An Angle Measurement and Fault Diagnosis System with Flying Alarm Function

A fault diagnosis system and angle measurement technology, applied in the field of measurement and control systems, can solve problems such as single measurement means, inability to complete angle measurement and real-time fault diagnosis at the same time, and fault diagnosis lag, so as to improve safety, improve fault diagnosis capabilities, and improve Effects of Validity and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation of the system will be described below in conjunction with the accompanying drawings.

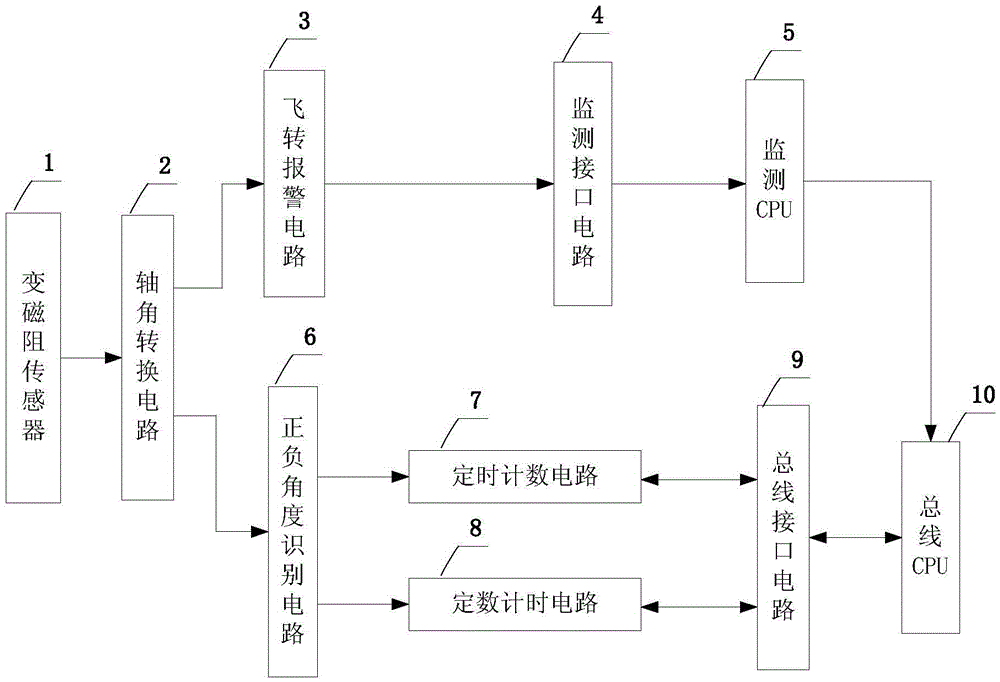

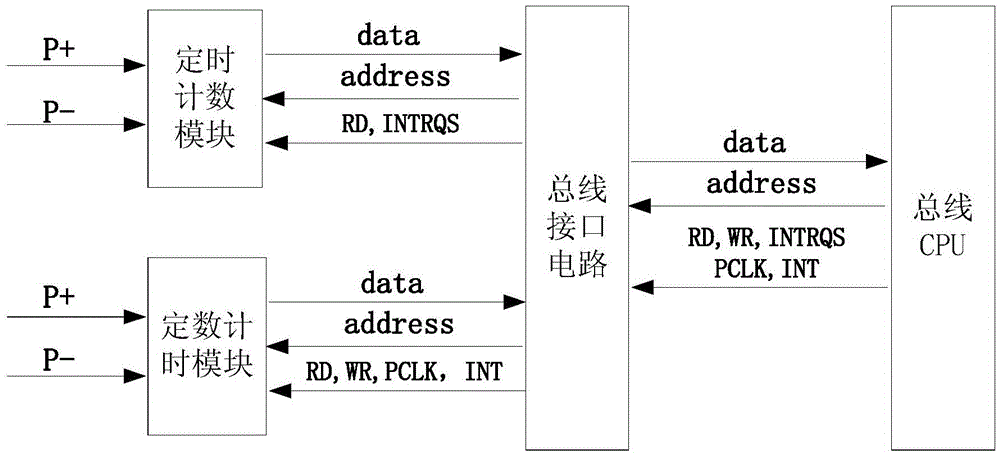

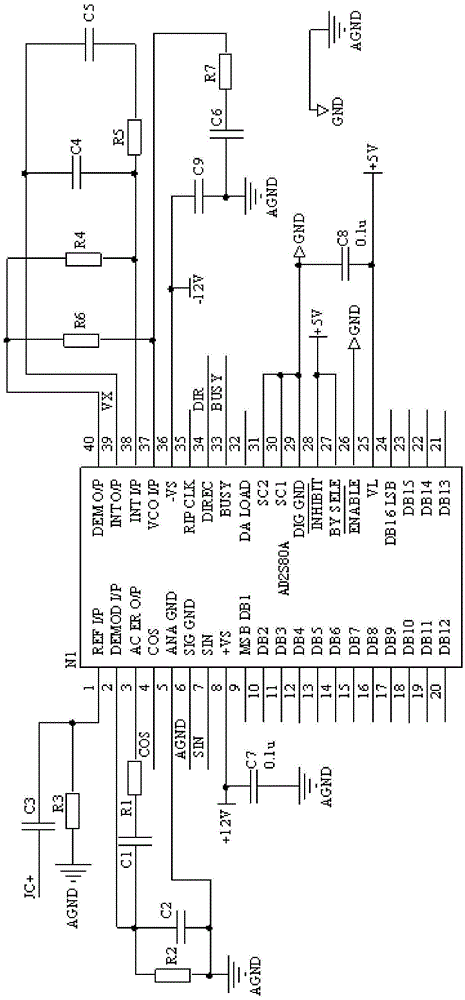

[0020] like figure 1 As shown, the present invention has an angle measurement and fault diagnosis system with a flying alarm function, including a variable reluctance sensor 1, a shaft angle conversion circuit 2, a flying alarm circuit 3, a monitoring interface circuit 4, a monitoring CPU 5, and a positive and negative angle identification circuit 6. Timing counting circuit 7, fixed number timing circuit 8, bus interface circuit 9, bus CPU10; variable reluctance sensor 1 is used to measure the motor speed; shaft angle conversion circuit 2 converts the output of variable reluctance sensor 1 into an angle pulse signal, Positive and negative logic signals and speed voltage signals; the angle pulse signal and the positive and negative logic signals are logically converted and signal processed by the positive and negative angle identification circuit 6, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com