Patents

Literature

38results about How to "Reduce temperature measurement error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

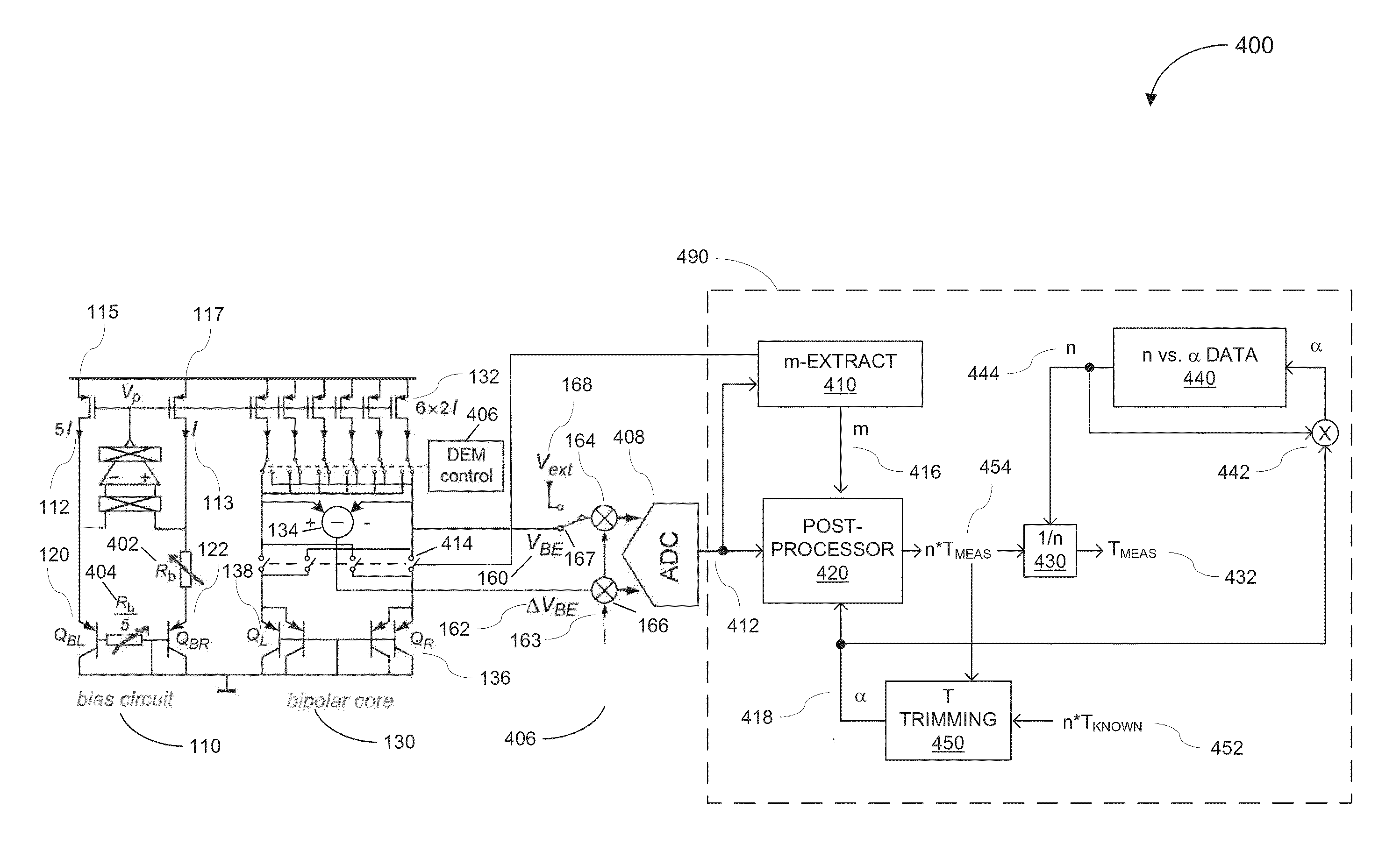

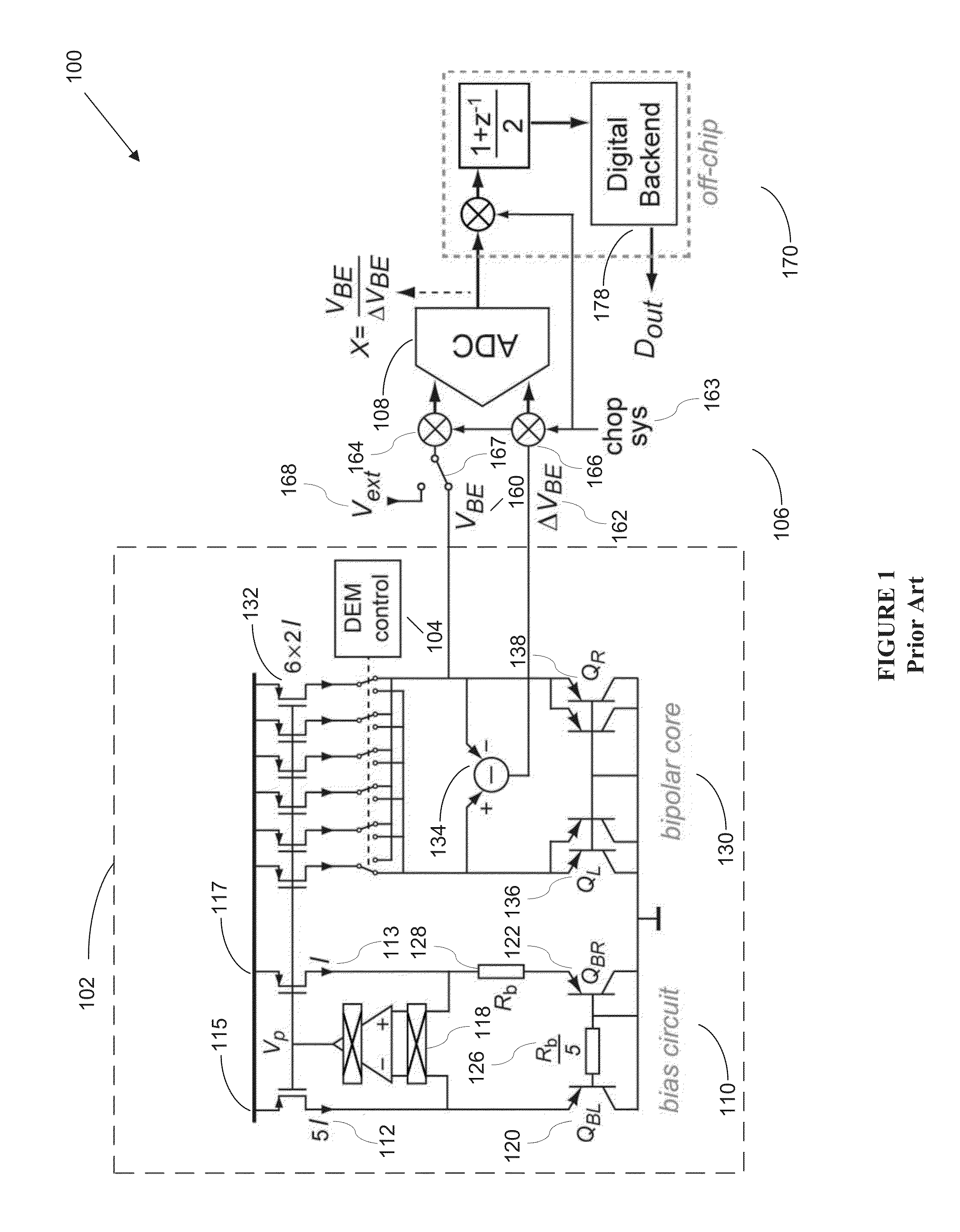

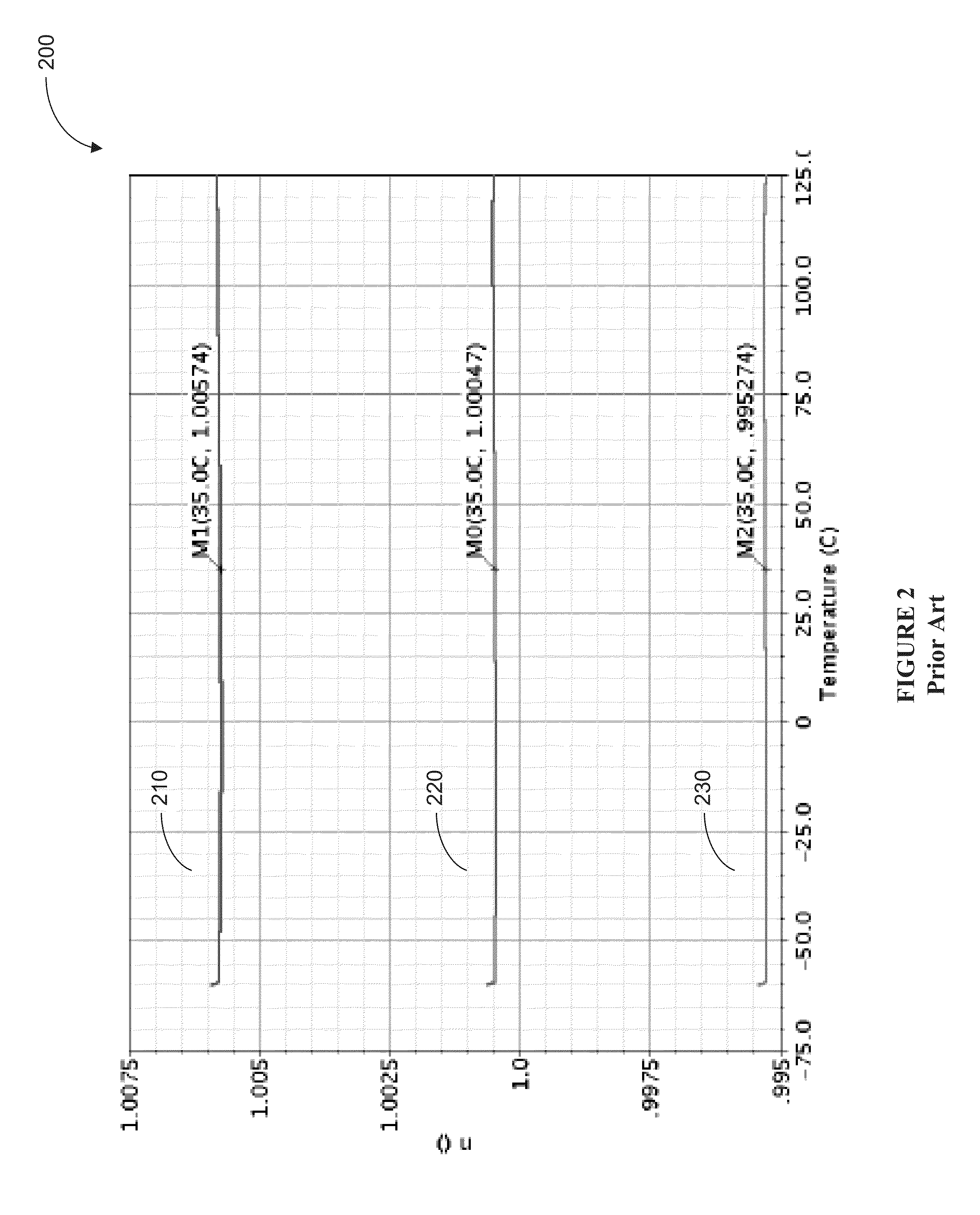

Systems and methods for on-chip temperature sensor

InactiveUS20150117495A1Reduce temperature measurement errorReduce mismatch effectsThermometers using electric/magnetic elementsUsing electrical meansElectrical and Electronics engineeringSaturation current

Various embodiments of the invention use the characteristics of BJTs to compute parameter values required to de-embed the effects of non-idealities including BJT's-mismatch in the reverse saturation current and process-dependent injection factor. In some embodiments, a temperature sensor circuit and method provide high temperature accuracy in a low-cost way by individually calibrating each part, thereby, eliminating the need to accurately measure temperature with a precision temperature sensor.

