Patents

Literature

33 results about "Variable reluctance sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

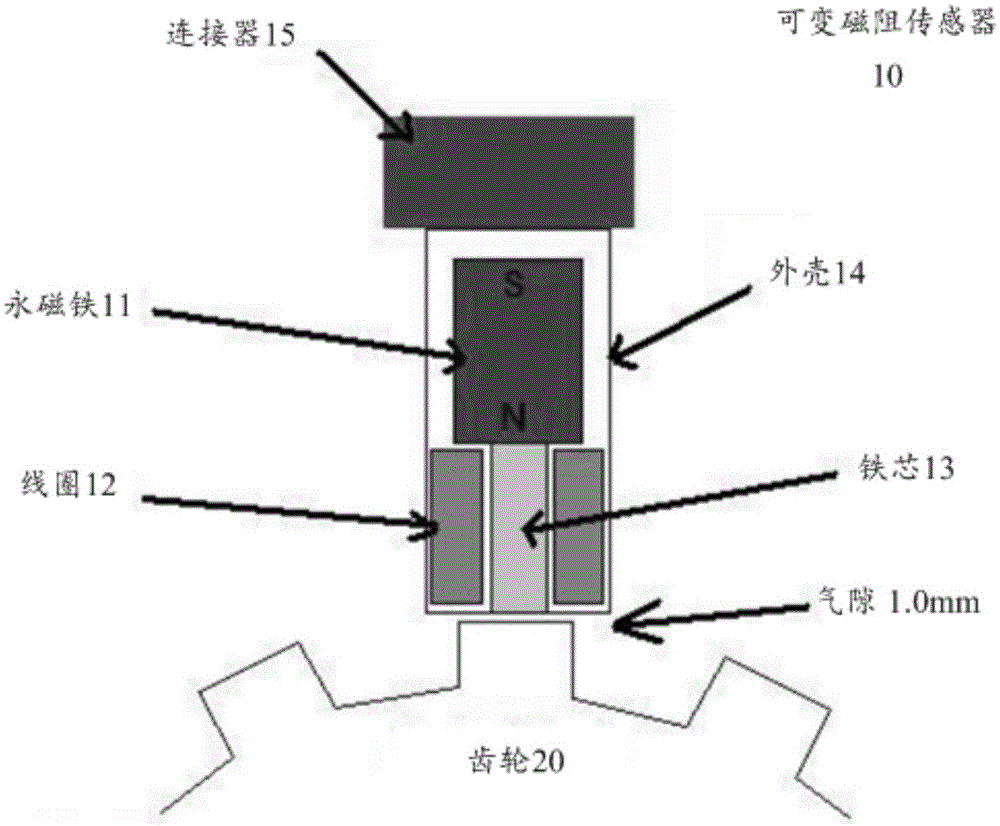

A variable reluctance sensor (commonly called a VR sensor) is a transducer that measures changes in magnetic reluctance. When combined with basic electronic circuitry, the sensor detects the change in presence or proximity of ferrous objects.

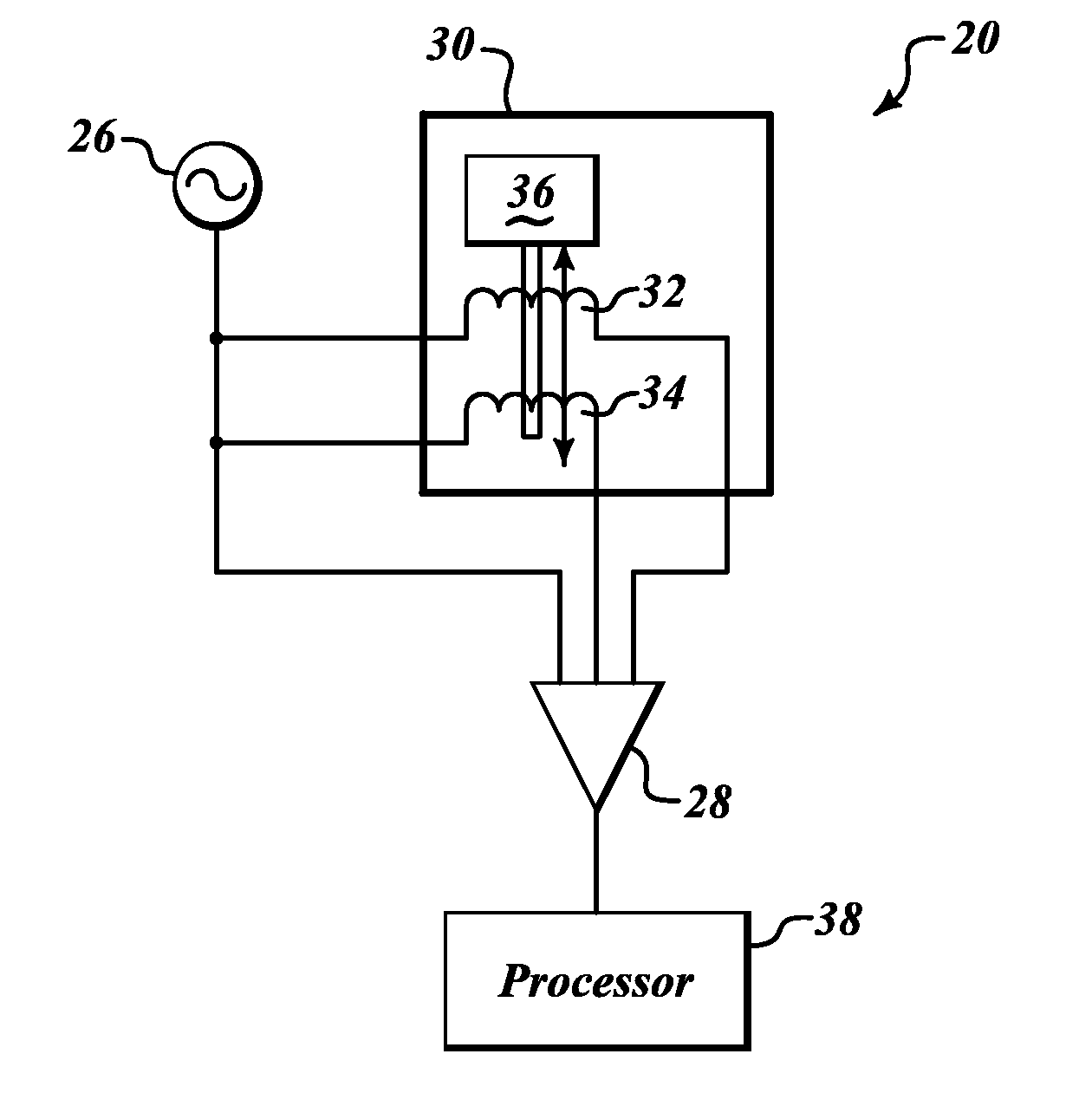

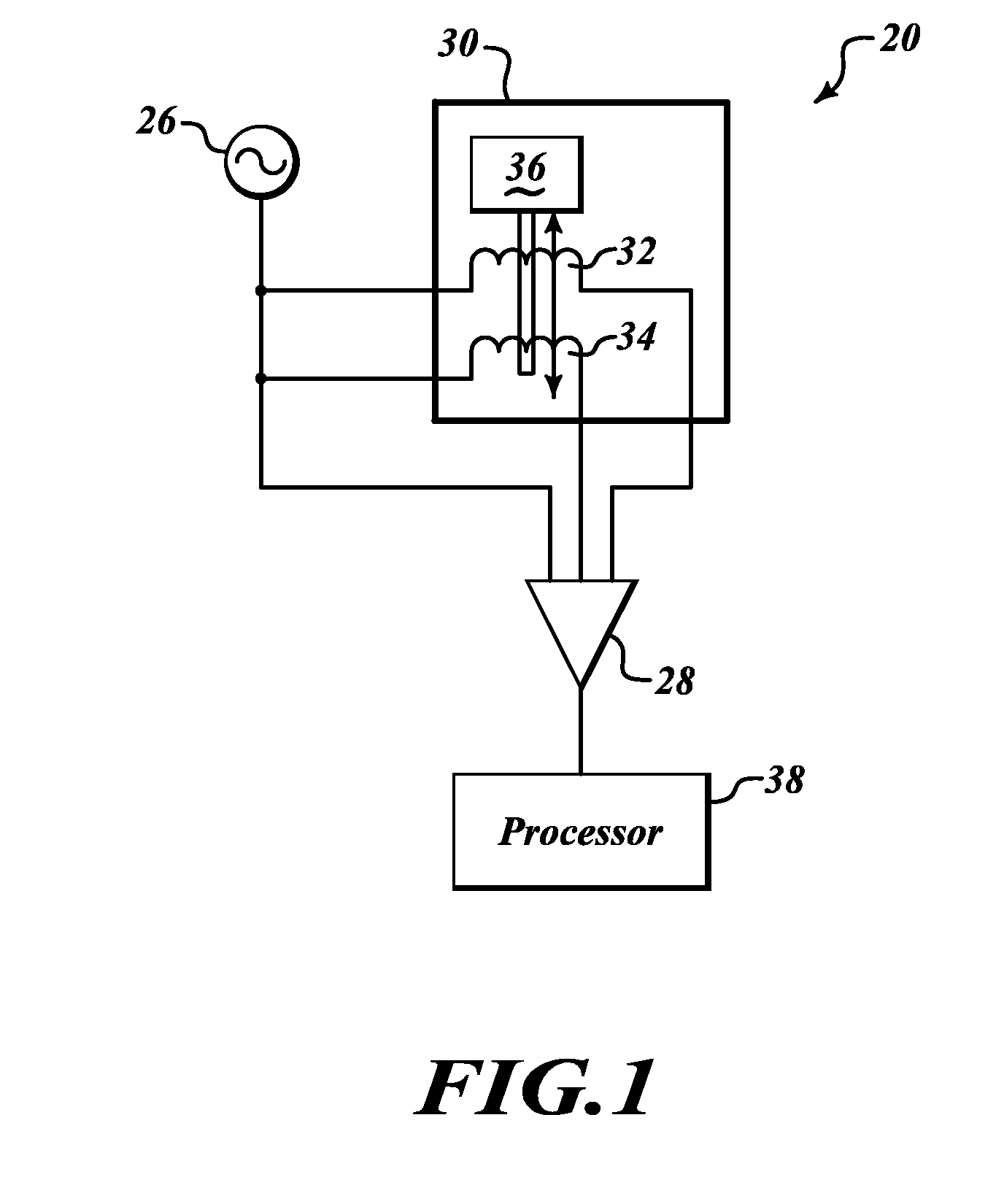

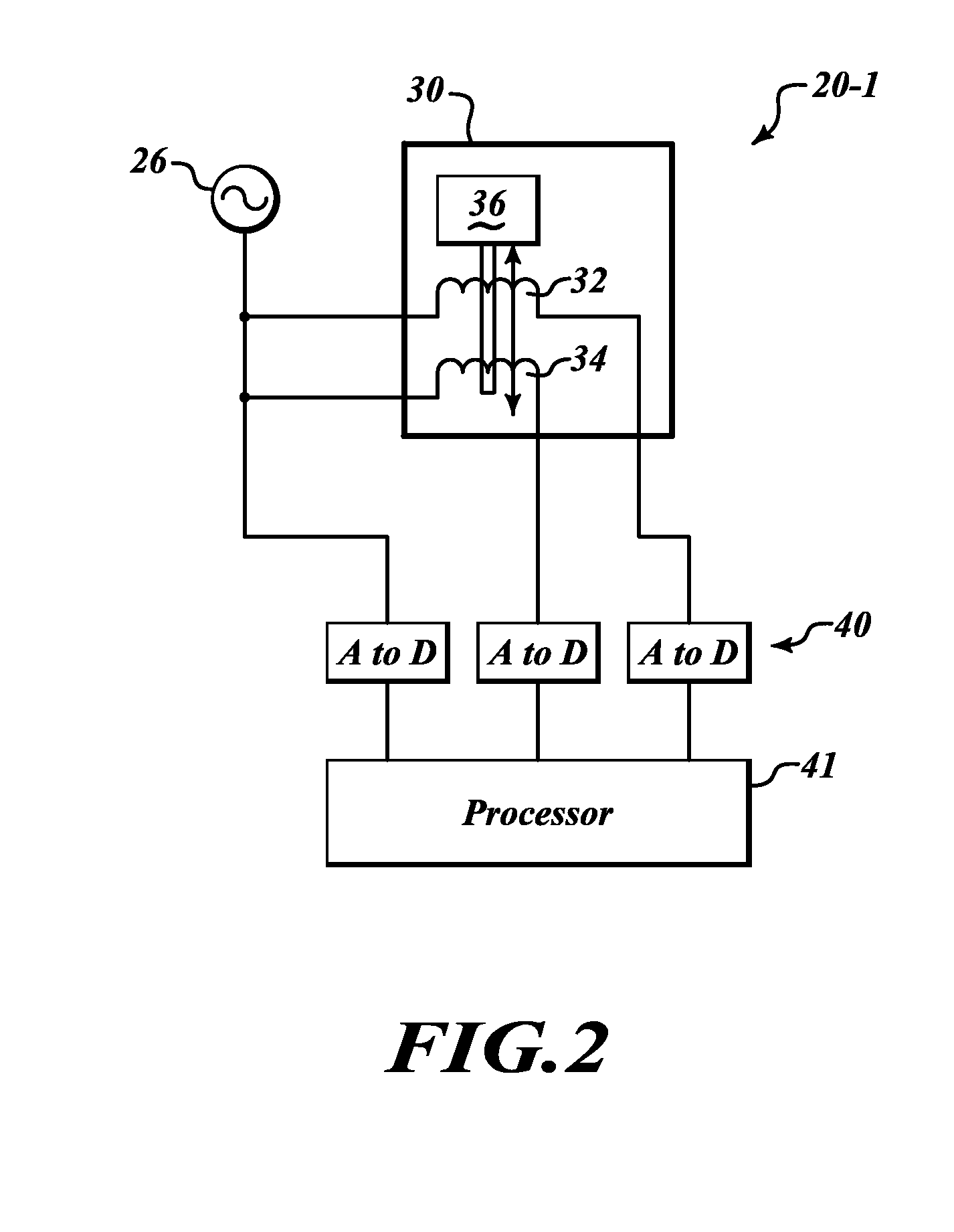

Circuit for compensating for time variation of temperature in an inductive sensor

InactiveUS20050093537A1Precise processAccurate temperatureUsing electrical meansStray field compensationVariable reluctance sensorTransducer

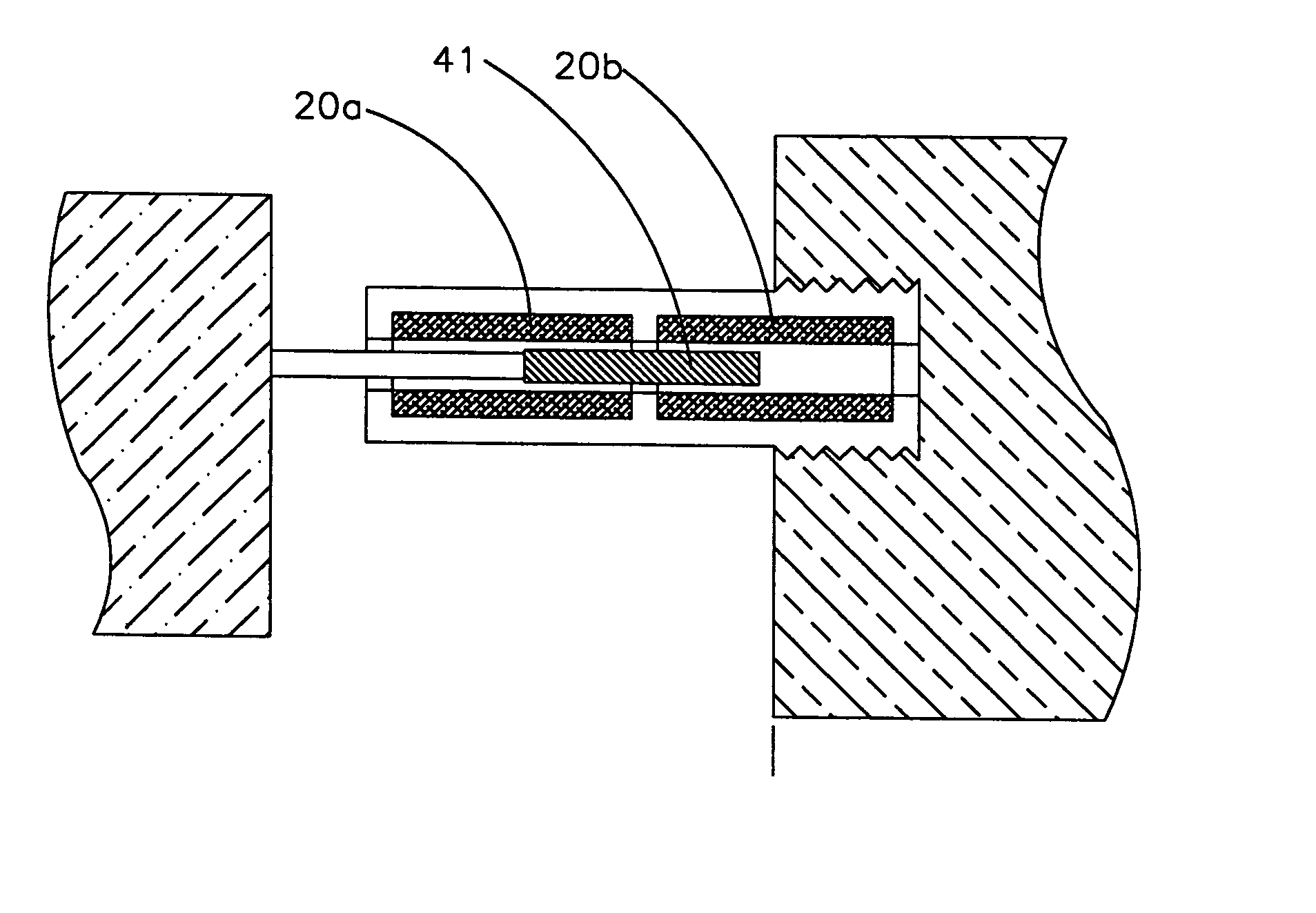

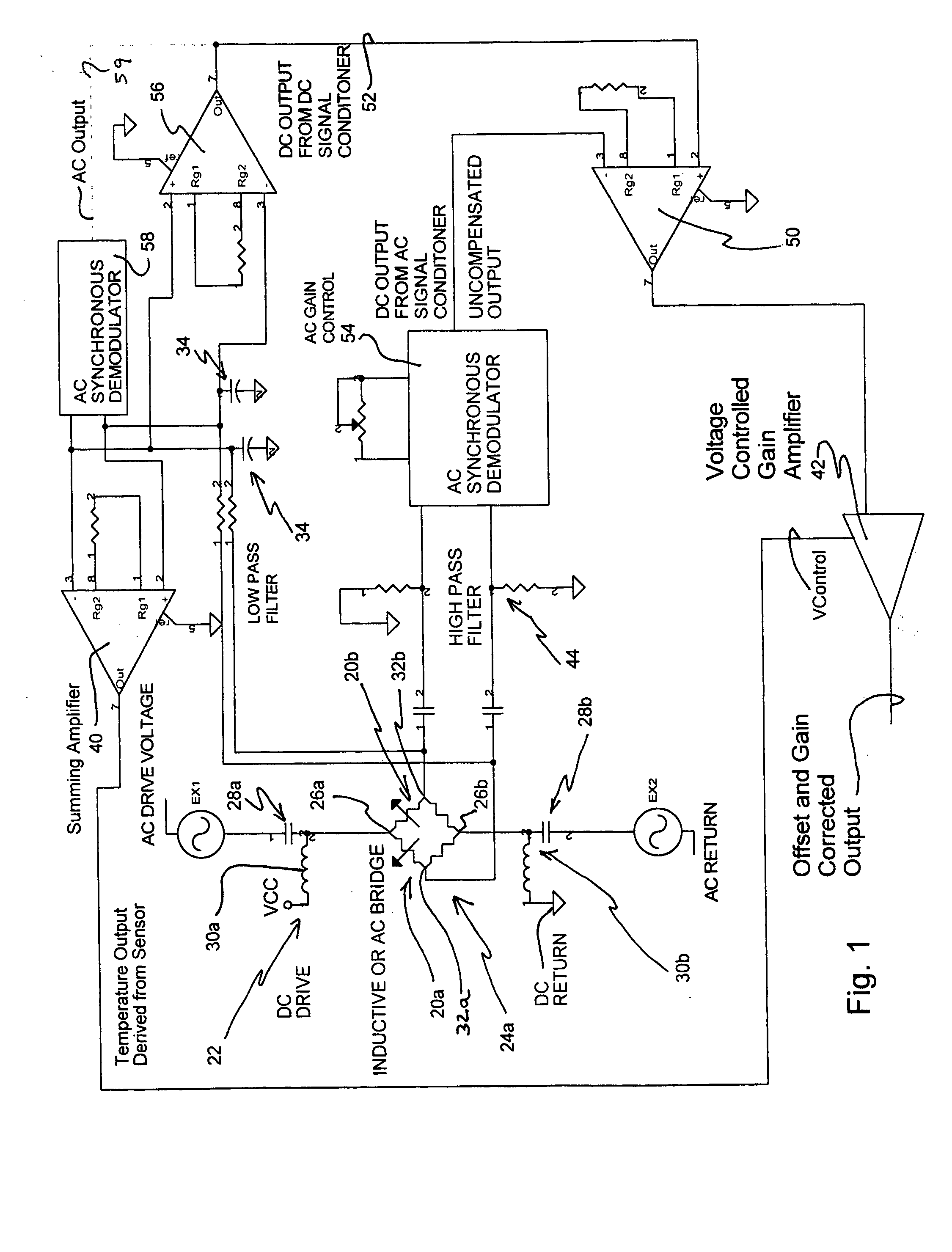

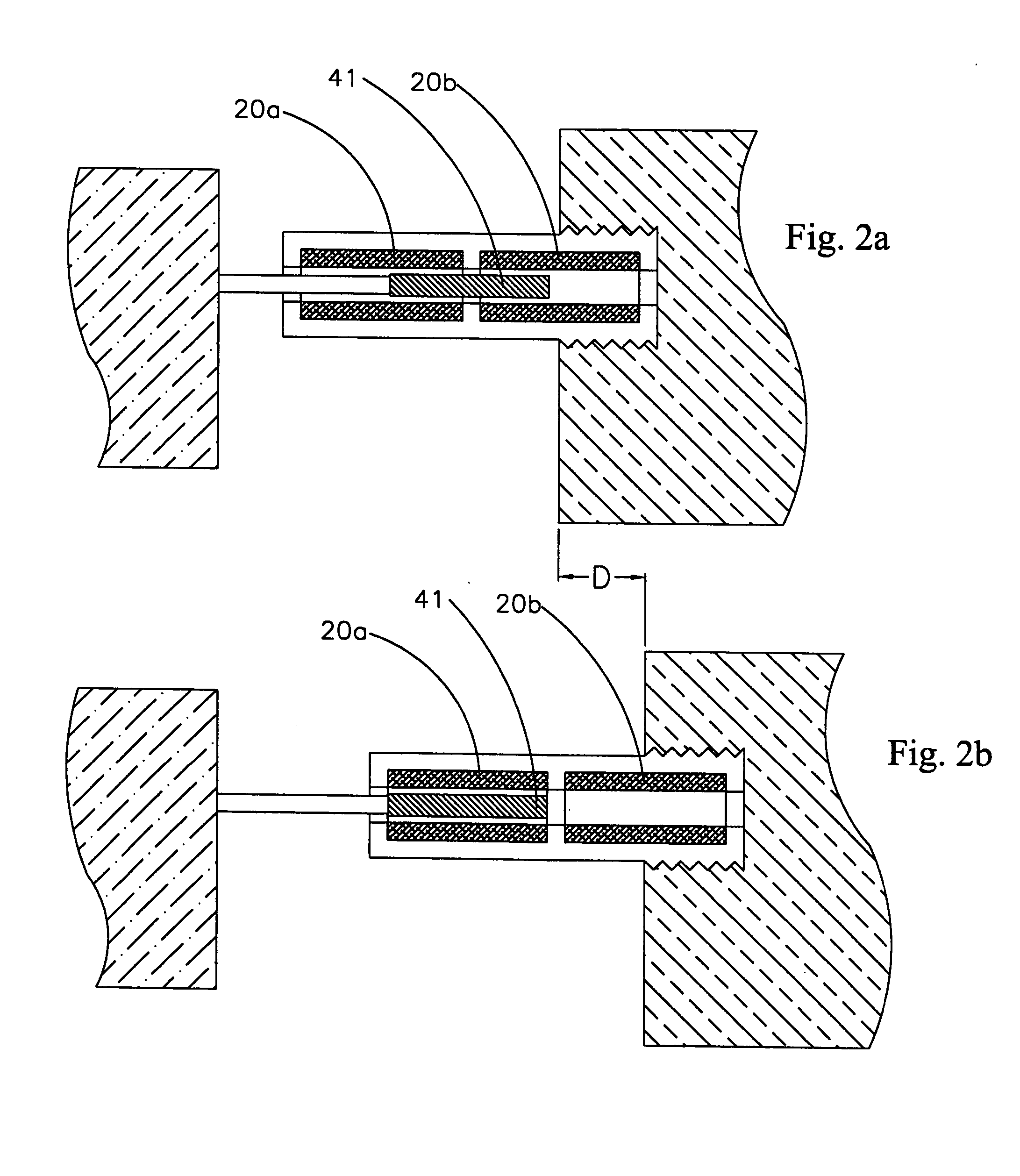

A sensing device includes a circuit that compensates for time and spatial changes in temperature. The circuit includes elements to correct for variation in permeability of a highly permeable core of a differential variable reluctance transducer as temperature changes. The circuit also provides correction for temperature gradients across coils of the transducer.

Owner:LORD CORP

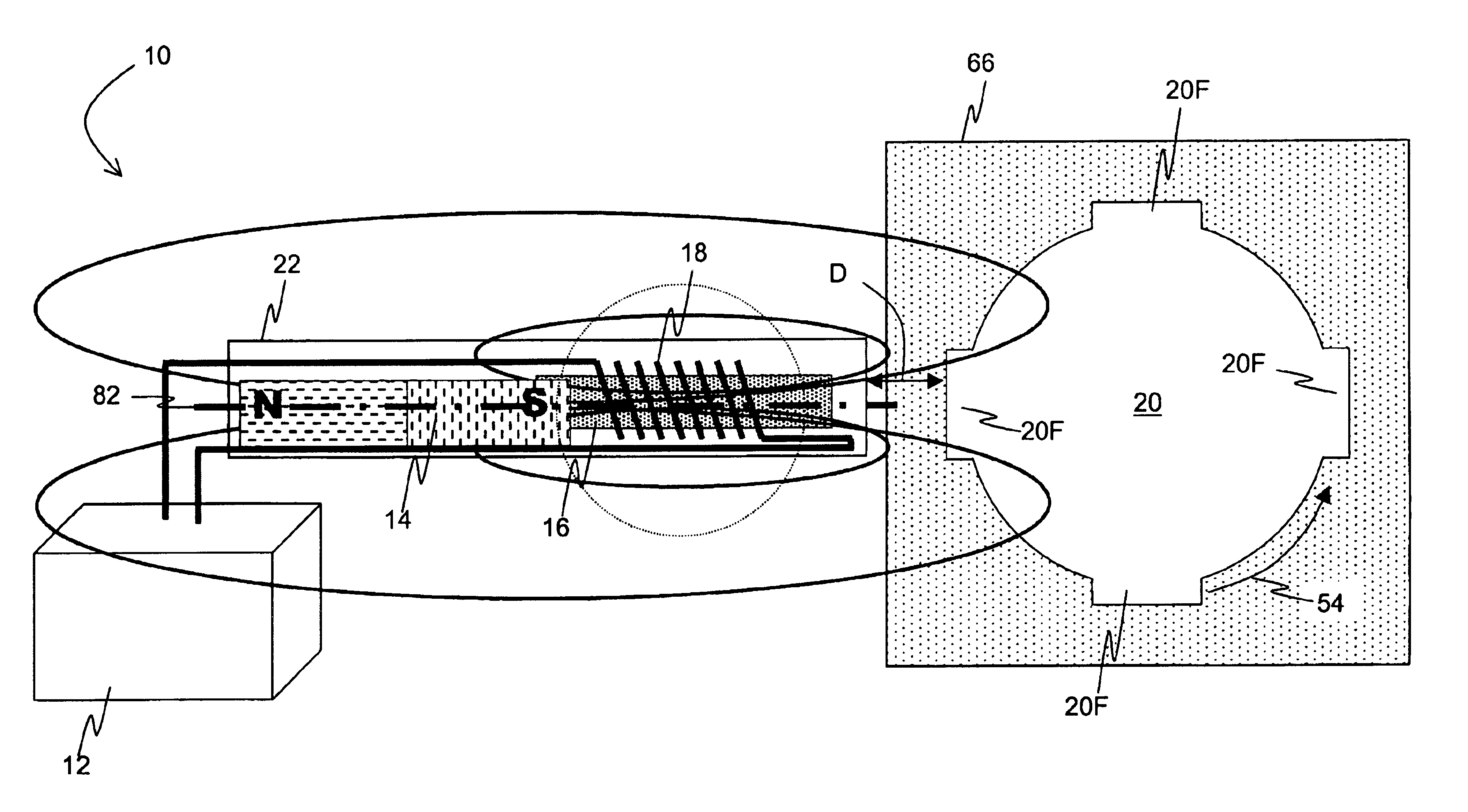

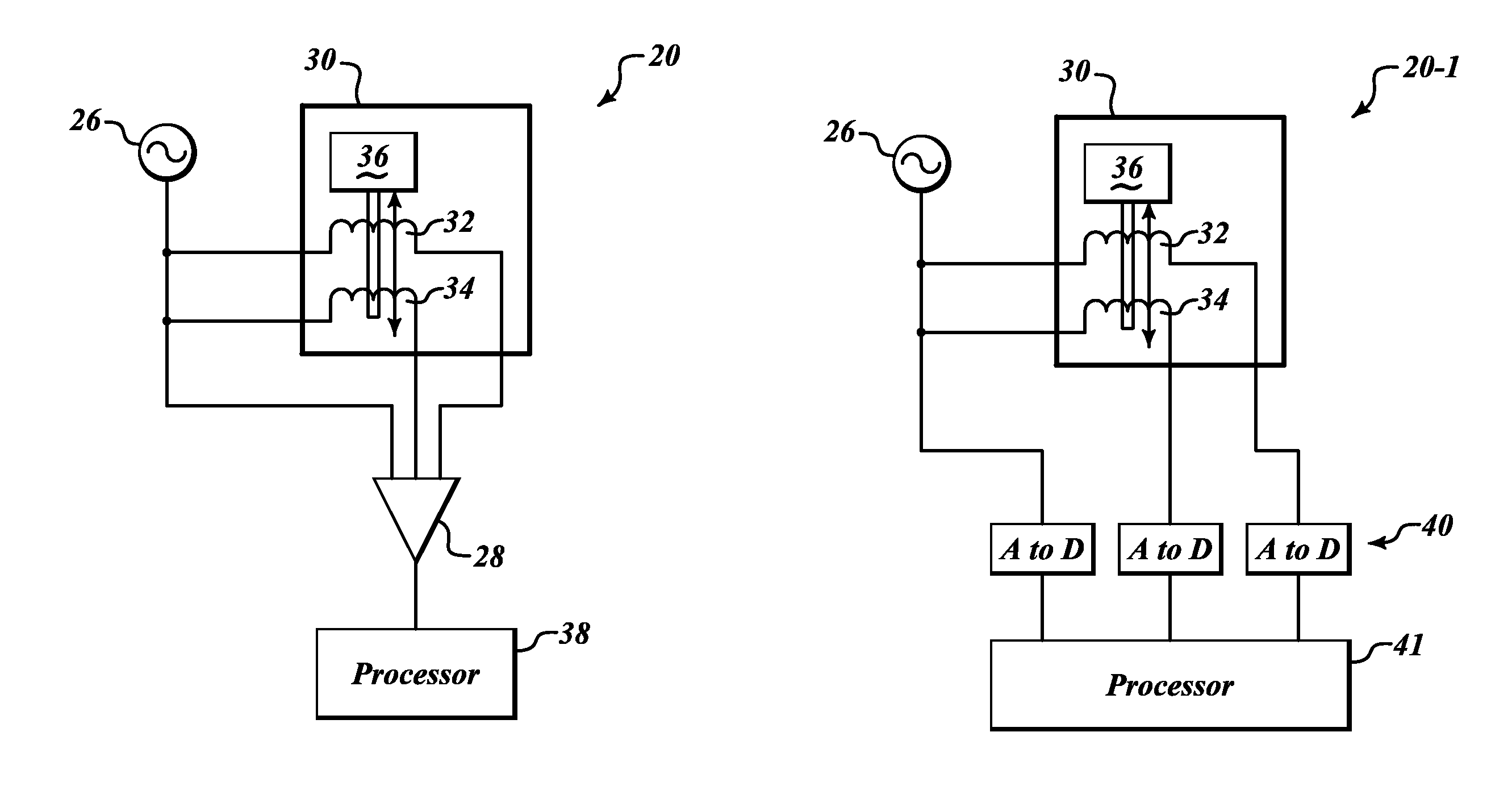

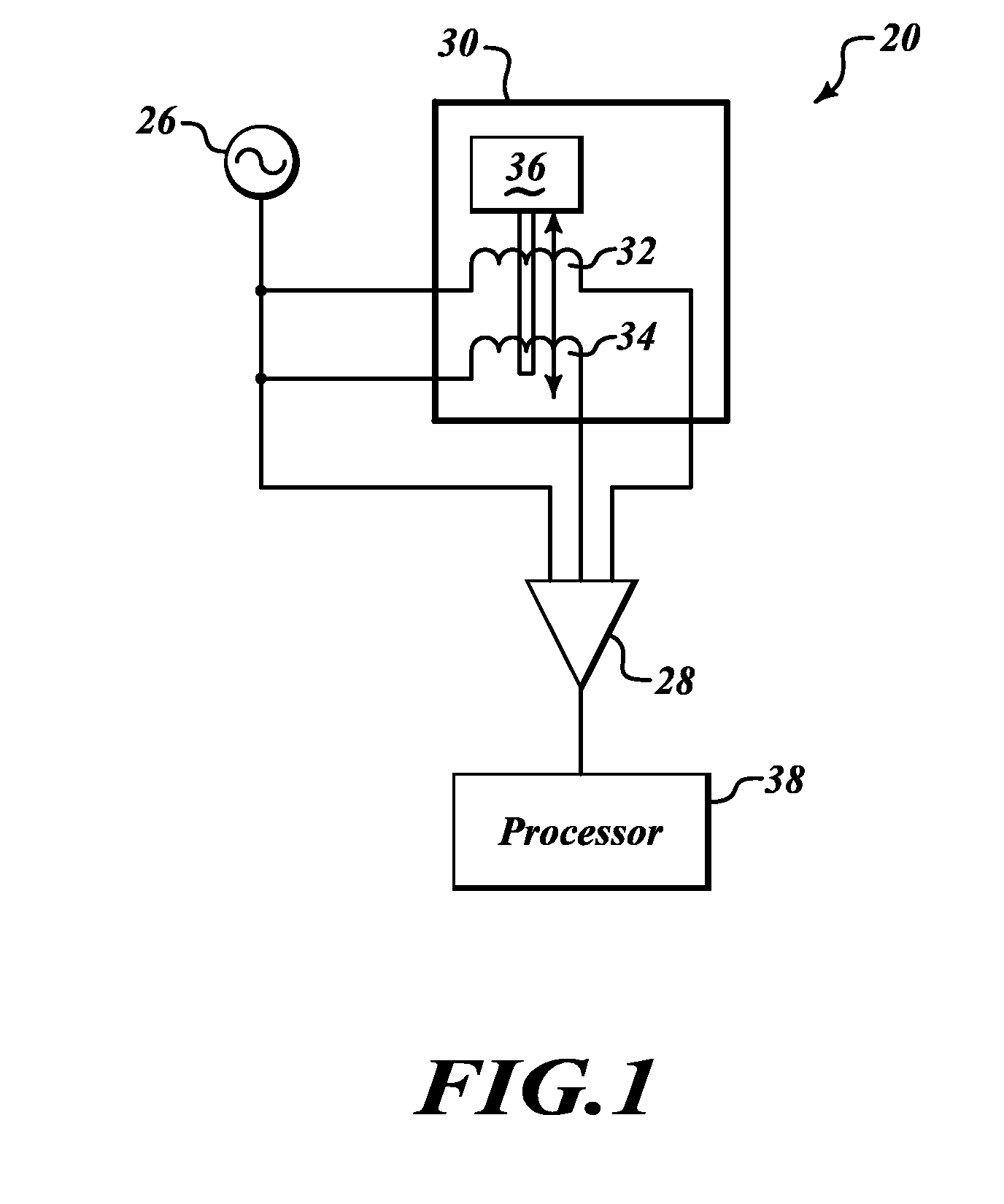

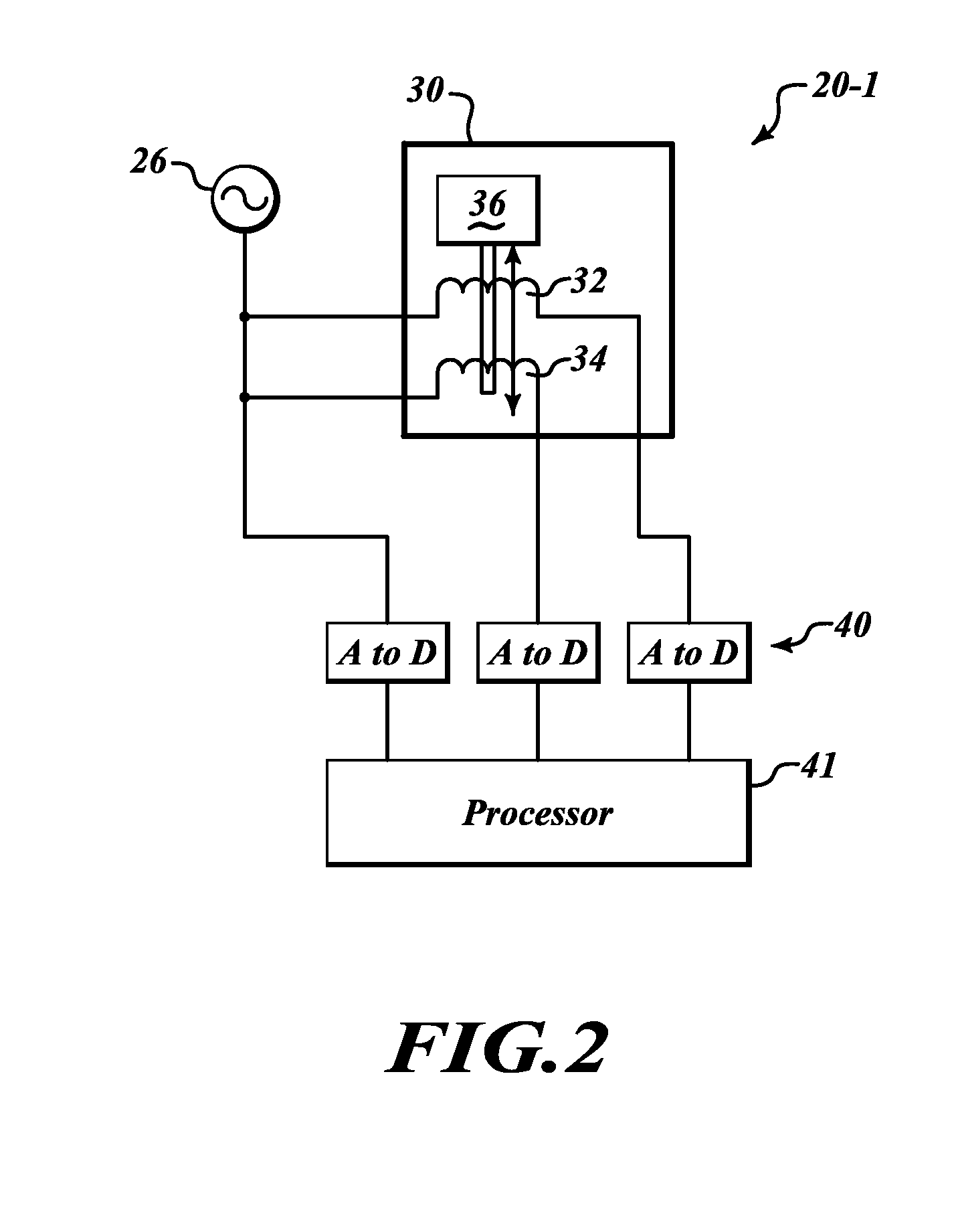

Hybrid inductive sensor

ActiveUS20050083041A1Large rewardLittle riskElectric/magnetic position measurementsUsing electrical meansProximity sensorVariable reluctance sensor

