Overturning stirring machine

A technology of turning mixer and turning connecting rod, which is applied in the direction of mixer with rotating container, mixer, food forming, etc., which can solve the problems of powder dust, high manual labor intensity, low manual operation efficiency, etc., and achieve convenient feeding And retrieving, mixing optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

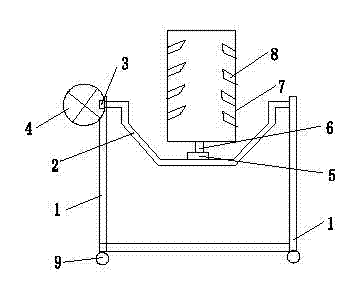

[0012] Combine below figure 1 Specific description embodiment:

[0013] An overturning mixer, comprising a frame 1, characterized in that, the frame 1 is movably provided with an overturning connecting rod 2, and one end of the overturning connecting rod 2 is connected with a worm device 3, and the vortex The lever device 3 is connected with a handle 4, and the turning rod 2 is provided with a motor, and the motor is connected with a worm gear reducer 5 through a belt, and the worm reducer 5 is connected with a rotating shaft 6 through a gear. The rotating shaft 6 is fixedly connected with a rotating drum 7, and a plurality of scrapers 8 are arranged in the rotating drum 7. Wherein, the inner side of the drum 7 is divided into an inner layer and an outer layer, and scrapers are alternately arranged on the inner layer and the outer layer, and the inclination directions of the scrapers of the inner layer and the scrapers of the outer layer are opposite. Wherein, the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com