Owner:MAXIM INTEGRATED PROD INC

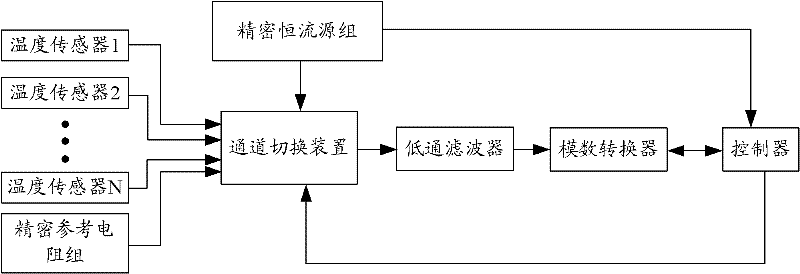

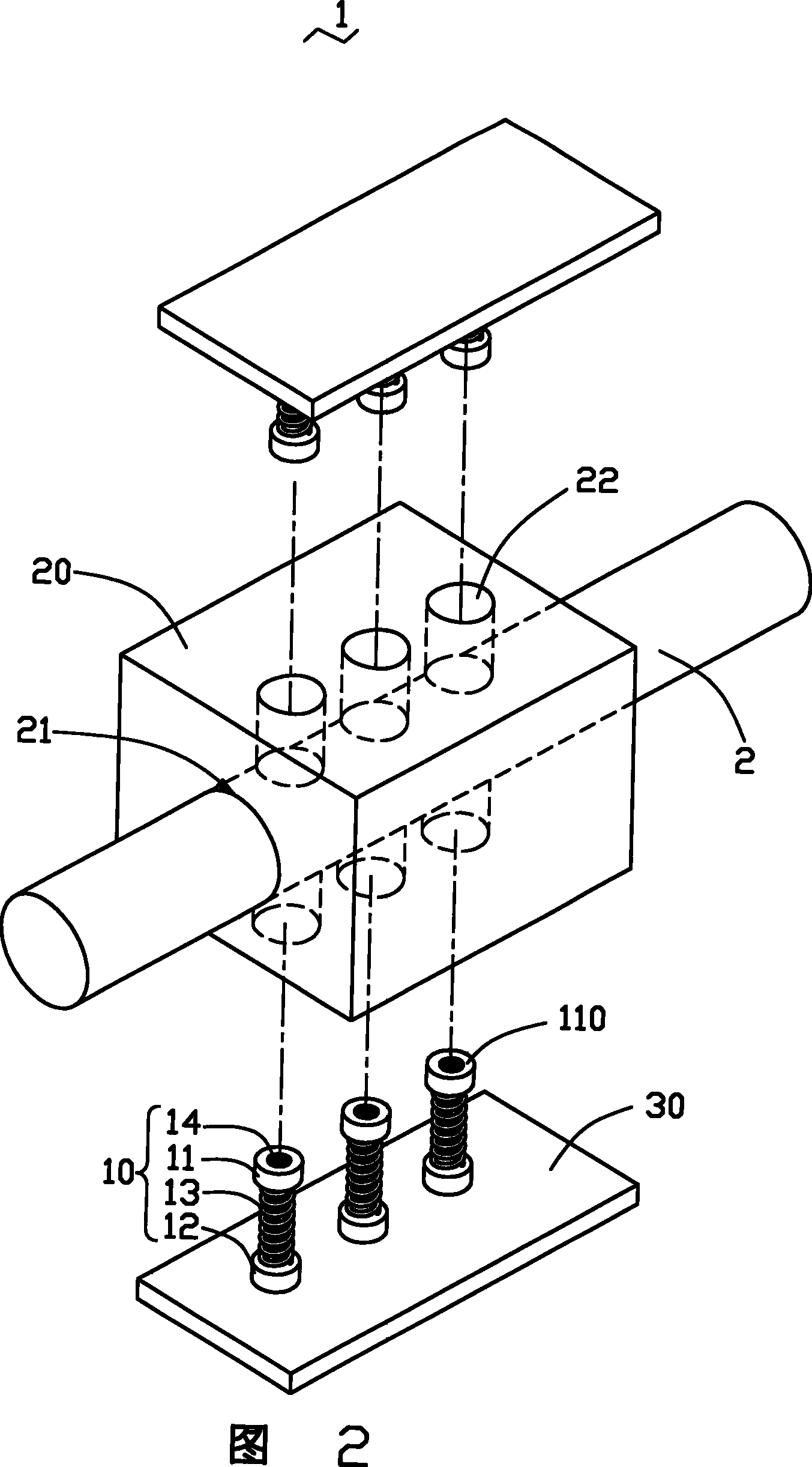

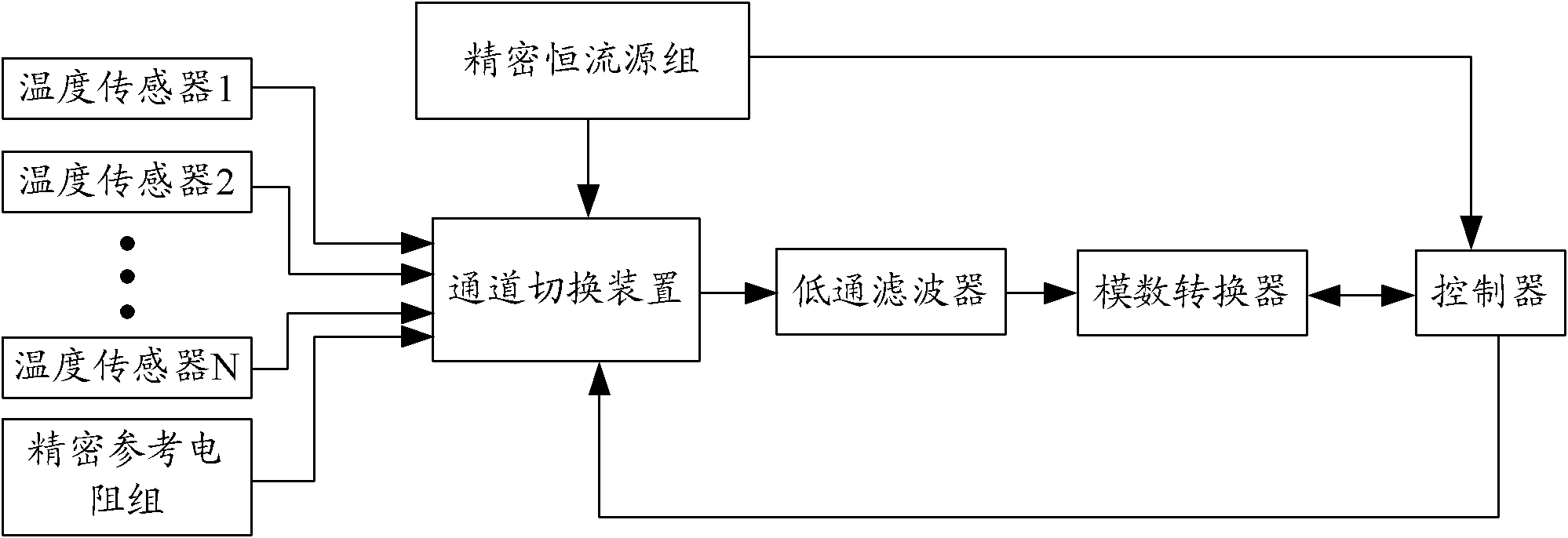

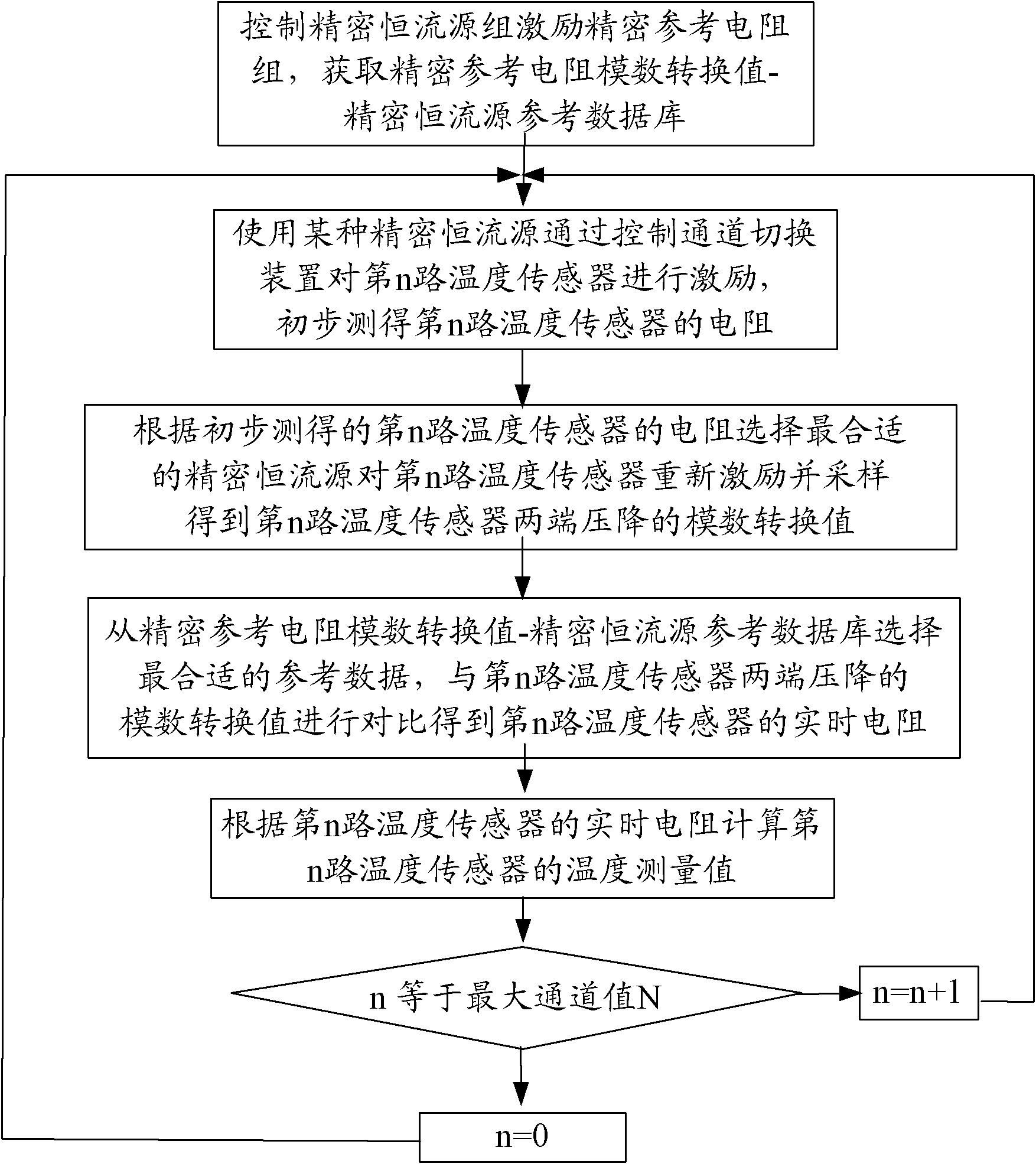

Temperature measuring device and temperature measuring method thereof

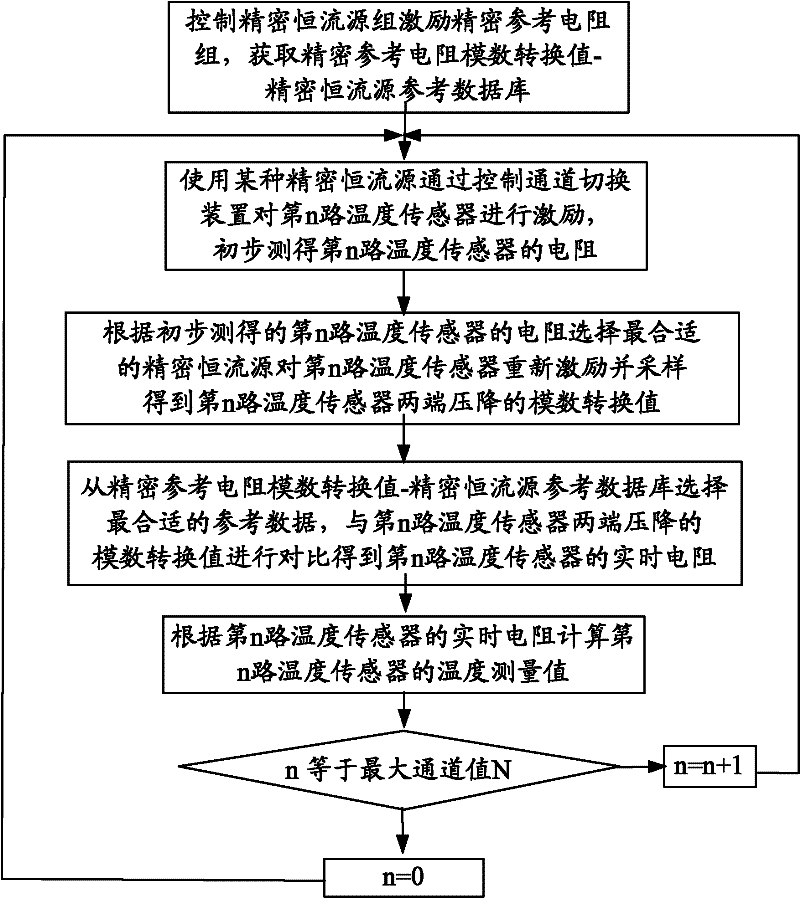

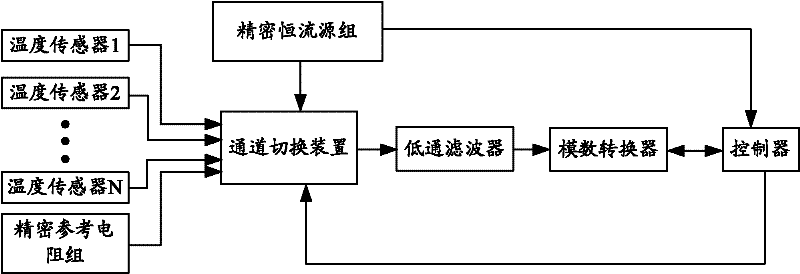

ActiveCN102539001AReduce temperature measurement errorThermometers using electric/magnetic elementsUsing electrical meansElectrical resistance and conductanceSignal processing circuits

The invention provides a temperature measuring device, comprising at least two paths of temperature sensors, a precise reference resistor group, a channel switching device, a precise constant-current source group, a low-pass filter, an analog / digital converter and a controller, wherein the temperature sensors and the channel switching device constitute a temperature measuring channel, and the low-pass filter and the analog / digital converter are connected to constitute a signal processing circuit; the temperature sensors, the precise constant-current source group and the precise reference resistor group are connected with the low-pass filter through the channel switching device; and the controller is respectively connected with the channel switching device, the precise constant-current sources and the analog / digital converter and used for controlling the selection of the precise reference resistors of the precise reference resistor group, the precise constant-current sources of the precise constant-current source group and temperature measuring channels and processing digital signals of the analog / digital converter.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

