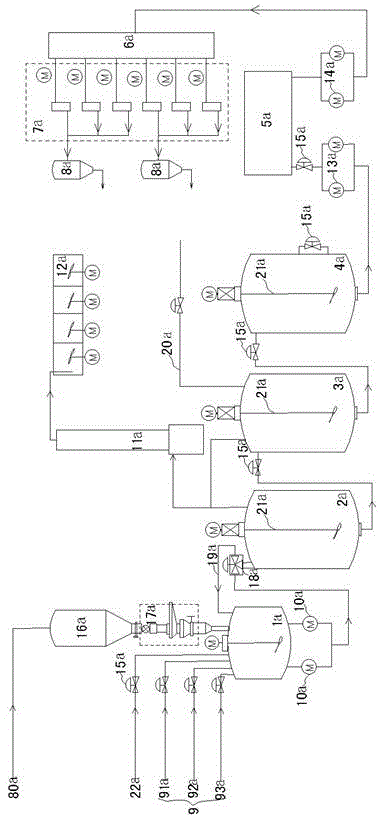

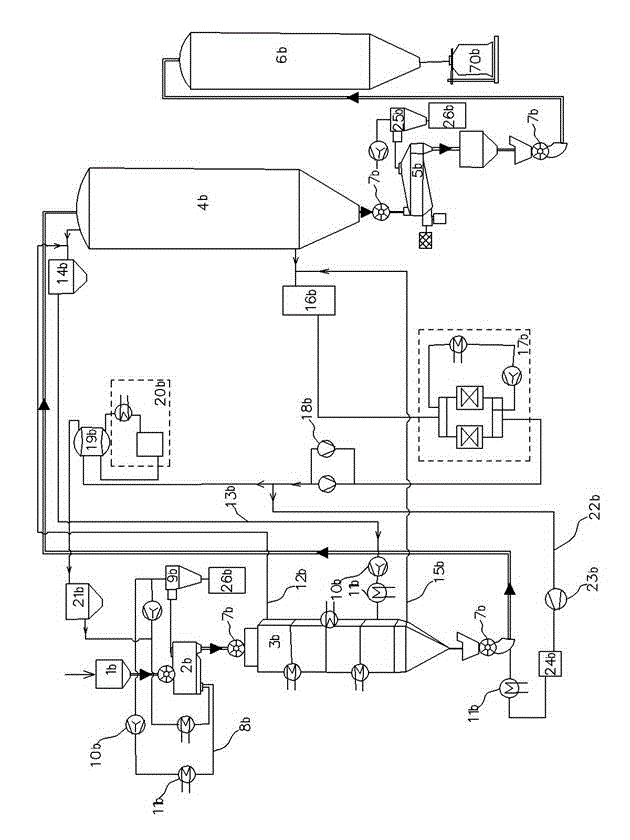

[0034] Such as figure 1 with figure 2 As shown, in this embodiment, the PET chip production system includes a polyester device, a solid-phase polycondensation device and several buffer bins 1 arranged between the polyester device and the solid-phase polycondensation device, and is characterized in that: The polyester plant comprises a slurry preparation device 1a, a first esterification reactor 2a, a second esterification reactor 3a, a pre-condensation reactor 4a, a final polycondensation reactor 5a, a melt filter 6a, and a cut-off reactor connected in sequence. Feeding device 7a and slice collection hopper 8a, also communicated with phthalic acid feed pipe 80a, ethylene glycol feed pipe 22a and additive feed pipe 9a on the described slurry preparation device 1a, described slurry preparation device 1a and Two slurry delivery pumps 10a are arranged in parallel between the first esterification reactors 2a, and the polyester plant also includes a connection with the first ester...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com