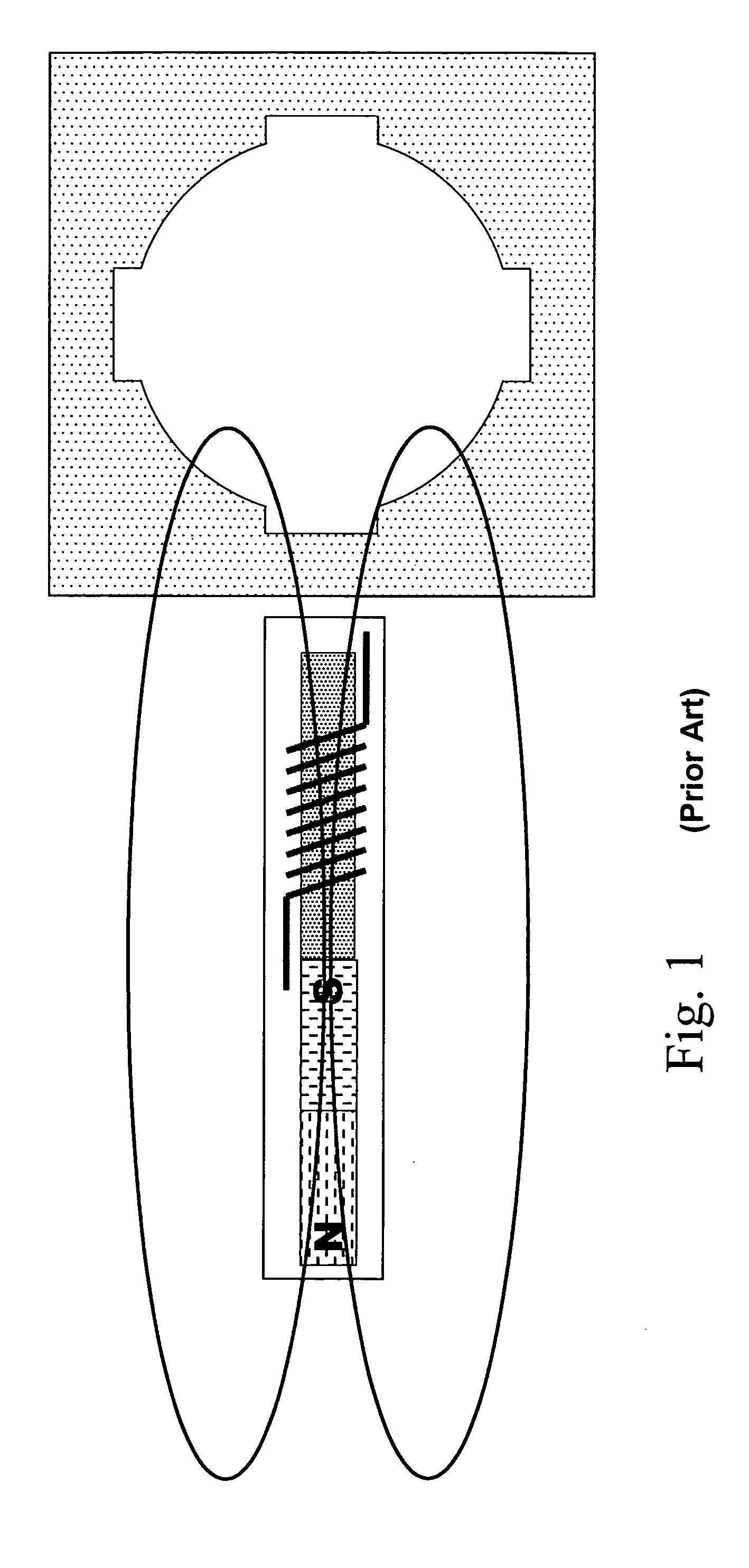

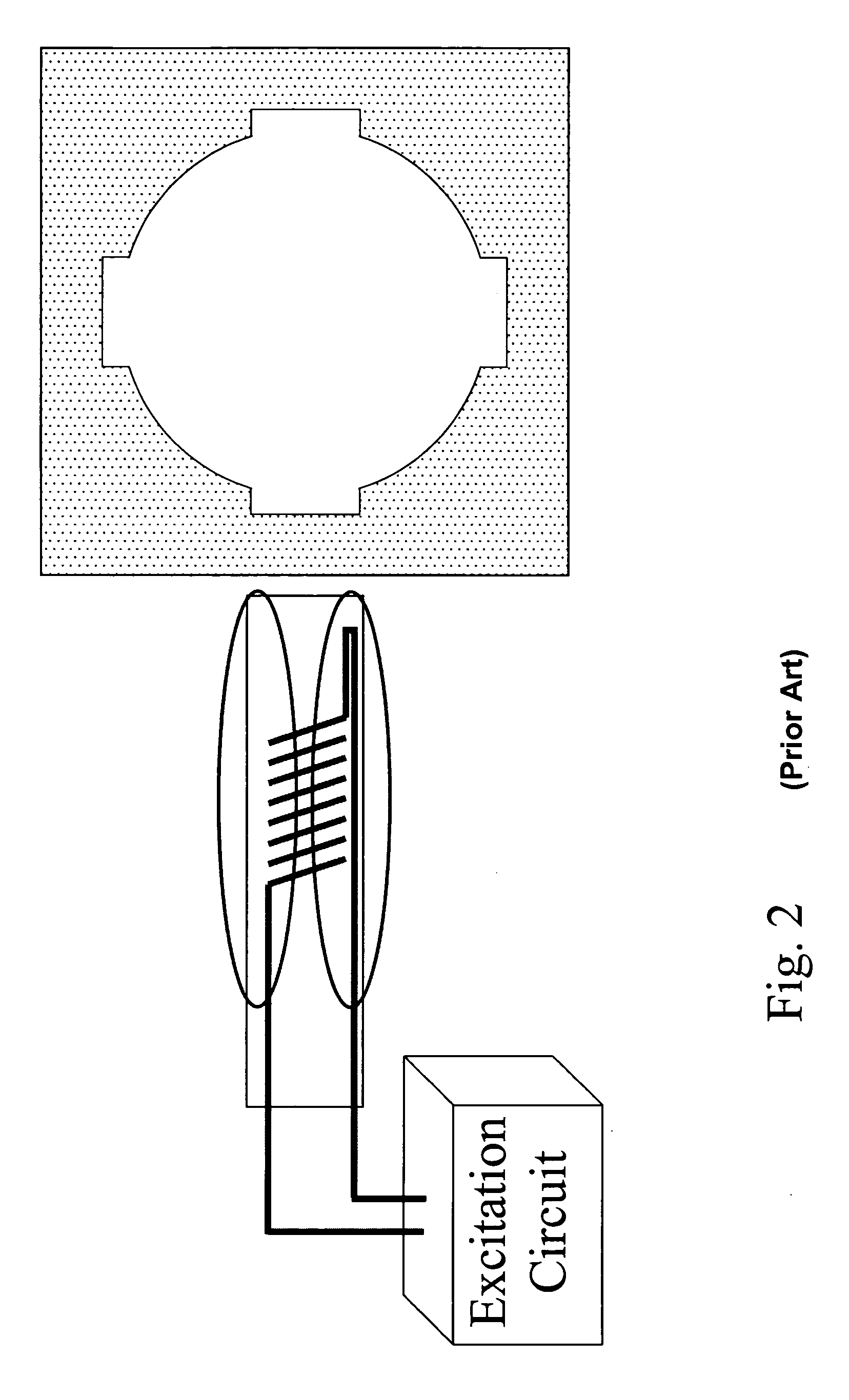

A hybrid speed and or proximity sensor may include a variable reluctance sensor with an added excitation circuit. Similarly, a hybrid speed and or proximity sensor may include a variable inductance proximity sensor having a magnet and a magnetically permeable pole piece added in the sensor. It is emphasized that this abstract is provided to comply with the rules requiring an abstract, which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:THE BOEING CO

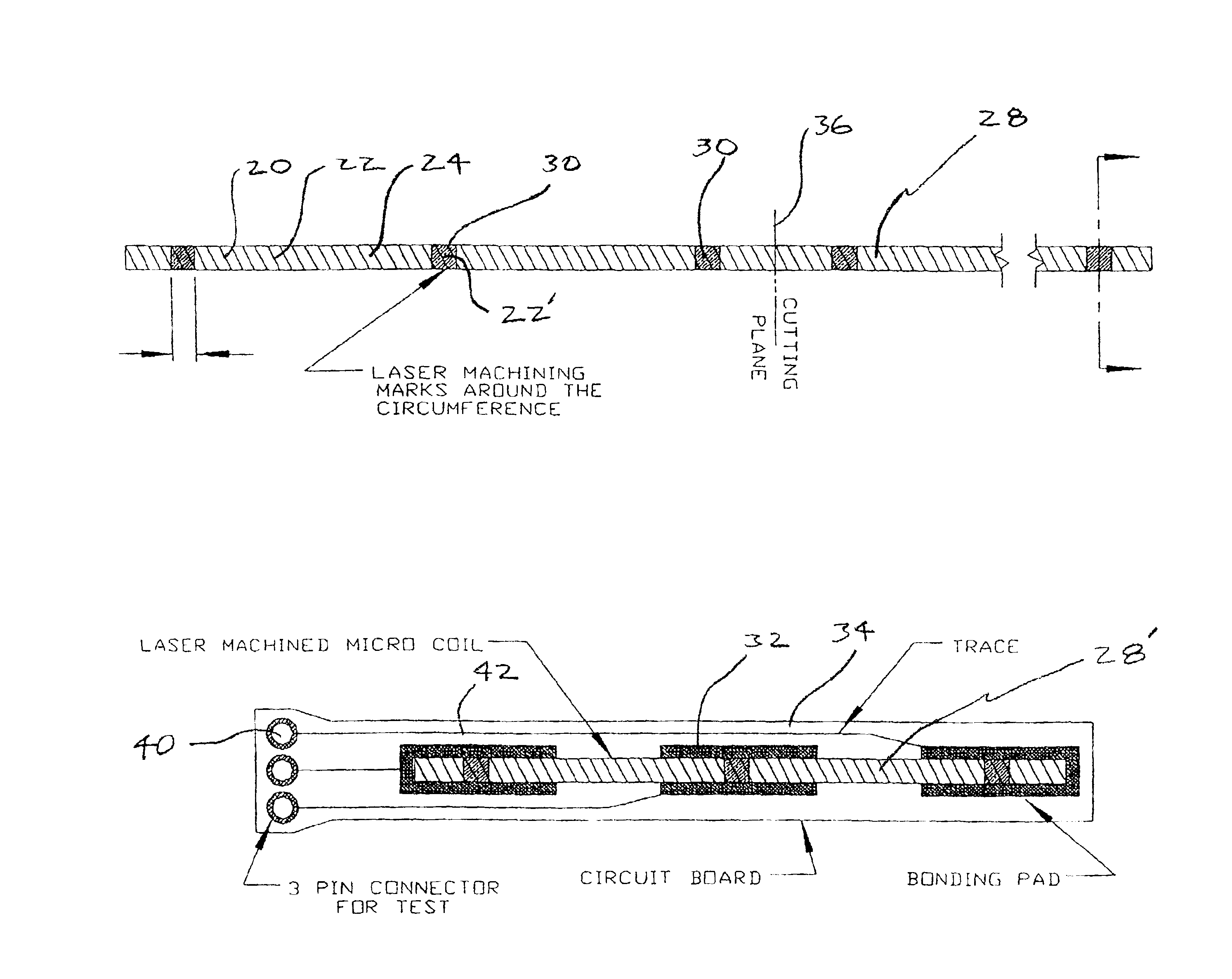

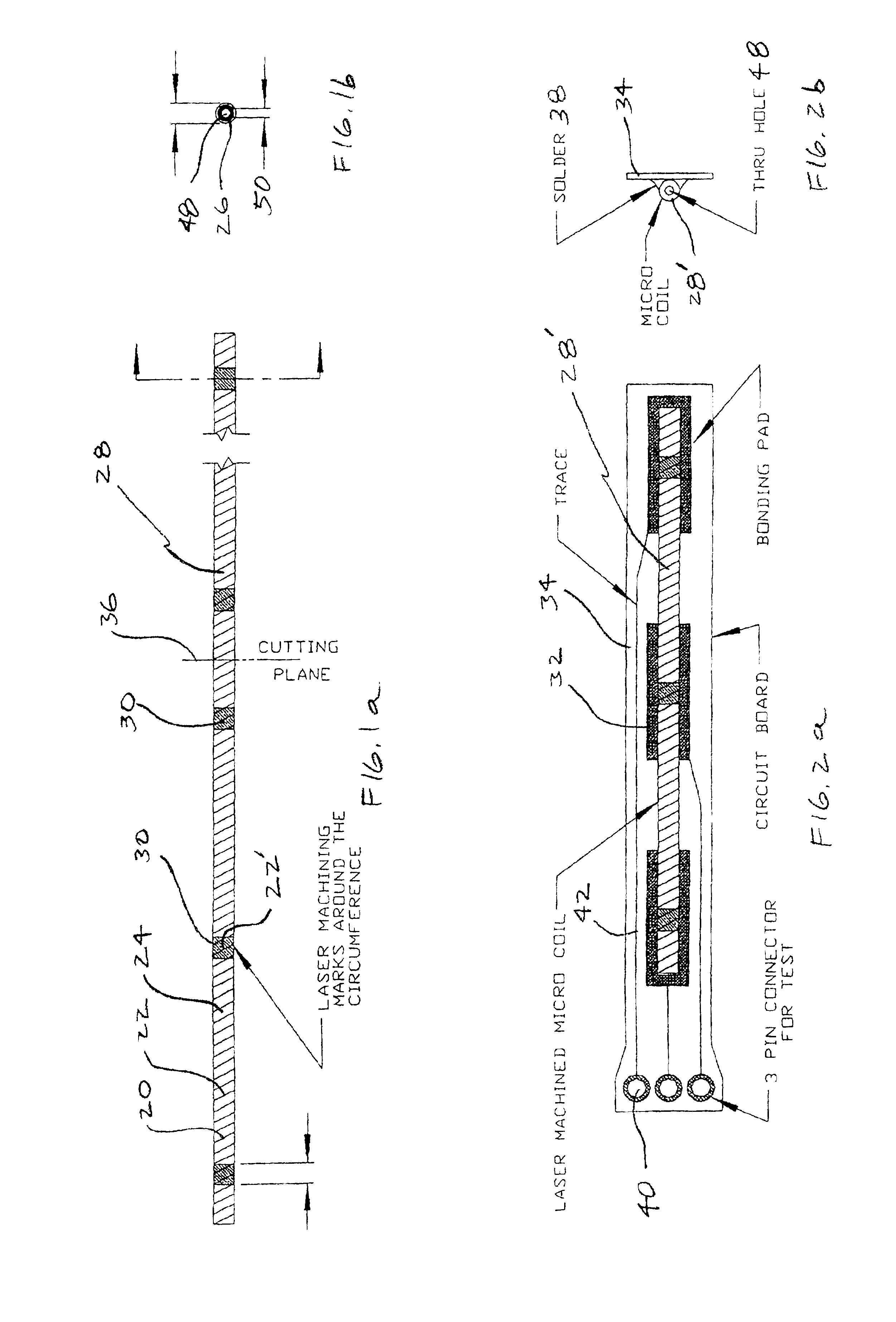

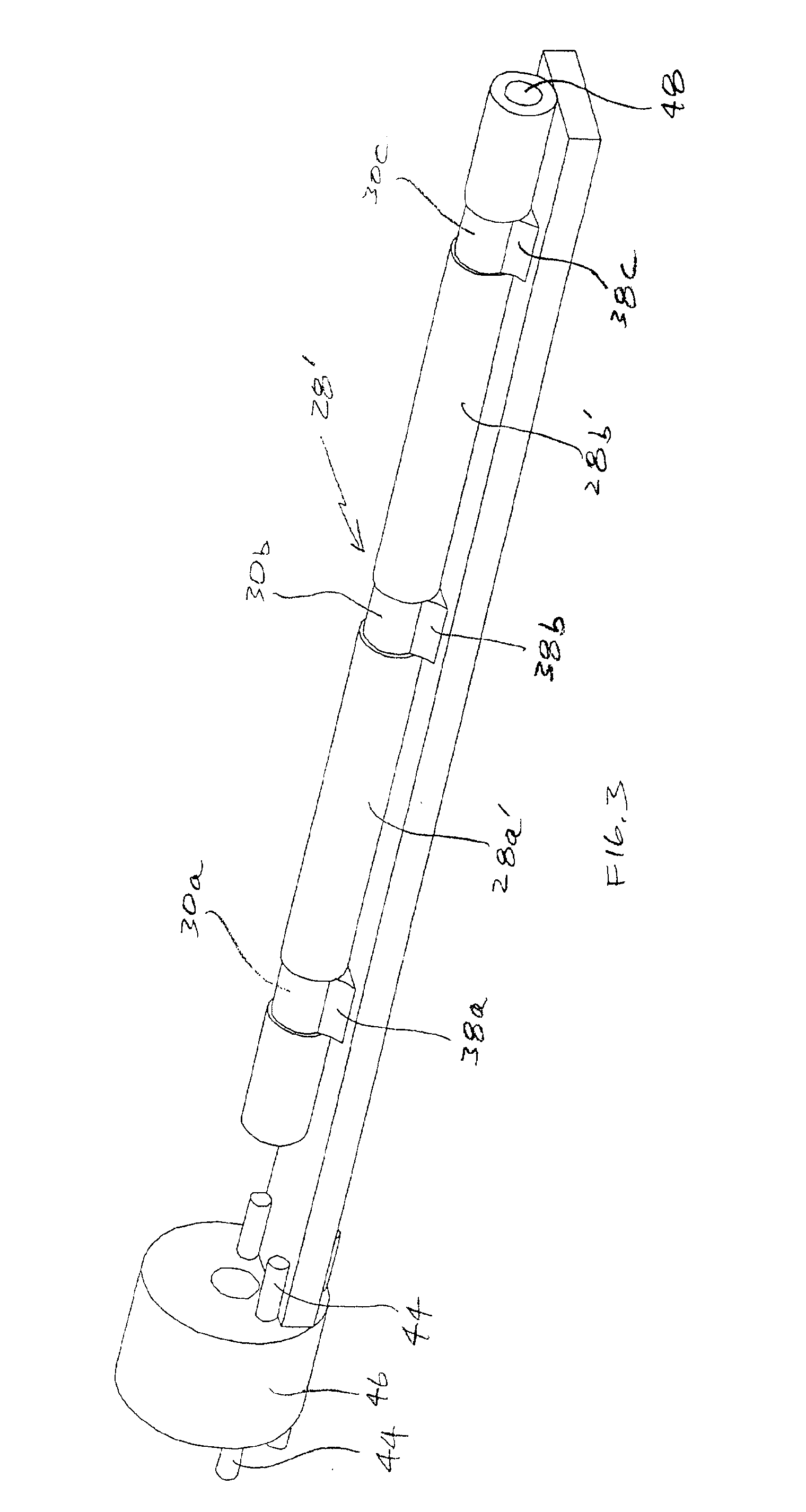

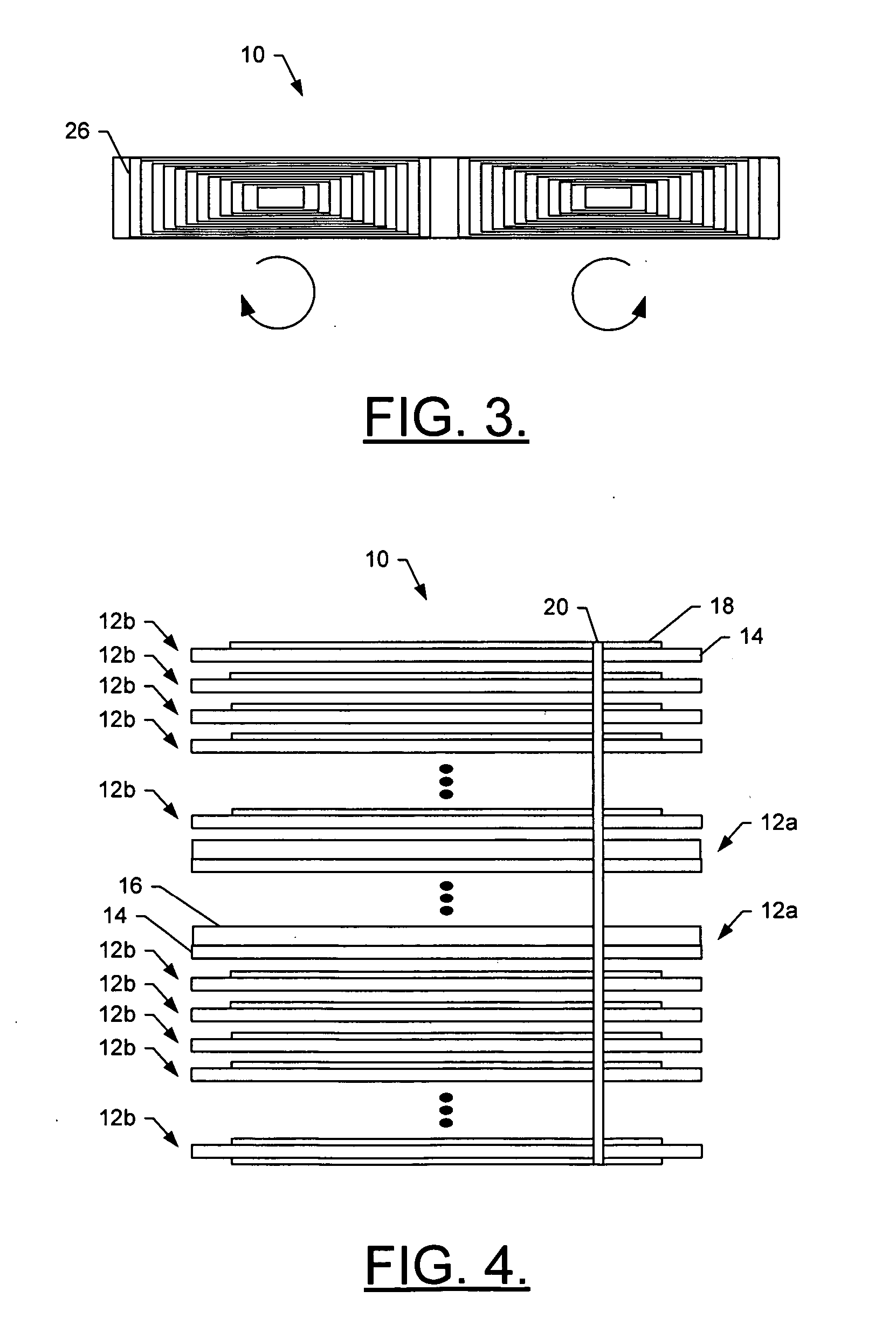

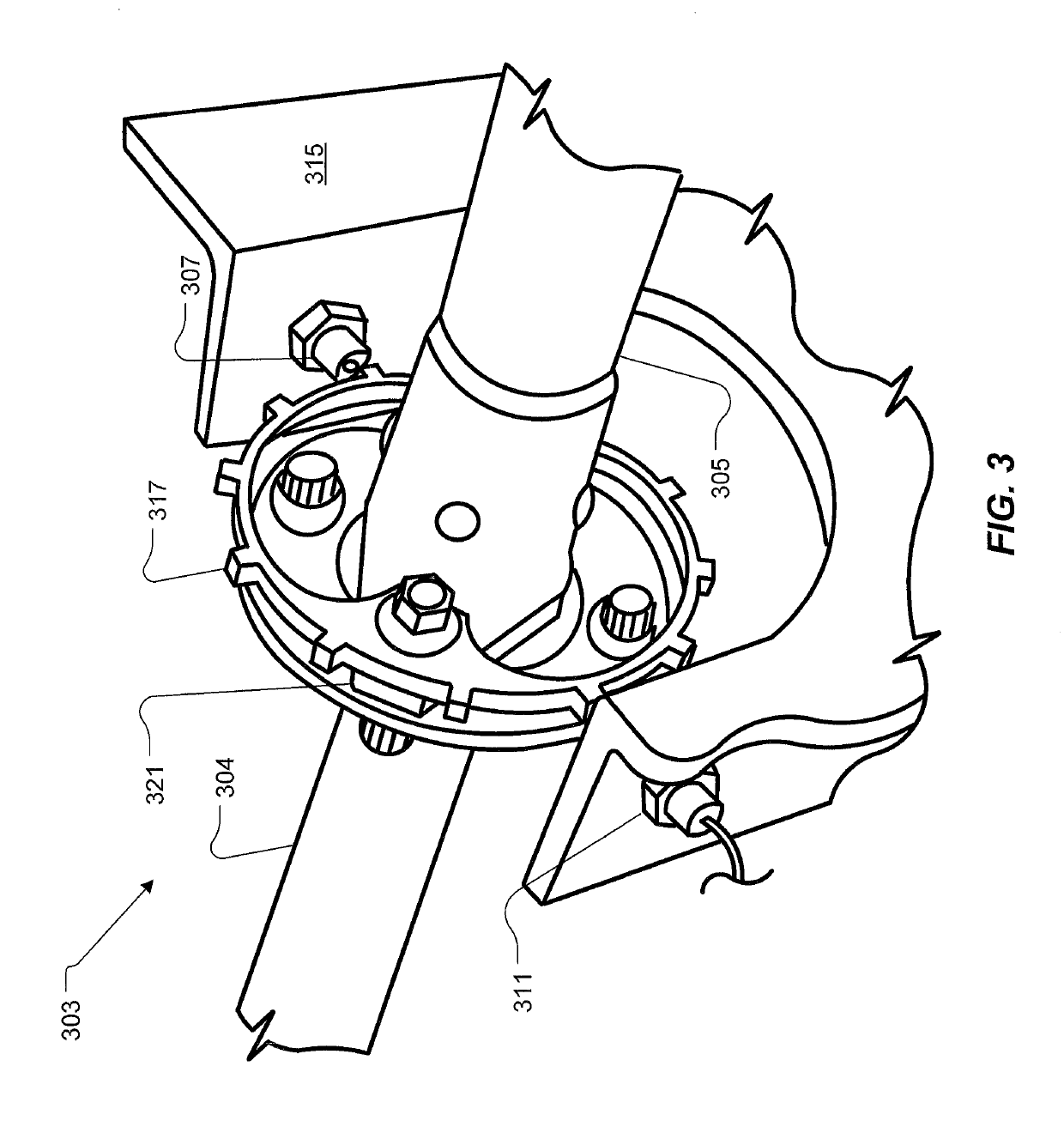

Method of fabricating a coil and clamp for variable reluctance transducer

InactiveUS6901654B2Low costPrinted circuit assemblingTransformers/inductances coils/windings/connectionsElectrical conductorVariable reluctance sensor

Improved coils and clamps for variable reluctance sensors are disclosed. A method of fabricating a discrete coil involves providing a conductor wound in a coil on a tube. The coil has a coil outer surface that has insulation. A window is opened in the insulation on the coil outer surface to expose conductor of the coil for a contact. A movable core is provided within the tube for adjusting inductance of the coil. In one embodiment, the coil and tube are diced into small coils after the windows for each coil are opened. Another aspect the invention is a clamp comprising an elastic material, a shape memory alloy, and an apparatus for activating the shape memory alloy. The clamp holds the moveable core in its peak position. When the alloy is activated it changes shape and provides a force on the elastic material to change clamping state for resetting the transducer. The coils and clamps can be used for a variety of purposes in addition to the variable reluctance sensors.