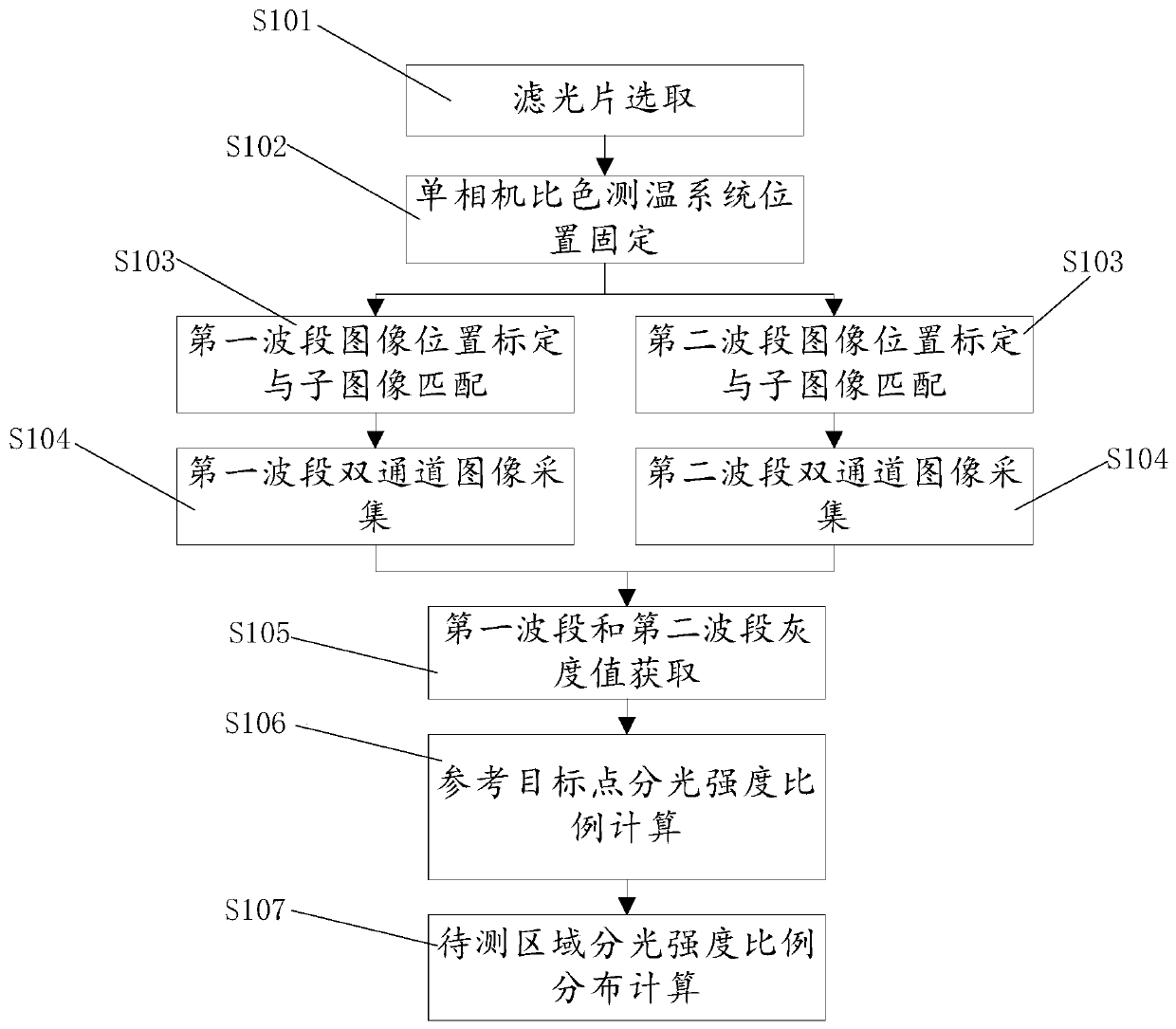

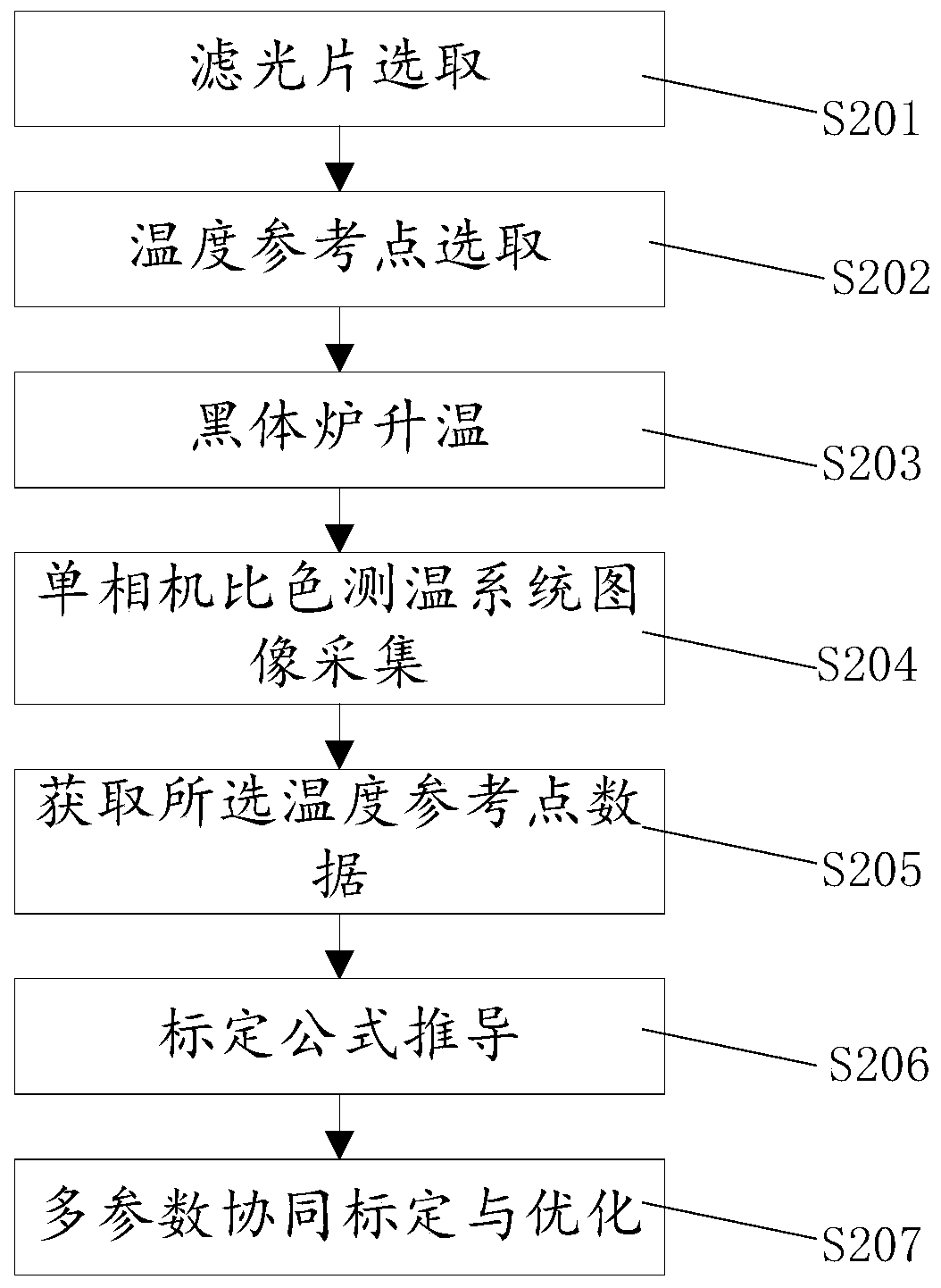

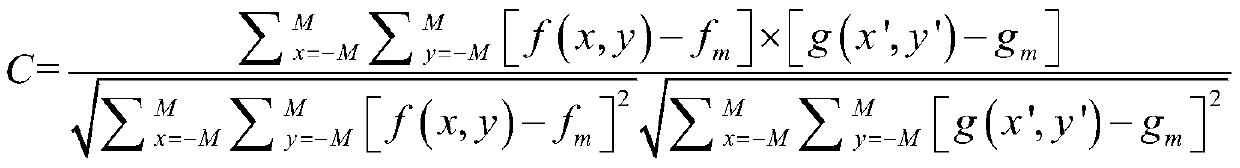

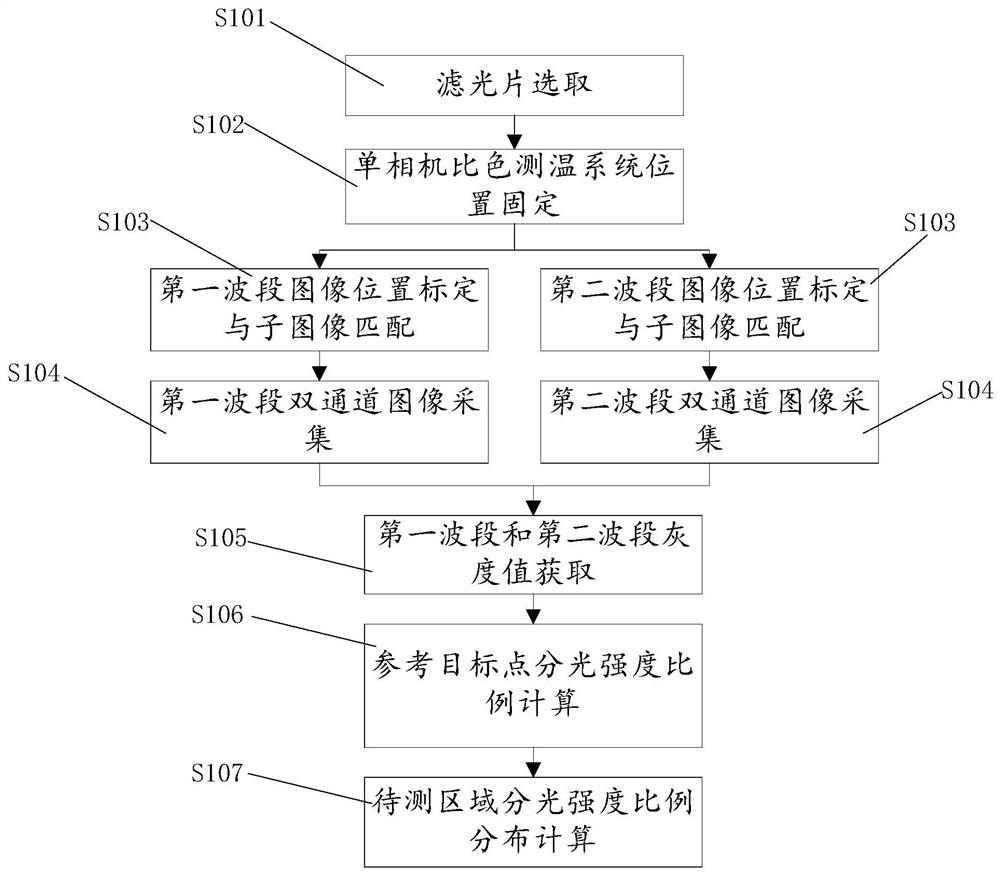

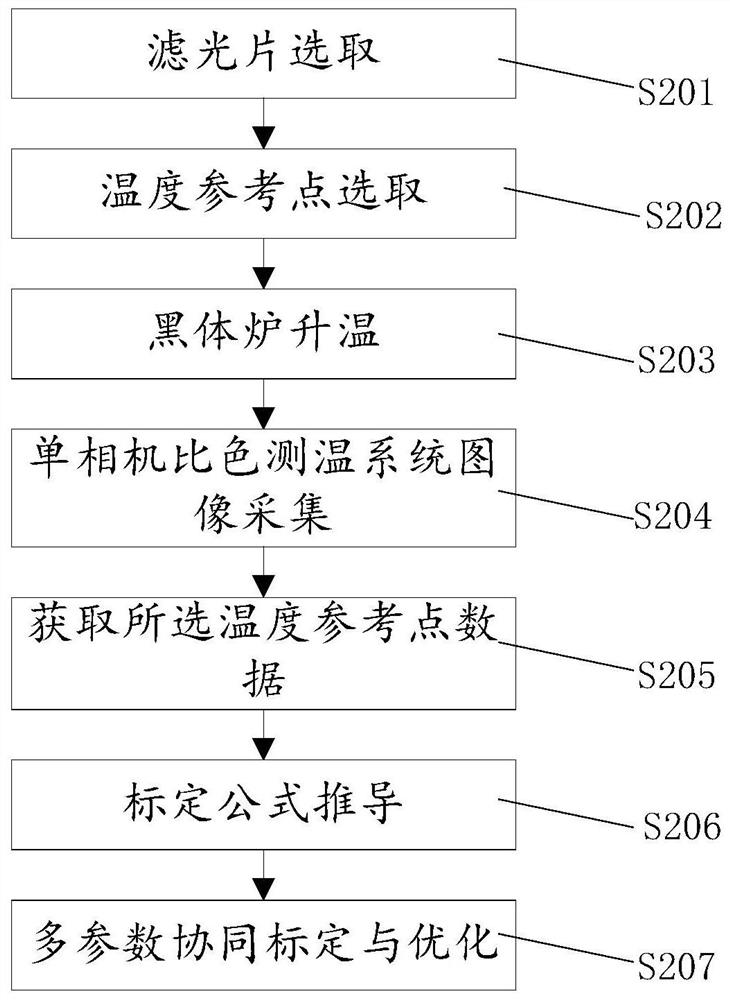

Optimized temperature measurement method based on single-camera colorimetric temperature measurement system

ActiveCN110954222ARealize the calibration of spectroscopic ratio distributionAvoid temperature measurement errorsPyrometry using electric radation detectorsPhysical chemistryLight filter

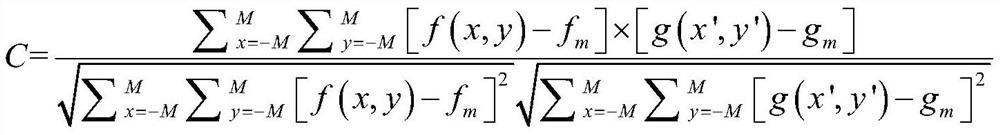

The invention discloses an optimized temperature measurement method based on a single-camera colorimetric temperature measurement system, and relates to calibration of spectral intensity proportion distribution, optimization of a pixel unit temperature calculation formula and calibratio and optimization of pixel unit temperature calculation formula parameters, wherein calibration of the spectral intensity proportion distribution comprises optical filter selection, single-camera colorimetric temperature measurement system position fixation, first waveband image and second waveband position calibration and sub-image matching, first waveband and second waveband dual-channel image collection, reference target point spectral intensity