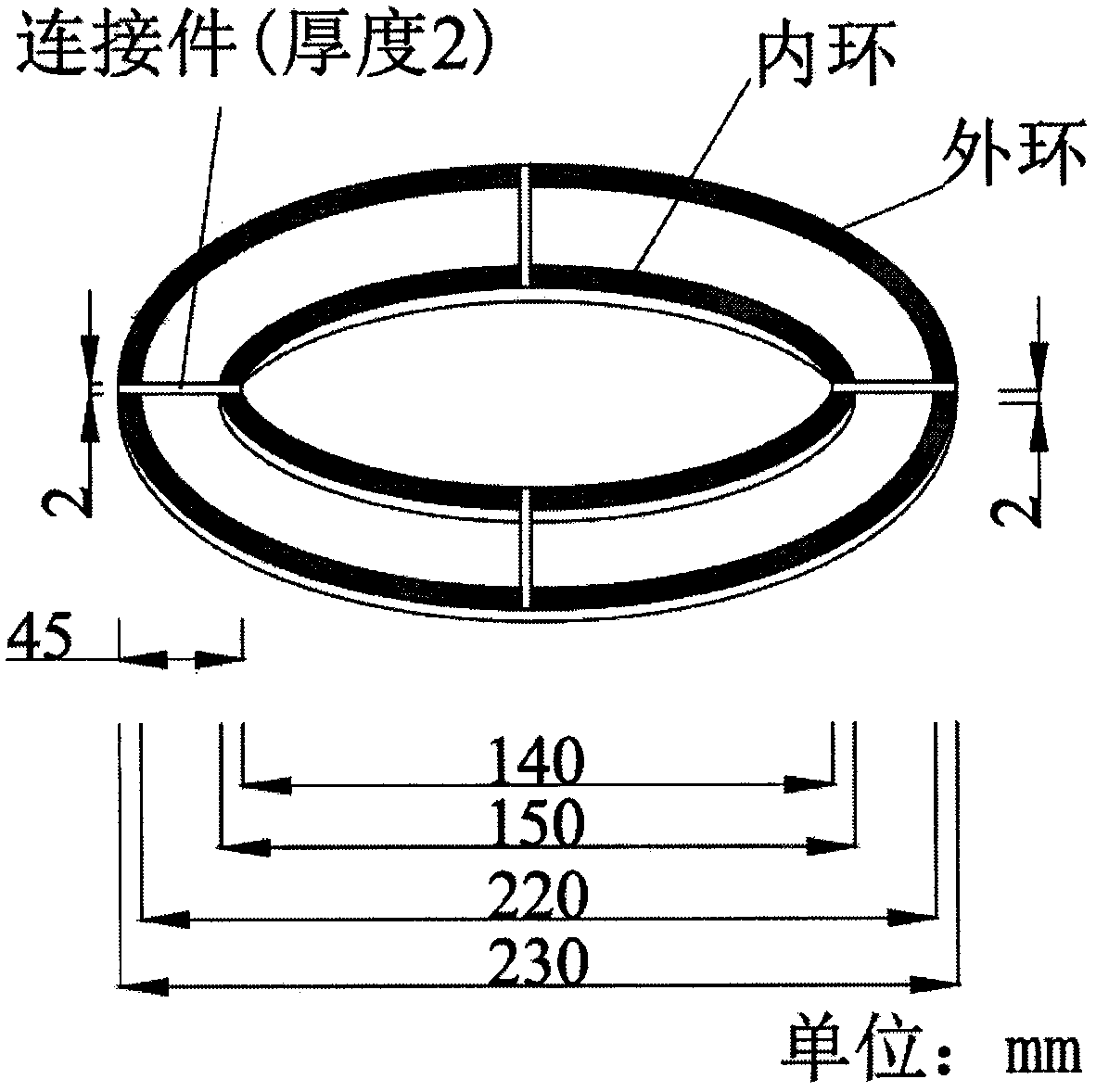

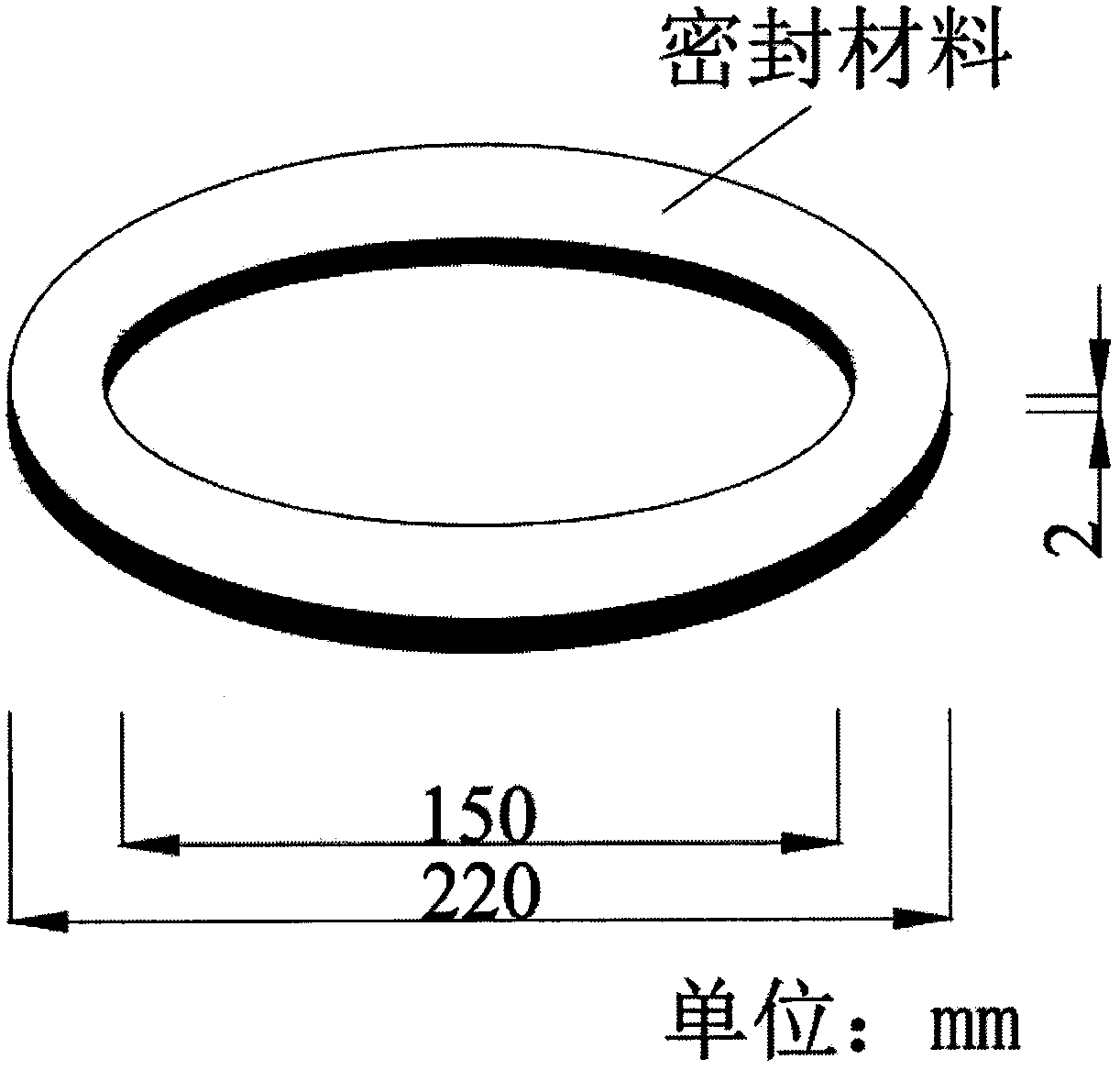

Sealing device and method for detecting water permeability coefficient of asphalt pavement

A sealing device, asphalt pavement technology, applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of uncertain specific location of sealing materials, poor sealing, non-unique water seepage area, etc. Reliable test results, easy demolding, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

[0027] The inventor has found in many years of engineering practice that the gap between the sealing water seepage meter and the road surface adopted in the asphalt pavement water seepage coefficient test method (T0971-2008) in the existing "Highway Subgrade Pavement Field Test Regulations" (JTG E60-2008) There are obvious deficiencies in the method: (1) The sealing material recommended by the specification cannot well seal the gap between the water seepage meter and the road surface, and side seepage often occurs during the test; (2) When testing for different times, due to the sealing material The shape is different, and the seepage area under the water seepage meter is different, resulting in different seepage coefficients, and the test results are not reliable. In order to solve the above-mentioned shortcomings, the present invention proposes a seal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com