Owner:LORD CORP

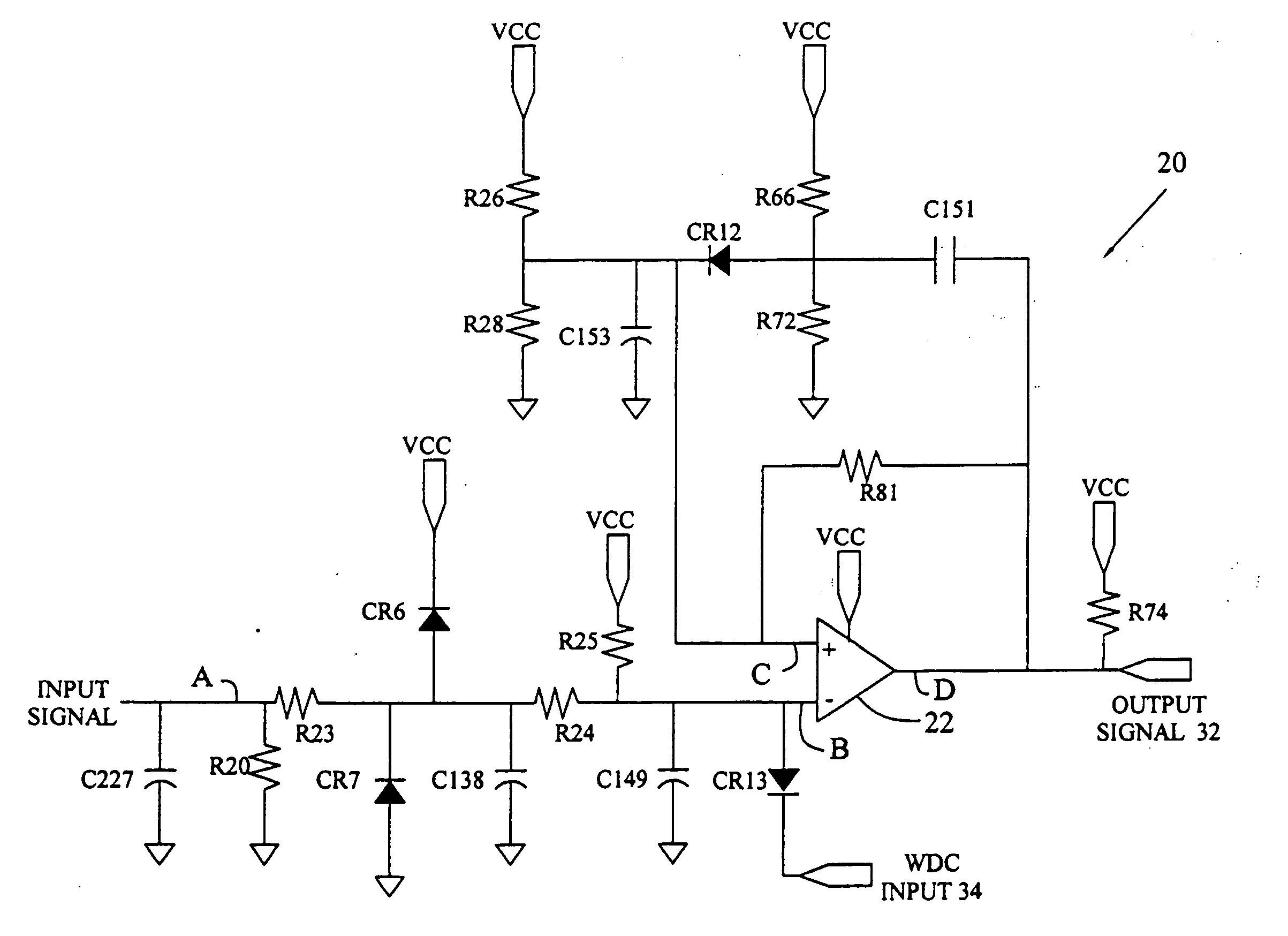

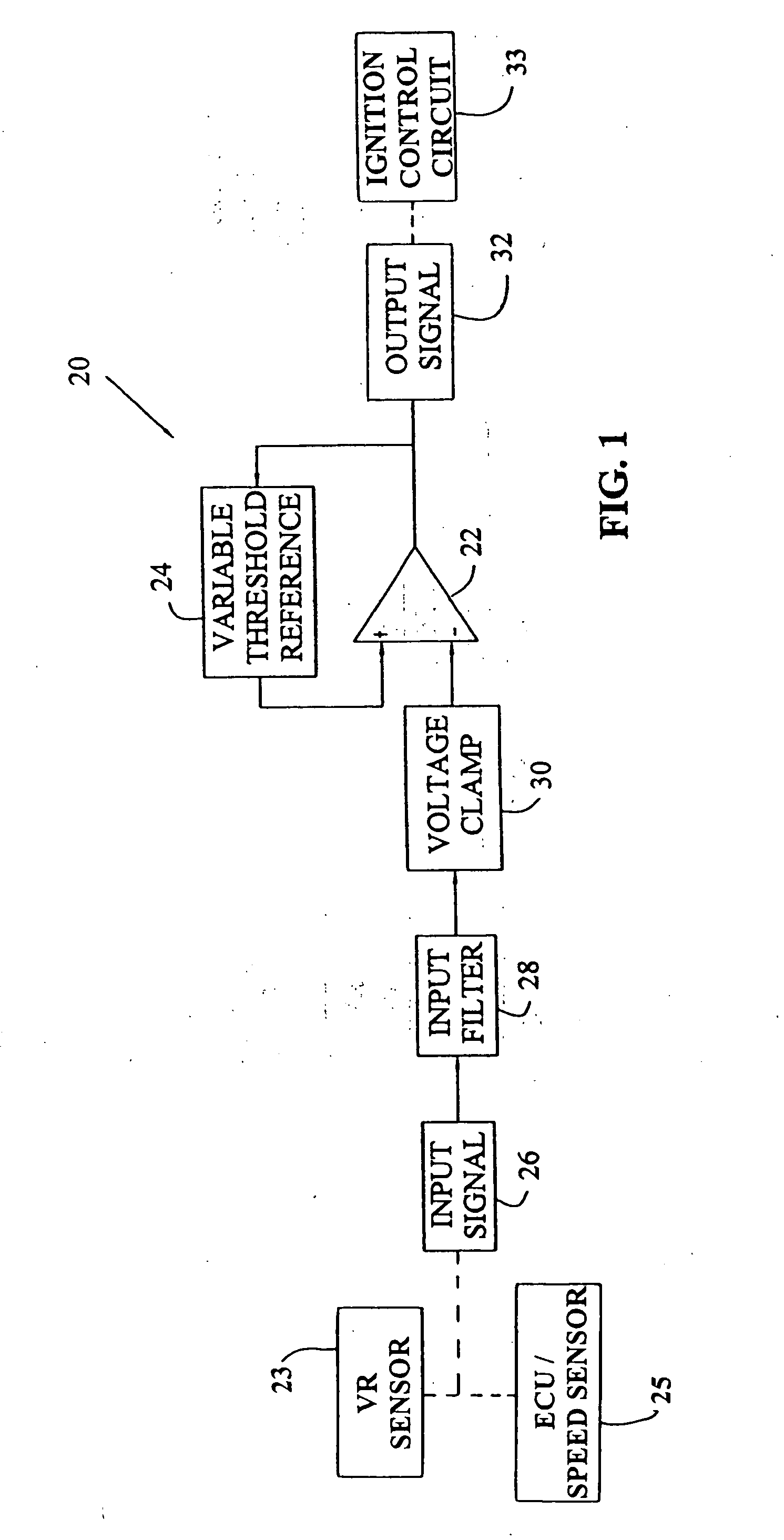

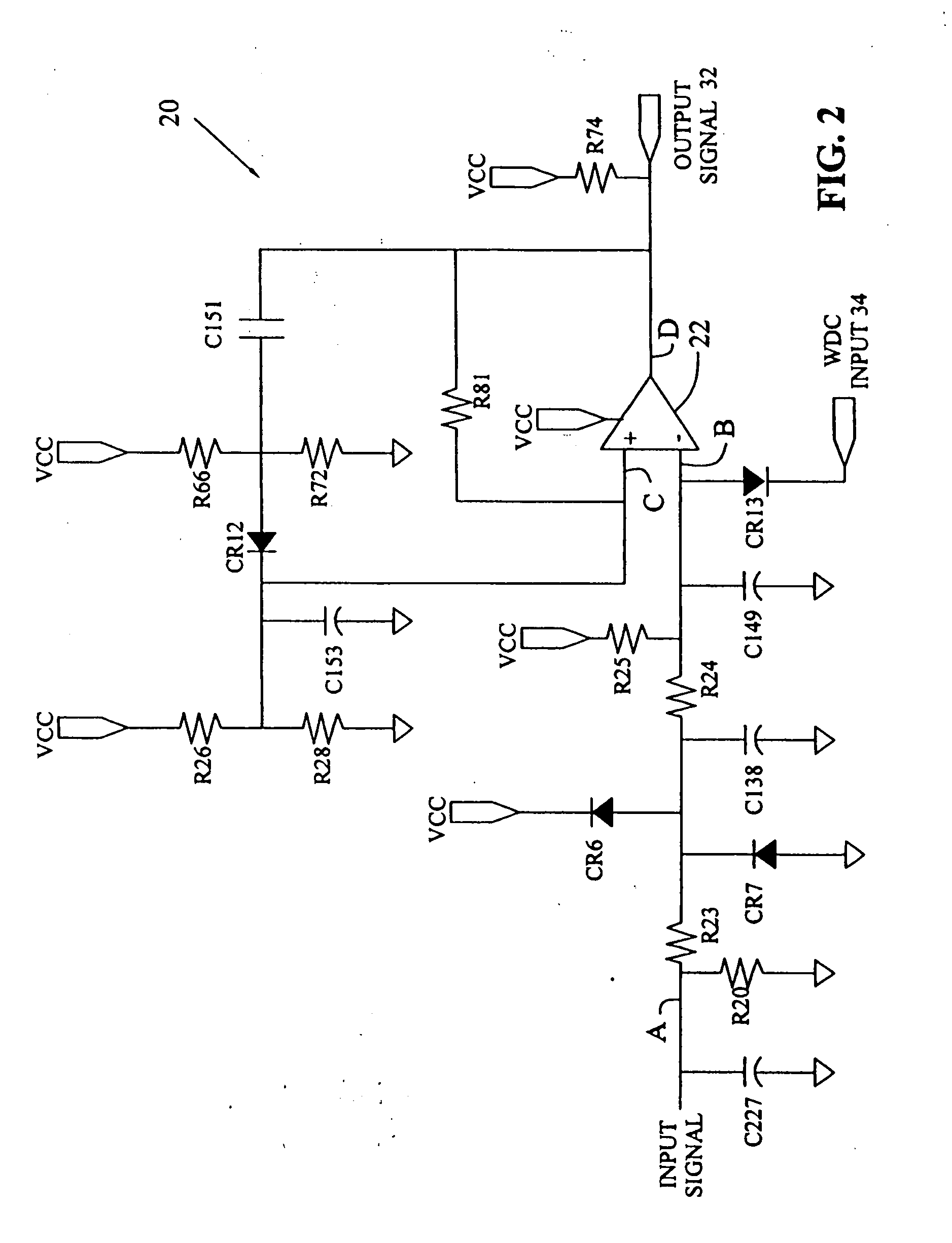

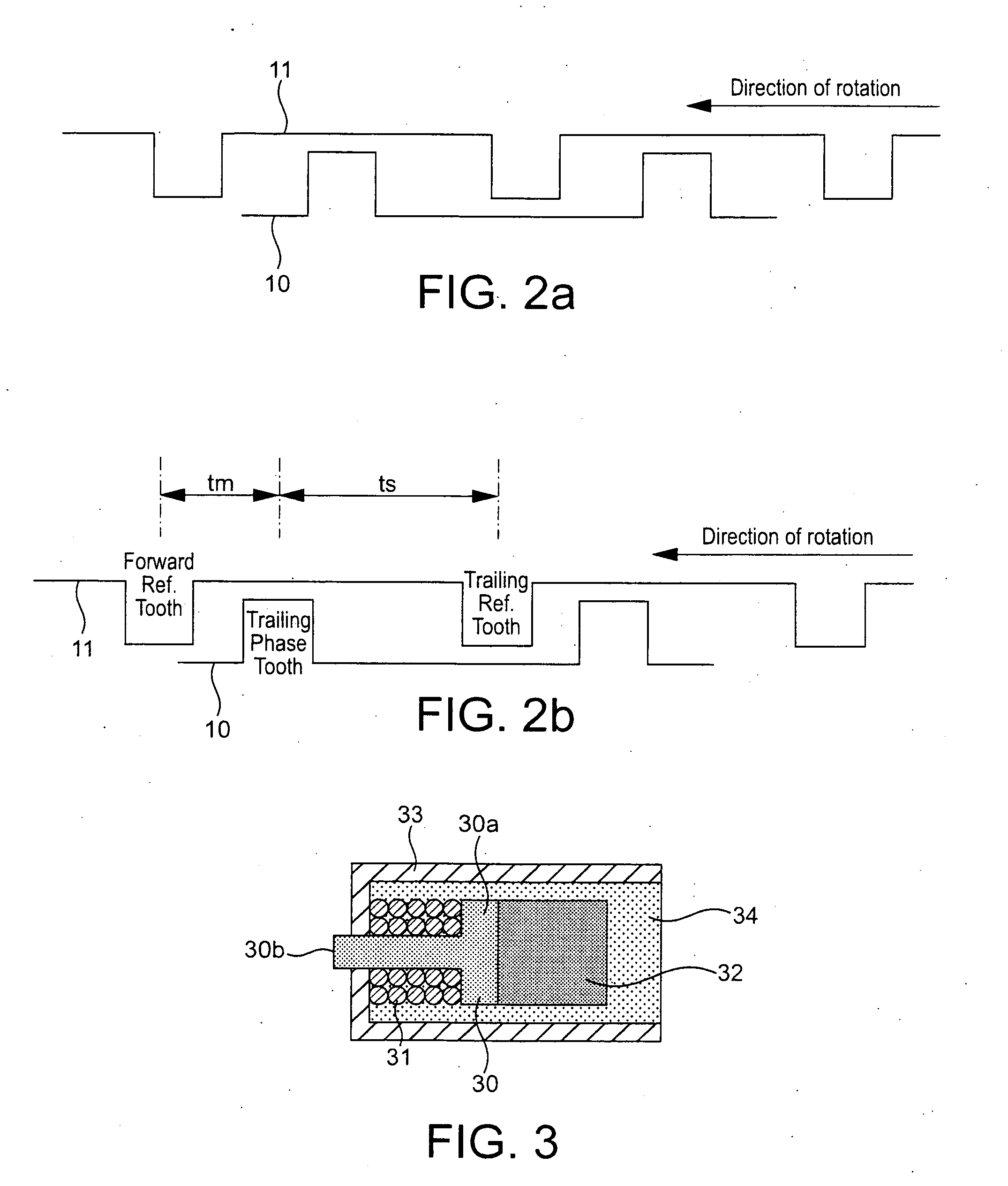

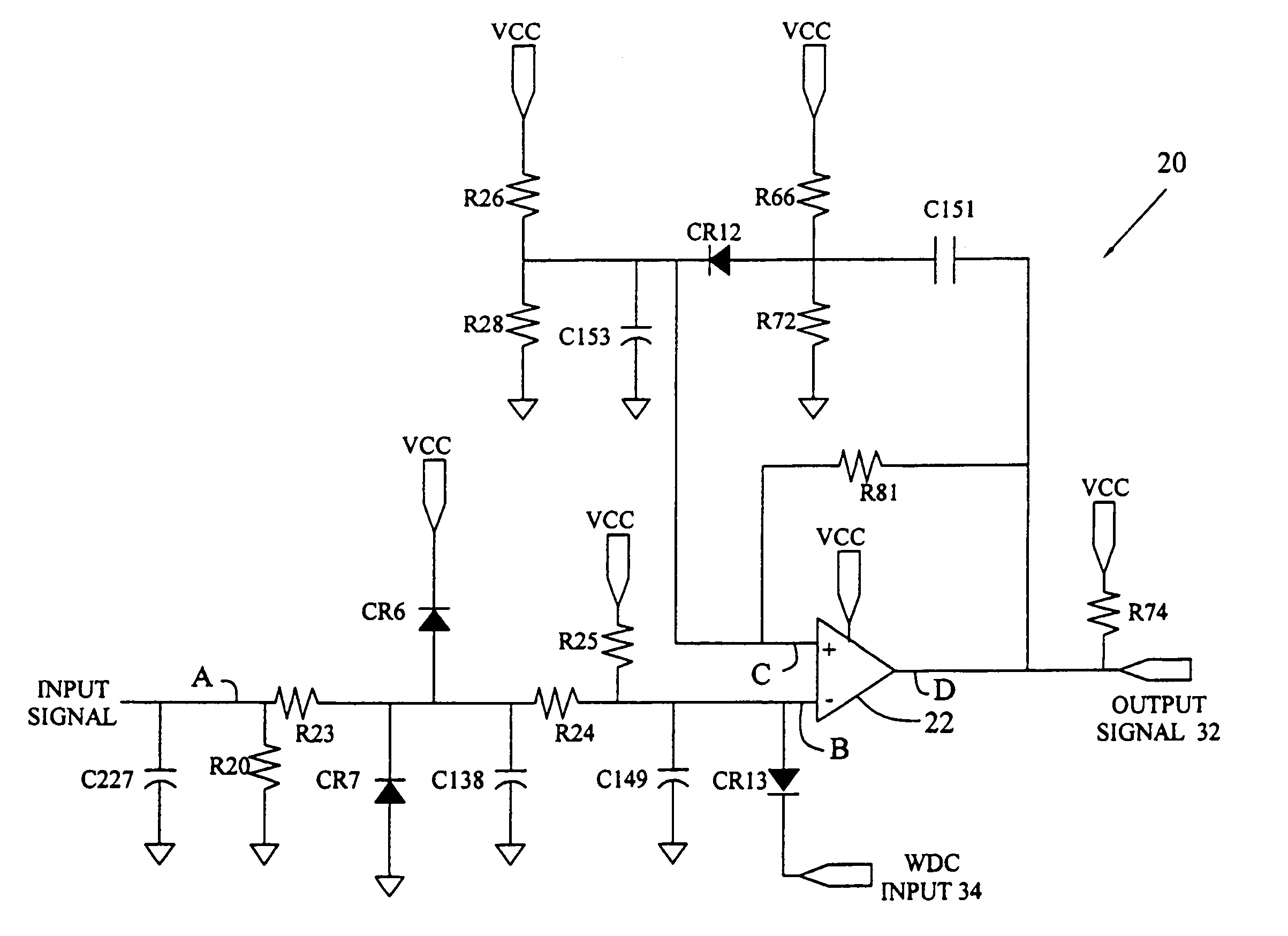

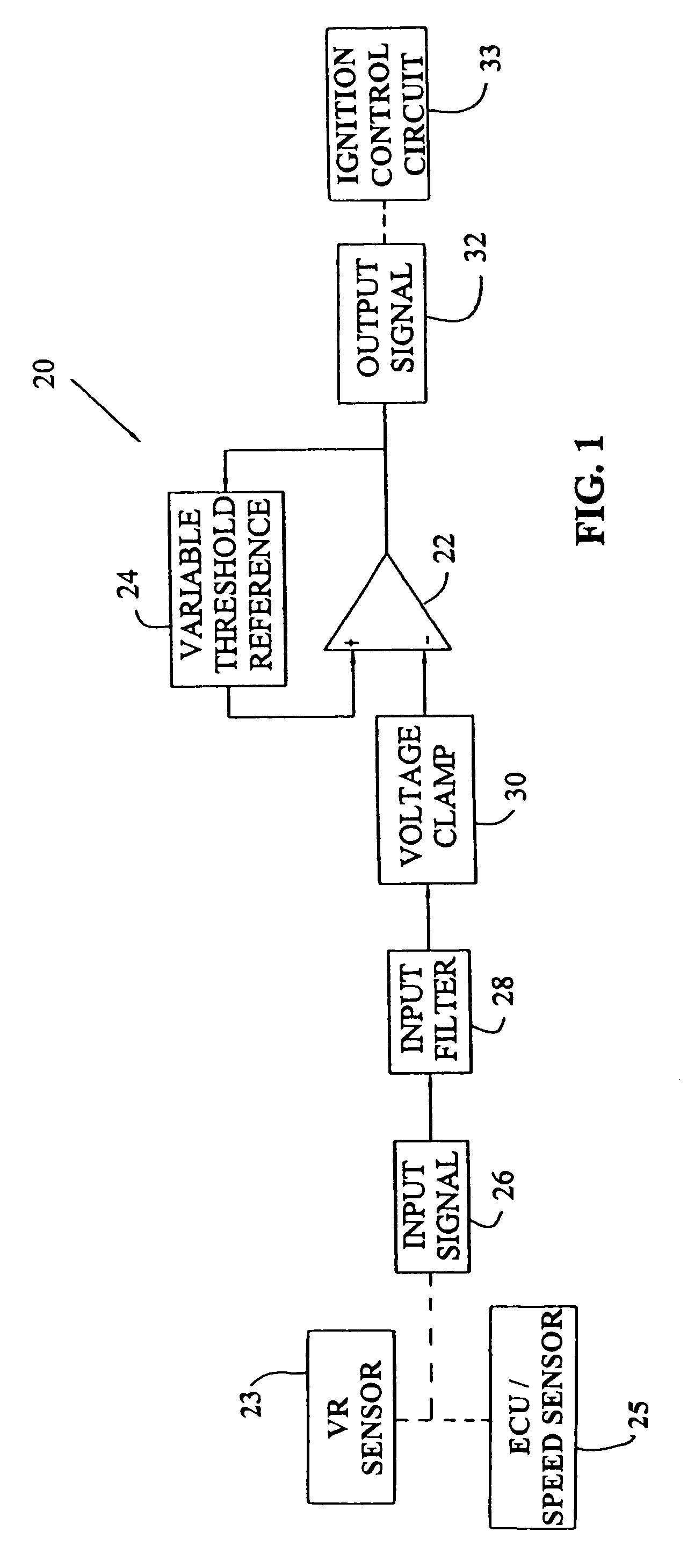

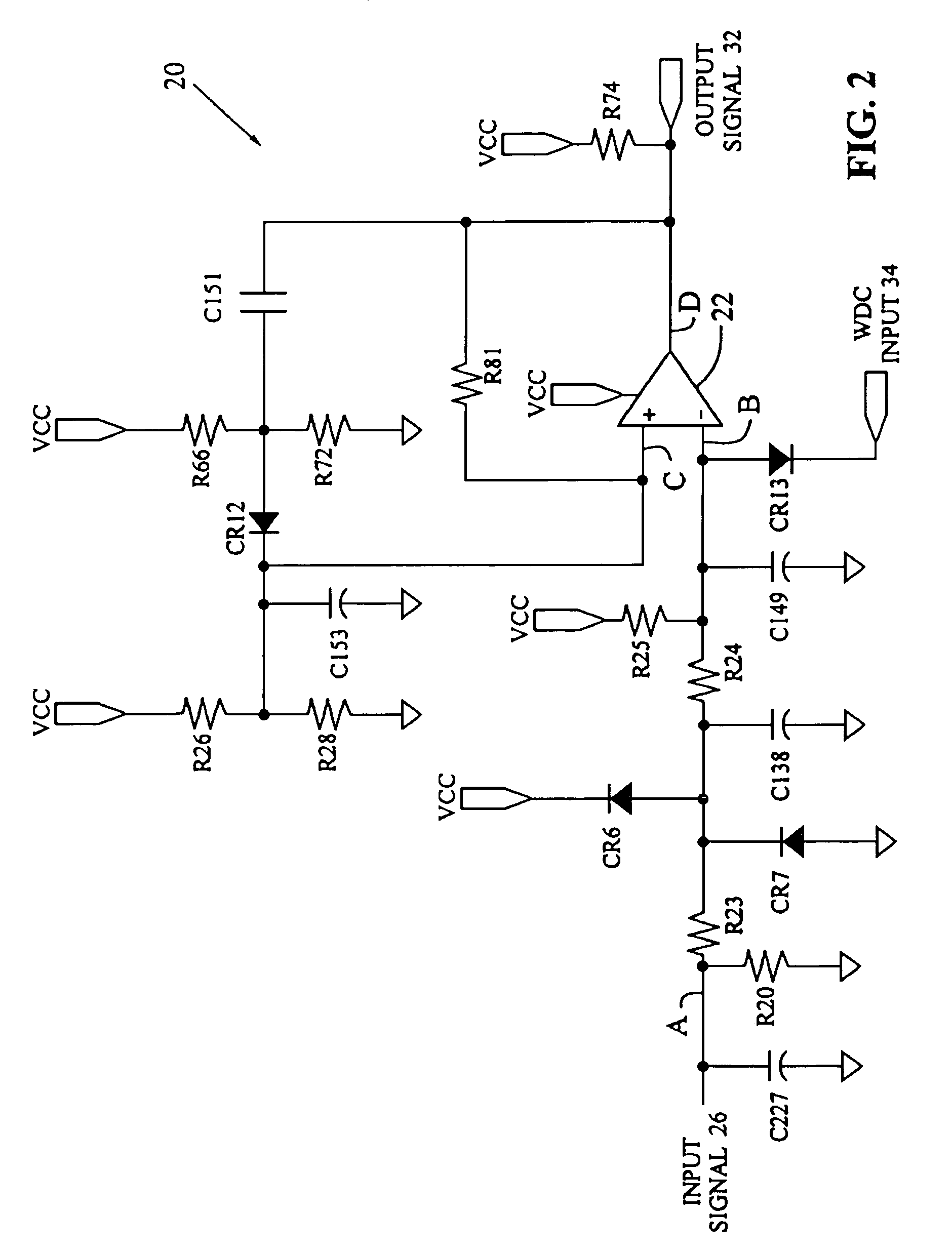

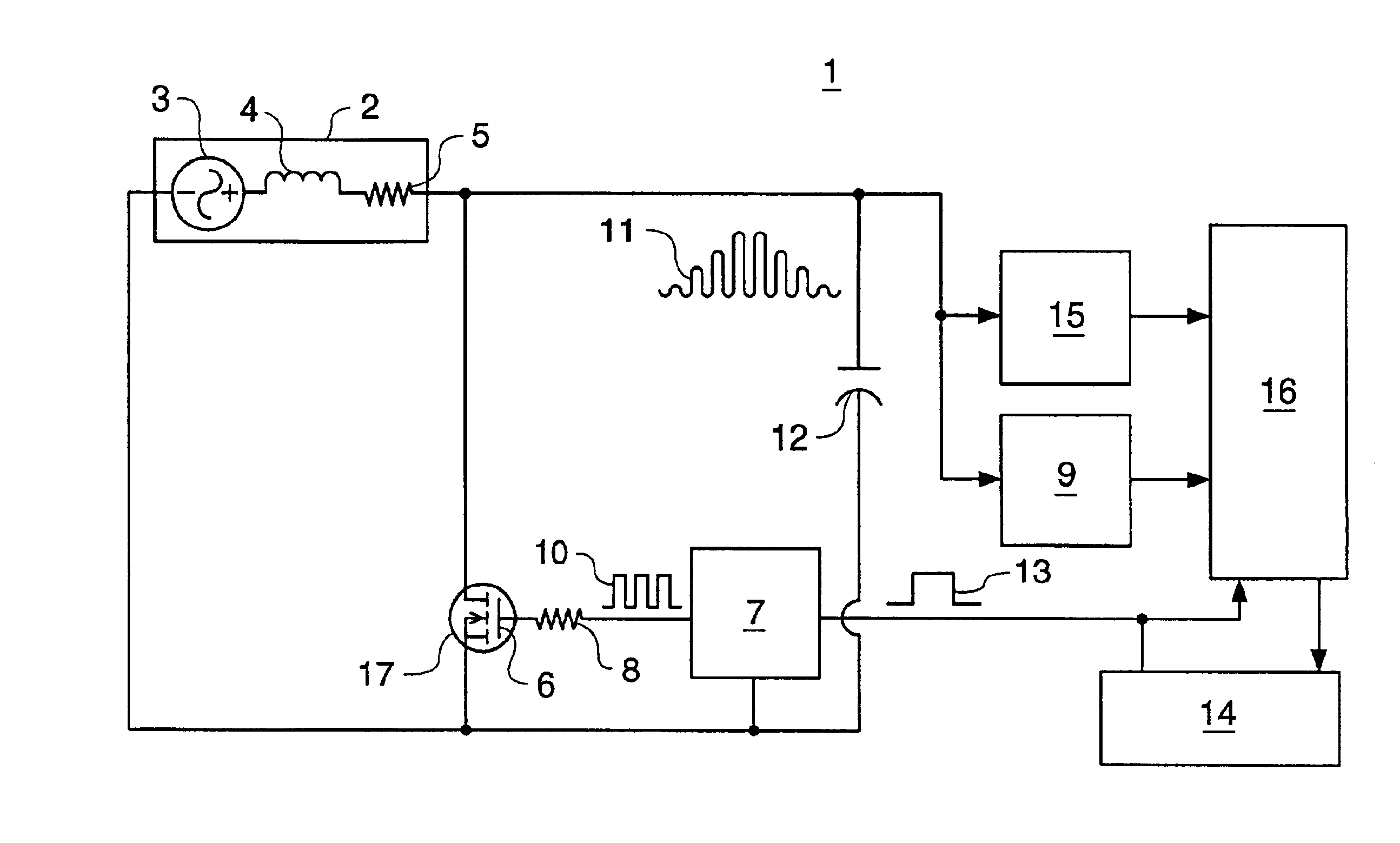

Variable threshold comparator interface circuit

ActiveUS20050134324A1Improve noise immunityMultiple input and output pulse circuitsElectric ignition installationSignal processing circuitsLow-pass filter

A signal processing circuit with a comparator having a fixed and a variable reference input is provided for detection of a positive quasi-sinusoidal waveform pulse. The signal detection circuit includes a low pass input filter, a voltage input clamp, a variable detection threshold, and a zero crossing detector. The circuit produces an approximately square wave output substantially coinciding with the positive pulse of the quasi-sinusoidal waveform received, for example, from a variable reluctance sensor. The circuit may be used as a positive to negative zero crossing detector having detection armed by a variable threshold of the positive quasi-sinusoidal pulse, thus providing variable noise immunity and a fixed phase relationship between the input and output signal for an input signal having a variable amplitude.

Owner:APTIV TECH LTD

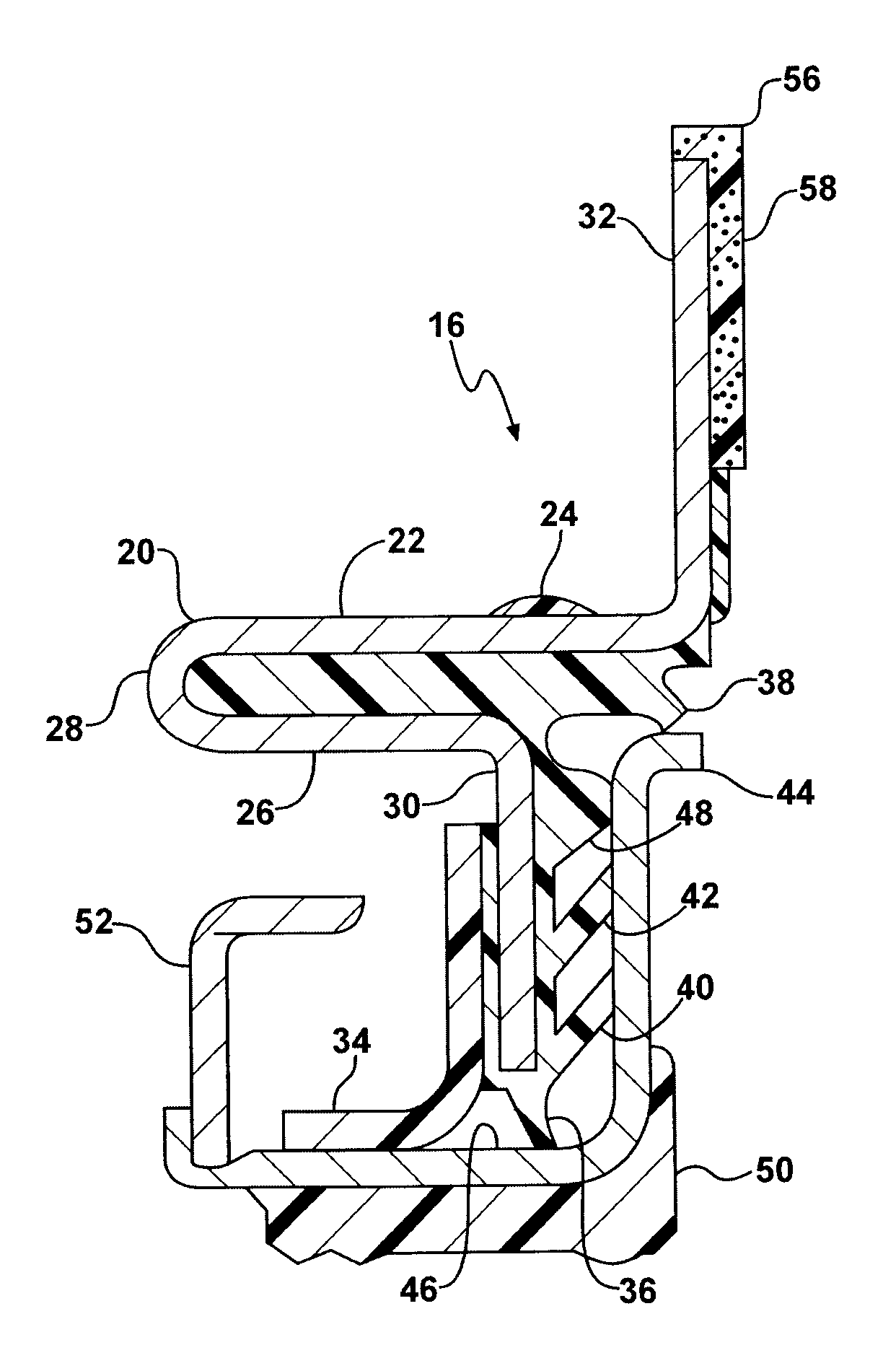

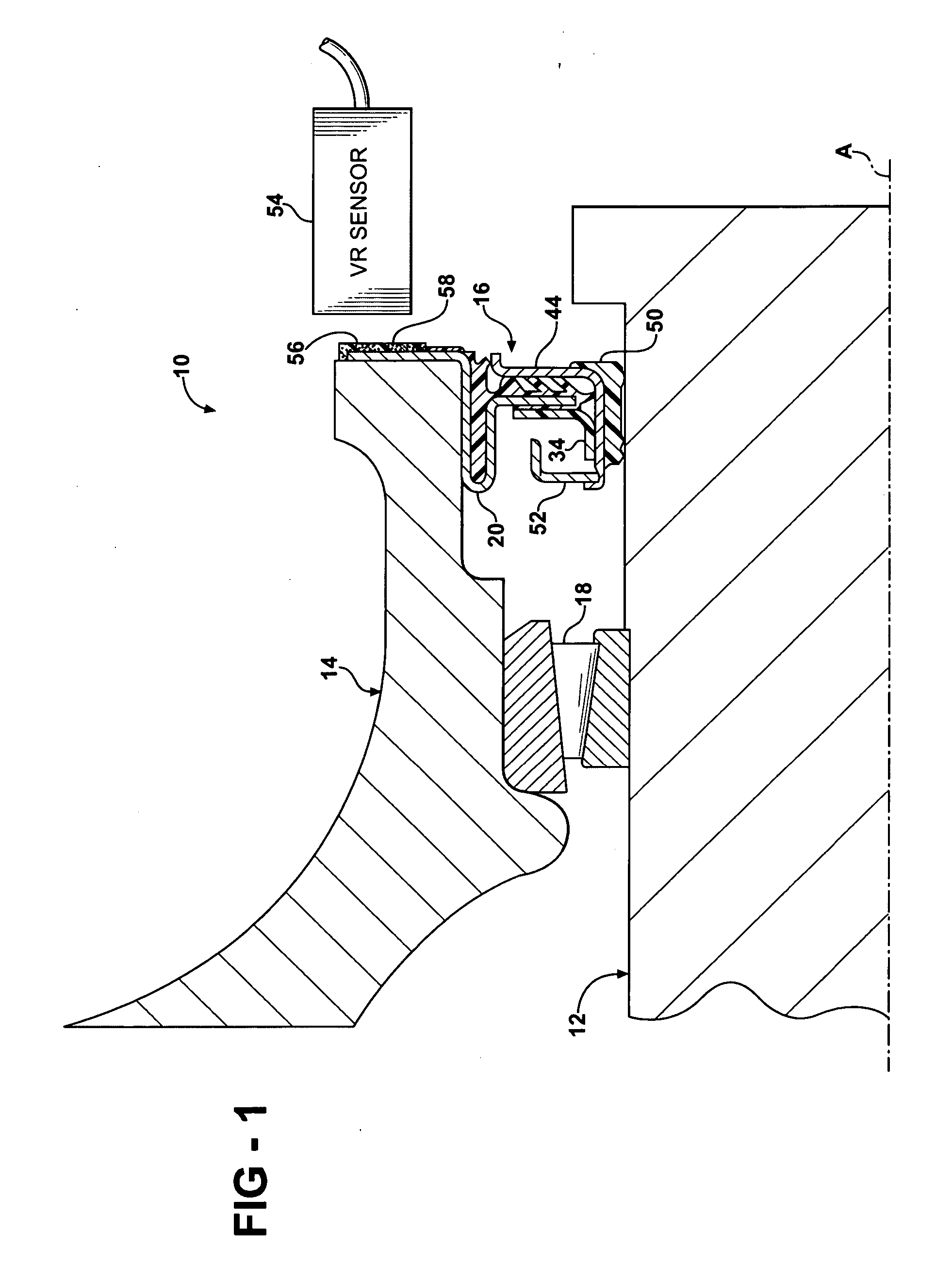

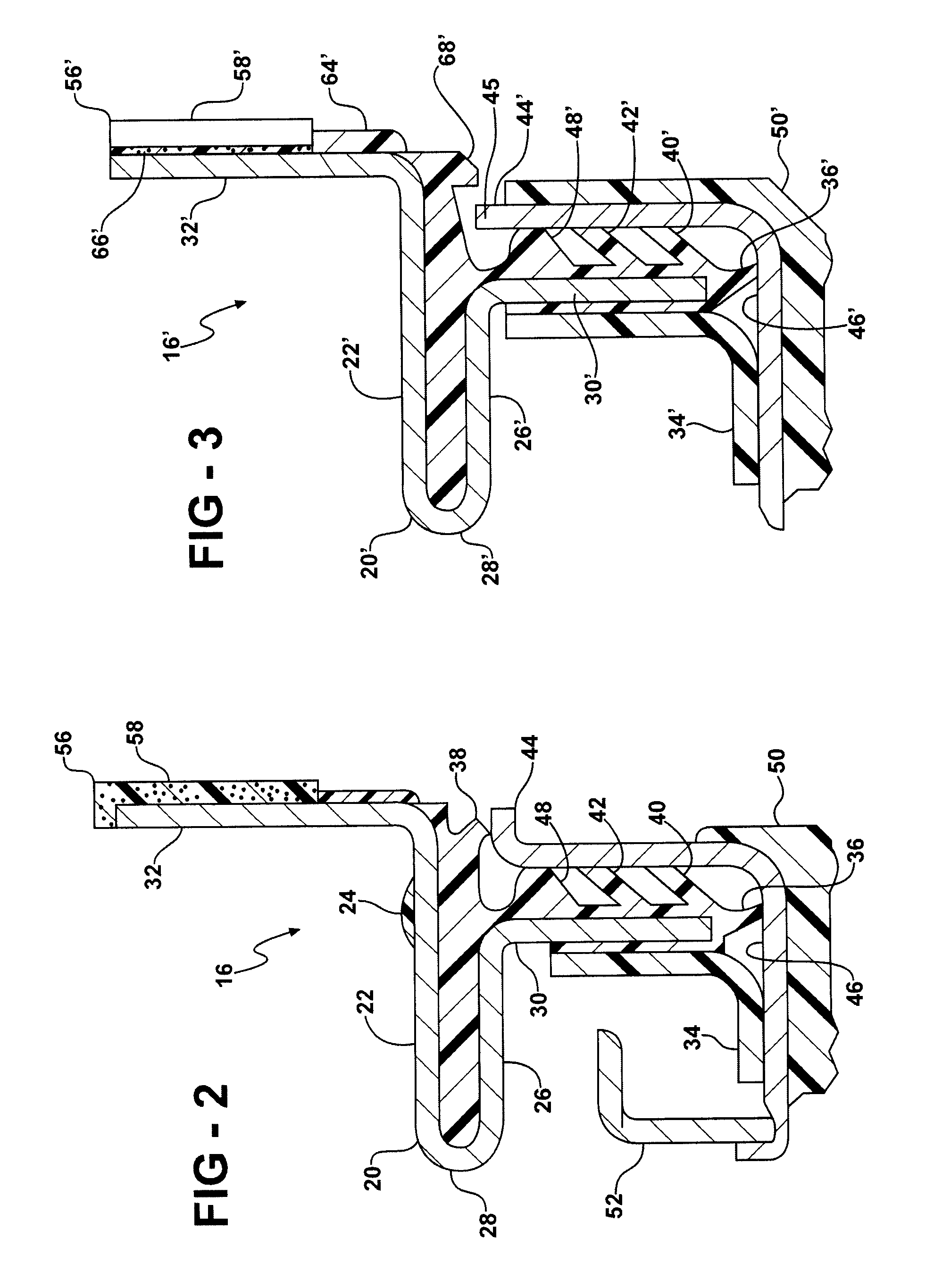

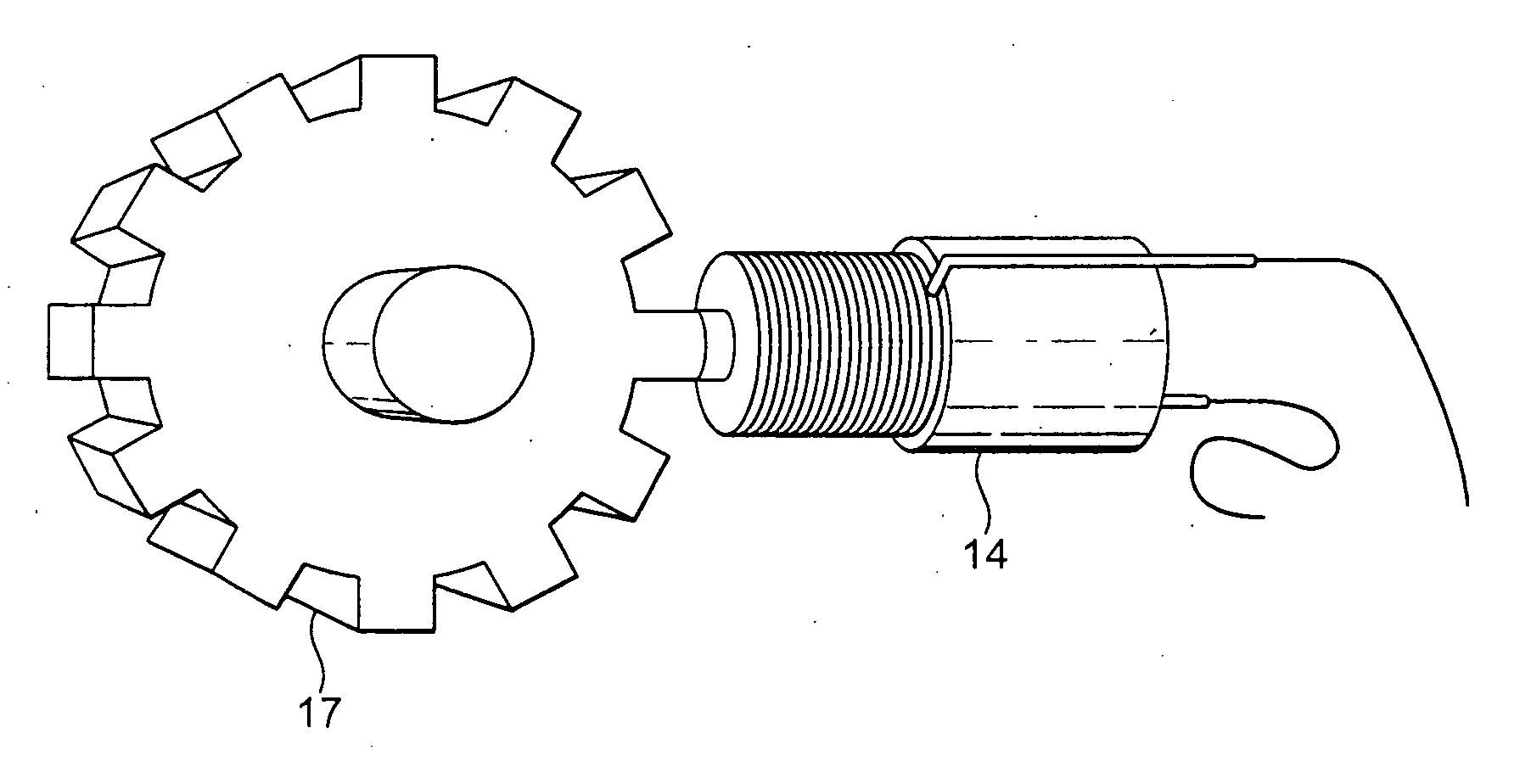

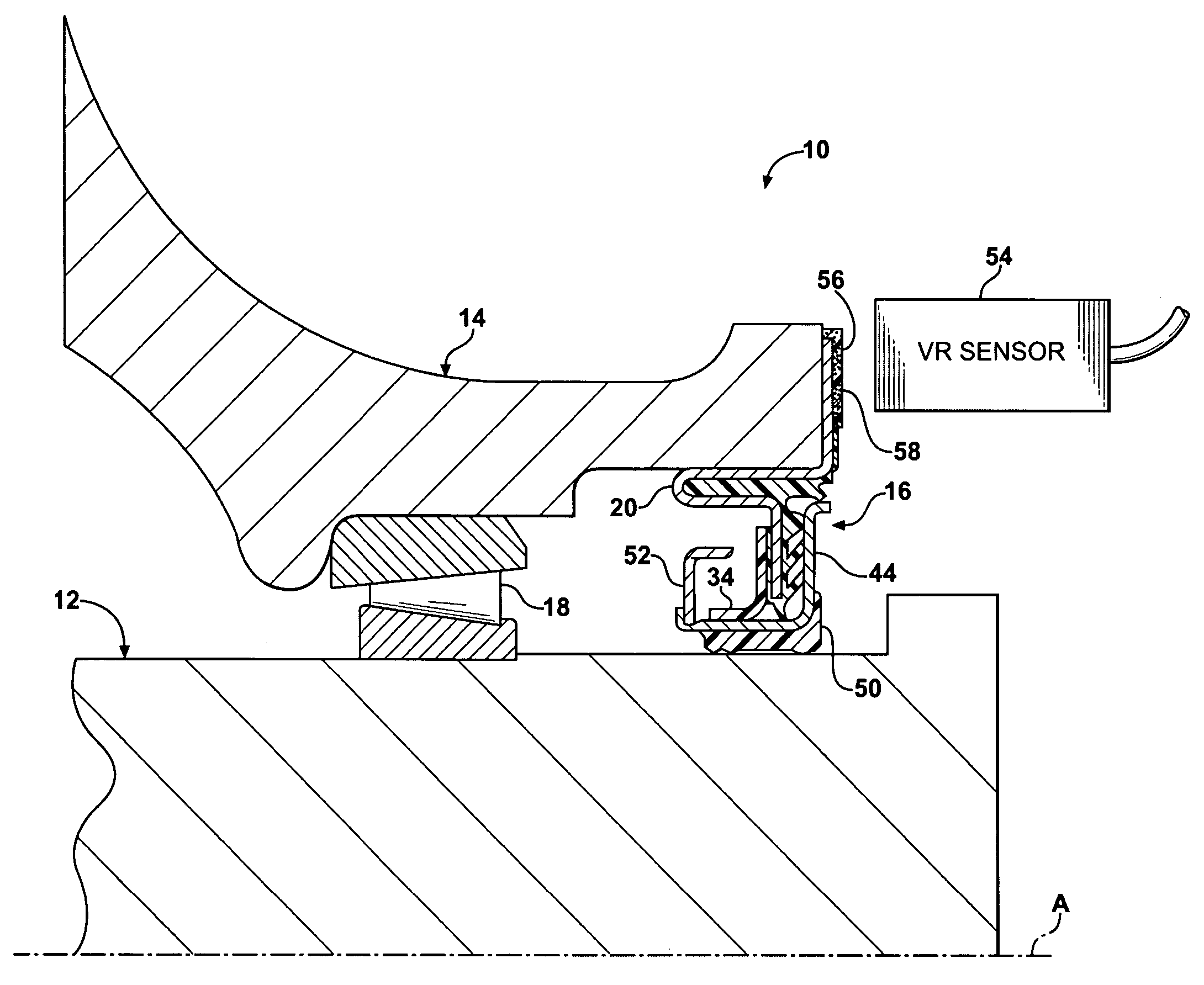

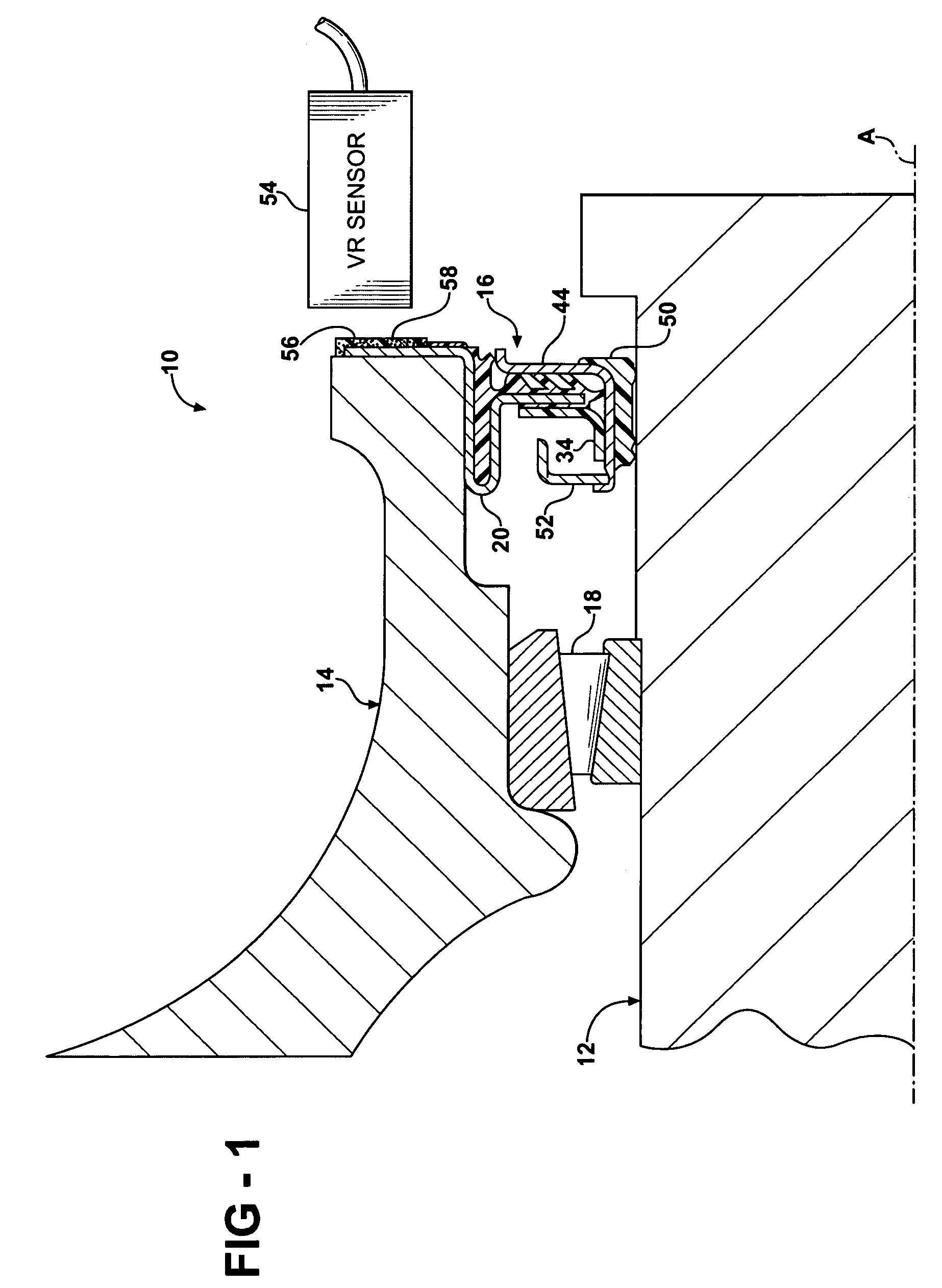

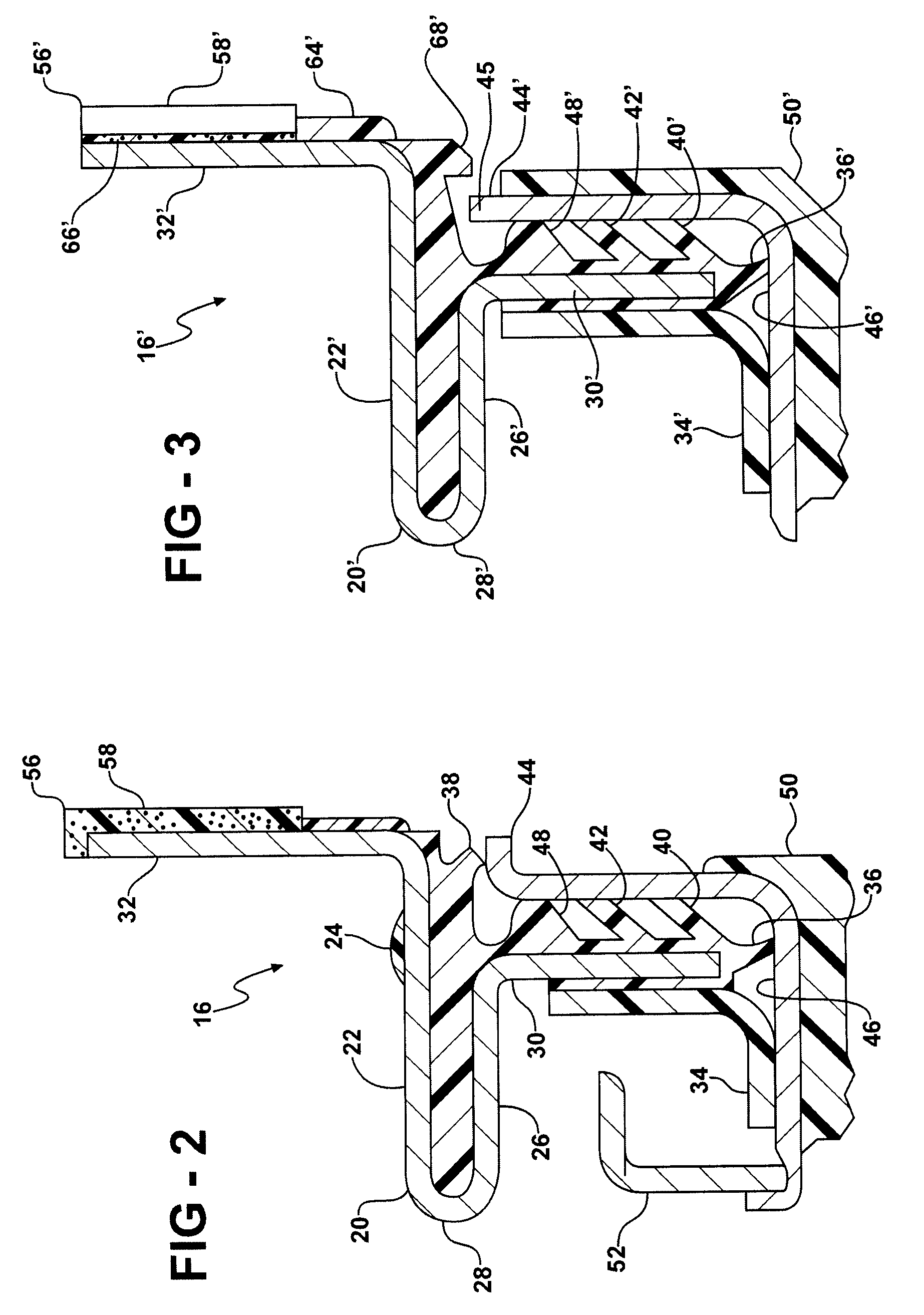

Oil bath encoder seal

InactiveUS20070211974A1Low costSmall sizeEngine sealsBearing assemblyVariable reluctance sensorEngineering

An oil lubricated rotating hub (14) and stationary spindle (12) assembly includes an oil bath seal (16, 16′) for establishing a dynamic sealing interface between the hub (14) and spindle (12). A wheel sensor assembly includes a variable reluctance senor (54) targeted at an encoder ring (56, 56′) which is integrated into the oil bath seal (16, 16′). The encoder ring (56, 56′) is of the permanent magnet type including a plurality of magnetically polarized sectors alternating between North and South polarities. The use of an encoder style target (56, 56′) in combination with a variable reluctance sensor (54) enables improved slow speed sensing with relatively large air gap spacing between the exposed (58, 58′) of the encoder ring (56, 56′) and the head of the VR sensor (54). Furthermore, the encoder ring (56, 56′) enables use of less expensive, lighter materials for the oil bath seal carrier (20, 20′).