proportion calculation and to-be-measured area spectral intensity proportion distribution calculation; optimization of the pixel unit temperature calculation formula comprises substituting the obtained reference target point spectral intensity proportion as anoptimization parameter into the temperature calculation formula of the temperature measurement system; calibration and optimization of the parameters of the pixel unit temperature calculation formulacomprises optical filter selection, reference temperature point selection, blackbody furnace temperature rise, image collection, calibration formula derivation and multi-parameter collaborative optimization. And the measured temperature is more accurate by optimizing the temperature measurement method.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

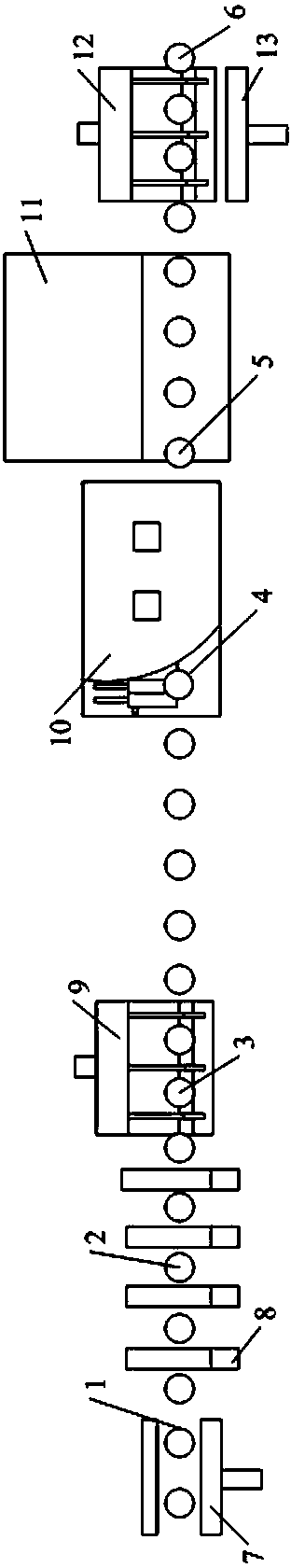

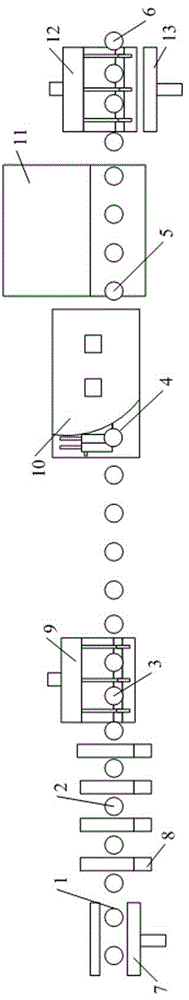

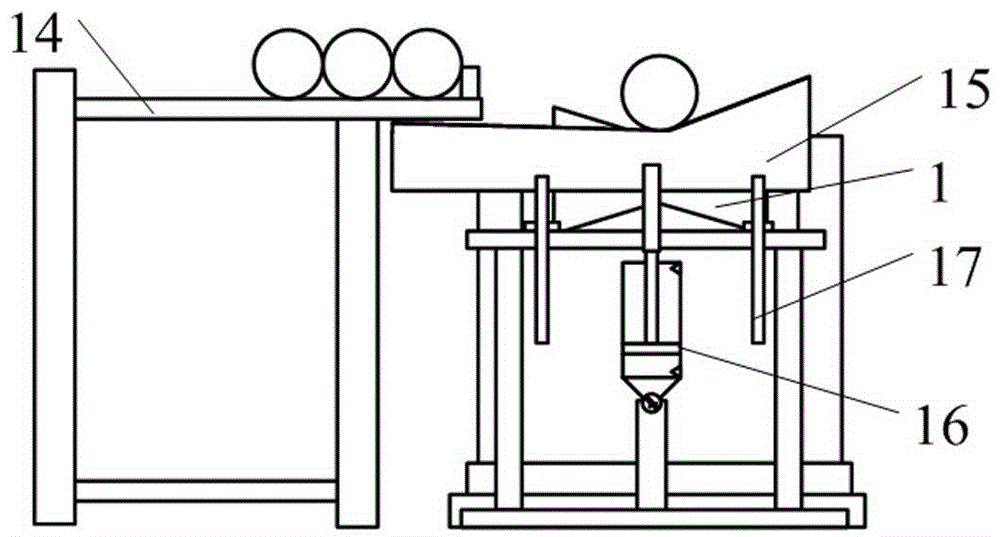

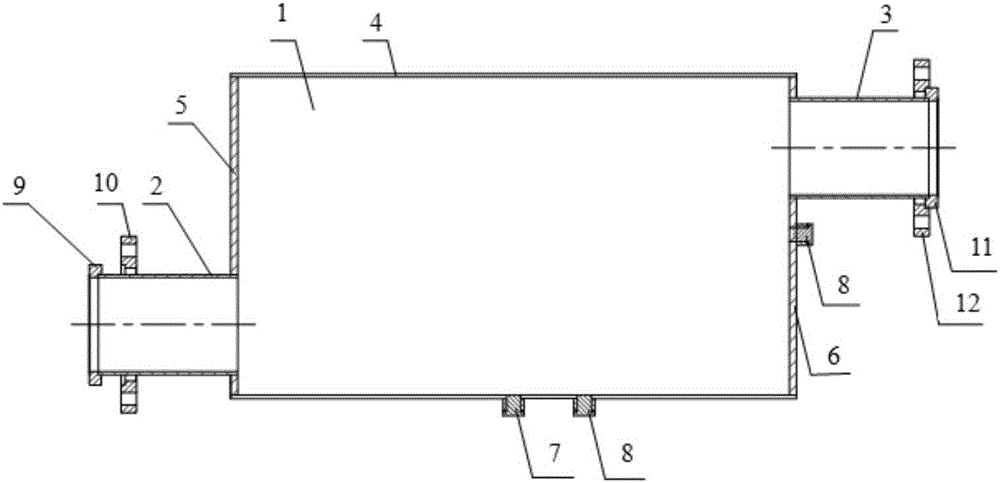

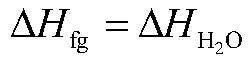

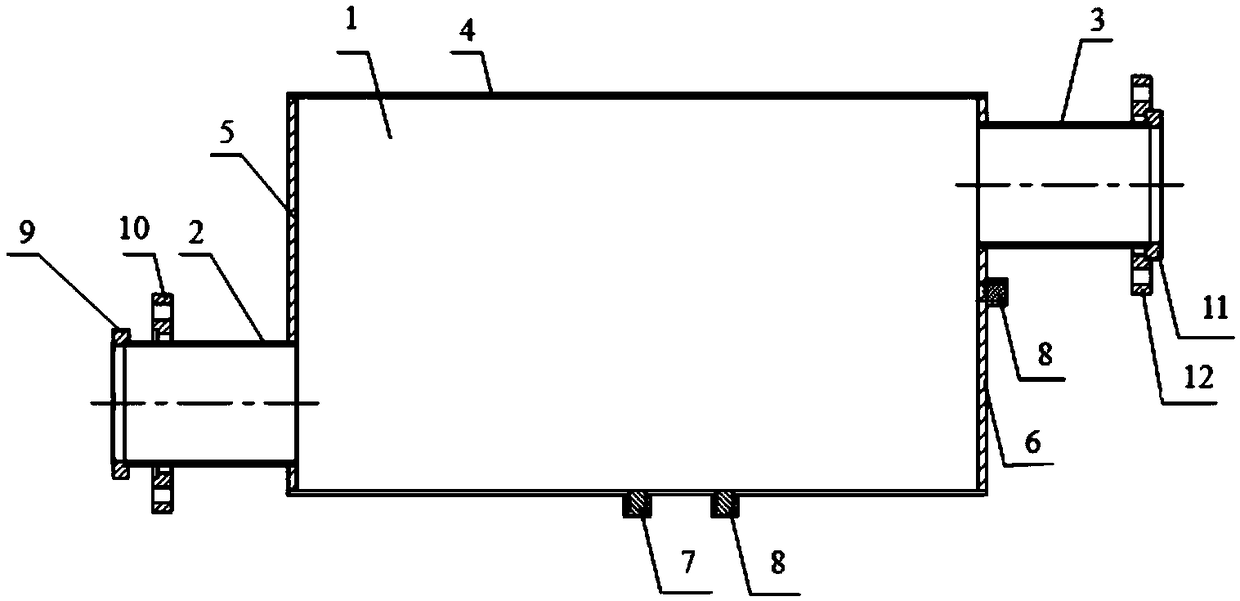

Multifunctional heat treatment system for steel pipe

ActiveCN104032112AMeet heat treatment process requirementsCompact designFurnace typesHeat treatment furnacesElectrical resistance and conductanceUltra fast