Owner:FEDERAL MOGUL WORLD WIDE

Hybrid inductive sensor

InactiveUS6969987B2Precise functionOptimization rangeElectric/magnetic position measurementsUsing electrical meansProximity sensorVariable reluctance sensor

A hybrid speed and or proximity sensor may include a variable reluctance sensor with an added excitation circuit. Similarly, a hybrid speed and or proximity sensor may include a variable inductance proximity sensor having a magnet and a magnetically permeable pole piece added in the sensor. It is emphasized that this abstract is provided to comply with the rules requiring an abstract, which will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:THE BOEING CO

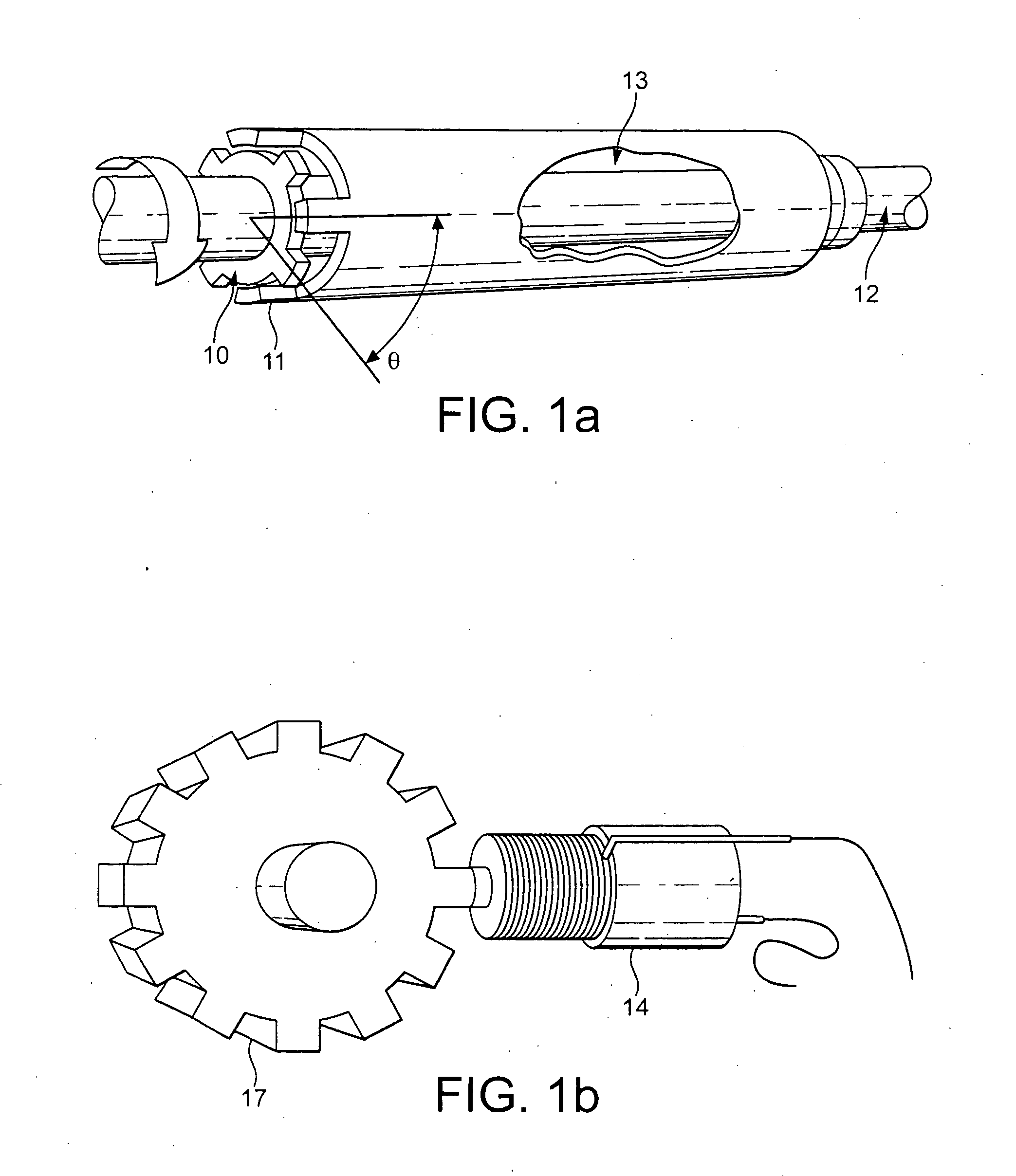

Speed or torque probe for gas turbine engines

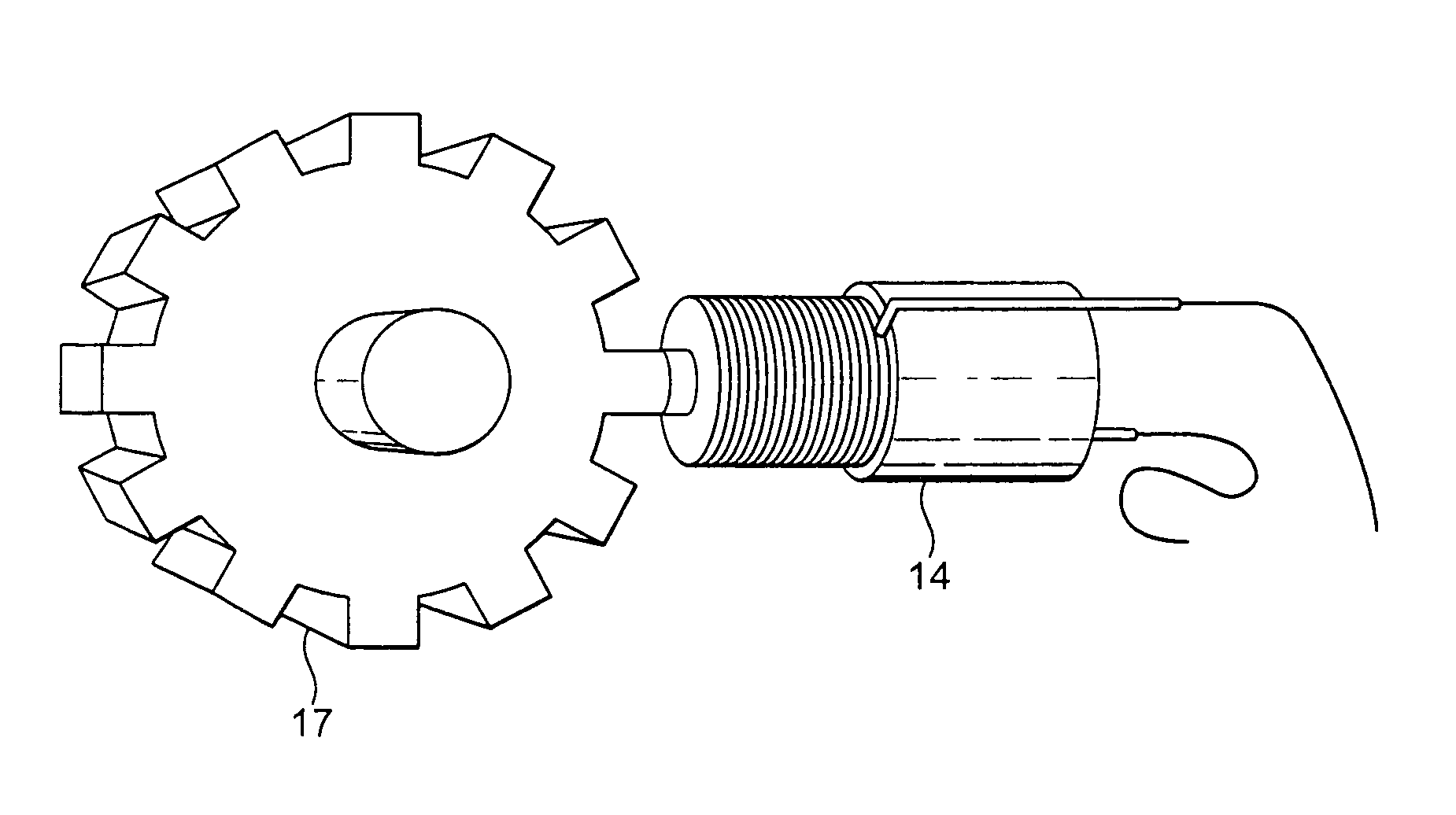

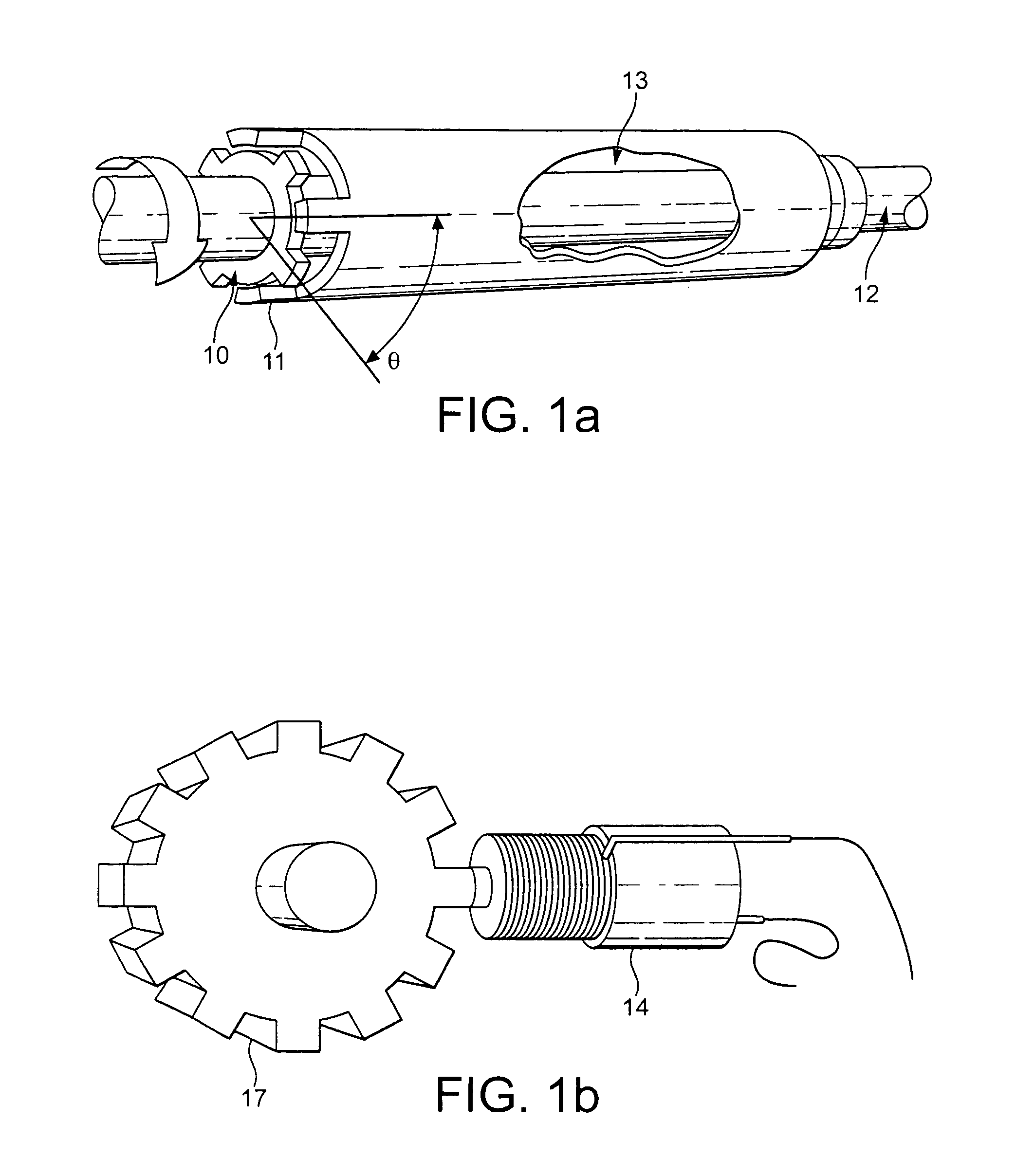

ActiveUS20110308331A1Relieve pressureEfficient transferWork measurementLinear/angular speed measurementVariable reluctance sensorMagnetic poles

There is provided a variable reluctance sensor for sensing the speed or torque of a shaft in a gear box or gas turbine engine, comprising a magnetic pole piece a conductive wire wrapped around the pole piece a housing surrounding the pole piece, the housing having a front face and at least one side wall, wherein, in use, the front face is positioned proximate to an object to be sensed wherein the pole piece is rigidly fixed to the side wall of the housing. This arrangement reduces microphony in the sensor.

Owner:WESTON AEROSPACE

Variable threshold comparator interface circuit

ActiveUS7049859B2Improve noise immunityMultiple input and output pulse circuitsElectric ignition installationSignal processing circuitsLow-pass filter

A signal processing circuit includes a comparator having a fixed and a variable reference input for detection of a positive quasi-sinusoidal waveform pulse. A signal detection circuit includes a low pass input filter, a voltage input clamp, a variable detection threshold, and a zero crossing detector. The circuit produces an approximately square wave output substantially coinciding with the positive pulse of the quasi-sinusoidal waveform received, from a variable reluctance sensor. The circuit has a positive to negative zero crossing detector armed by a variable threshold of the positive quasi-sinusoidal pulse, thus providing variable noise immunity and a fixed phase relationship between the input and output signal for an input signal having a variable amplitude.

Owner:APTIV TECH LTD

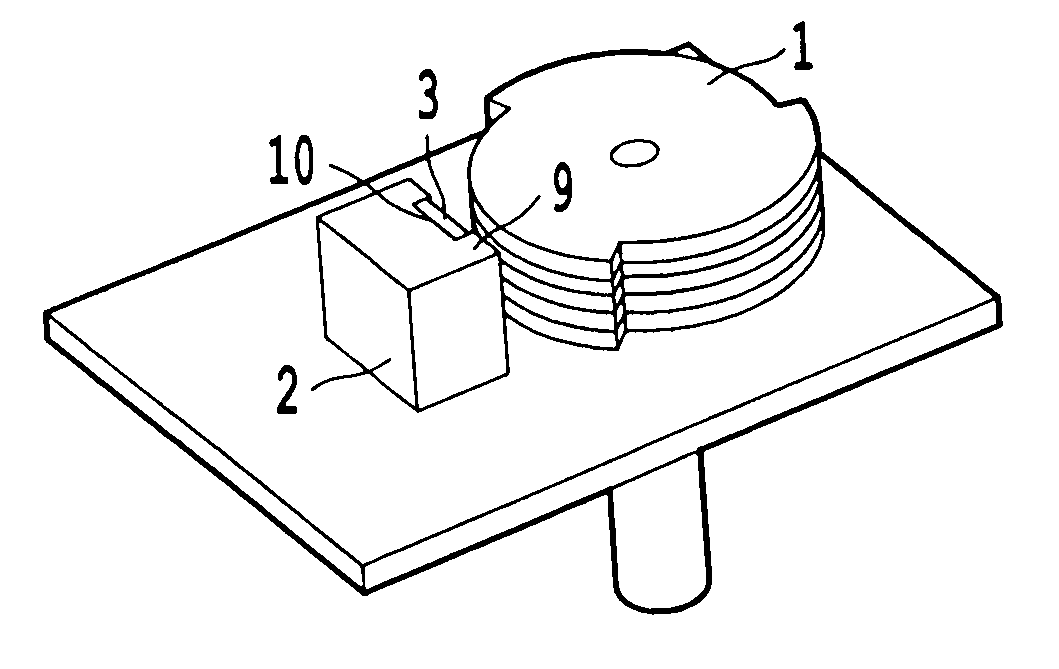

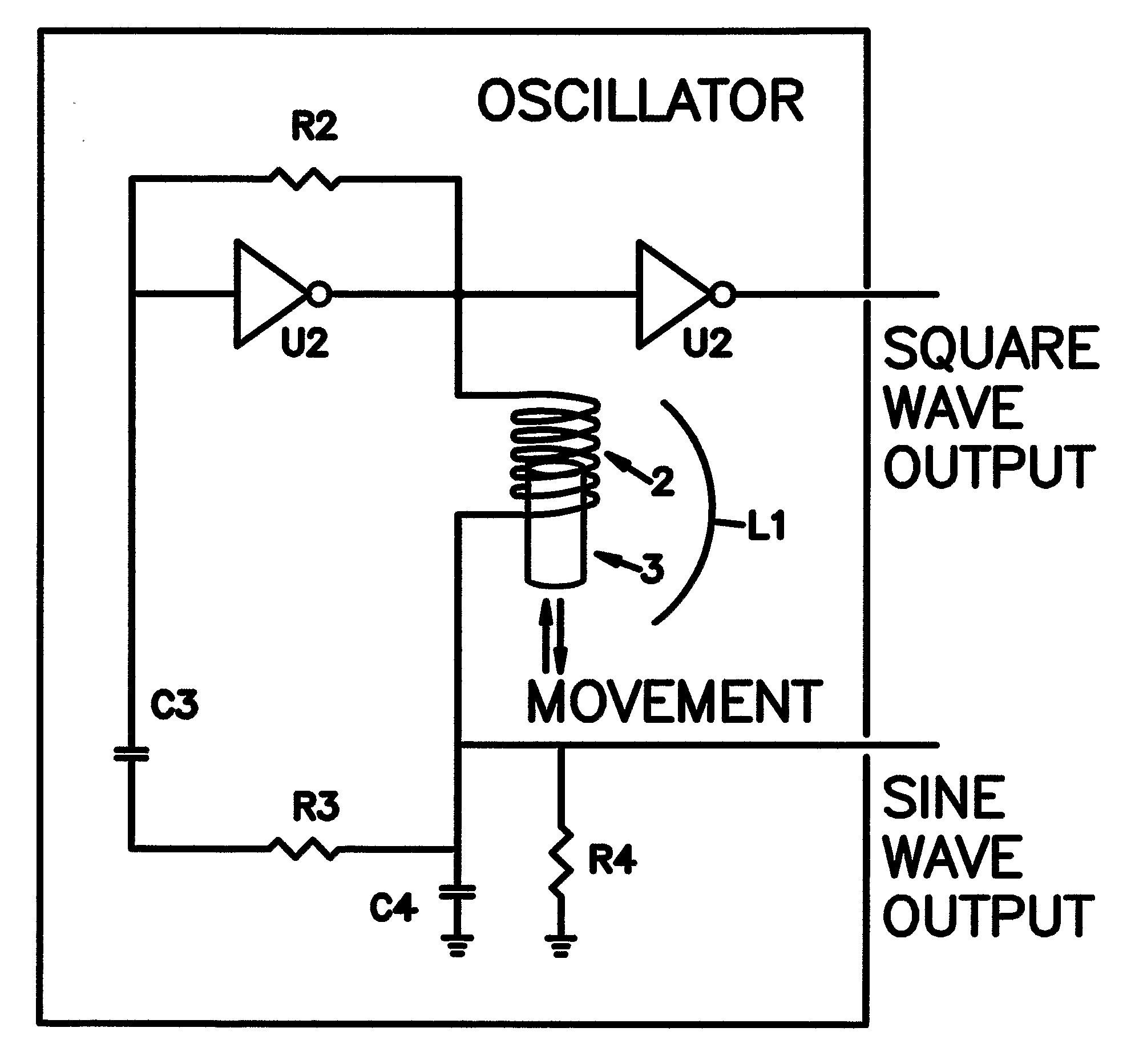

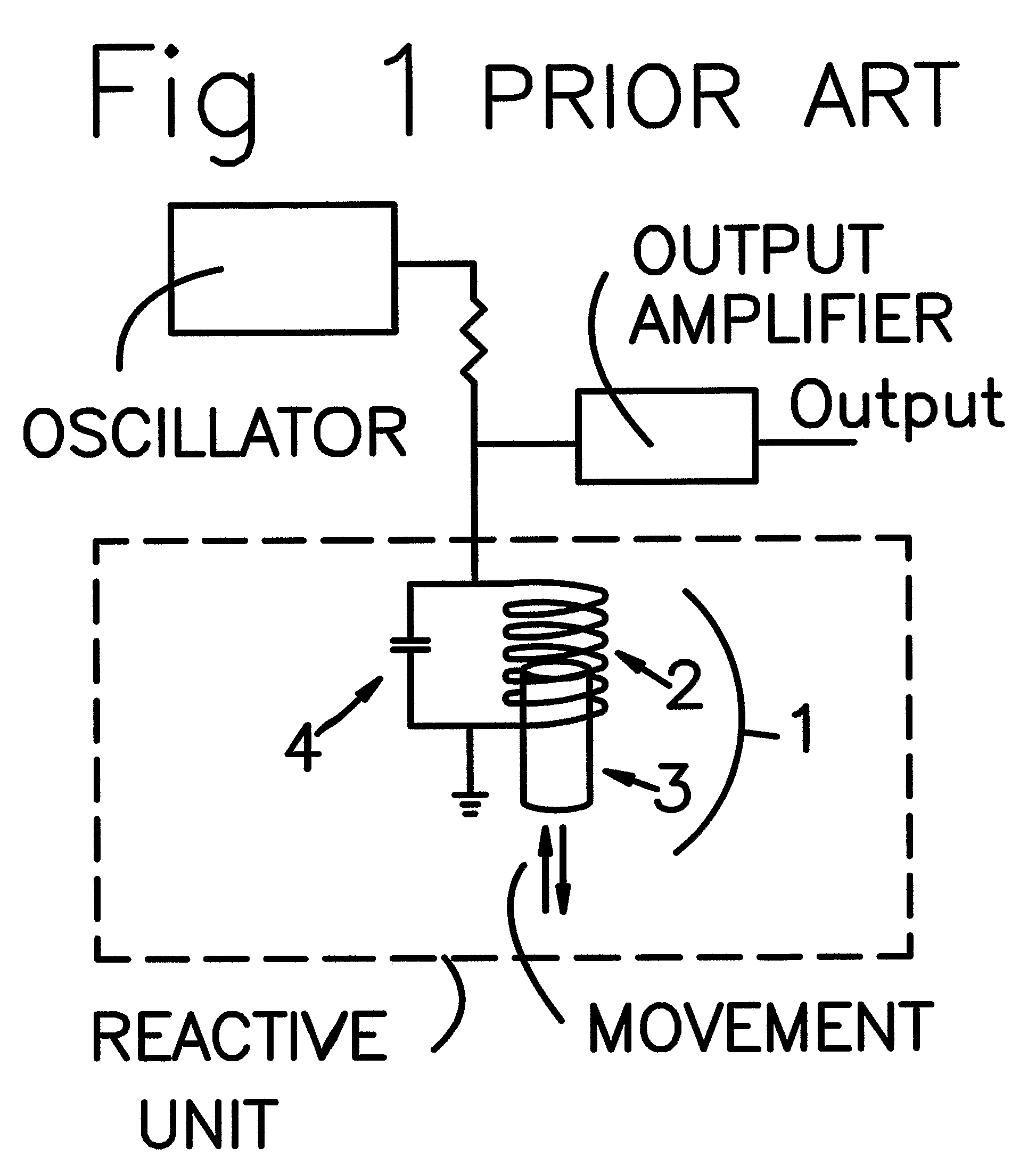

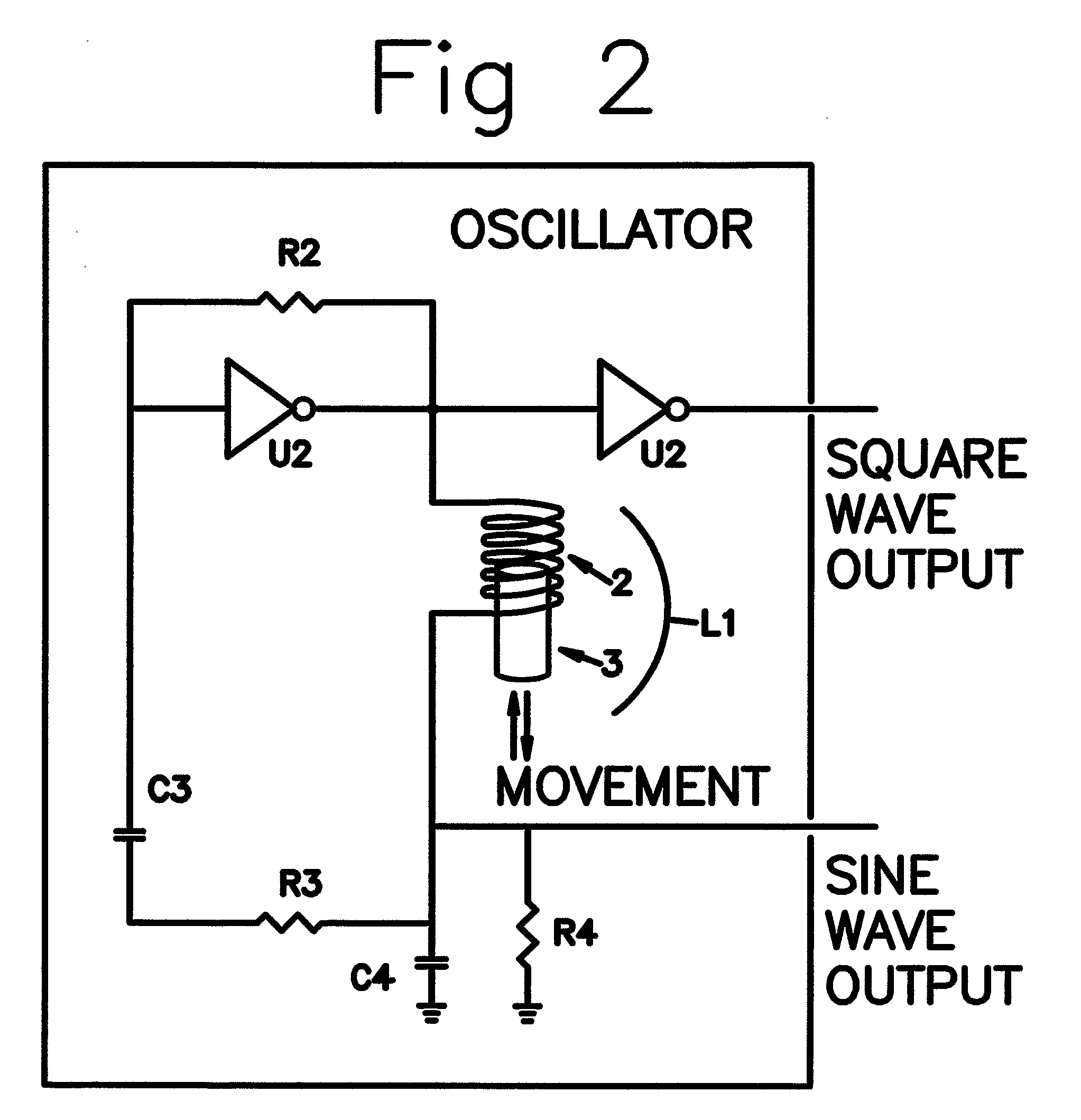

Induction sensor

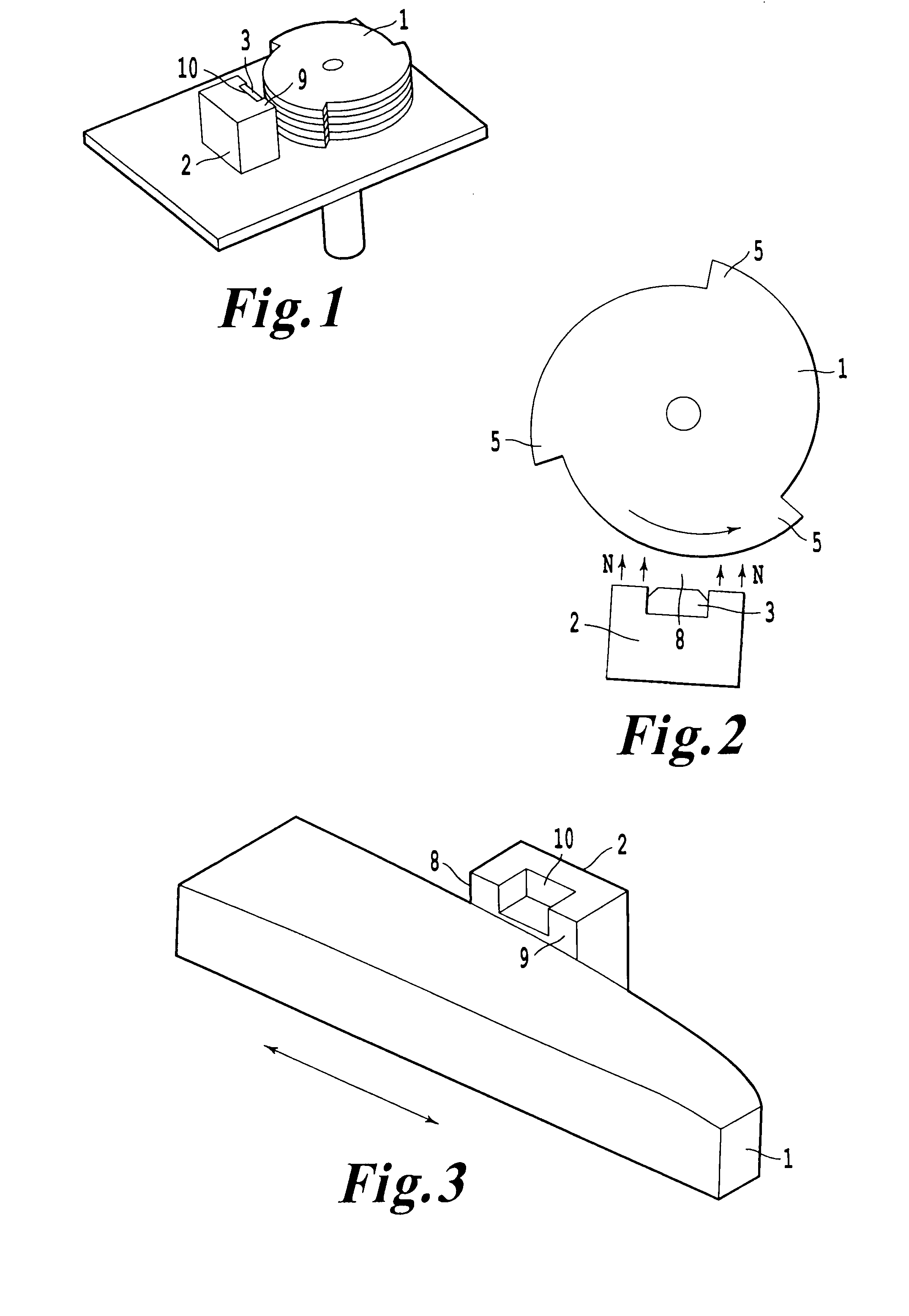

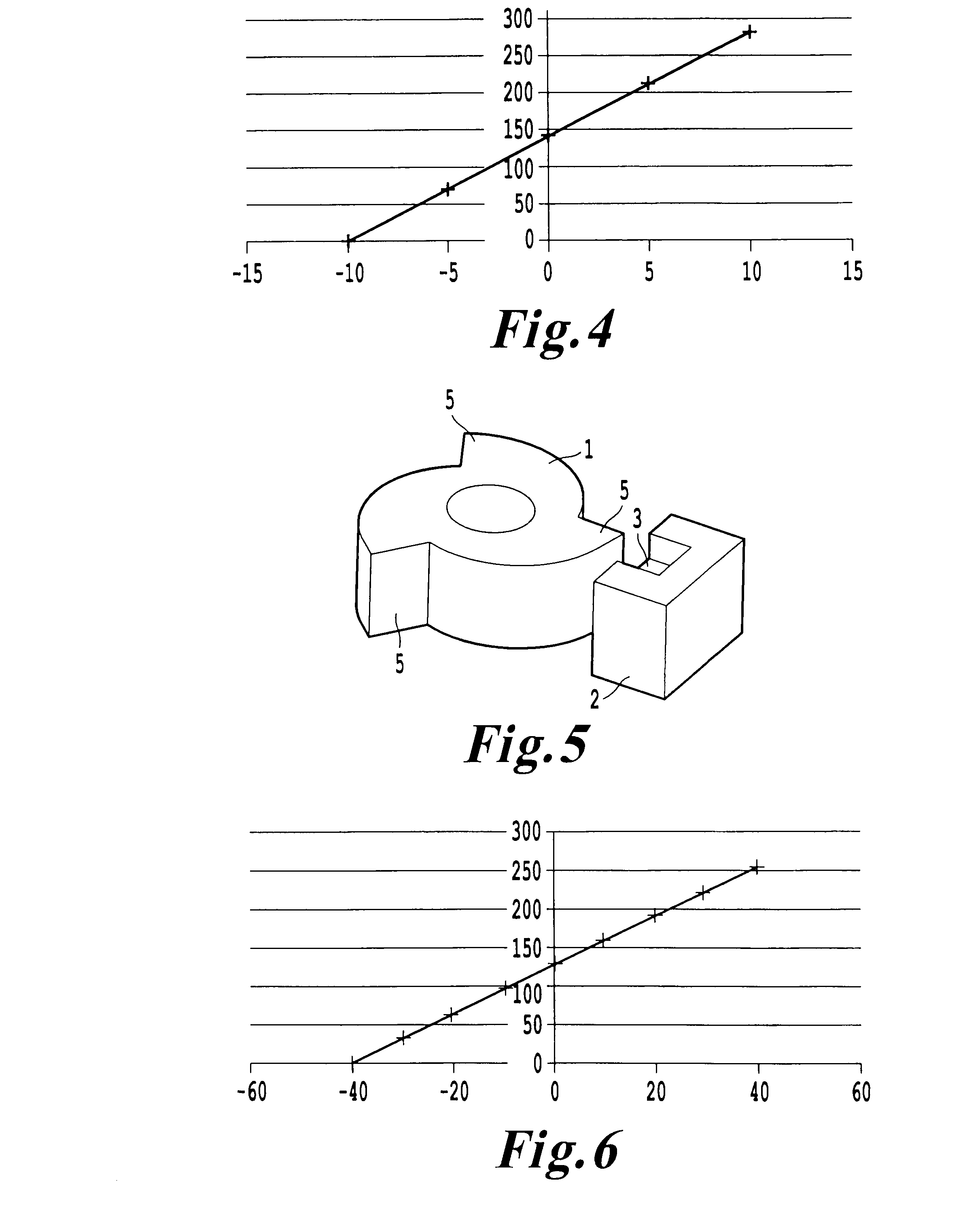

InactiveUS7528597B2Improve performanceImprove output linearityAcceleration measurement using interia forcesMaterial analysis by electric/magnetic meansVariable reluctance sensorPosition sensor

Position sensor circuits are disclosed for use with variable reluctance sensors. Variable reluctance sensors are described for linear, angular and rotary position measurement and for acceleration measurement.

Owner:DIGISENSORS

Oil bath encoder seal

InactiveUS7455459B2Low costSmall sizeEngine sealsBearing assemblyVariable reluctance sensorCombined use

An oil lubricated rotating hub (14) and stationary spindle (12) assembly includes an oil bath seal (16, 16′) for establishing a dynamic sealing interface between the hub (14) and spindle (12). A wheel sensor assembly includes a variable reluctance senor (54) targeted at an encoder ring (56, 56′) which is integrated into the oil bath seal (16, 16′). The encoder ring (56, 56′) is of the permanent magnet type including a plurality of magnetically polarized sectors alternating between North and South polarities. The use of an encoder style target (56, 56′) in combination with a variable reluctance sensor (54) enables improved slow speed sensing with relatively large air gap spacing between the exposed (58, 58′) of the encoder ring (56, 56′) and the head of the VR sensor (54). Furthermore, the encoder ring (56, 56′) enables use of less expensive, lighter materials for the oil bath seal carrier (20, 20′).

Owner:FEDERAL MOGUL WORLD WIDE

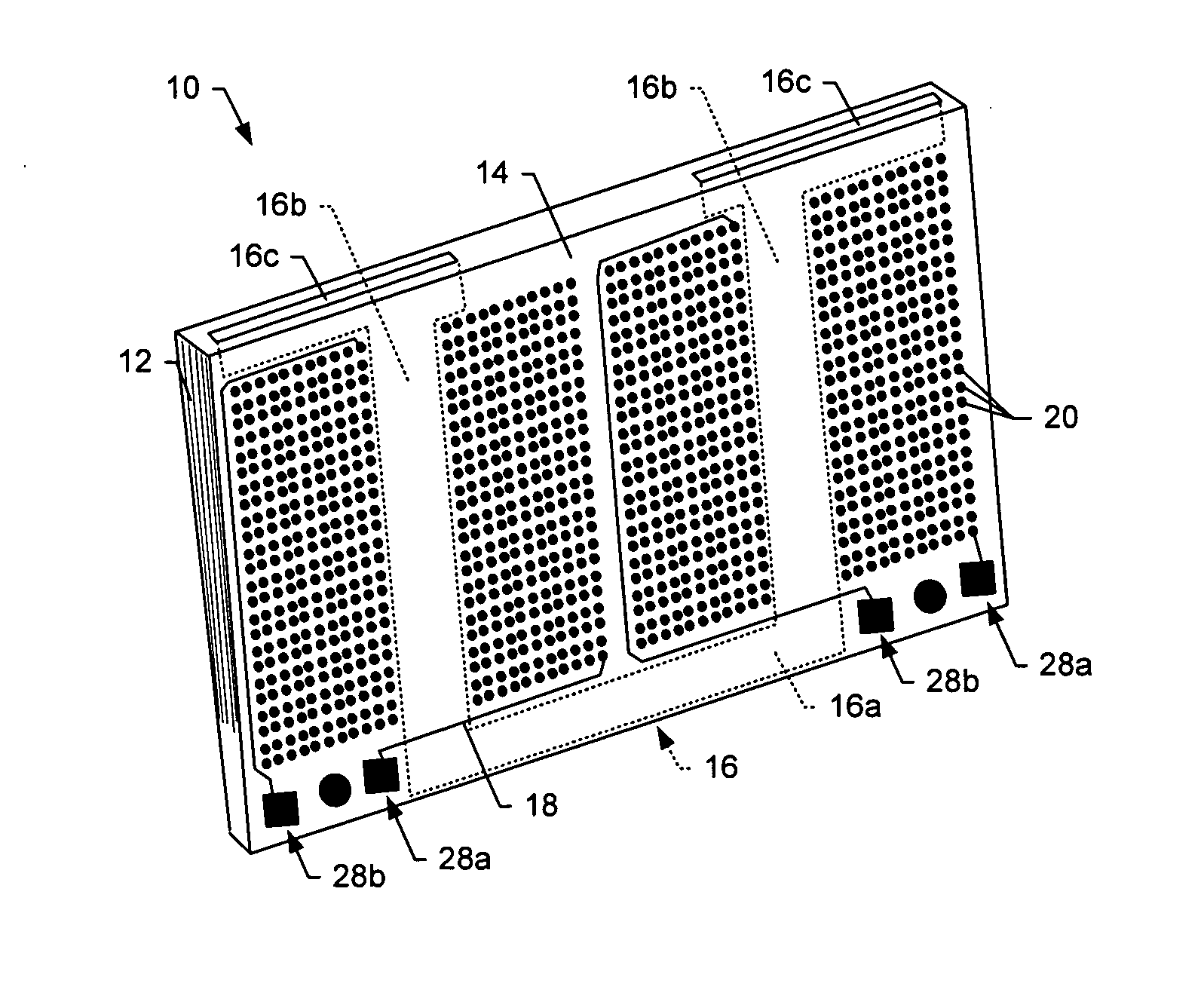

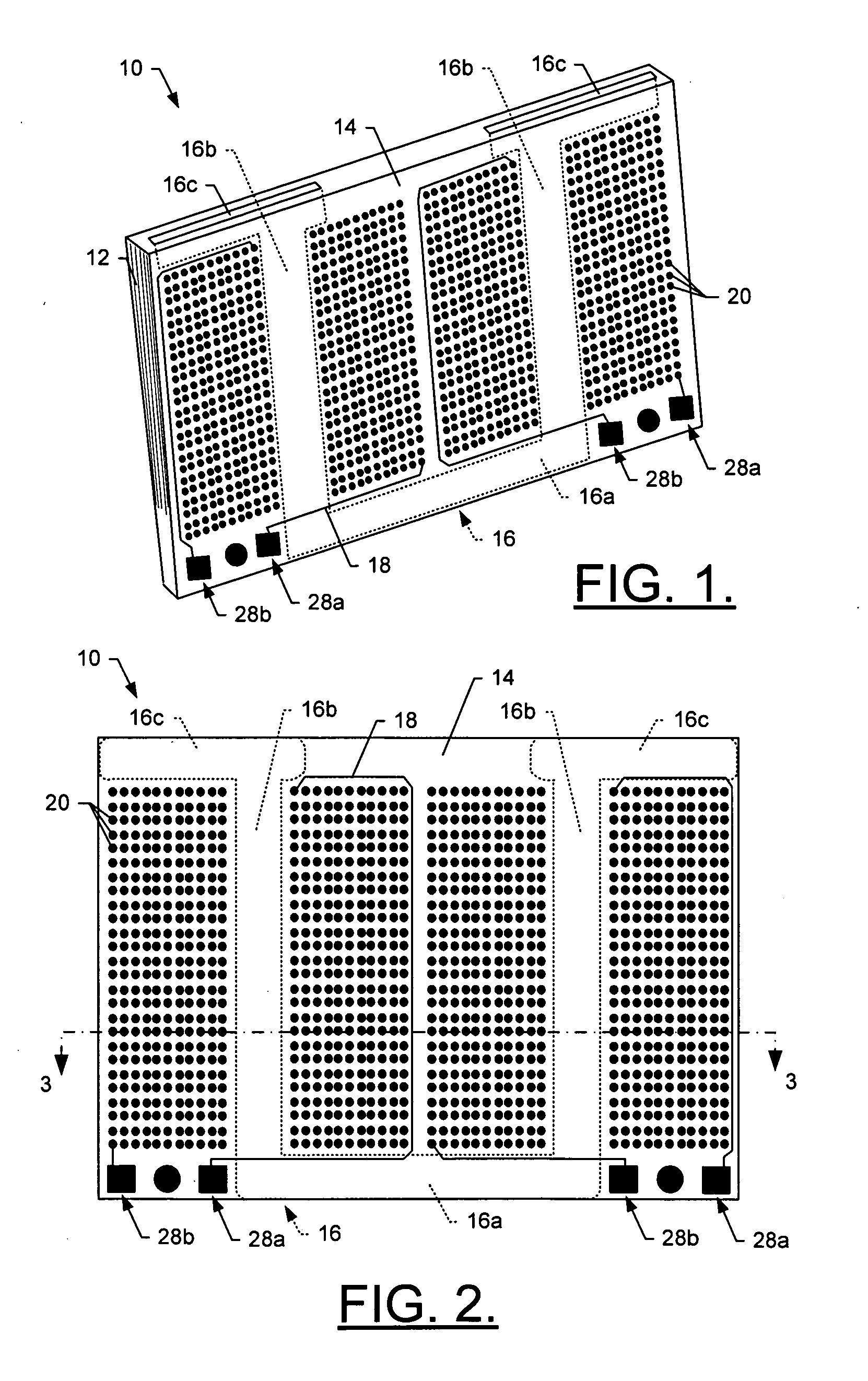

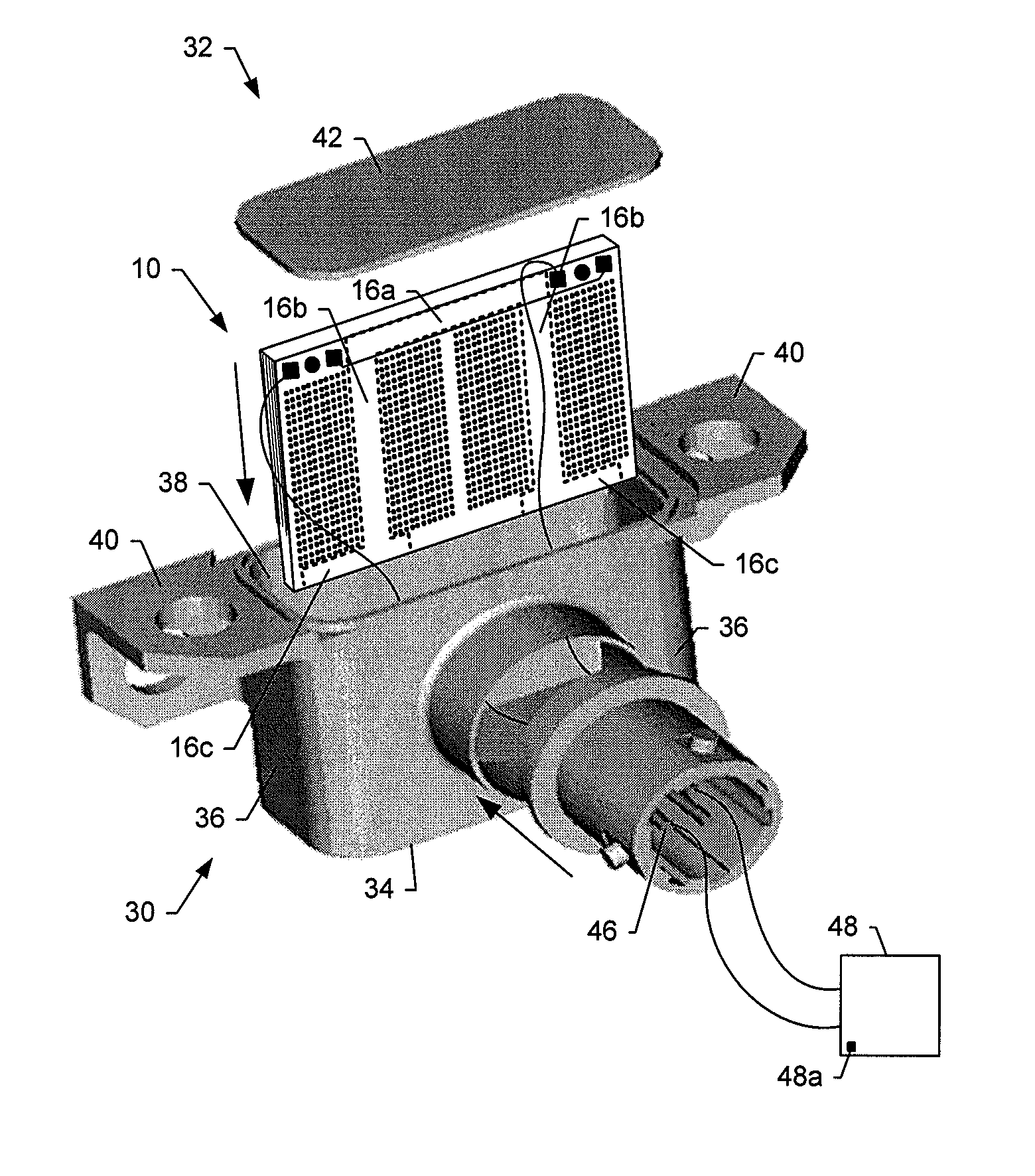

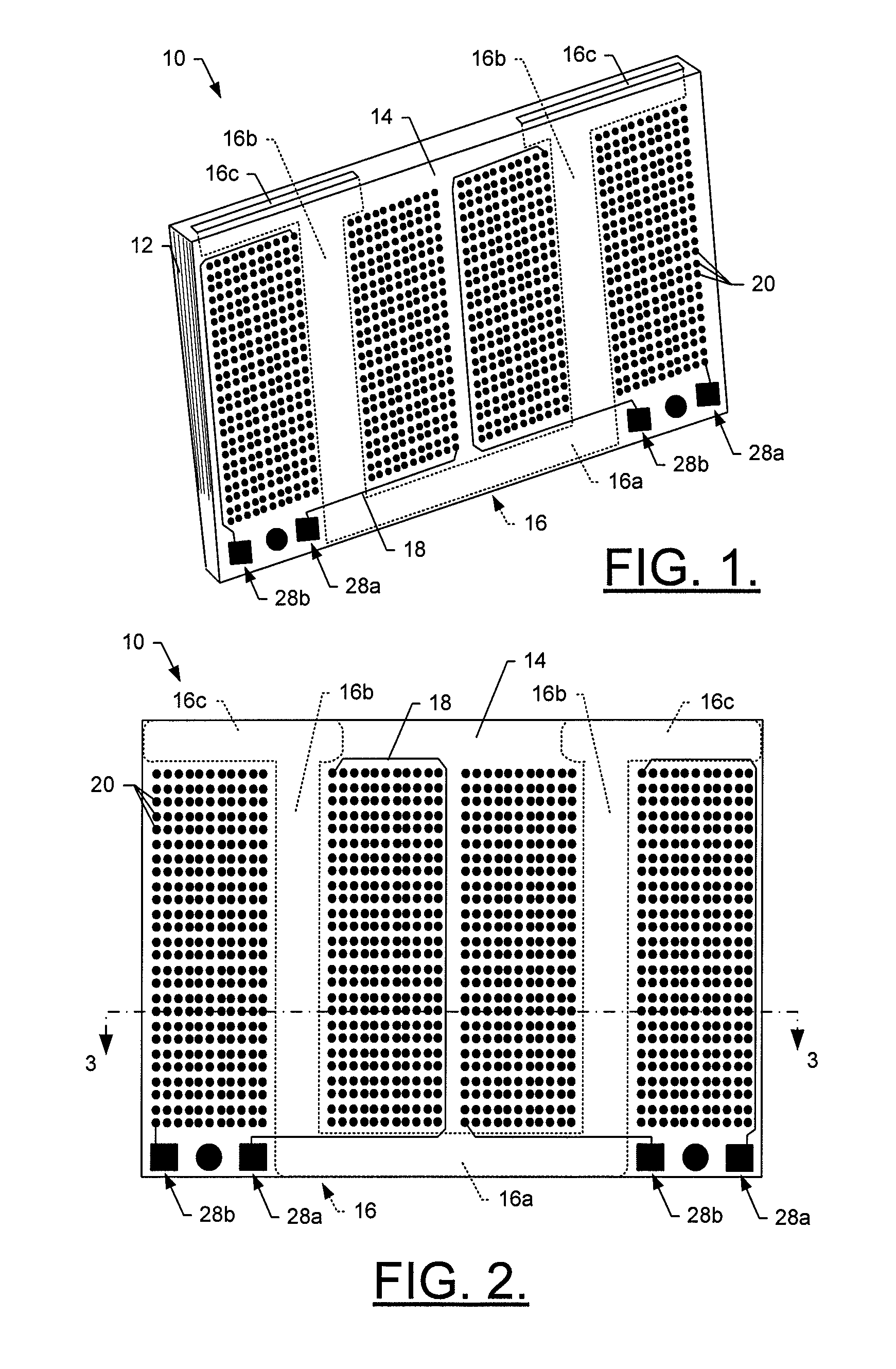

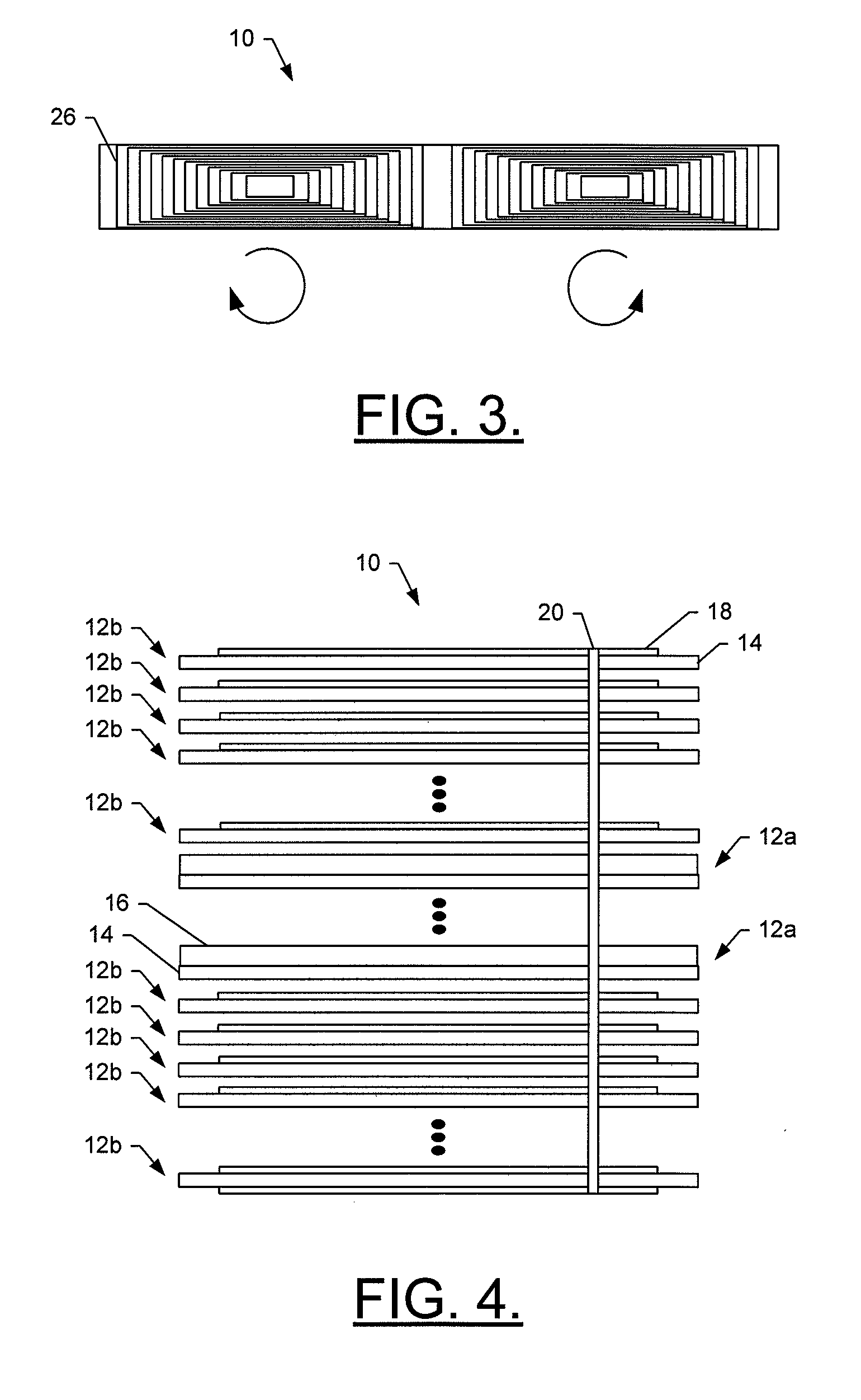

Printed circuit card-based proximity sensor and associated method of detecting a proximity of an object

ActiveUS20060113991A1Low costImprove reliabilityWave amplification devicesMagnetic field measurement using flux-gate principleElectricityProximity sensor

A proximity sensor assembly includes a multilayer printed wiring board proximity sensor, the proximity sensor being operable as either a variable-reluctance sensor or an eddy current loss sensor. The proximity sensor includes a plurality of layers configured to form at least one wound coil disposed about at least a portion of a core. The coils are electrically driven to generate an alternating magnetic field such that the inductance of the coils changes when a permeable or conductive object is moved in relation to the magnetic field. The change in inductance is recognized and used to detect the proximity and presence of an object relative to the sensor.

Owner:SIMMONDS PRECISION PRODS

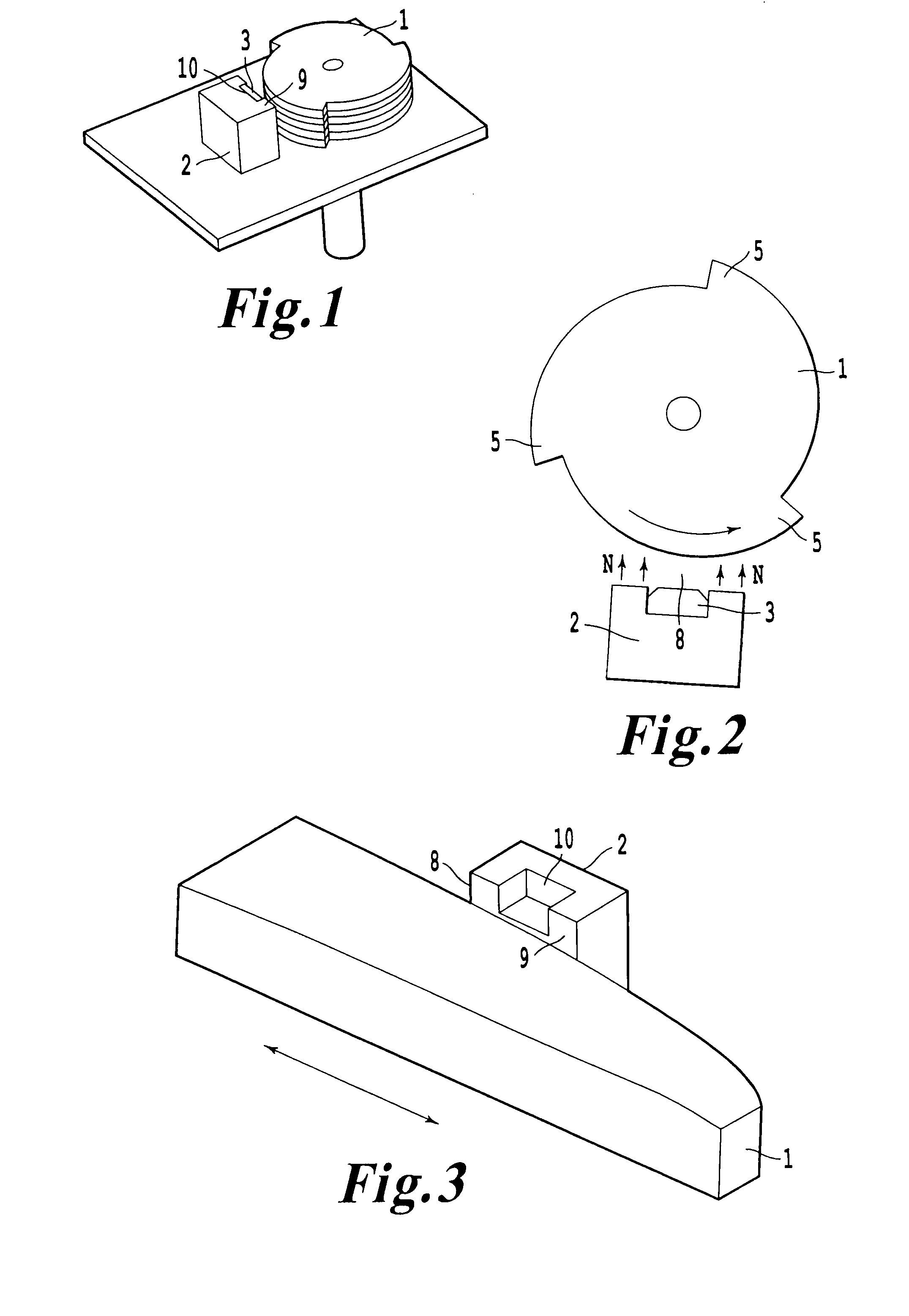

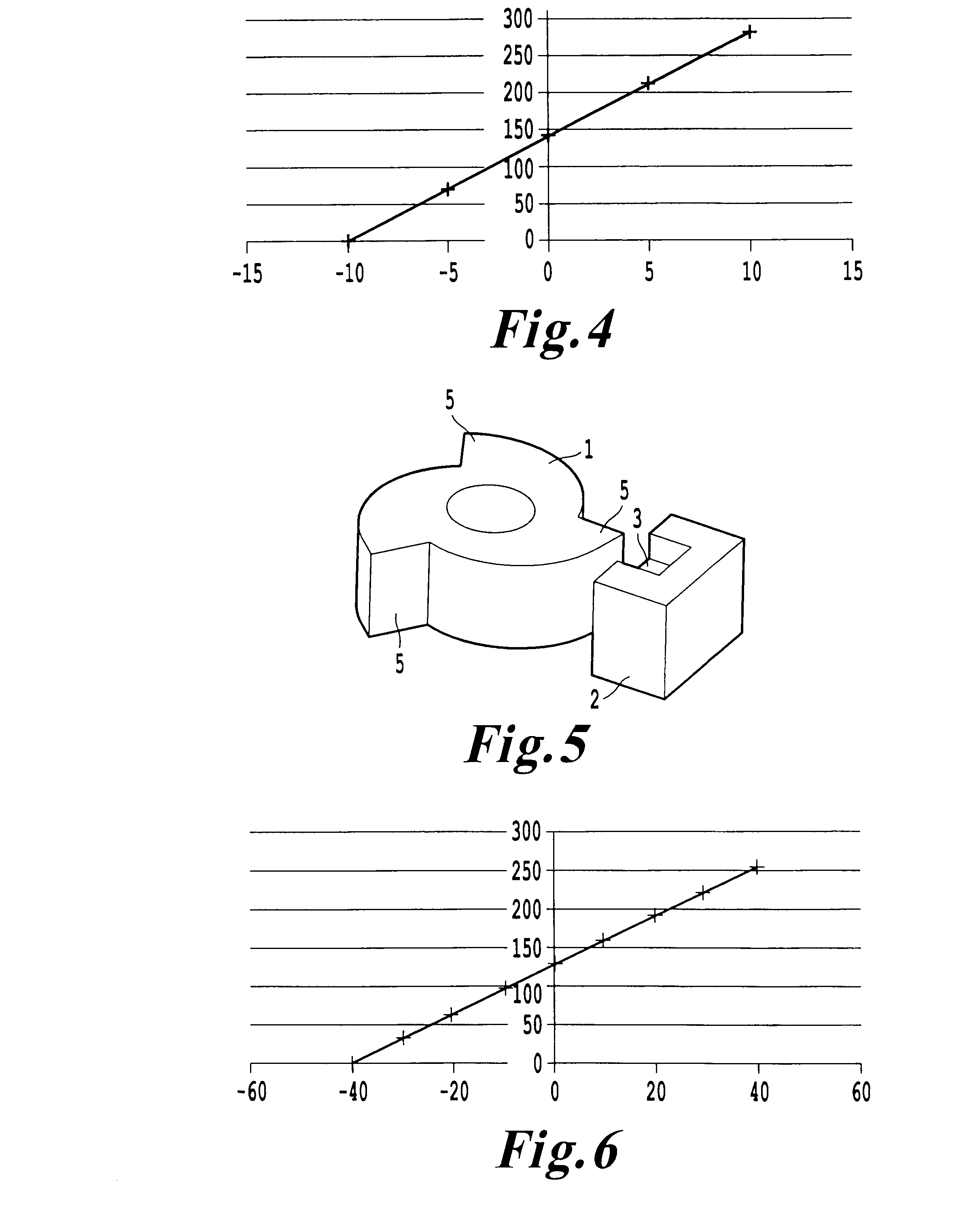

Variable reluctance position sensor

ActiveUS20110043194A1Improve linearityLarge travelMagnetic measurementsUsing electrical meansVariable reluctance sensorPosition sensor

A variable reluctance analog position device designed to determine the position variation of a target made from a ferromagnetic material. The device includes at least one magnet, the target and the magnet defining a gap therebetween. A magnetosensitive element detects induction variation produced in the gap by relative movement of the target relative to the magnet. The magnet is magnetized in a direction essentially perpendicular to the front surface of the magnet, which defines one edge of the gap. The magnet includes a cavity open at the front surface thereof and the magnetosensitive element is housed in the cavity. Moreover, the target is provided with a specific geometric configuration determined such that the induction variation according to the position of the target corresponds to a pre-defined function.

Owner:MOVING MAGNET TECH

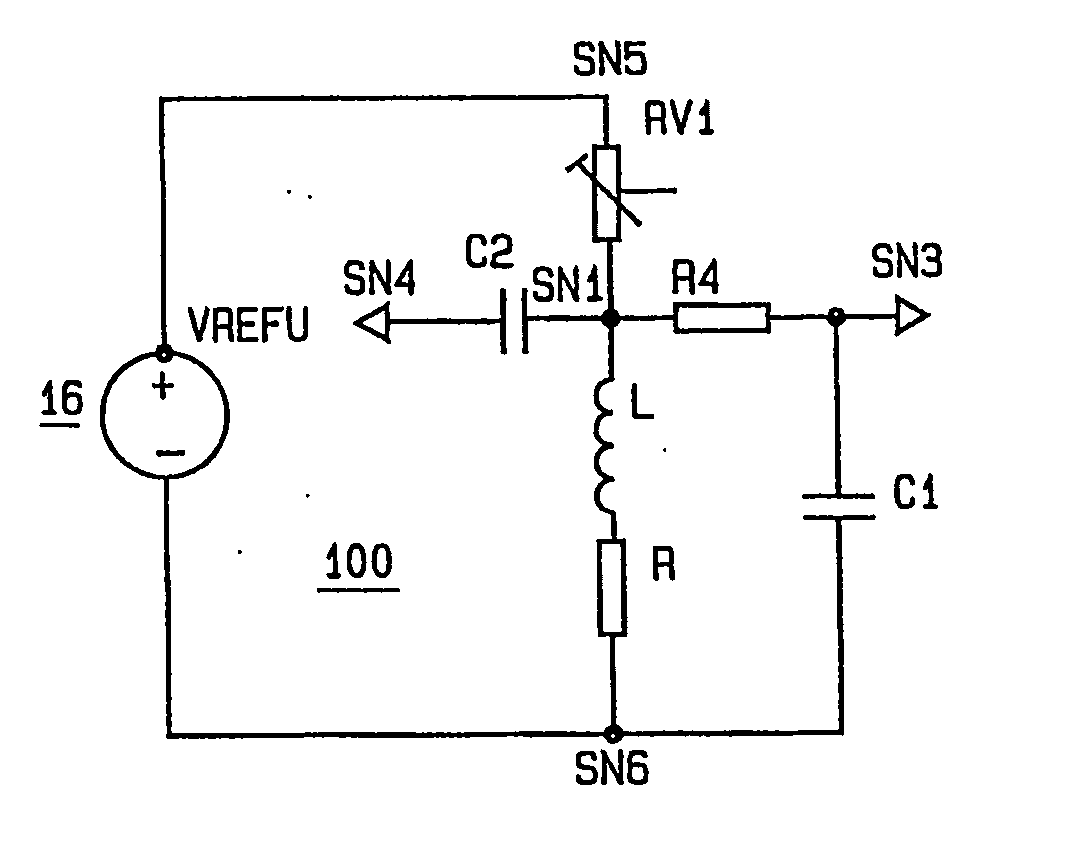

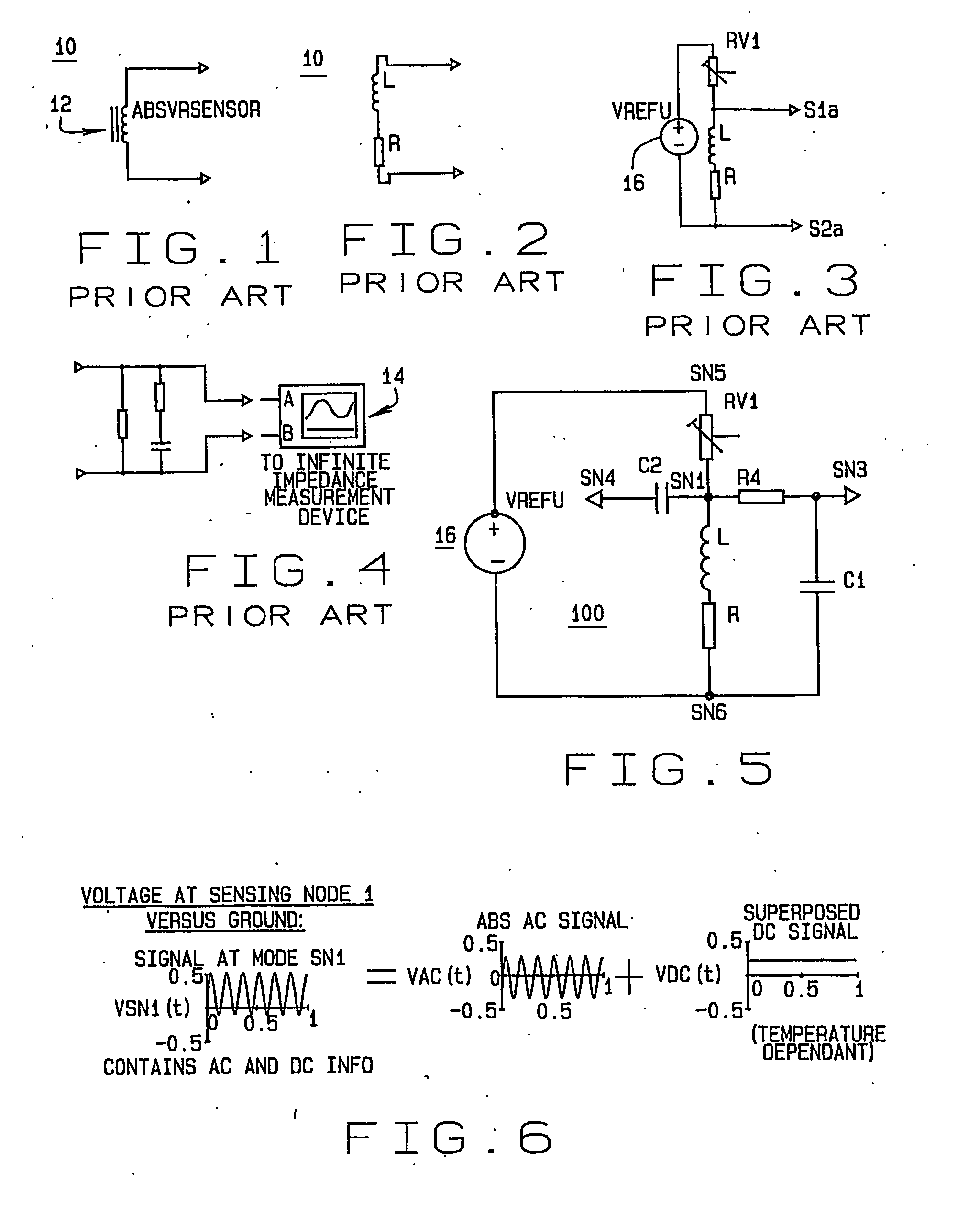

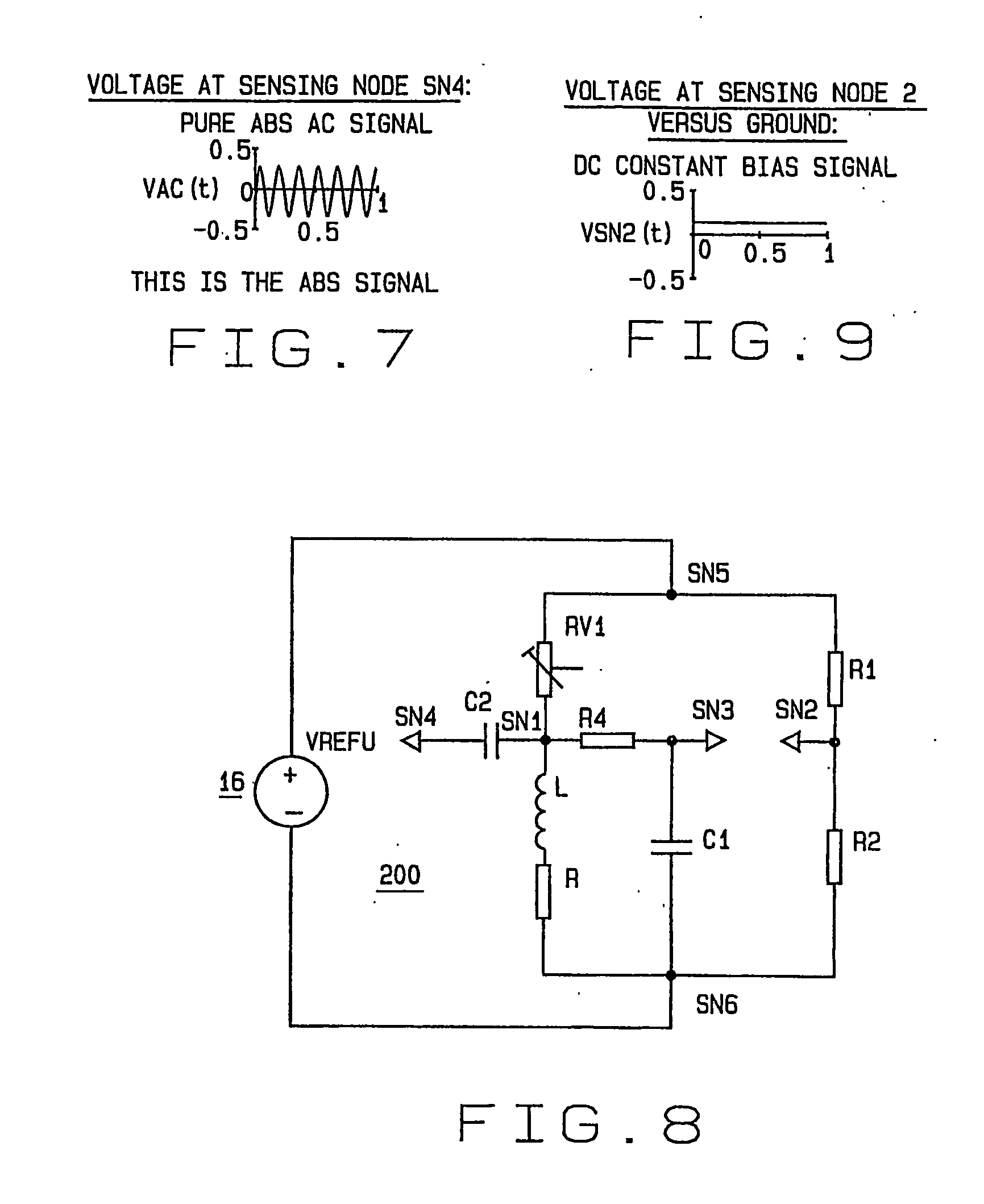

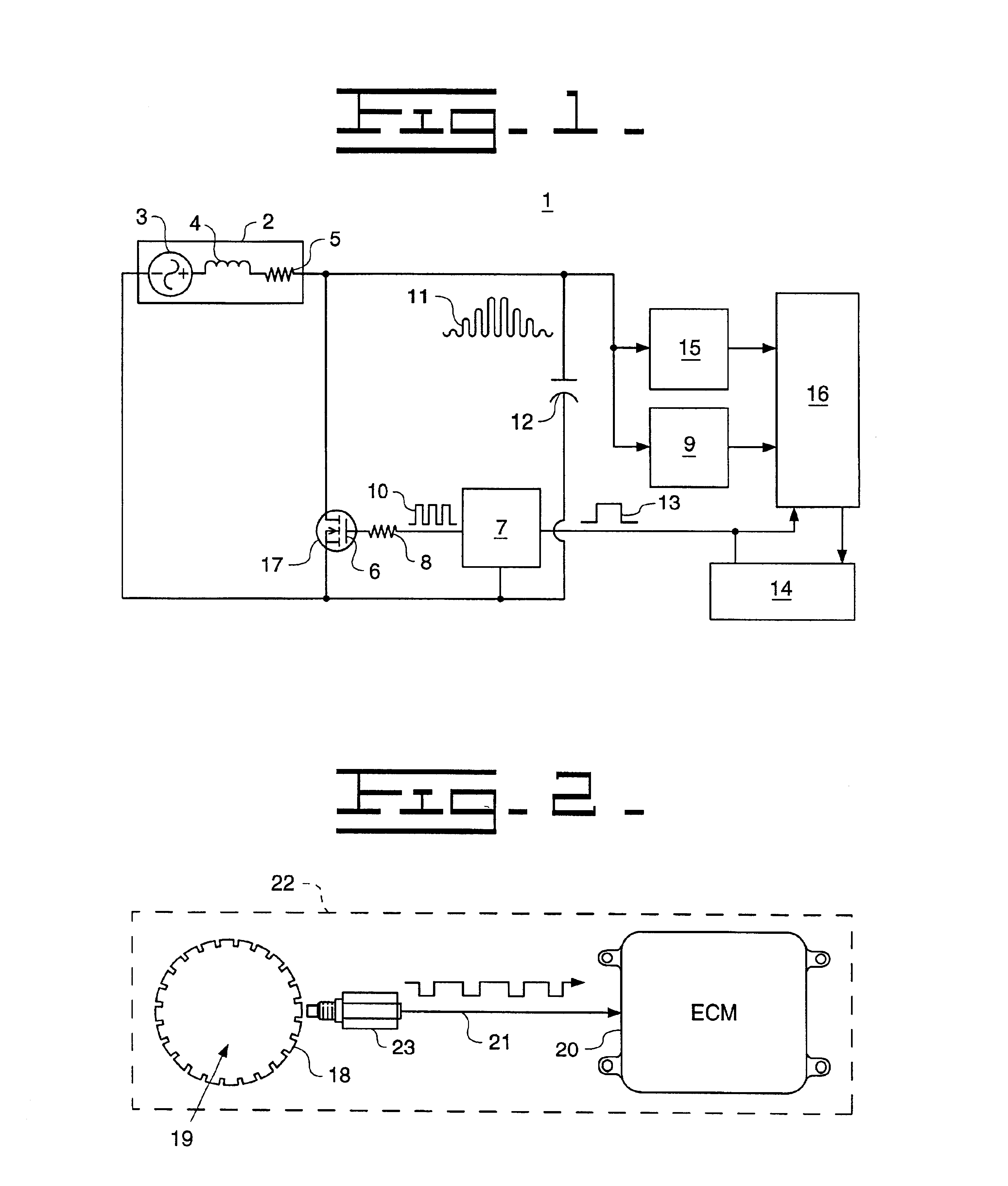

Rotation sensor with temperature measuring feature

InactiveUS7573391B2Thermometer detailsThermometers using material expansion/contactionTraction control systemVariable reluctance sensor