The invention discloses a multifunctional heat treatment system for a steel pipe. The heat treatment system comprises six groups of roller paths, a medium-frequency induction furnace device, a high-temperature resistance furnace device, an ultra fast cooling device, an outward sprinkling and inward spraying device and a low-temperature resistance furnace device, wherein the six groups of roller paths consist of a feeding roller path group, a medium-frequency induction heating roller path group, an air cooling roller path group, an ultra fast cooling roller path group, an outward sprinkling and inward spraying roller path group and a discharging roller path group which are arranged in sequence; the medium-frequency induction furnace device is arranged between two adjacent roller paths of the medium-frequency induction heating roller path group; the high-temperature resistance furnace device is arranged on one side of the air cooling roller path group; the ultra fast cooling roller path group is arranged in the ultra fast cooling device; the outward sprinkling and inward spraying device is arranged on one side of the outward sprinkling and inward spraying roller path group; and the low-temperature resistance furnace device is arranged on one side of the discharging roller path group. According to the system, the whole process line is compact in design, the operation is simple and convenient, needed equipment can be combined and selected according to process requirements, and various heat treatment process requirements of the steel pipe are met.

Owner:沈阳科安捷材料技术有限公司

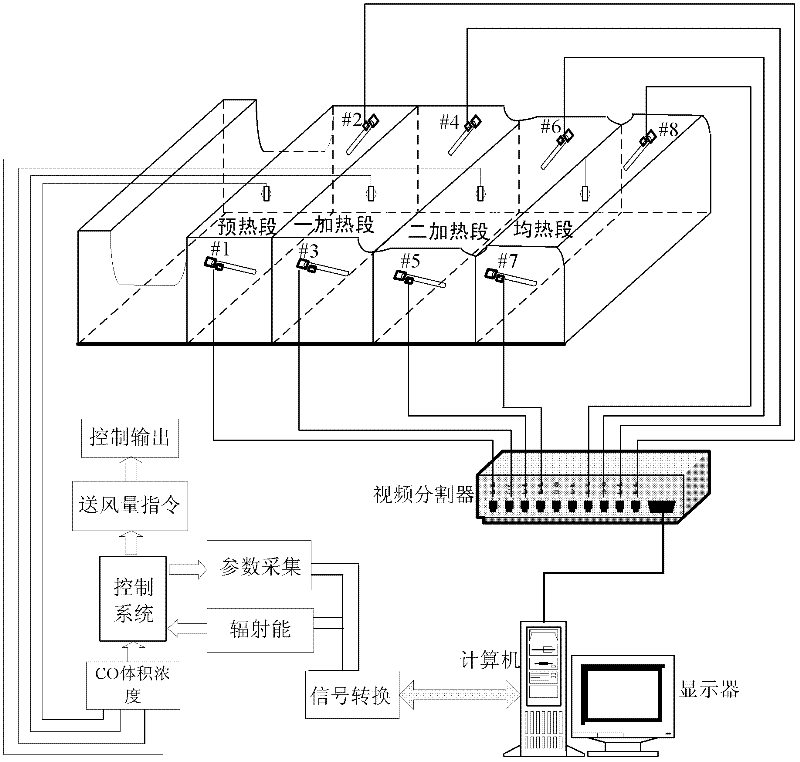

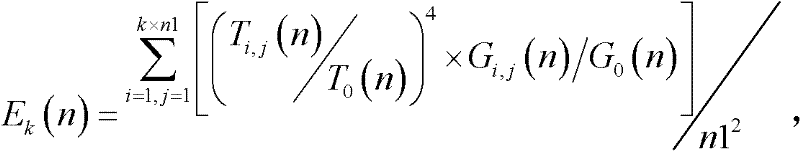

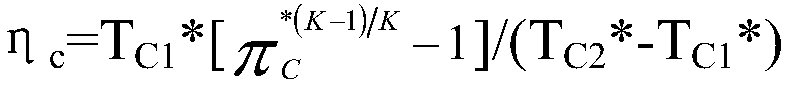

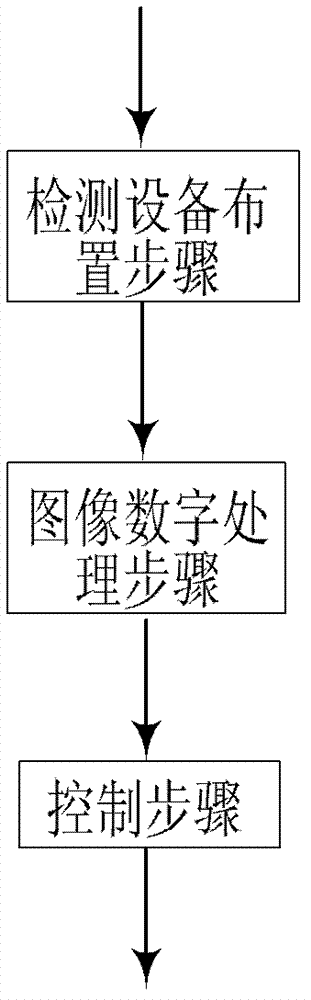

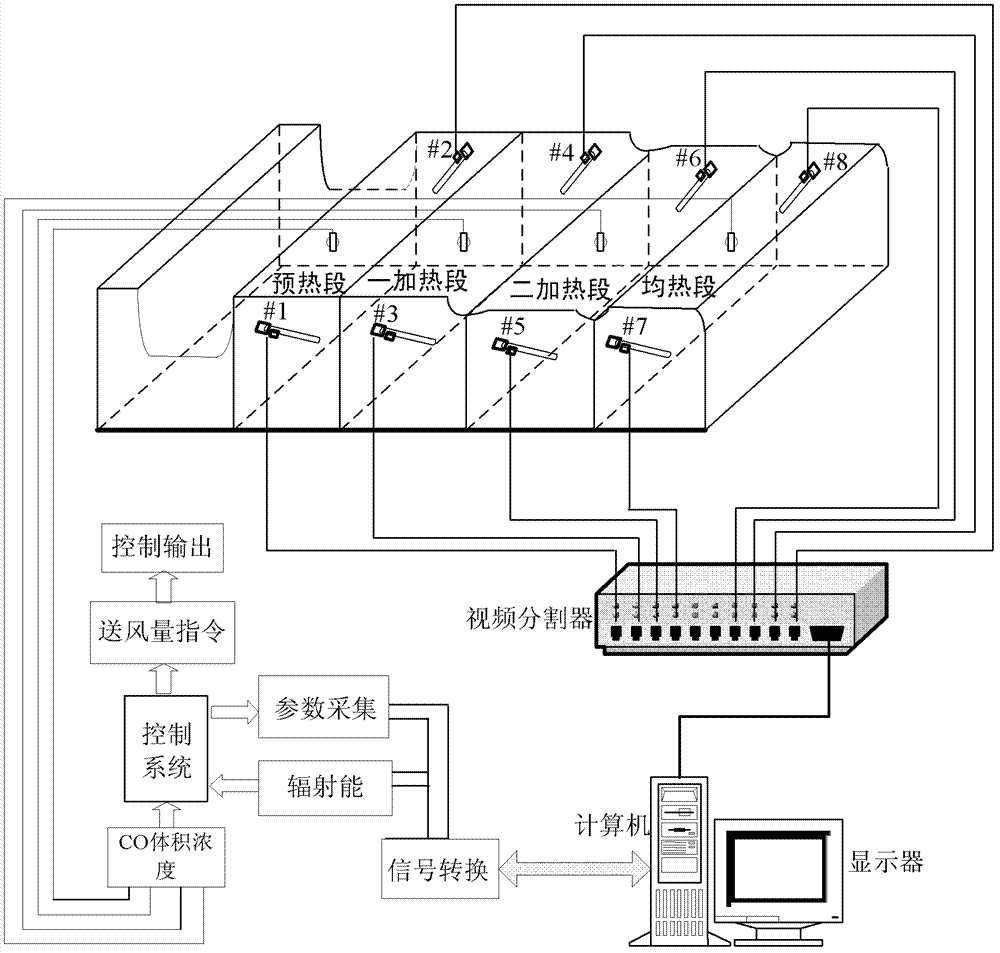

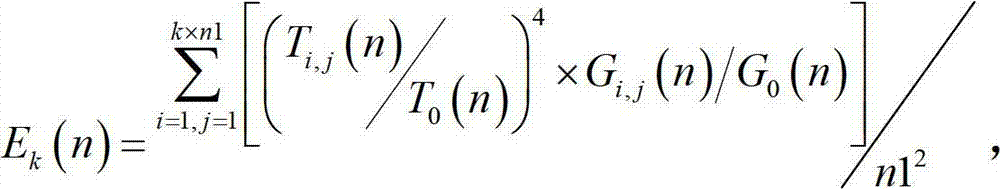

A method for controlling the atmosphere field of a heating furnace

ActiveCN102297451AAchieve runnabilityRealize energy savingFuel supply regulationObservational errorCombustion

The invention discloses a method for regulating and controlling an air-flowing environment of a heating furnace, which belongs to the field of combustion monitoring and controlling, is applicable to detection and optimal control over combustion of a heating furnace and solves the problems that a mode is needed to be retrained when actual operation work conditions are deviated from preset conditions of the model or when parameters for supporting model operation are detected to be abnormal because an empirical mode is applied in the internal combustion monitoring of the traditional furnace. Themethod comprises the steps of equipment arrangement detection, image number processing and control. According to the method disclosed by the invention, a radioactive energy signal is extracted from flame image in different arranged sections of the heating furnace and is combined with air-flowing environments in the different sections for detecting and calculating reasonable air / combustion ratio, thus the oxidation and burn of steel and furnace tubes caused by the improper air-flowing environments in the heating furnace are reduced and the irregularity of quality of products in different batches is prevented. According to the method, proper air-flowing environments in the furnace can be created, temperature measuring errors are reduced and operation optimization, energy saving and emissionreduction of the heating furnace are realized.