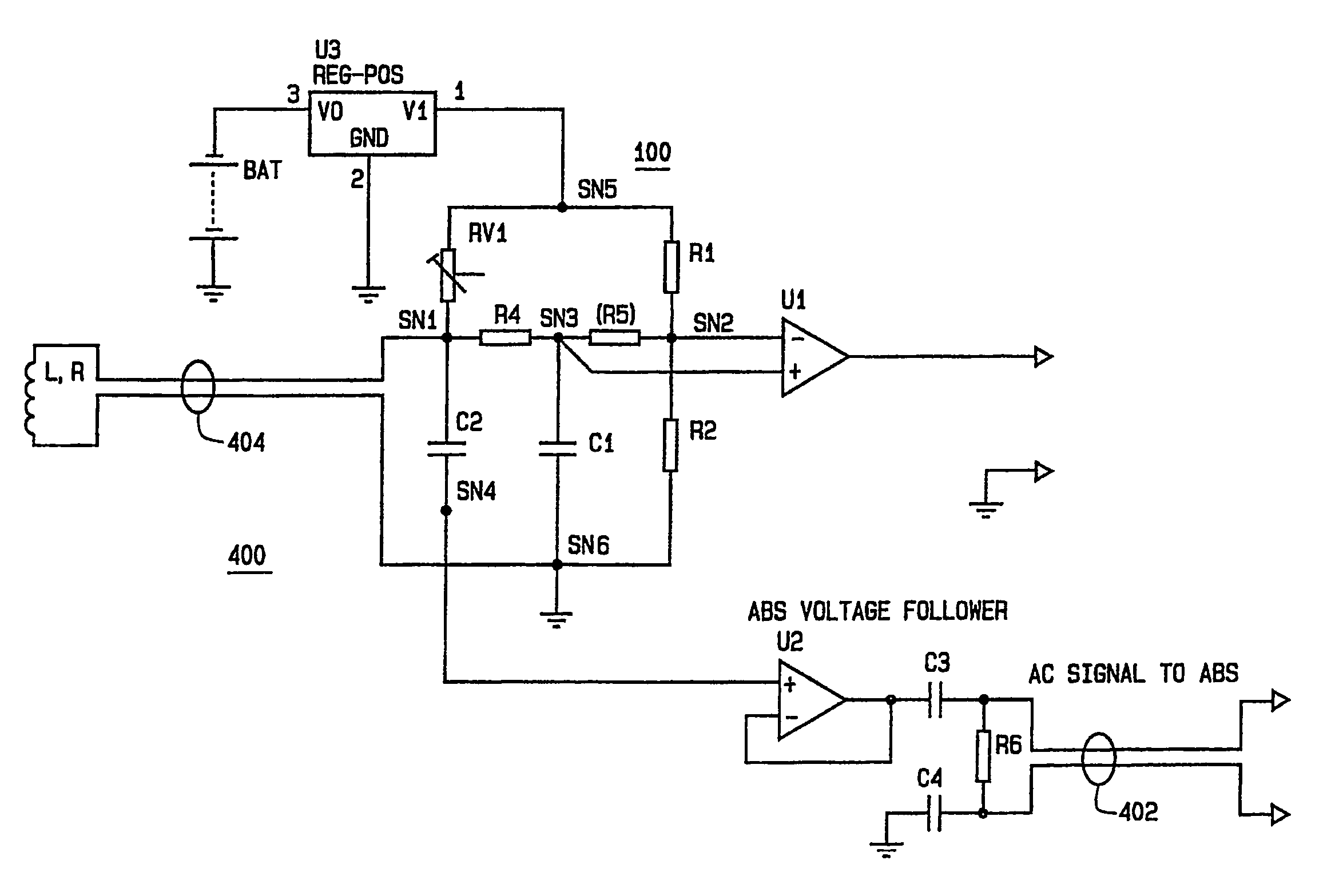

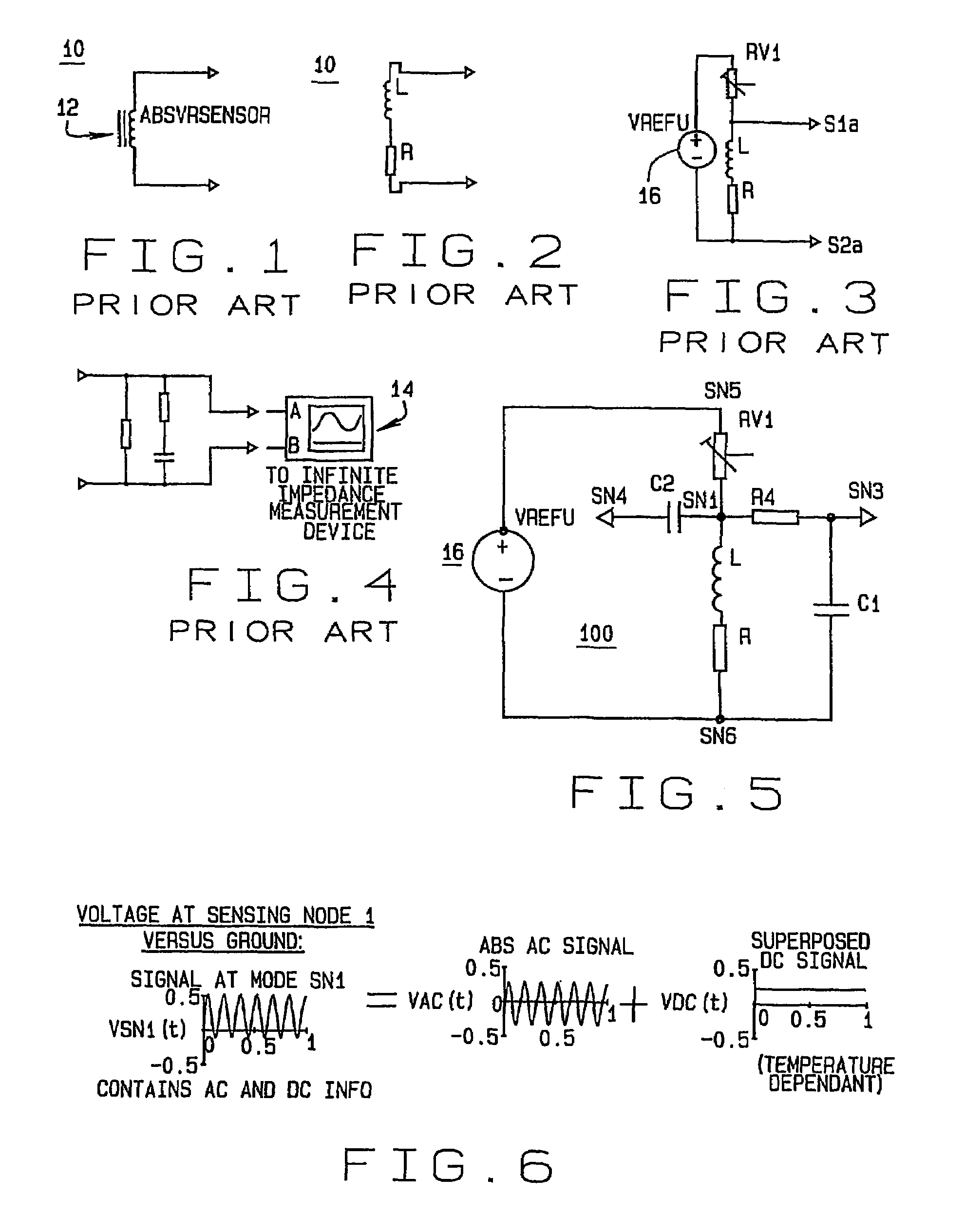

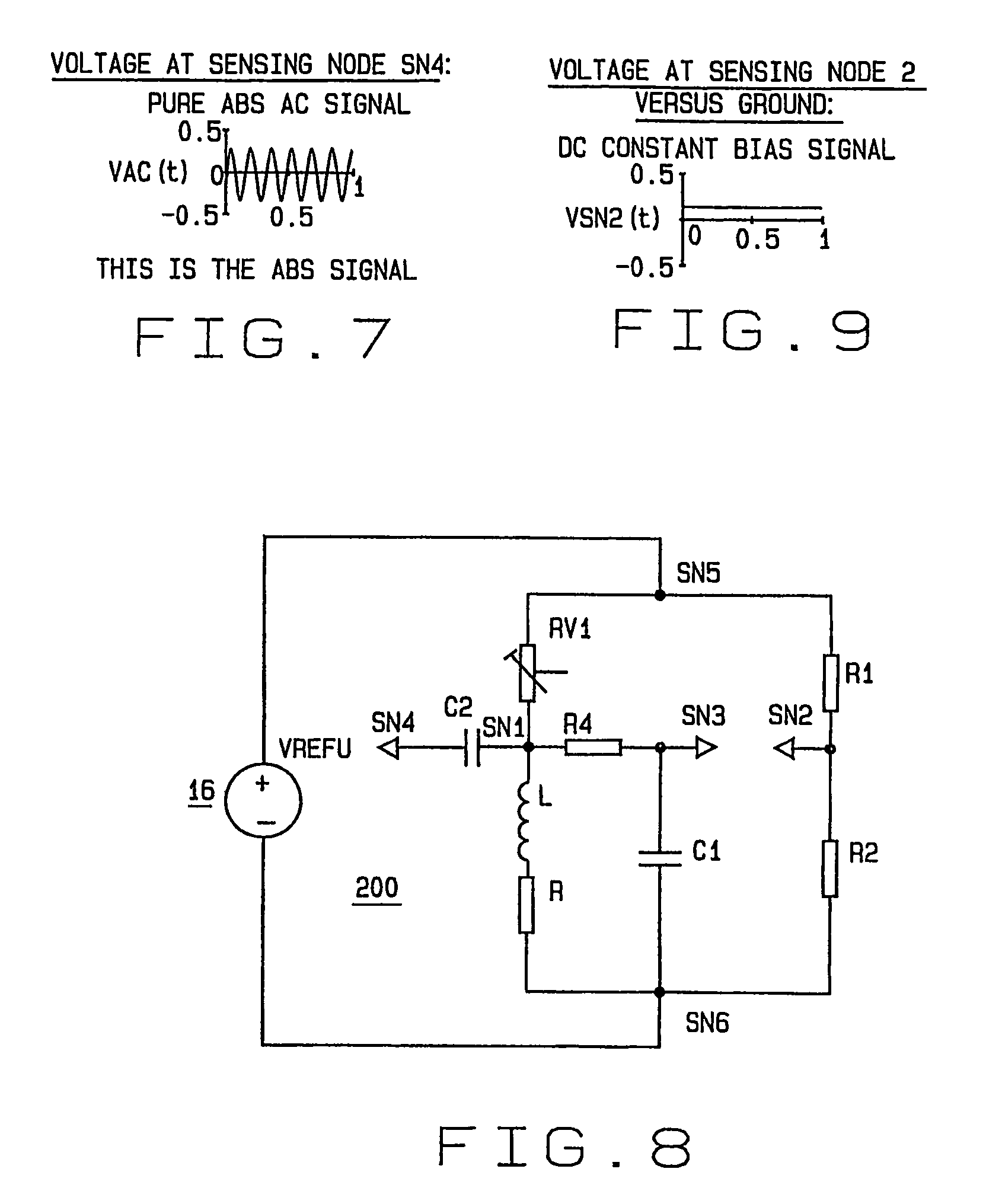

A temperature sensing system (100) for use with a variable reluctance sensor such as found in vehicle wheel bearing applications, which utilizes existing sensors (12) such as the antilock braking system or traction control system sensors as a direct current resistive temperature gauge. The temperature sensing system (100) includes electrical components (R4, C1) configured to separate the DC voltage (VDC(t)) representative of sensor temperature from the original magnetically induced AC voltage output signal (VSN1(t)) representative of the rotation such as vehicle wheel speed, thereby permitting the temperature sensing system (100) to be retrofitted and installed in vehicles or other components without significant alteration to an existing wiring harness or electrical components.

Owner:THE TIMKEN CO

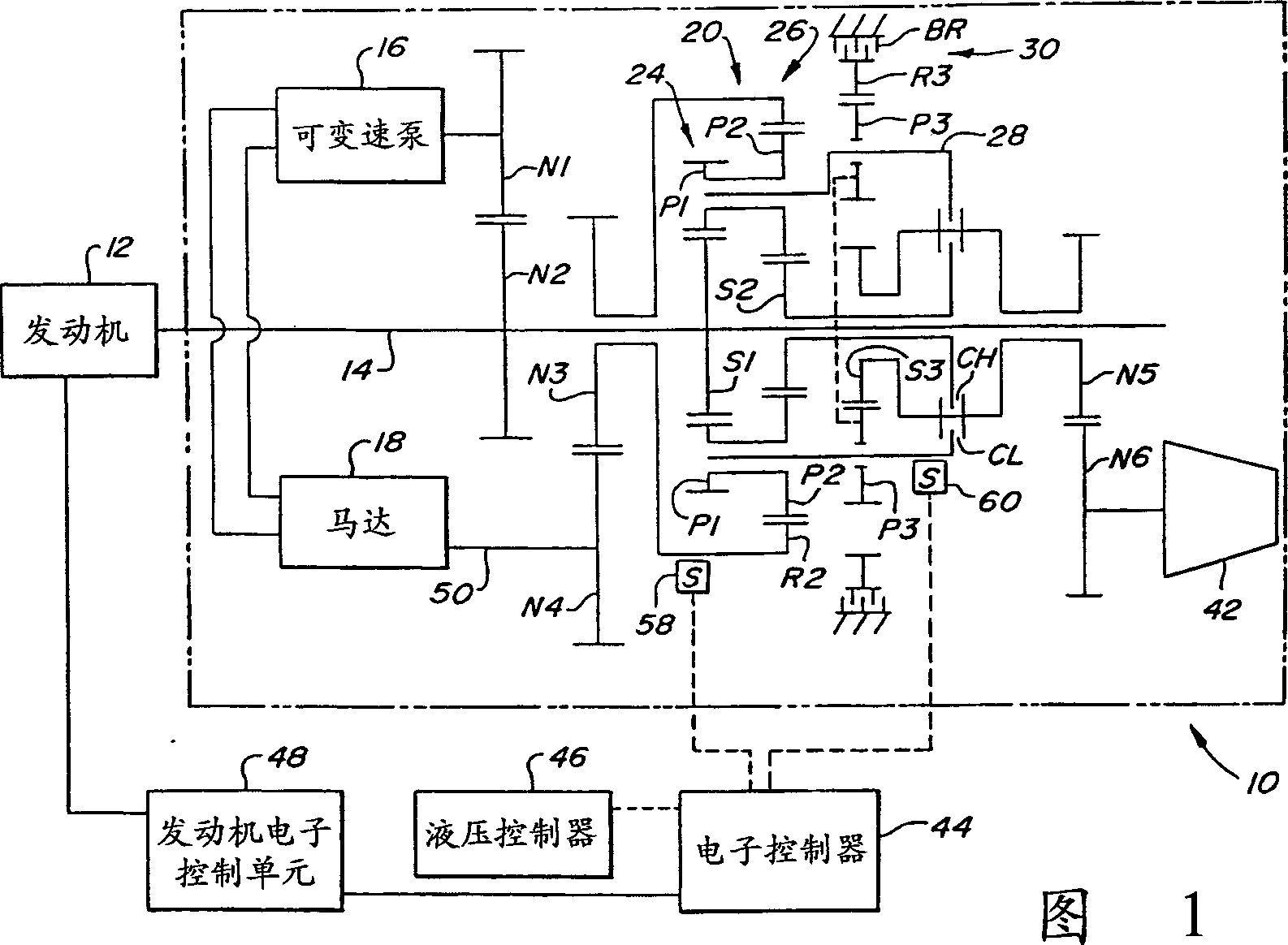

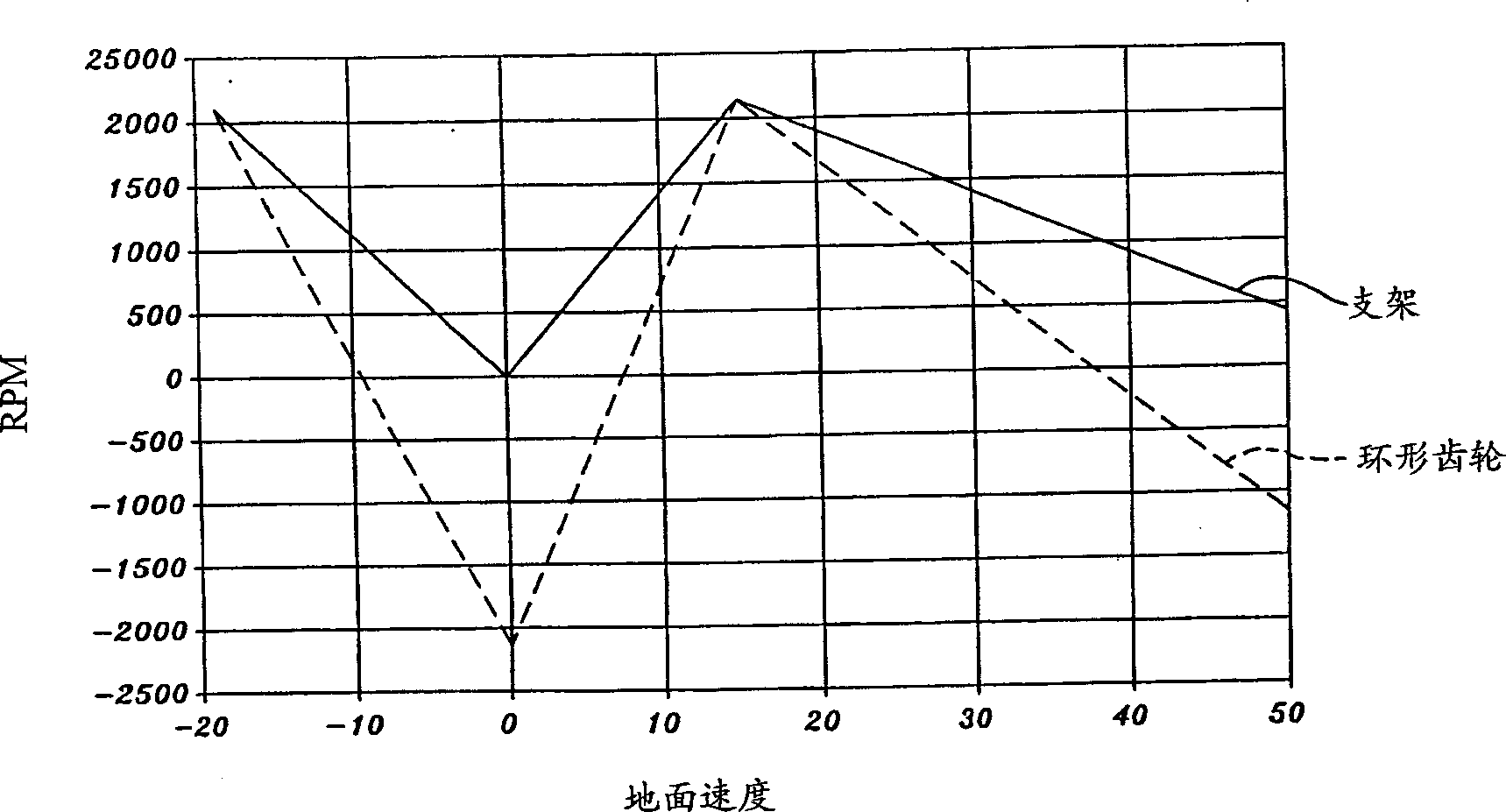

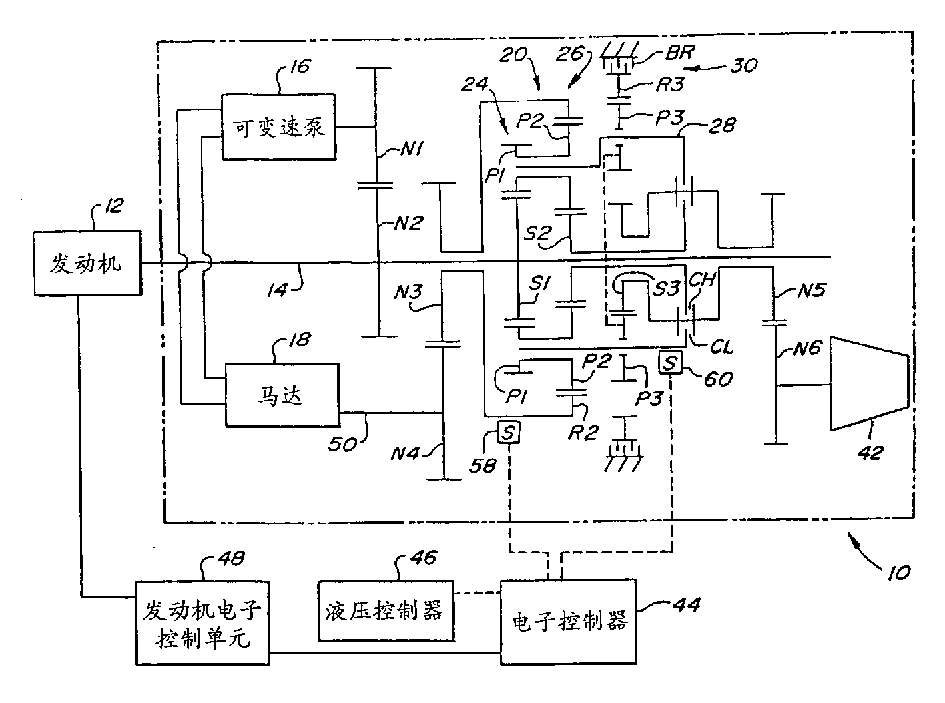

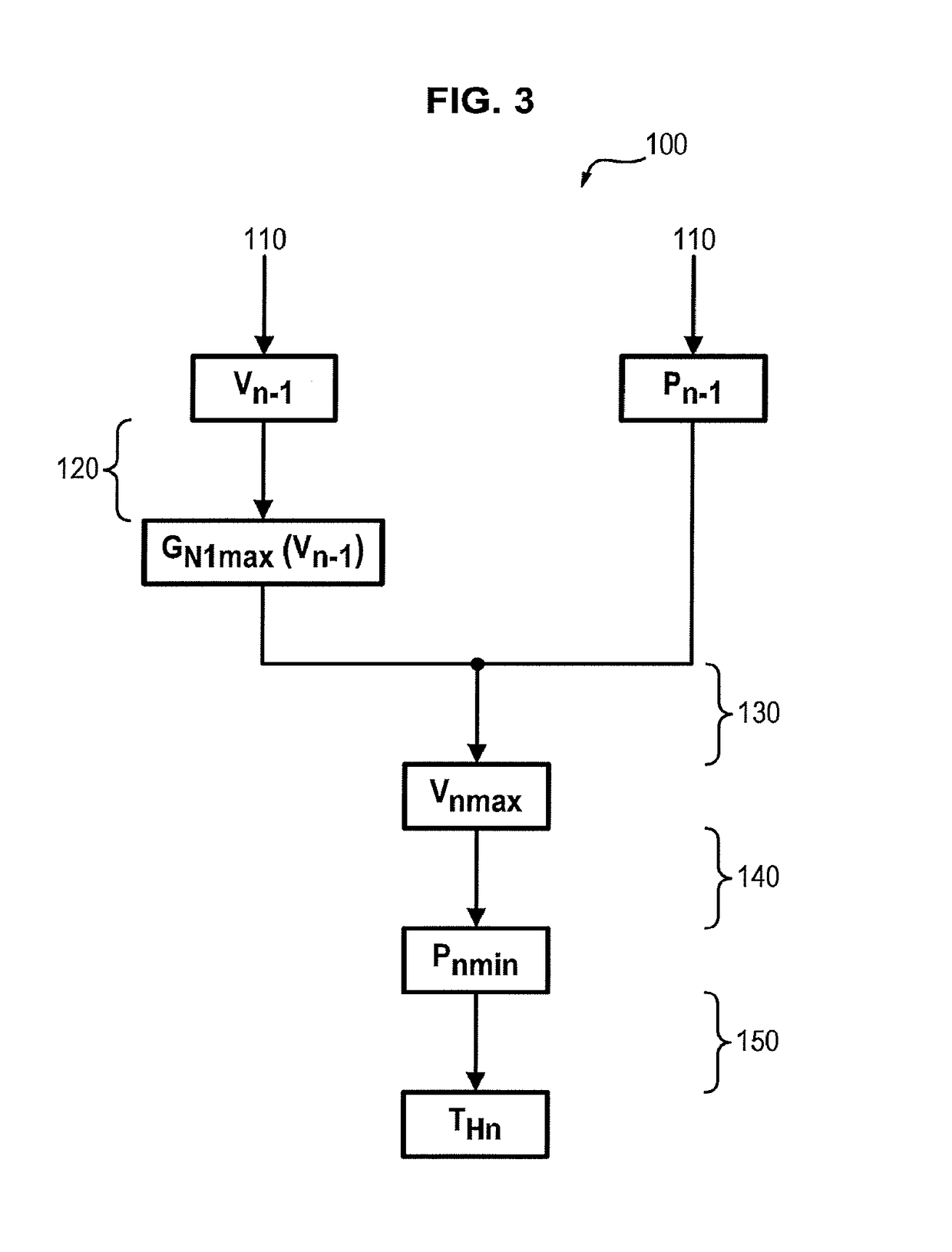

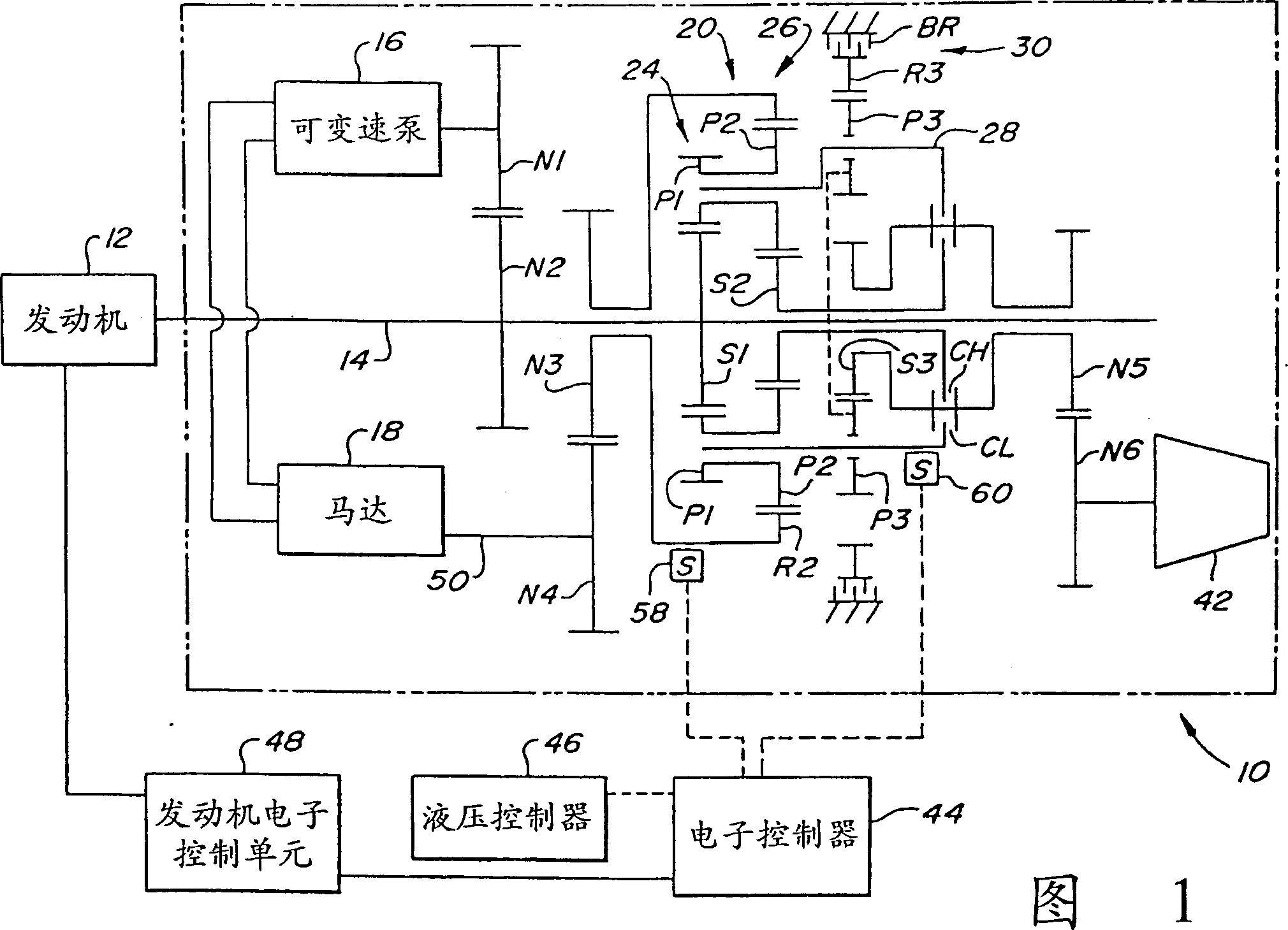

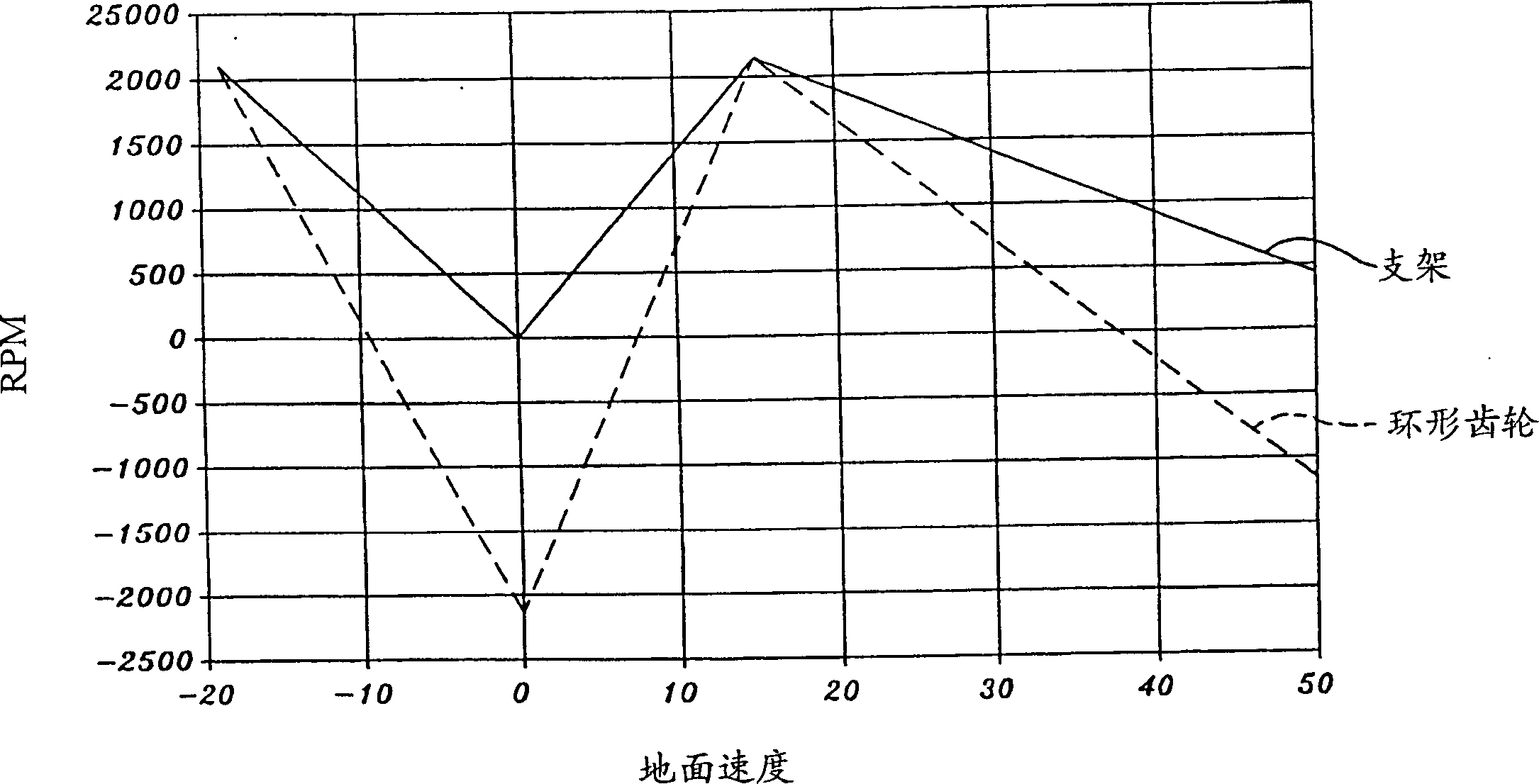

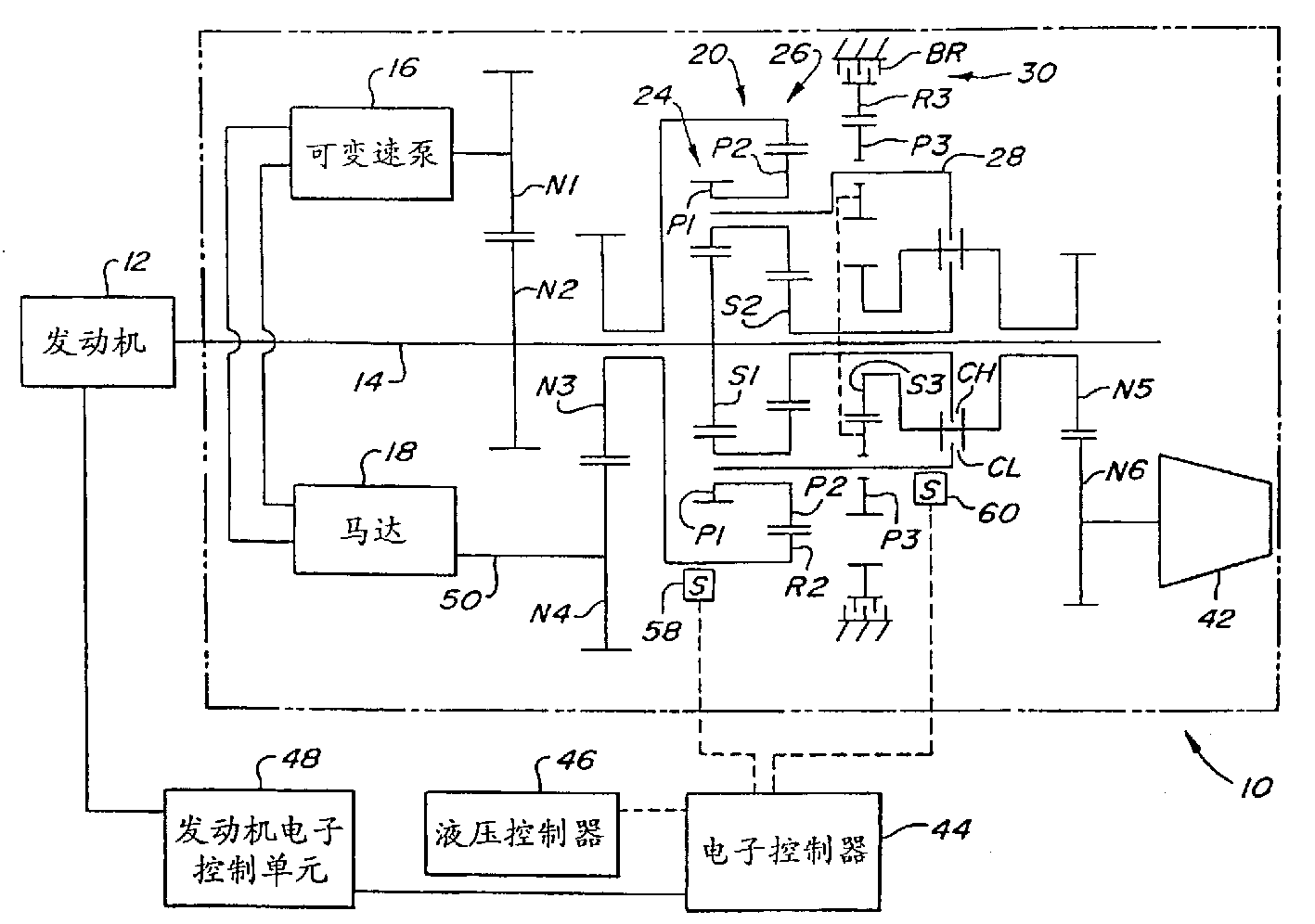

Device and method for determining hydraulic unit output speed in hydraulic mechanical gearing means

The output speed of a hydrostatic unit in a transmission is determined using a pair of variable reluctance sensors, one on a gear driven by the hydrostatic unit output and the other on the carrier of the planetary system. One of the two sensors will always be measuring a relatively high speed from which the hydro output is directly determined or indirectly determined using the current engine speed. Thus the frequency of the speed sensor used to determine the hydrostatic unit output speed is not decreased at slow hydrostatic unit output speeds.

Owner:DEERE & CO +1

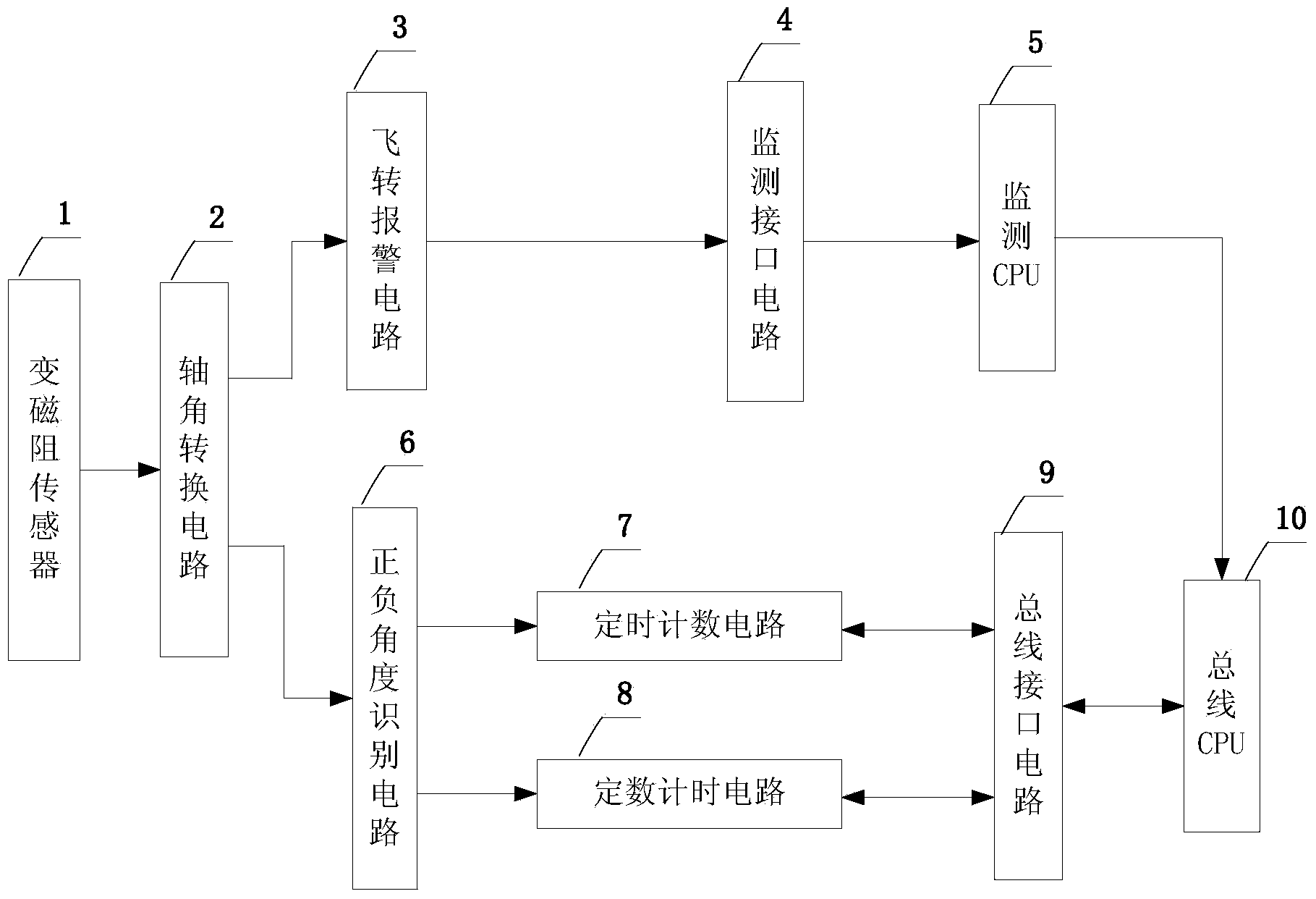

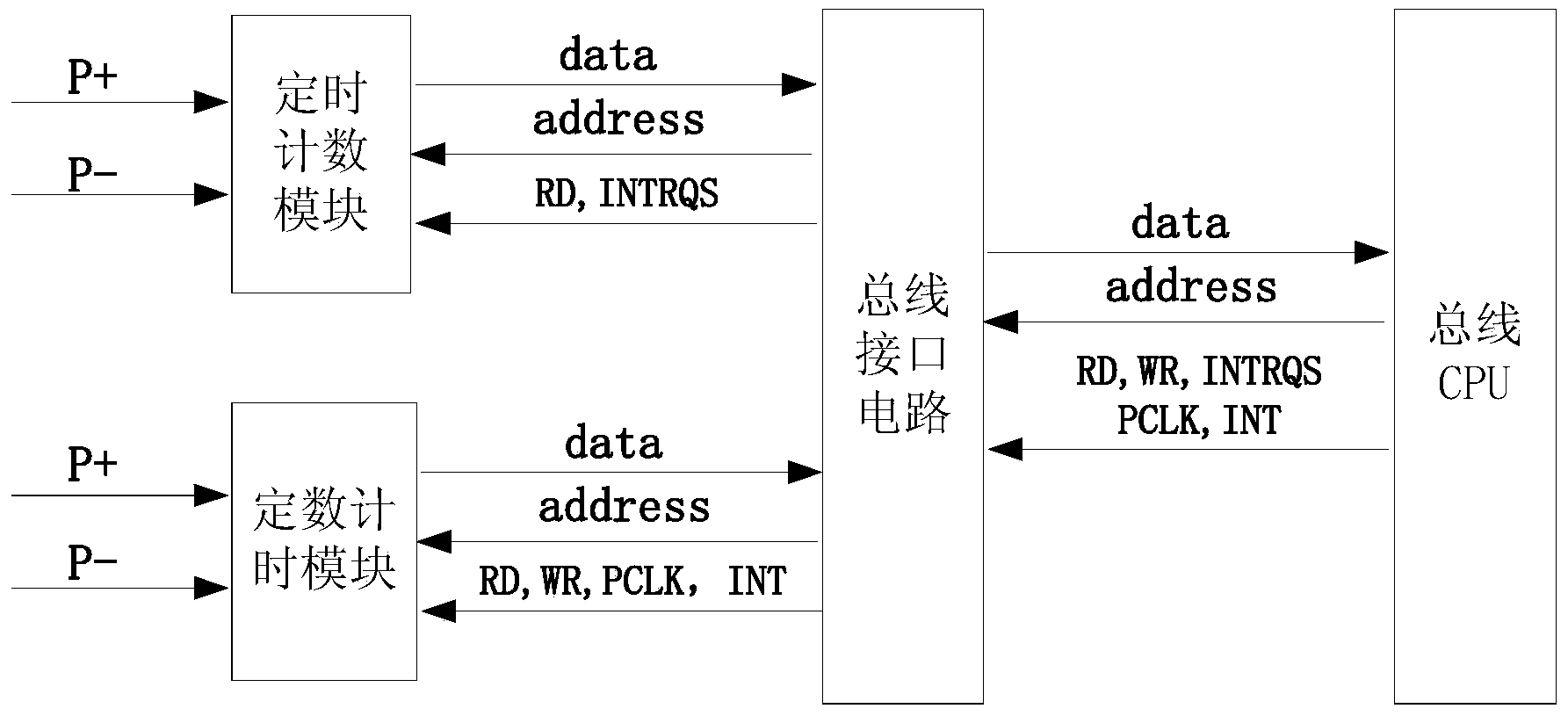

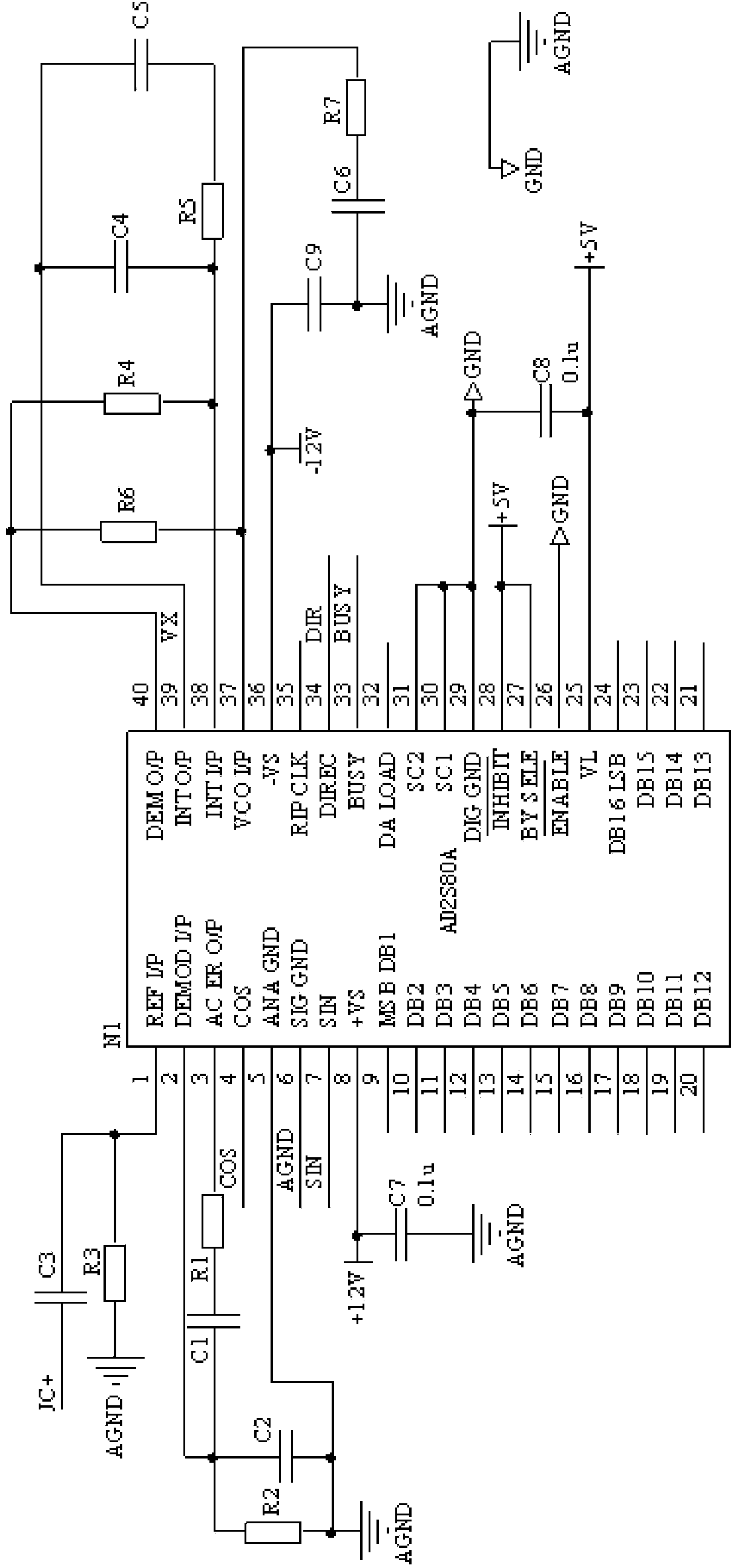

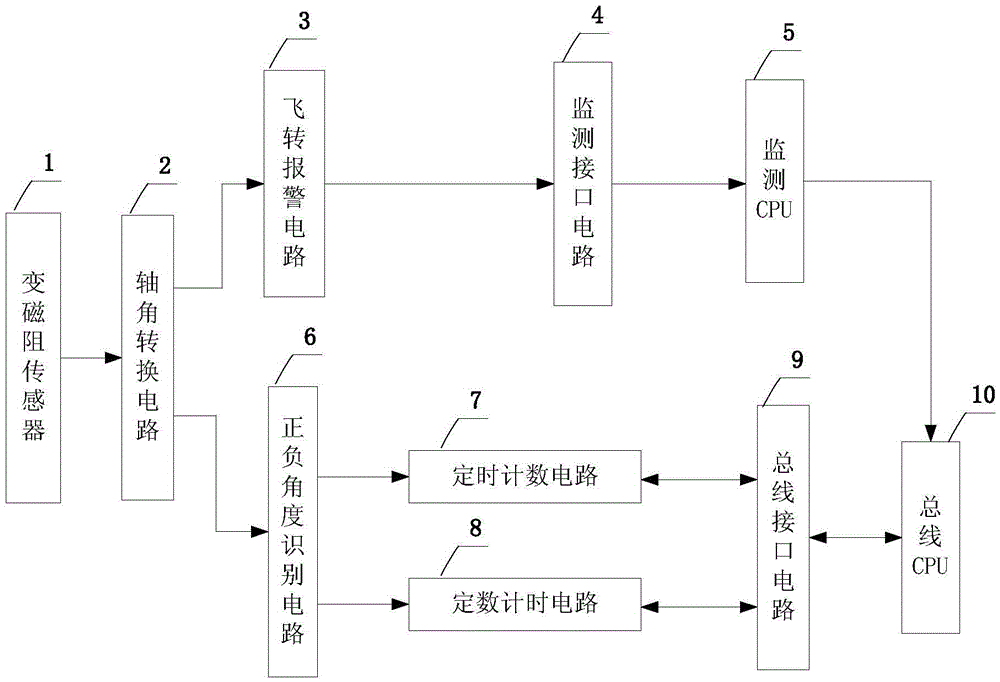

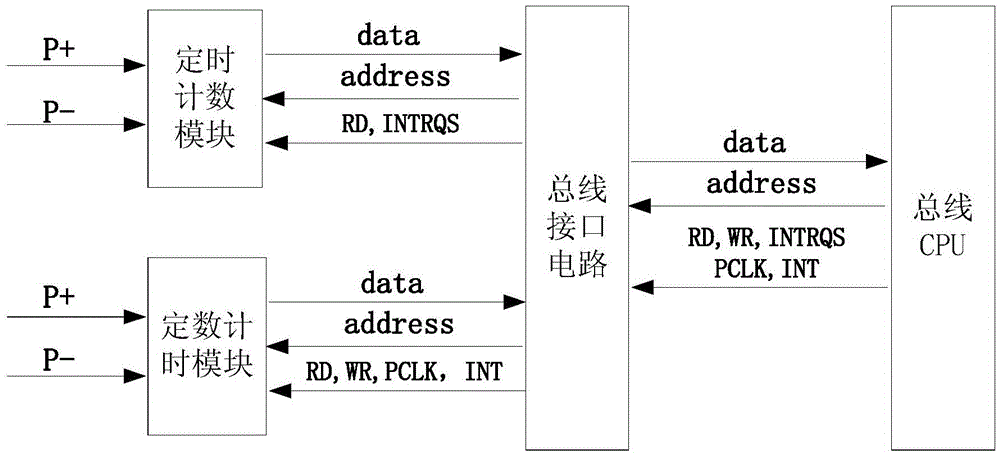

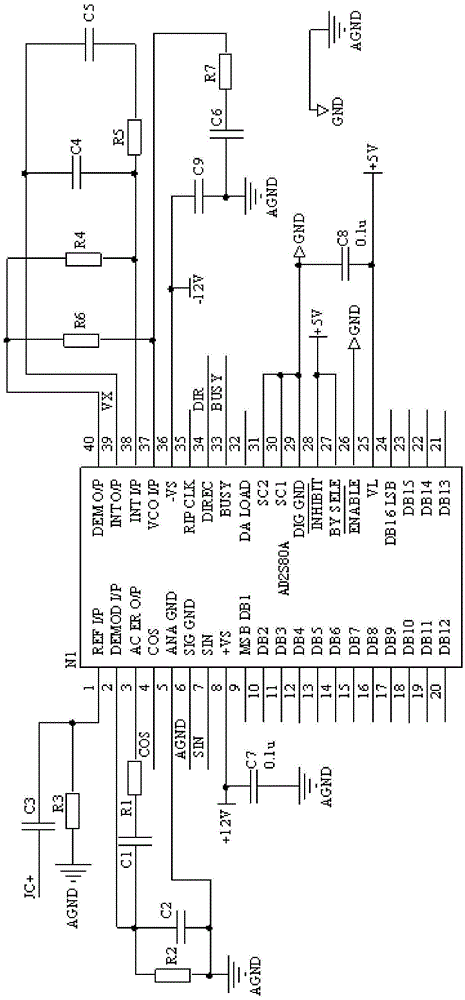

Angle measurement and fault diagnose system with spinning warning function

ActiveCN103776364AWith measuring angleWith measurement functionUsing electrical meansVariable reluctance sensorDefinite time

An angle measurement and fault diagnose system with a spinning warning function comprises a variable reluctance sensor (1), a shaft angle conversion circuit (2), a spinning warning circuit (3), a monitoring interface circuit (4), a monitoring CPU (5), a positive and negative angle identification circuit (6), a definite time counting circuit (7), a definite number timing circuit (8), a bus interface circuit (9) and a bus CPU (10). The shaft angle conversion circuit converts the output of the variable reluctance sensor into a pulse signal, the signal can be exported to the bus CPU by passing the positive and negative angle identification circuit, the definite time counting circuit, the definite number timing circuit and the bus interface circuit, and can be used for angle measurement and orientation identification. The spinning warning circuit is used for judging whether a tested object is over speed, and sends the over speed signal to the monitoring CPU through the monitoring interface circuit. The spinning warning circuit is simple in structure, has the functions of spinning warning, angle measurement and fault diagnose, can improve the reliability of the angle data measurement.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Rotation sensor with temperature measuring feature

InactiveUS20070129908A1Thermometer detailsThermometers using material expansion/contactionEngineeringRotation sensor

A temperature sensing system (100) for use with a variable reluctance sensor such as found in vehicle wheel bearing applications, which utilizes existing sensors (12) such as the antilock braking system or traction control system sensors as a direct current resistive temperature gauge. The temperature sensing system (100) includes electrical components (R4, C1) configured to separate the DC voltage (VDC(t)) representative of sensor temperature from the original magnetically induced AC voltage output signal (VSN1(t)) representative of the rotation such as vehicle wheel speed, thereby permitting the temperature sensing system (100) to be retrofitted and installed in vehicles or other components without significant alteration to an existing wiring harness or electrical components.

Owner:THE TIMKEN CO

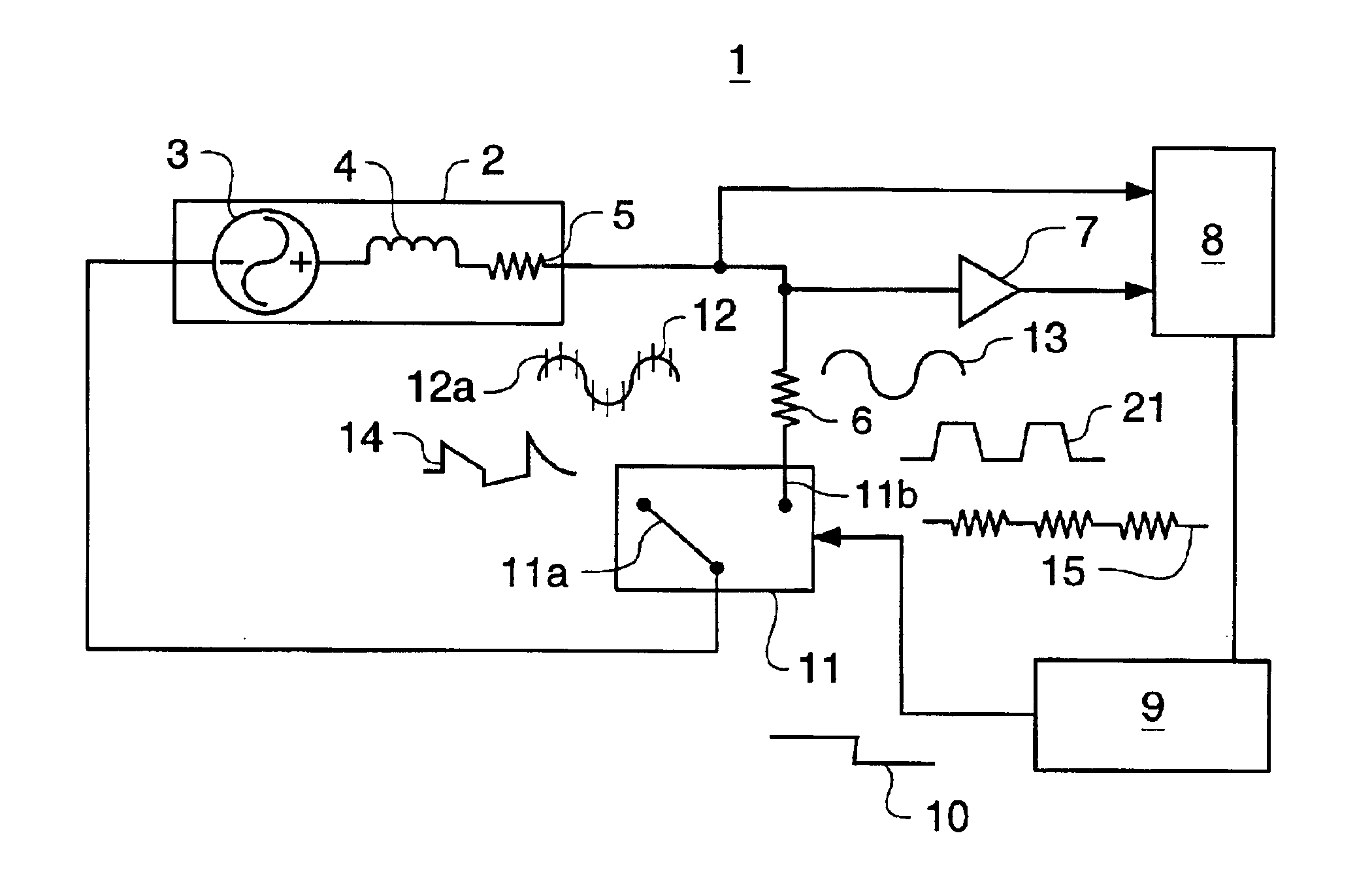

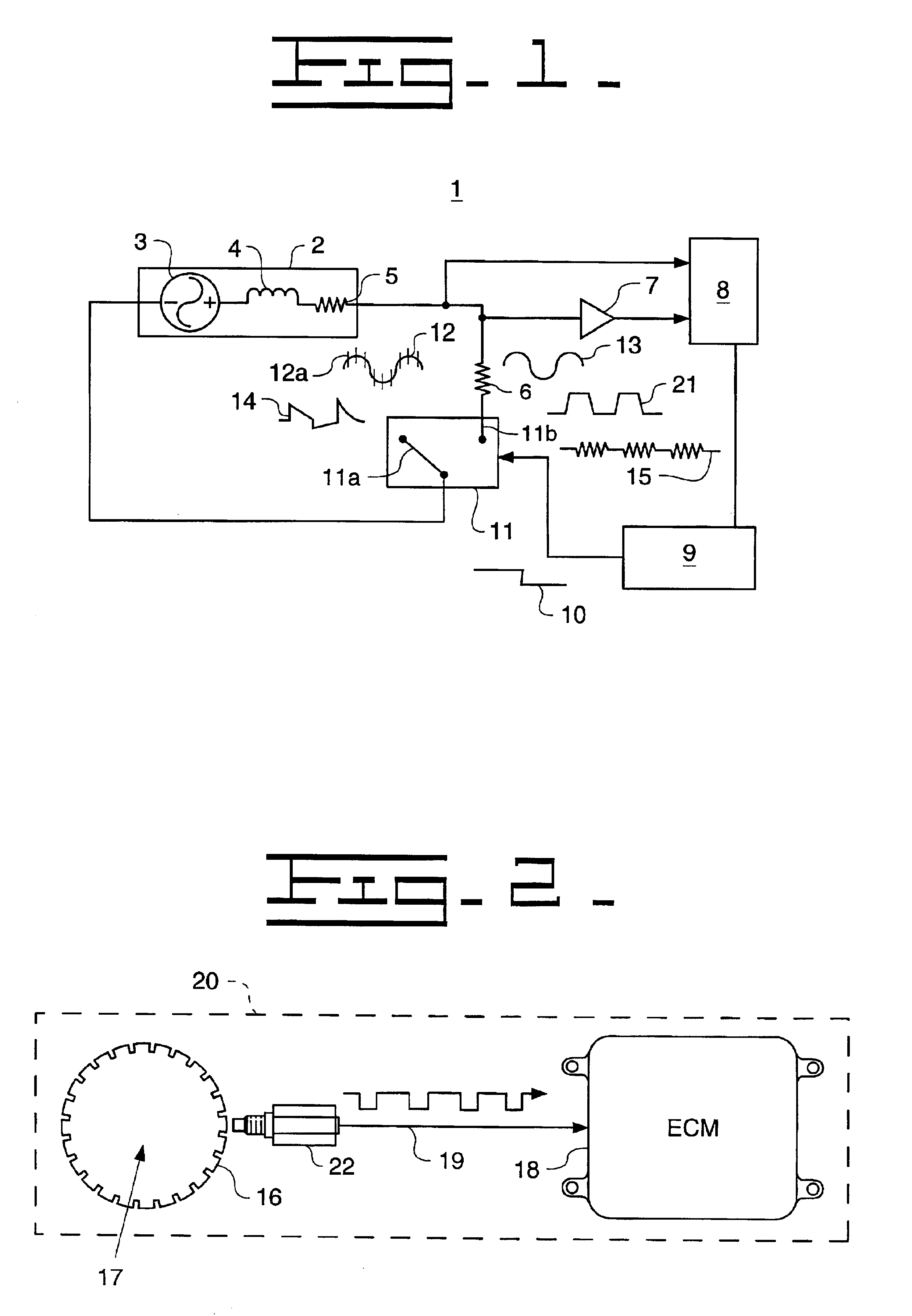

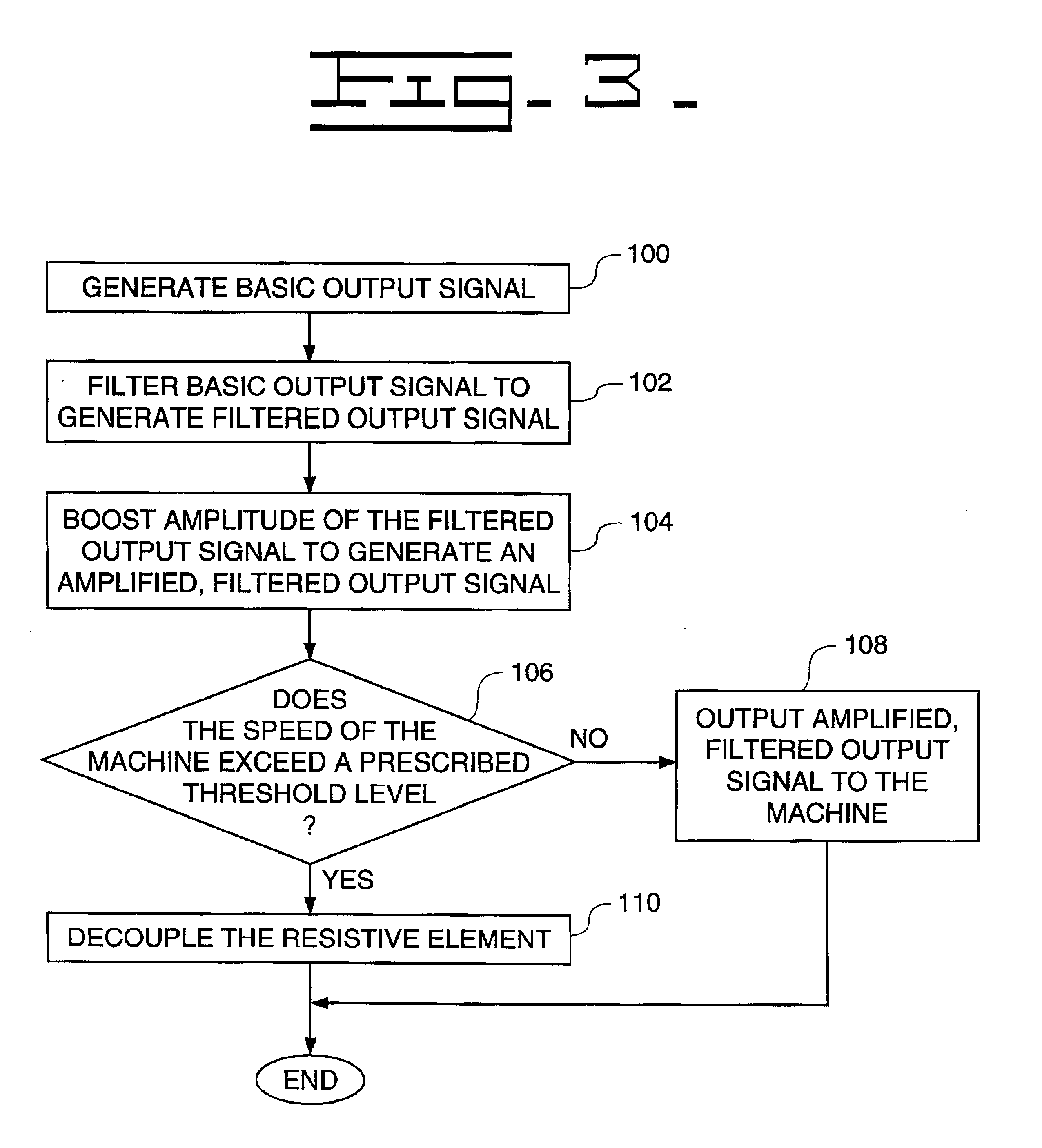

Amplification circuit for increasing variable reluctance sensor output

An apparatus and method for measuring a characteristic, such as speed, of a machine. A variable reluctance sensor (VRS) is coupled to a resistive element, which filters a portion of a basic output signal generated by the VRS having a frequency above a prescribed threshold level, thus removing high-frequency noise from the basic output signal. An amplifier amplifies the filtered output signal. The filtered, amplified output signal has an increased signal-to-noise ratio such that the machine characteristic, i.e. speed, can be more accurately measured during a slow speed operation. A controller generates a control signal received by a switching device to decouple the resistive element when machine speed exceeds a prescribed threshold level. Then, the basic output signal is used to measure the characteristic of the machine during normal machine operation.

Owner:CATERPILLAR INC

Variable reluctance position sensor

InactiveUS7990136B2Improve linearityReduce manufacturing costUsing electrical meansConverting sensor output electrically/magneticallyVariable reluctance sensorRelative motion

A variable reluctance analog position device designed to determine the position variation of a target made from a ferromagnetic material. The device includes at least one magnet, the target and the magnet defining a gap therebetween. A magnetosensitive element detects induction variation produced in the gap by relative movement of the target relative to the magnet. The magnet is magnetized in a direction essentially perpendicular to the front surface of the magnet, which defines one edge of the gap. The magnet includes a cavity open at the front surface thereof and the magnetosensitive element is housed in the cavity. Moreover, the target is provided with a specific geometric configuration determined such that the induction variation according to the position of the target corresponds to a pre-defined function.

Owner:MOVING MAGNET TECH

Speed or torque probe for gas turbine engines

ActiveUS8549931B2Relieve pressureEfficient transferWork measurementLinear/angular speed measurementVariable reluctance sensorMagnetic poles

There is provided a variable reluctance sensor for sensing the speed or torque of a shaft in a gear box or gas turbine engine, comprising a magnetic pole piece a conductive wire wrapped around the pole piece a housing surrounding the pole piece, the housing having a front face and at least one side wall, wherein, in use, the front face is positioned proximate to an object to be sensed wherein the pole piece is rigidly fixed to the side wall of the housing. This arrangement reduces microphony in the sensor.