Owner:HUAZHONG UNIV OF SCI & TECH

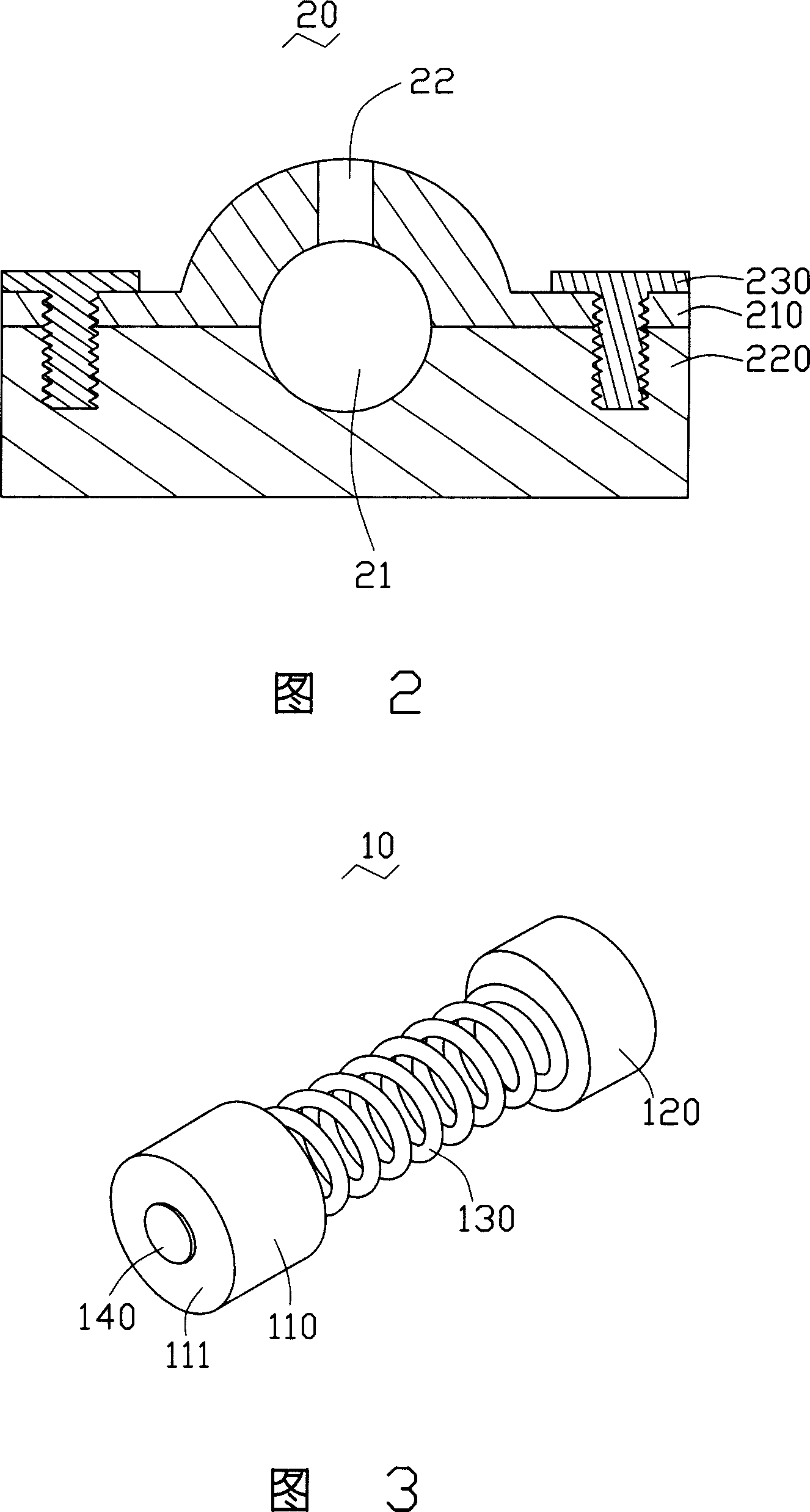

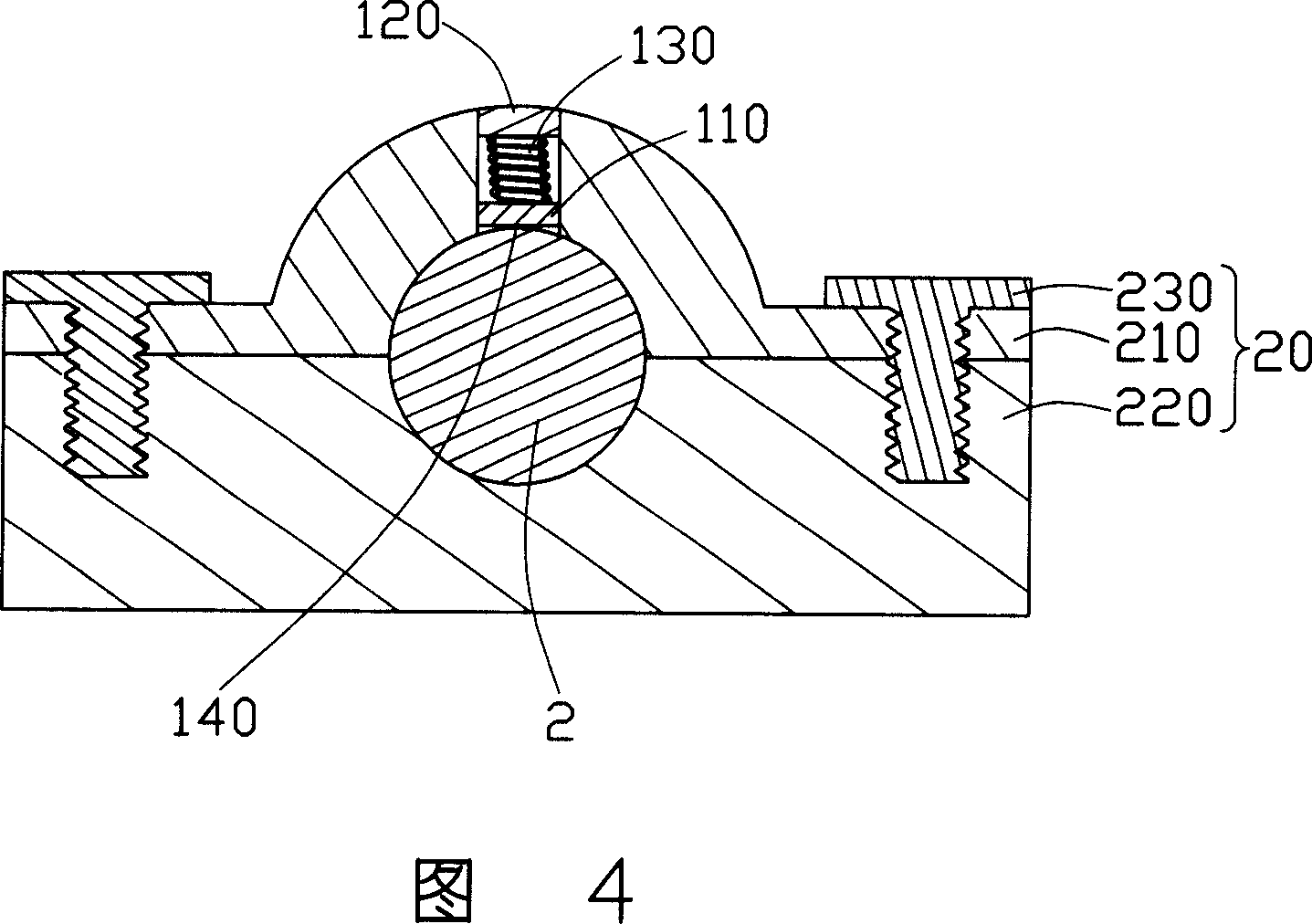

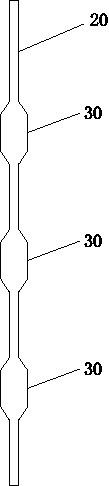

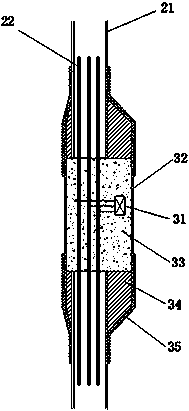

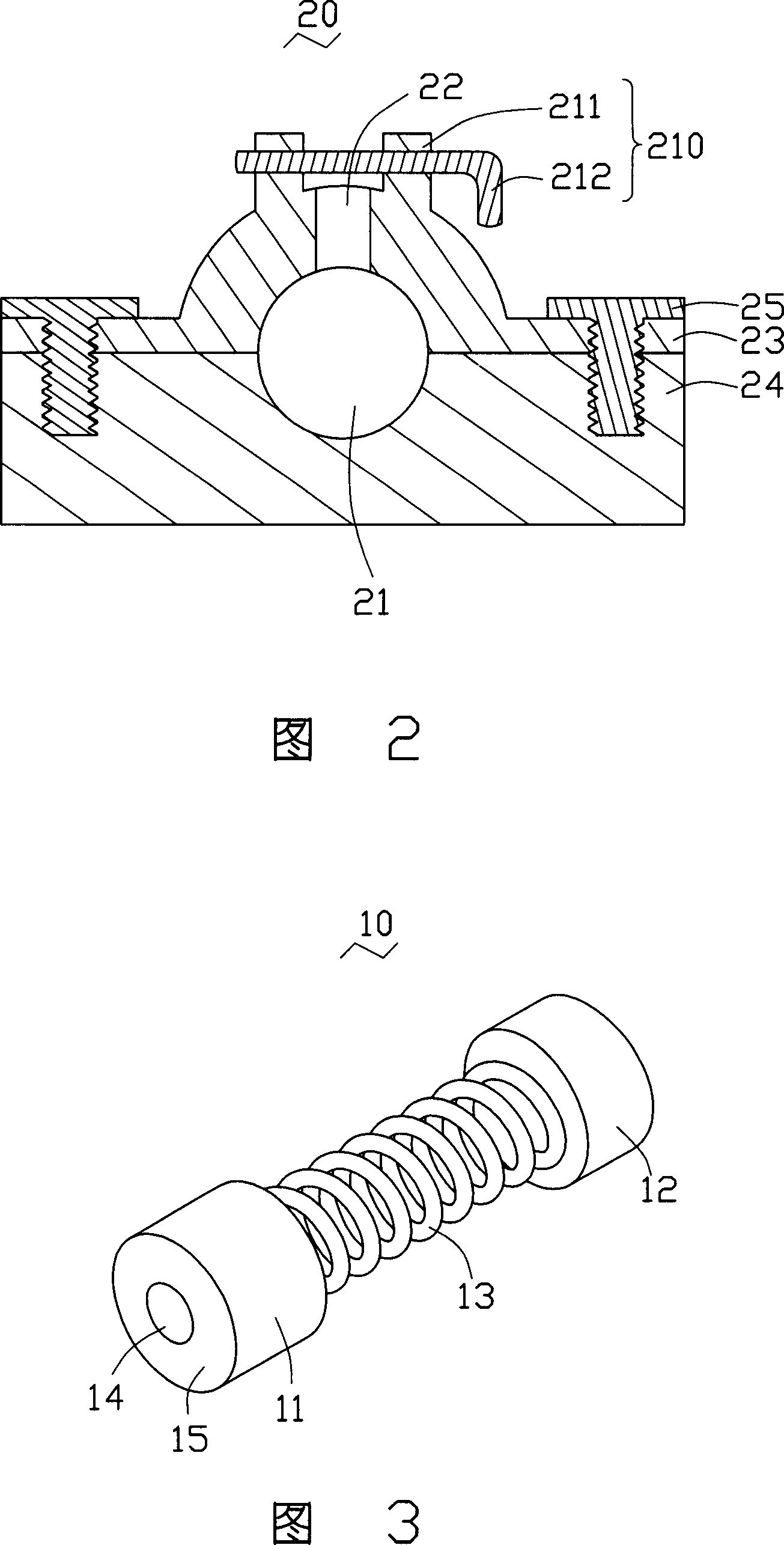

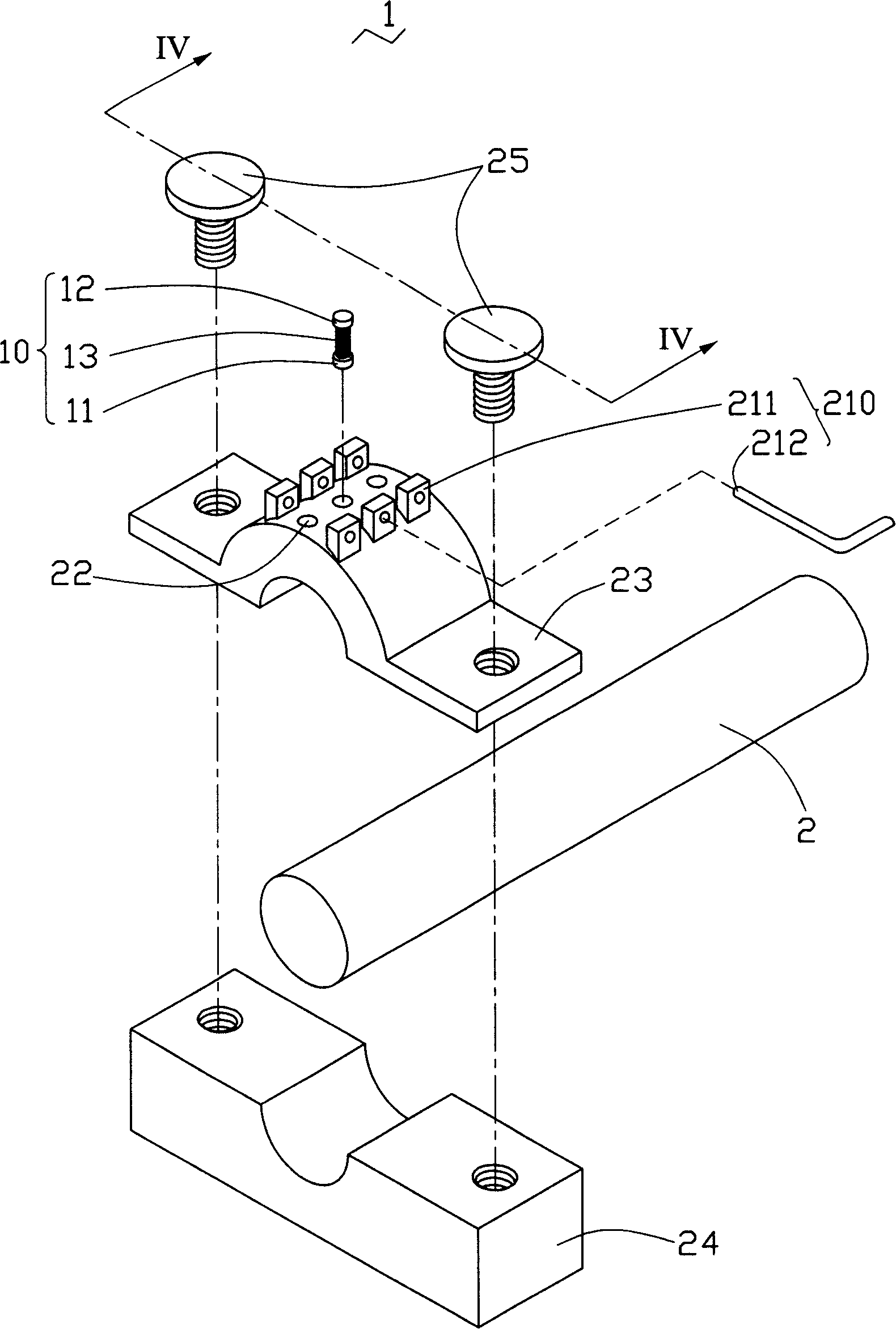

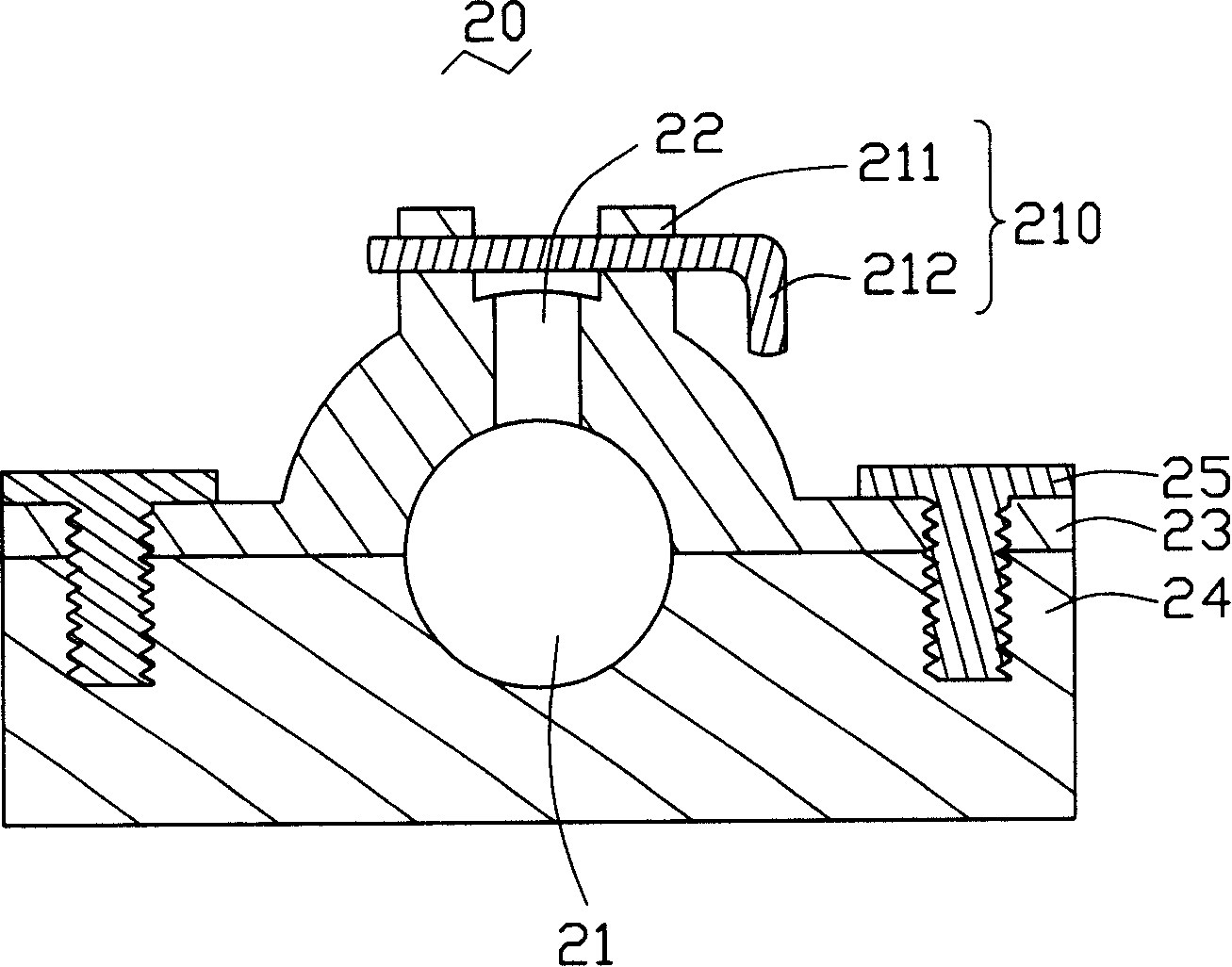

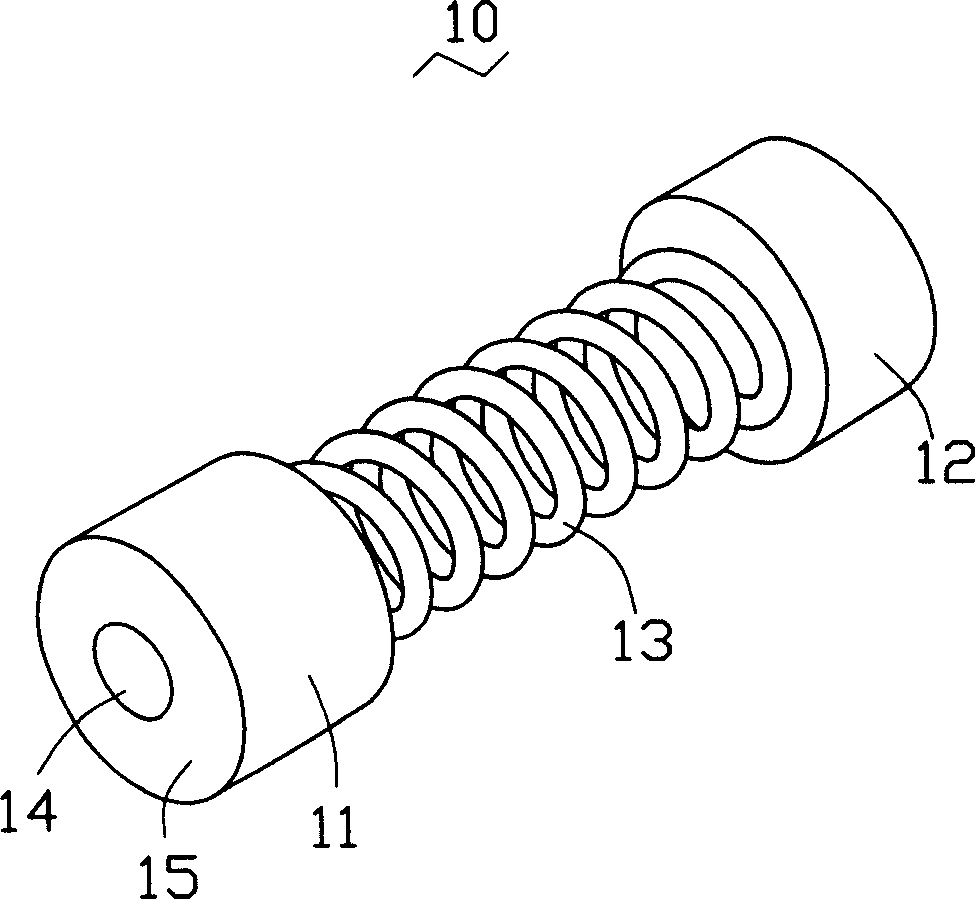

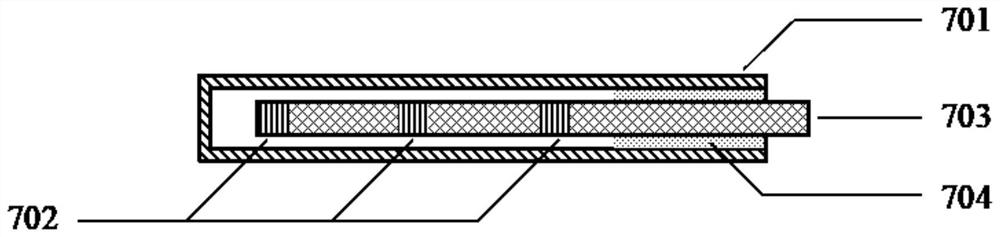

Hot-pipe temperature measuring device

InactiveCN1982858AReduce temperature measurement errorReduce cost of measurementThermometers using electric/magnetic elementsUsing electrical meansTemperature measurementEngineering

A temperature measurement device of heat tube is prepared as setting a containing cavity for holding heat tube to be measured and an insertion hole for placing measurement component on holding unit; forming measurement component by carrying block, a pressing block, a spring being supported between two said blocks and a thermal couple being stuck closely with carrying block at surface far from said spring and being used to measure temperature of heat tube.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