Owner:WESTON AEROSPACE

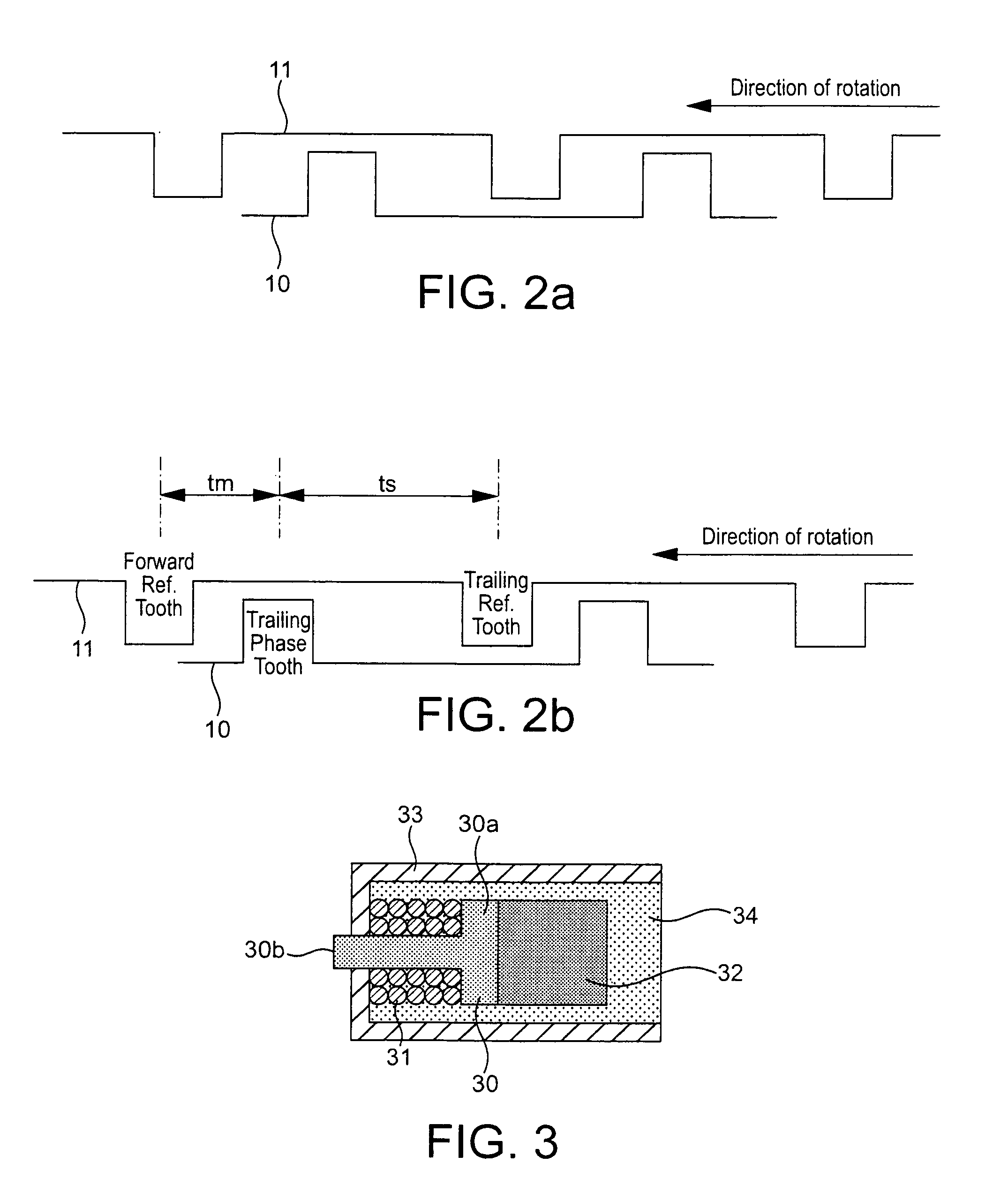

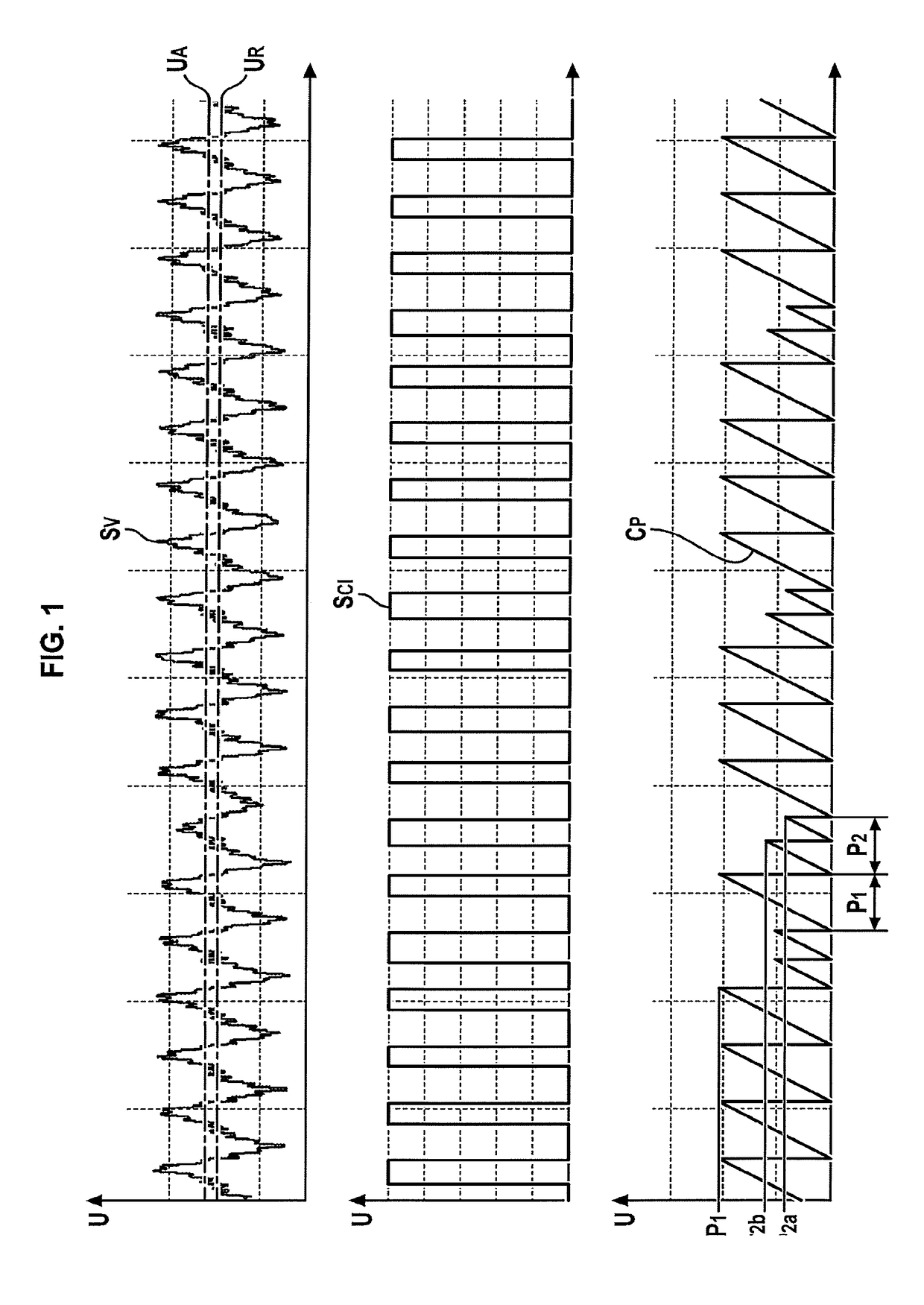

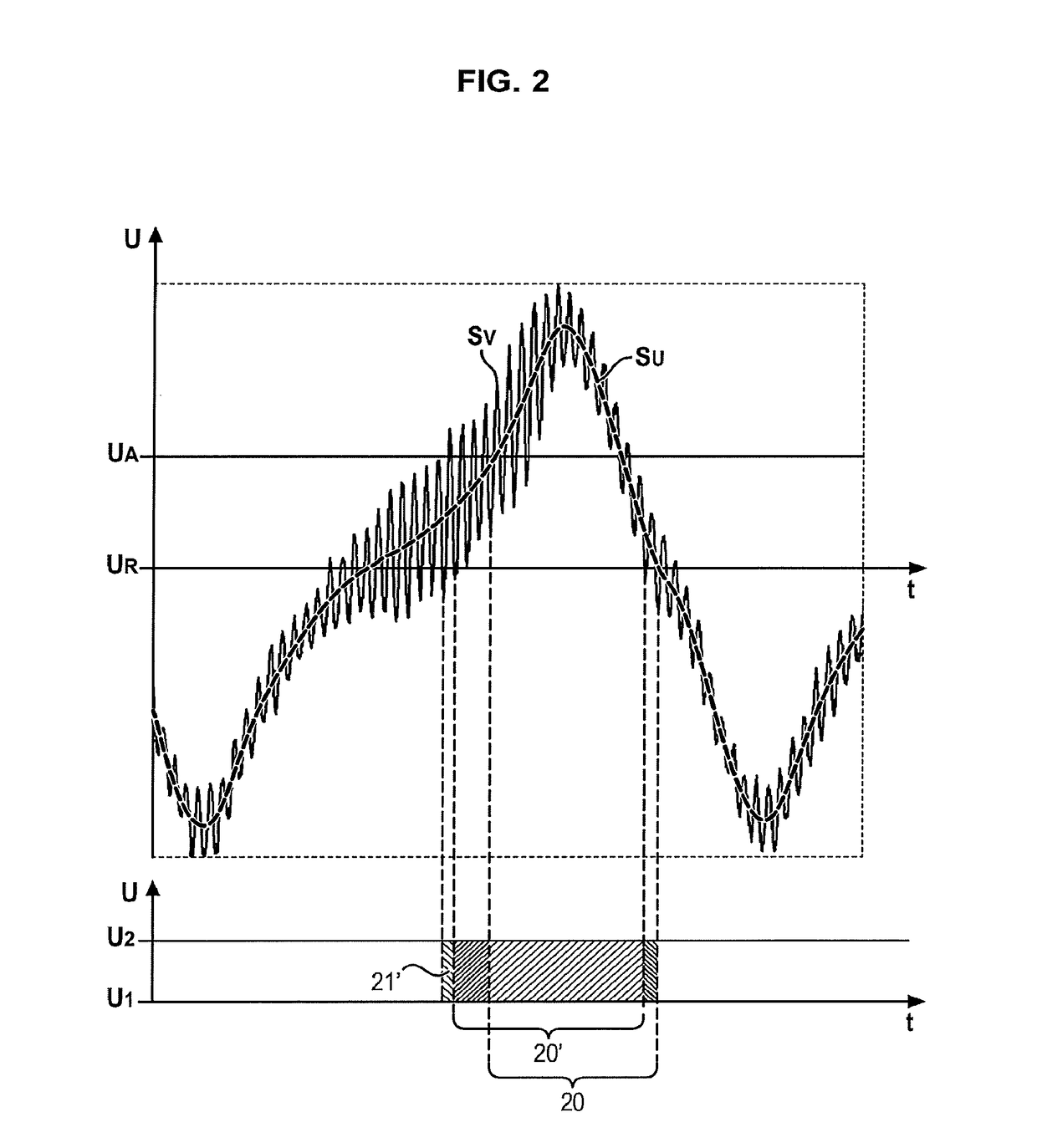

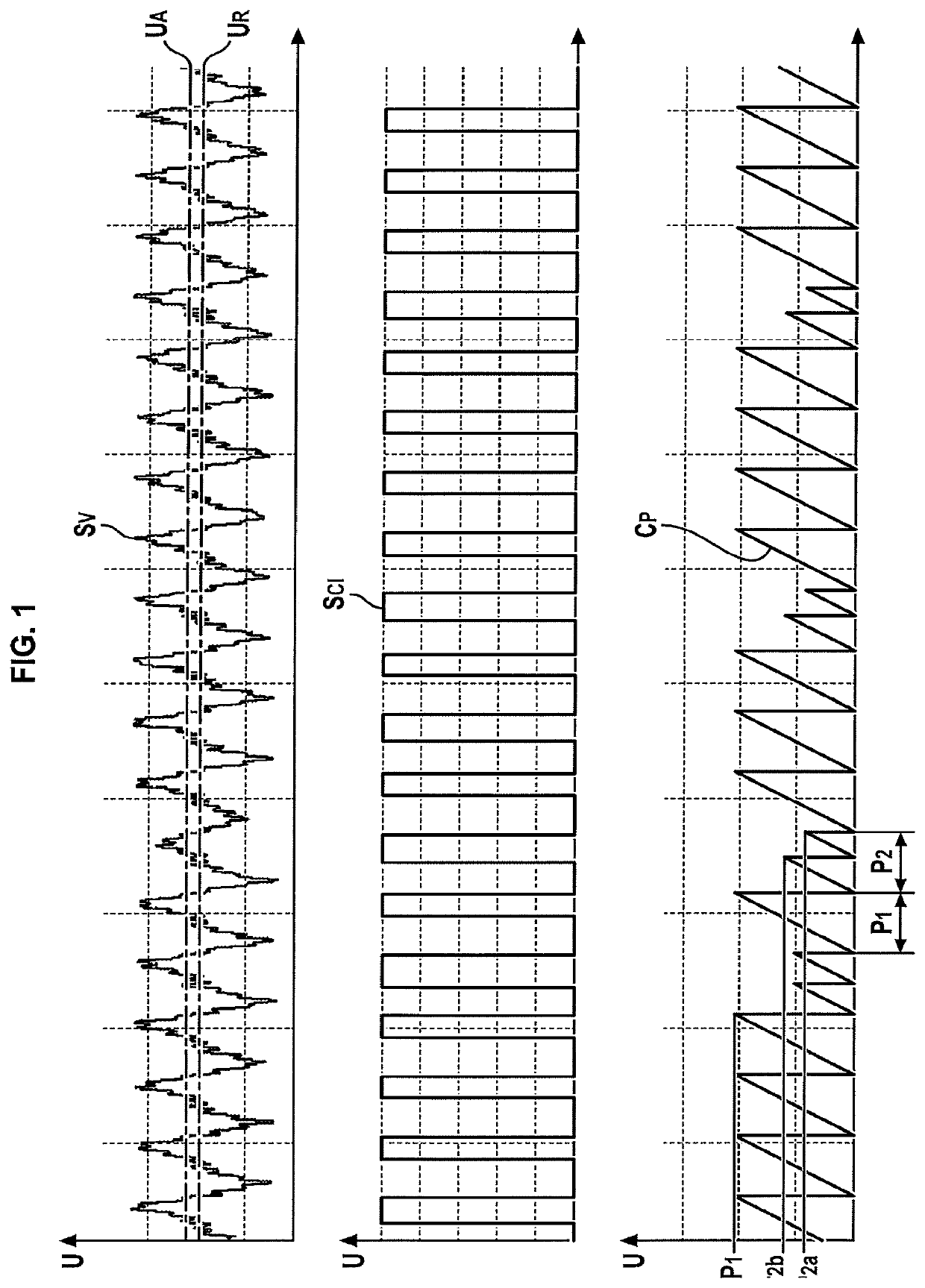

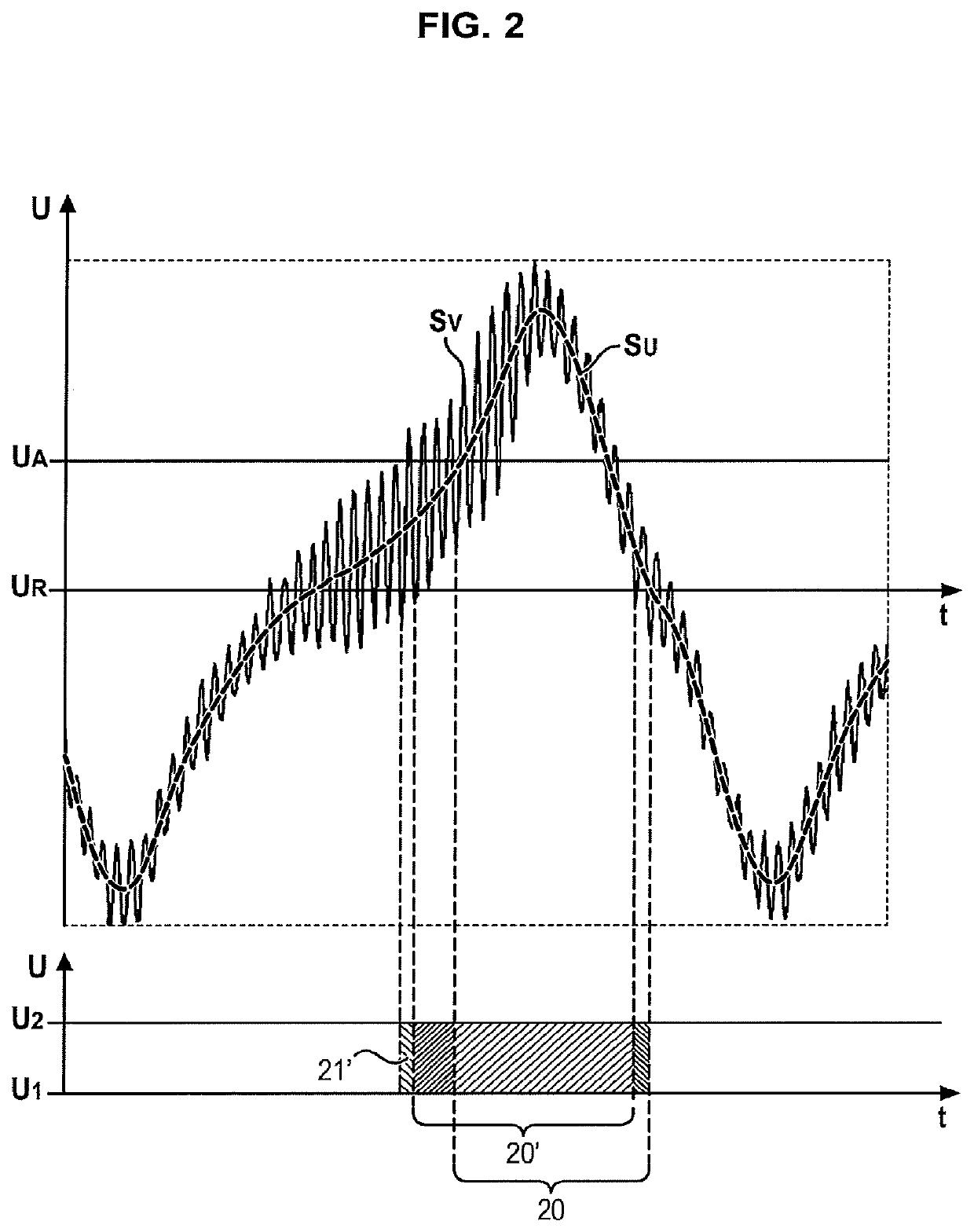

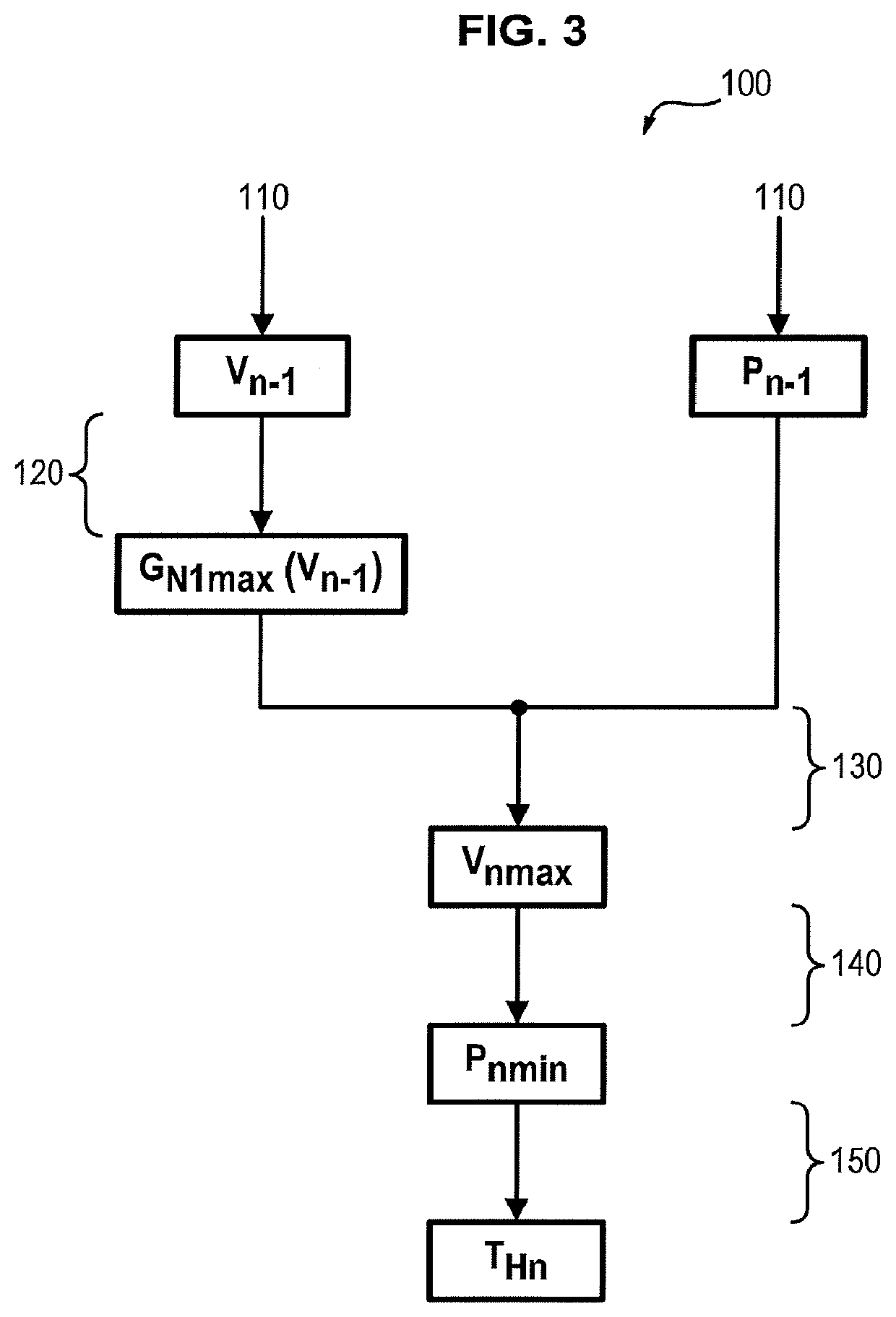

Processing method for a rotation speed signal of an aircraft engine shaft affected by noise

A processing method of an alternating signal produced by a variable reluctance sensor, including steps consisting of a raw window signal switching toward a low voltage level, respectively toward a high voltage level, calculation of a processed window signal using a value of the switching continuation duration calculated as a function of a value of shaft rotation speed, and based on the raw window signal, measurement of the shaft rotation speed, each switching of the processed window signal triggering the locking of the processed window signal, for a duration exactly equal to the switching continuation duration, so that the switches of the raw window signal are not translated into switches of the processed window signal during the locking, the processed window signal no longer being locked once the switching continuation duration has expired.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

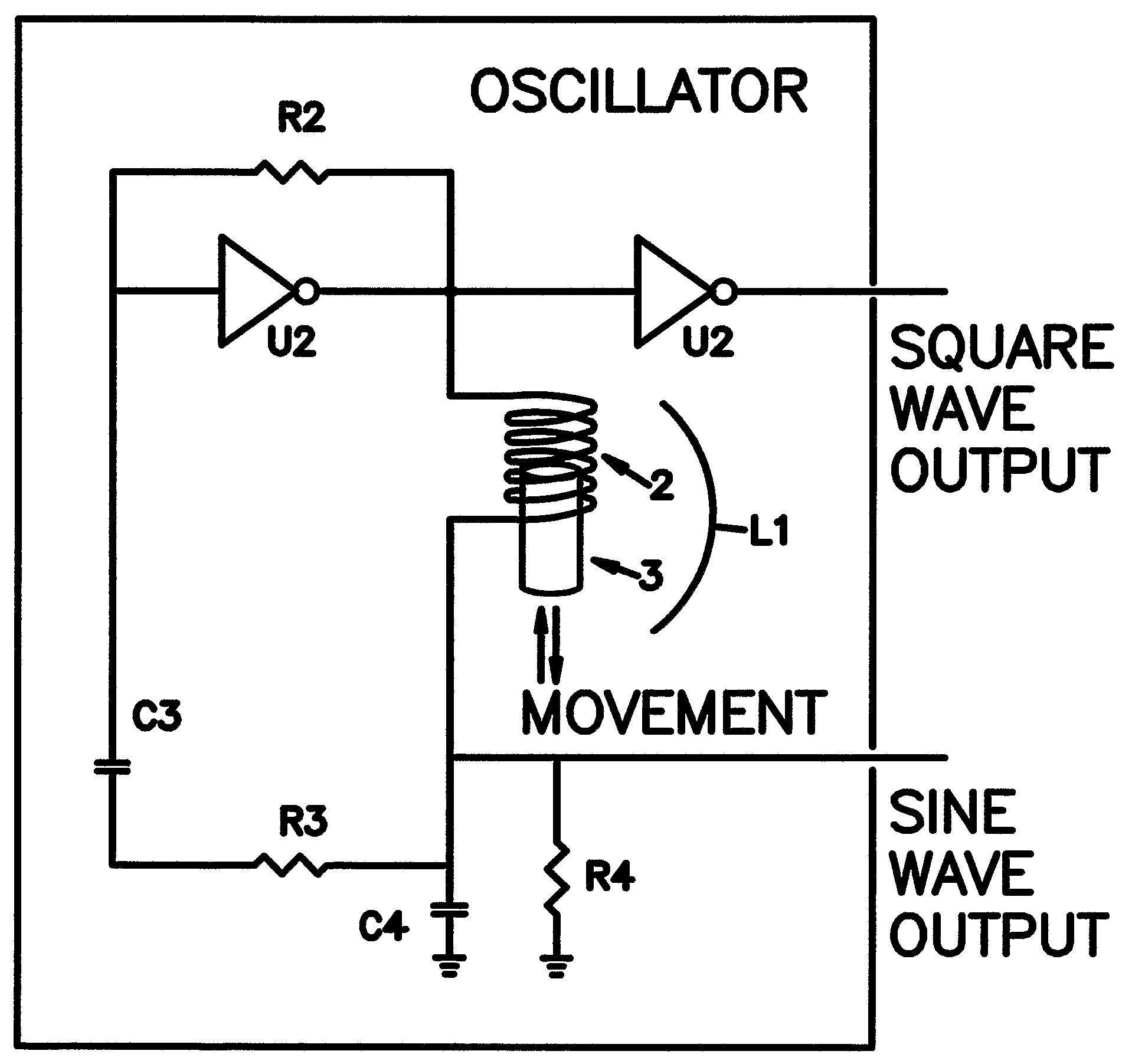

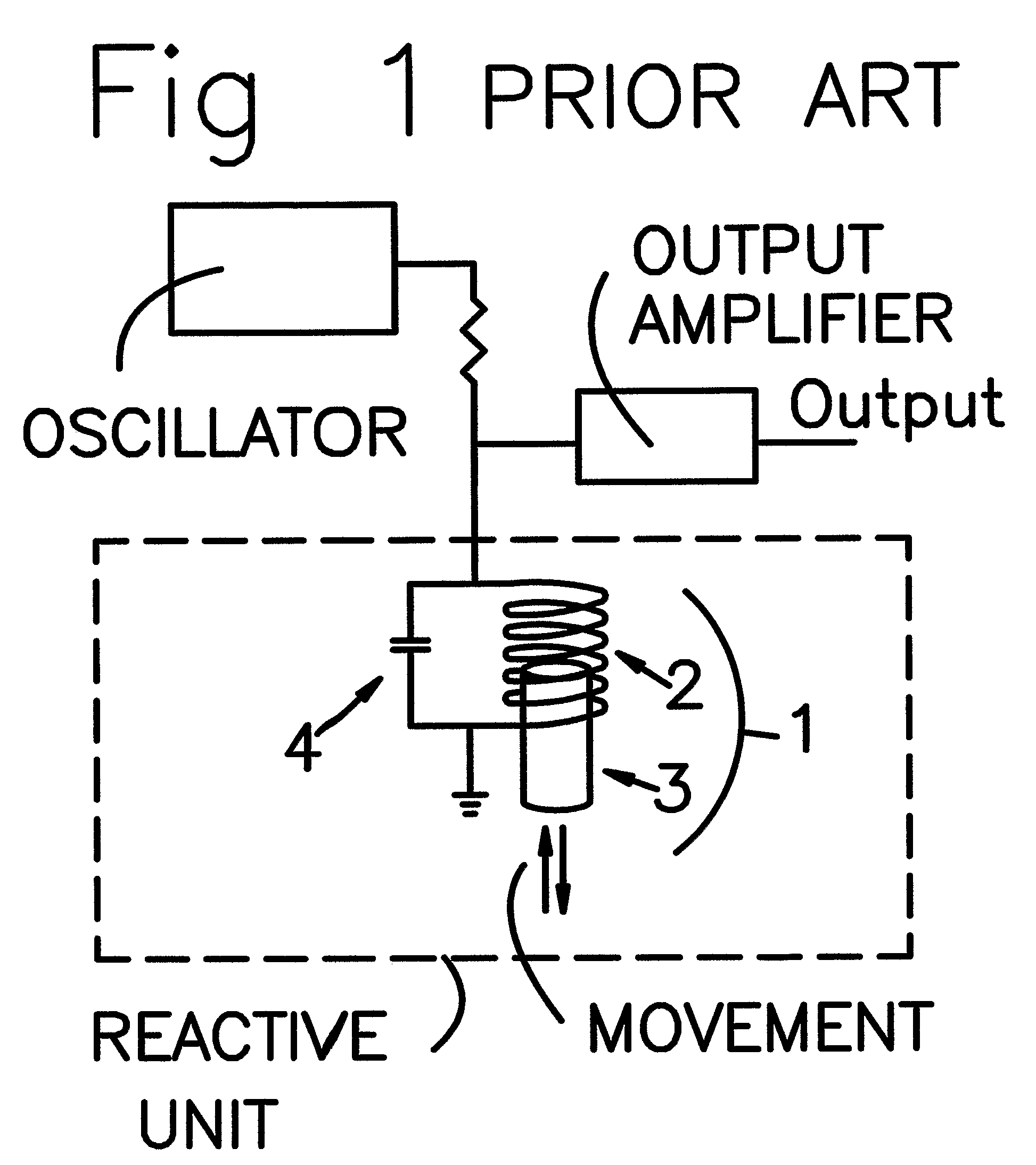

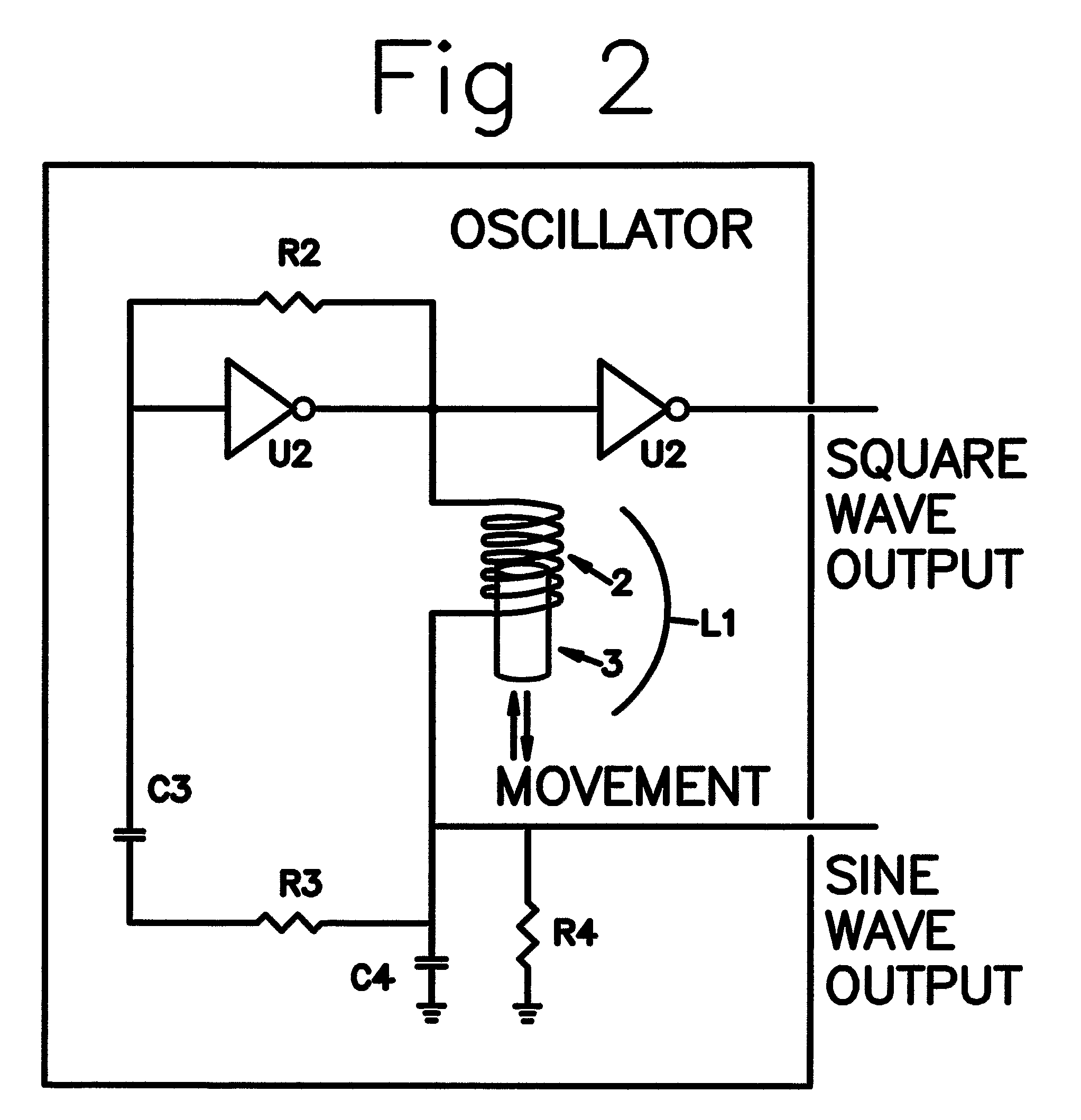

Resonant circuit for increasing variable reluctance sensor output

InactiveUS6885186B2Sampled-variable control systemsComputer controlSignal-to-noise ratio (imaging)Variable reluctance sensor

An apparatus and method for measuring a characteristic of a machine. A variable reluctance sensor (VRS) is coupled to the machine. A first switching device and capacitor, coupled in parallel with the VRS, boosts a variable amplitude of a basic output signal generated by the VRS to increase the signal-to-noise ratio. A control input of the first switching device receives signals, and a modified output signal is generated by the first switching device, having a variable amplitude that is substantially higher than the variable amplitude of the VRS. The modified output signal has an increased signal-to-noise ratio such that machine speed can be more accurately measured during a start-up phase.

Owner:CATERPILLAR INC

Printed circuit card-based proximity sensor and associated method of detecting a proximity of an object

ActiveUS20060290347A1Low costImprove reliabilityMagnetic field measurement using flux-gate principleElectronic switchingElectricityProximity sensor

A proximity sensor assembly includes a multilayer printed wiring board proximity sensor, the proximity sensor being operable as either a variable-reluctance sensor or an eddy current loss sensor. The proximity sensor includes a plurality of layers configured to form at least one wound coil disposed about at least a portion of a core. The coils are electrically driven to generate an alternating magnetic field such that the inductance of the coils changes when a permeable or conductive object is moved in relation to the magnetic field. The change in inductance is recognized and used to detect the proximity and presence of an object relative to the sensor.

Owner:SIMMONDS PRECISION PRODS

Induction Sensor

InactiveUS20070279138A1Improve performanceImprove output linearityAcceleration measurement using interia forcesUsing electrical meansVariable reluctance sensorPosition sensor

Position sensor circuits are disclosed for use with variable reluctance sensors. Variable reluctance sensors are described for linear, angular and rotary position measurement and for acceleration measurement.

Owner:DIGISENSORS

Systems and methods for performing vibration analysis using a variable-reluctance sensor

InactiveUS8400145B2Subsonic/sonic/ultrasonic wave measurementMagnetic property measurementsVariable reluctance sensorElectrical and Electronics engineering

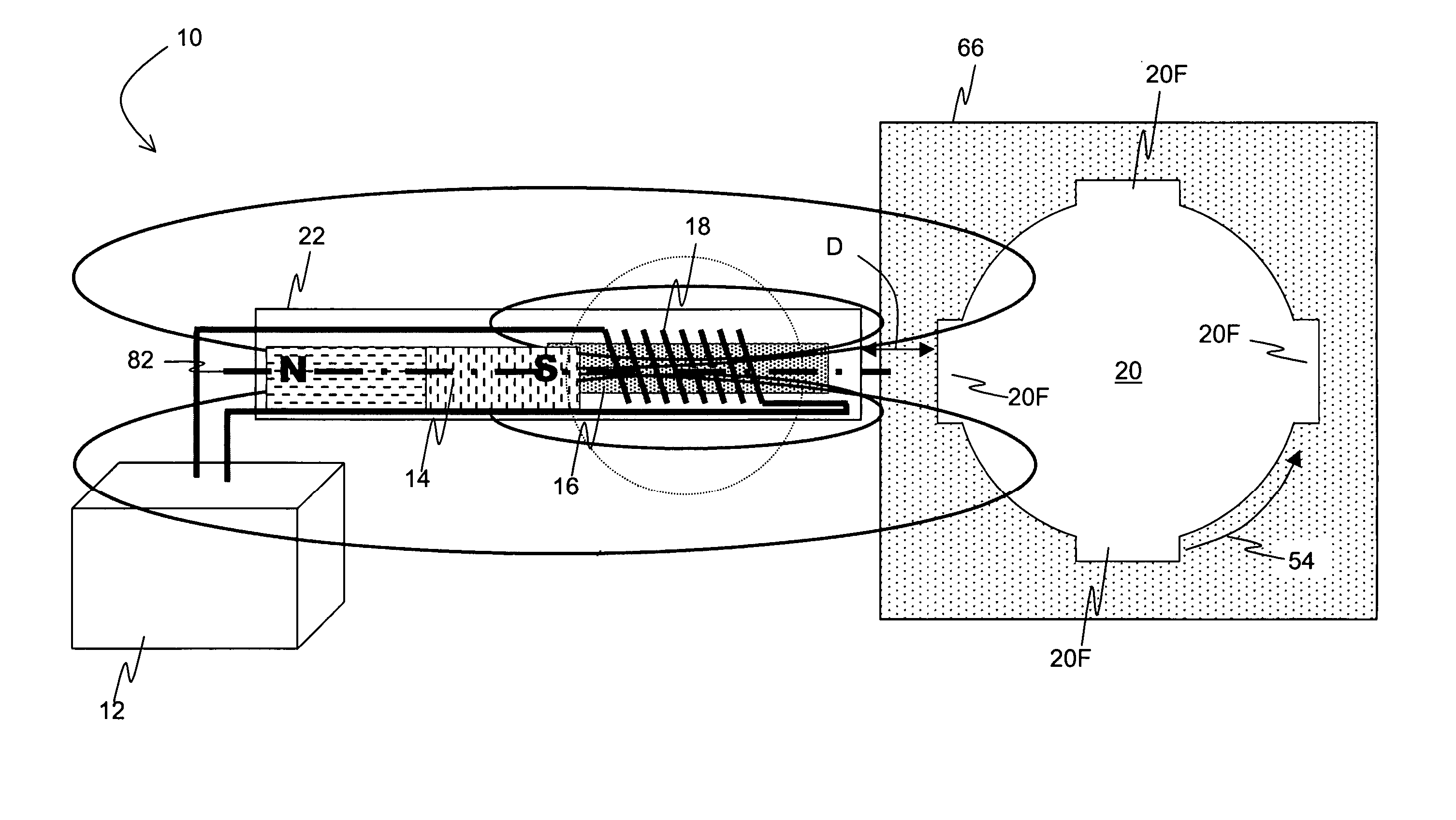

A balanced bridge variable-reluctance sensor with no internal circuit components, springs, or dielectric for performing vibration analysis in high-vibration, high-temperature, and other extreme environments. The present invention includes a variable-reluctance sensor in a vibration-sensing capacity. The present invention has inherently high reliability due to its simplicity. The sensor is solidly mounted to a structure that is being monitored and allows a vibration wave to pass through a floating sensor bridge. The sensor vibrates at the same frequency as the application being measured.

Owner:HONEYWELL INT INC

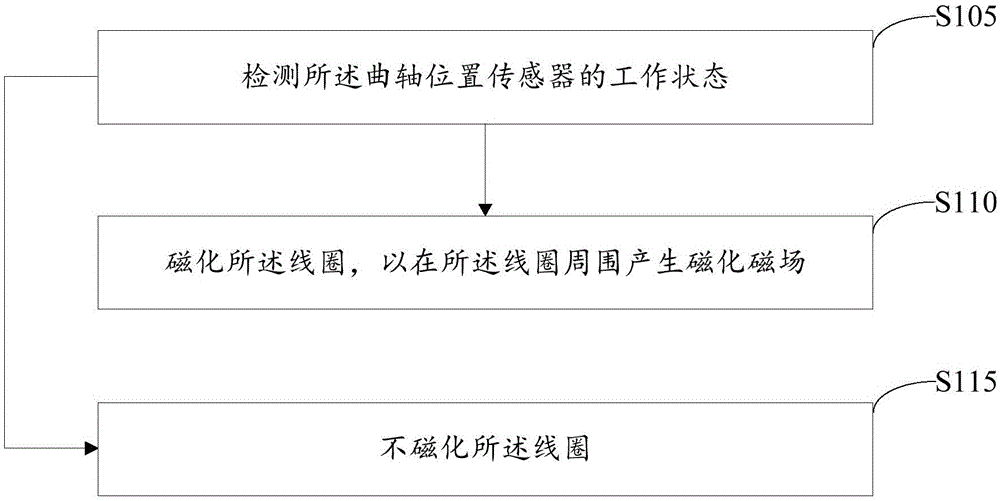

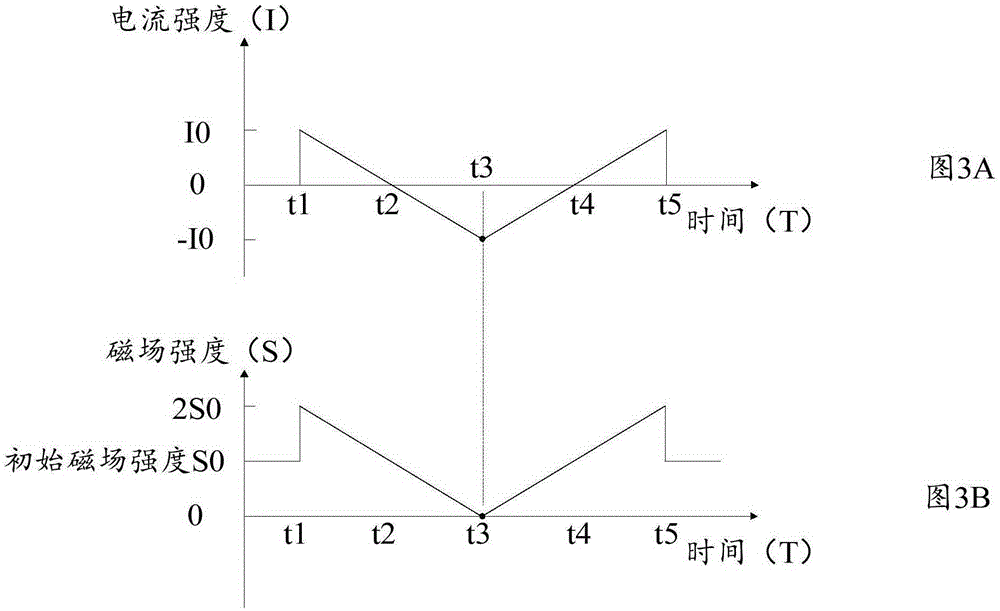

Purification method and device for variable-reluctance transducer

InactiveCN105127149AAutomatic cleaningReduce maintenance costsConverting sensor output electrically/magneticallyCleaning processes and apparatusPurification methodsVariable reluctance sensor

The invention discloses a purification method and device for a variable-reluctance transducer. The variable-reluctance transducer at least comprises a permanent magnet and a coil. The method includes the steps that the coil is magnetized, so that a magnetized magnetic field is generated around the coil; and the magnetized magnetic field is used for being overlapped with a fixed magnetic field around the permanent magnet, so that the total magnetic field around the variable-reluctance transducer is zero in at least at one period of time, and irony particles attracted onto the variable-reluctance transducer due to attraction of the fixed magnetic field are removed. Accordingly, by means of the purification method and device, the variable-reluctance transducer can be cleaned automatically, the variable-reluctance transducer does not need to be detached from the mounting position manually, and thus maintenance cost is lowered remarkably.

Owner:QOROS

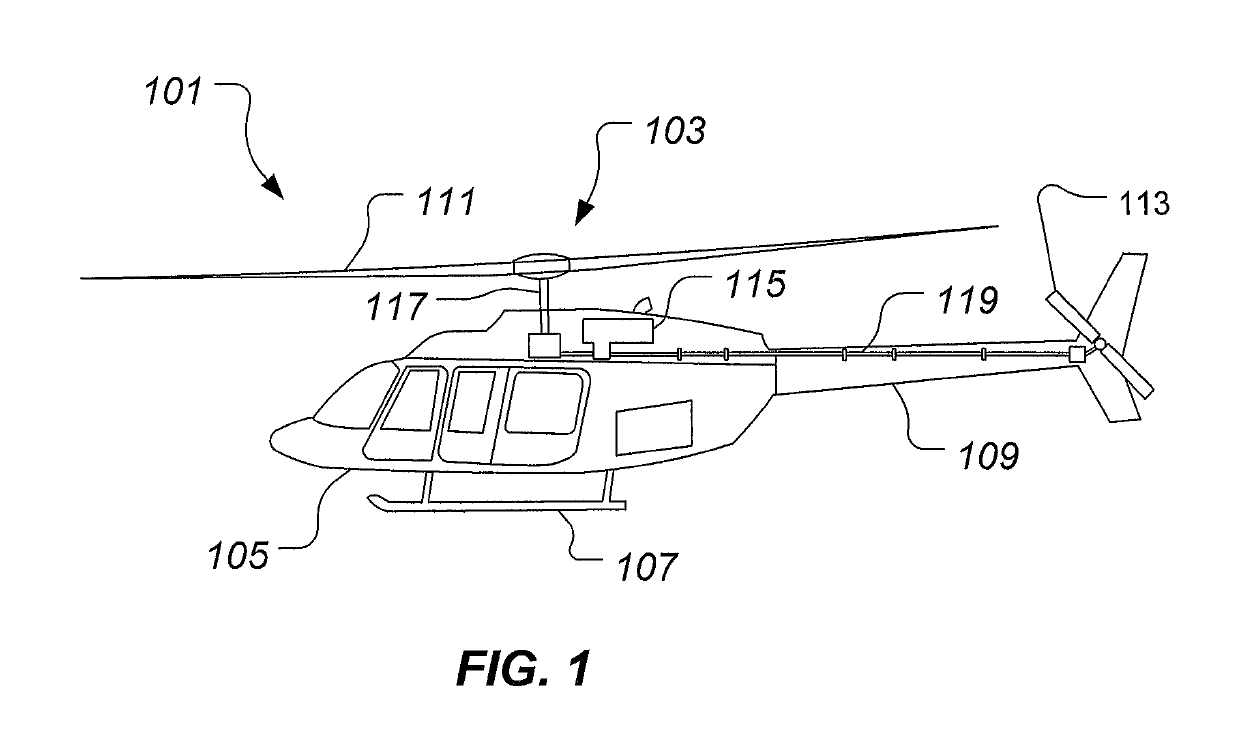

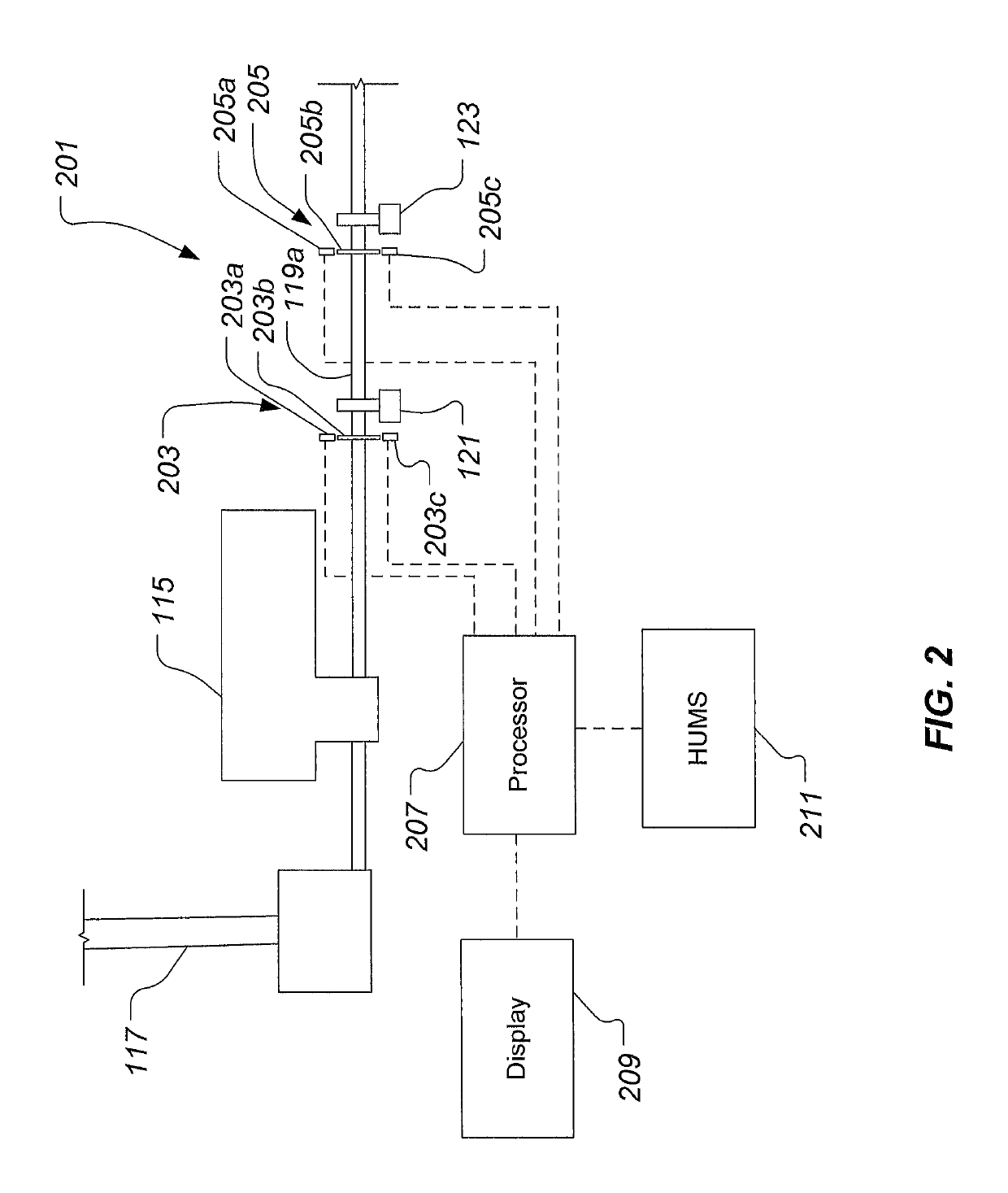

Torsional anomalies detection system

Owner:BELL HELICOPTER TEXTRON INC

Systems and methods for performing vibration analysis using a variable-reluctance sensor

InactiveUS20120007590A1Improve reliabilityInvention is simpleSubsonic/sonic/ultrasonic wave measurementMagnetic property measurementsVariable reluctance sensorEngineering

A balanced bridge variable-reluctance sensor with no internal circuit components, springs, or dielectric for performing vibration analysis in high-vibration, high-temperature, and other extreme environments. The present invention includes a variable-reluctance sensor in a vibration-sensing capacity. The present invention has inherently high reliability due to its simplicity. The sensor is solidly mounted to a structure that is being monitored and allows a vibration wave to pass through a floating sensor bridge. The sensor vibrates at the same frequency as the application being measured.

Owner:HONEYWELL INT INC

Processing method for a rotation speed signal of an aircraft engine shaft affected by noise

ActiveUS10830786B2Turbine/propulsion fuel controlMachines/enginesVariable reluctance sensorLow voltage

A processing method of an alternating signal produced by a variable reluctance sensor, including steps consisting of a raw window signal switching toward a low voltage level, respectively toward a high voltage level, calculation of a processed window signal using a value of the switching continuation duration calculated as a function of a value of shaft rotation speed, and based on the raw window signal, measurement of the shaft rotation speed, each switching of the processed window signal triggering the locking of the processed window signal, for a duration exactly equal to the switching continuation duration, so that the switches of the raw window signal are not translated into switches of the processed window signal during the locking, the processed window signal no longer being locked once the switching continuation duration has expired.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Device and method for determining hydraulic unit output speed in hydraulic mechanical gearing means

The output speed of a hydrostatic unit in a transmission is determined using a pair of variable reluctance sensors, one on a gear driven by the hydrostatic unit output and the other on the carrier of the planetary system. One of the two sensors will always be measuring a relatively high speed from which the hydro output is directly determined or indirectly determined using the current engine speed. Thus the frequency of the speed sensor used to determine the hydrostatic unit output speed is not decreased at slow hydrostatic unit output speeds.

Owner:DEERE & CO +1

An Angle Measurement and Fault Diagnosis System with Flying Alarm Function

ActiveCN103776364BImprove effectivenessImprove reliabilityUsing electrical meansVariable reluctance sensorDefinite time

An angle measurement and fault diagnose system with a spinning warning function comprises a variable reluctance sensor (1), a shaft angle conversion circuit (2), a spinning warning circuit (3), a monitoring interface circuit (4), a monitoring CPU (5), a positive and negative angle identification circuit (6), a definite time counting circuit (7), a definite number timing circuit (8), a bus interface circuit (9) and a bus CPU (10). The shaft angle conversion circuit converts the output of the variable reluctance sensor into a pulse signal, the signal can be exported to the bus CPU by passing the positive and negative angle identification circuit, the definite time counting circuit, the definite number timing circuit and the bus interface circuit, and can be used for angle measurement and orientation identification. The spinning warning circuit is used for judging whether a tested object is over speed, and sends the over speed signal to the monitoring CPU through the monitoring interface circuit. The spinning warning circuit is simple in structure, has the functions of spinning warning, angle measurement and fault diagnose, can improve the reliability of the angle data measurement.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com