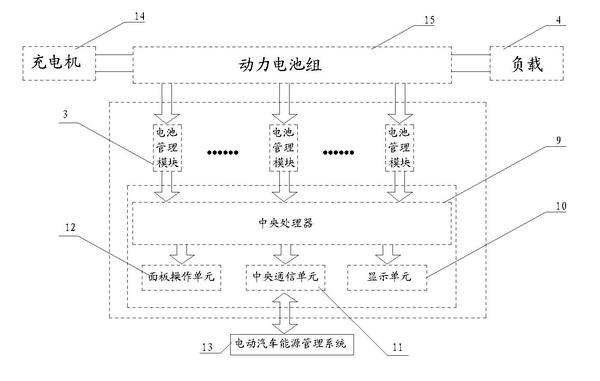

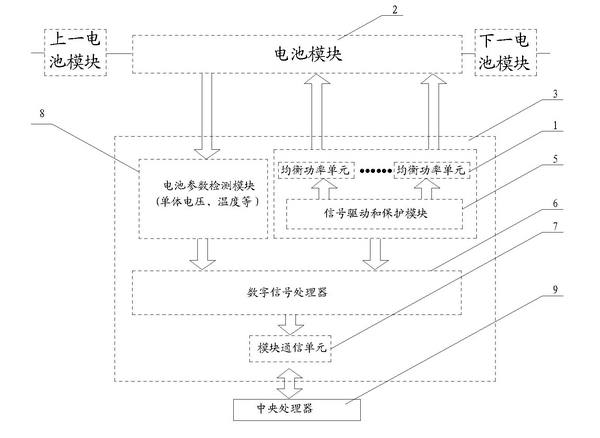

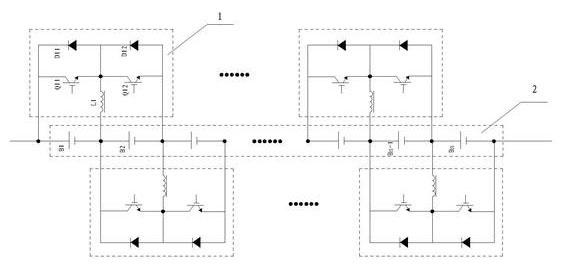

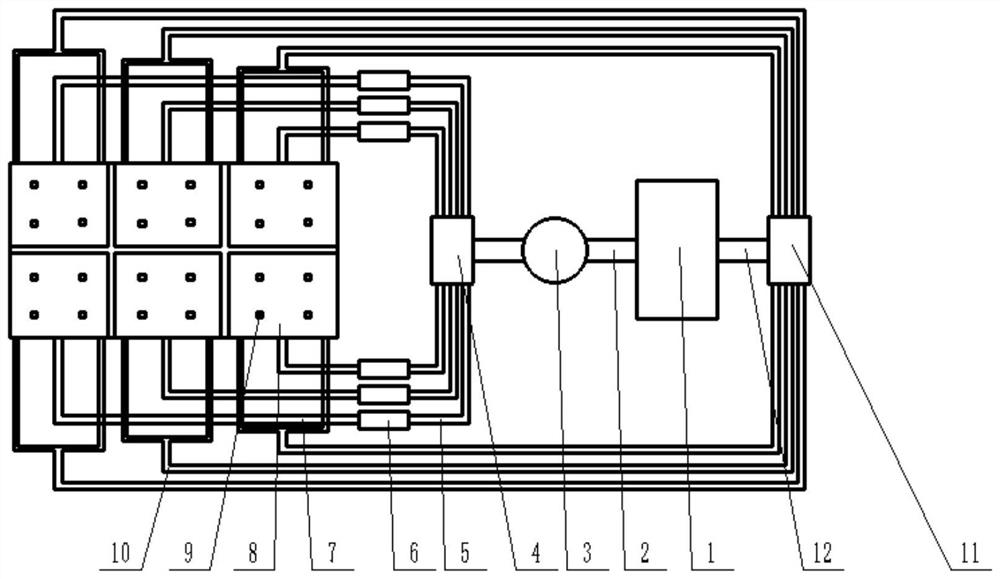

Battery management and lossless equalization system

InactiveCN102231552AEnsure safetyExtended service lifeBatteries circuit arrangementsElectric powerPower batteryCommunication unit

Provide is a battery management and lossless equalization system which is used to manage and control the consistency of the monomer cells in an electric automobile battery. A charger is connected with a load through a power battery. A cell management module is in a cascade connection with a display unit, a central communication unit and a panel operation unit through a central processor. The central processor is connected to an electric automobile energy management system. It is possible to carry out a real-time on-site measurement on power battery total voltage, total current and various parameters of the monomer cells and carry out estimation on the inconsistency of the monomer cells. A dynamic on-site lossless equalization is carried out to charging, discharging and standing of the monomer cells. Meanwhile, necessary control is implemented to ensure the safety of the battery and prolong the service life of the battery. According to the invention, the inconsistency of the monomer cells can be equalized, there is no energy loss, the equalization efficiency is high, the equalization effect is good, the inconsistency difference of the voltages of the monomer cells is less than 20mv and the precisions of voltage measurement and temperature measurement are high.

Owner:湖北德普电气股份有限公司

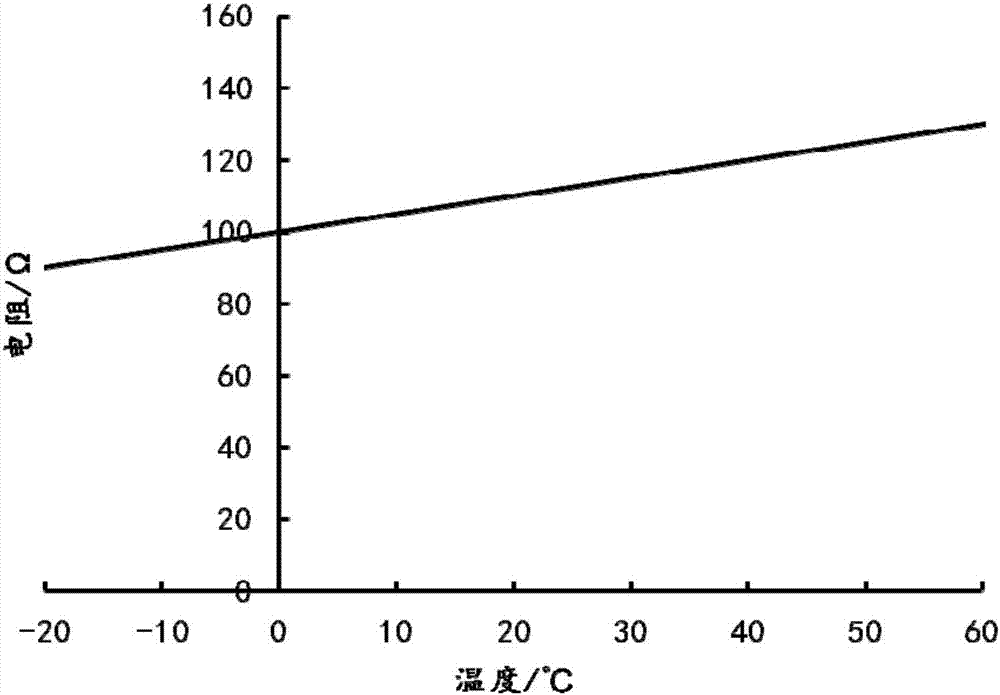

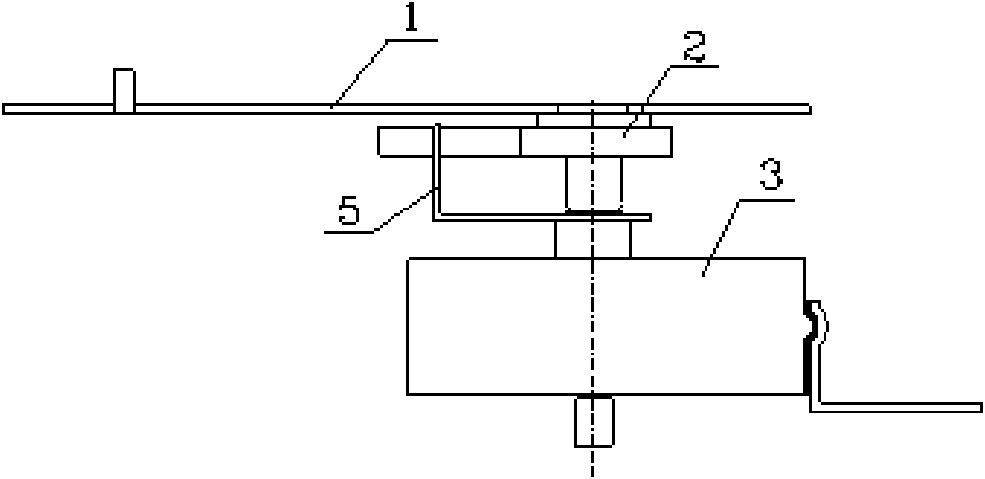

Liquid nitrogen temperature continuously and automatically measuring device

InactiveCN102661816AFast transmissionReduce temperature measurement errorThermometers using electric/magnetic elementsUsing electrical meansElectrical resistance and conductanceComputer control system

The invention relates to a liquid nitrogen temperature continuously and automatically measuring device. The measuring device is characterized by comprising a platinum resistance thermometer (1), a digital voltmeter (2), a computer control system (3) and a constant-current source (5), wherein the platinum resistance thermometer (1) is arranged on the required test temperature point and is fixed; the constant-current source (5) is placed close to the platinum resistance thermometer (1), the constant-current source (5) provides working current for the platinum resistance thermometer (1), and the output of the constant-current source (5) is connected with the two ends of a current lead of the platinum resistance thermometer (1); the digital voltmeter (2) is communicated with the computer control system (3); and a voltage testing line of the digital voltmeter (2) accesses to the voltage leads of the two ends of the platinum resistance thermometer (1), is used for testing the voltage value of the platinum resistance thermometer (1), and transmitting the detected voltage value to the computer control system (3).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

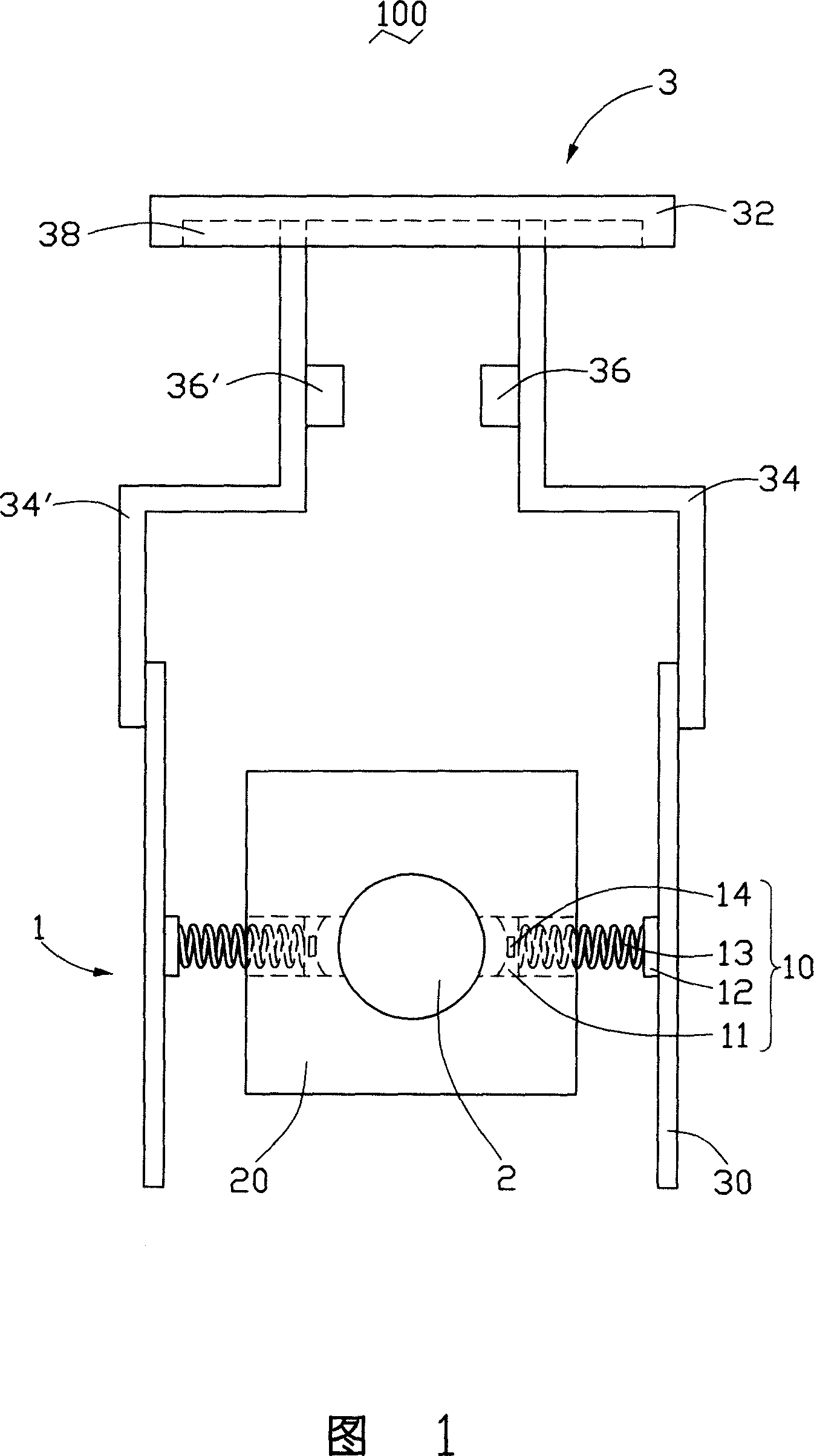

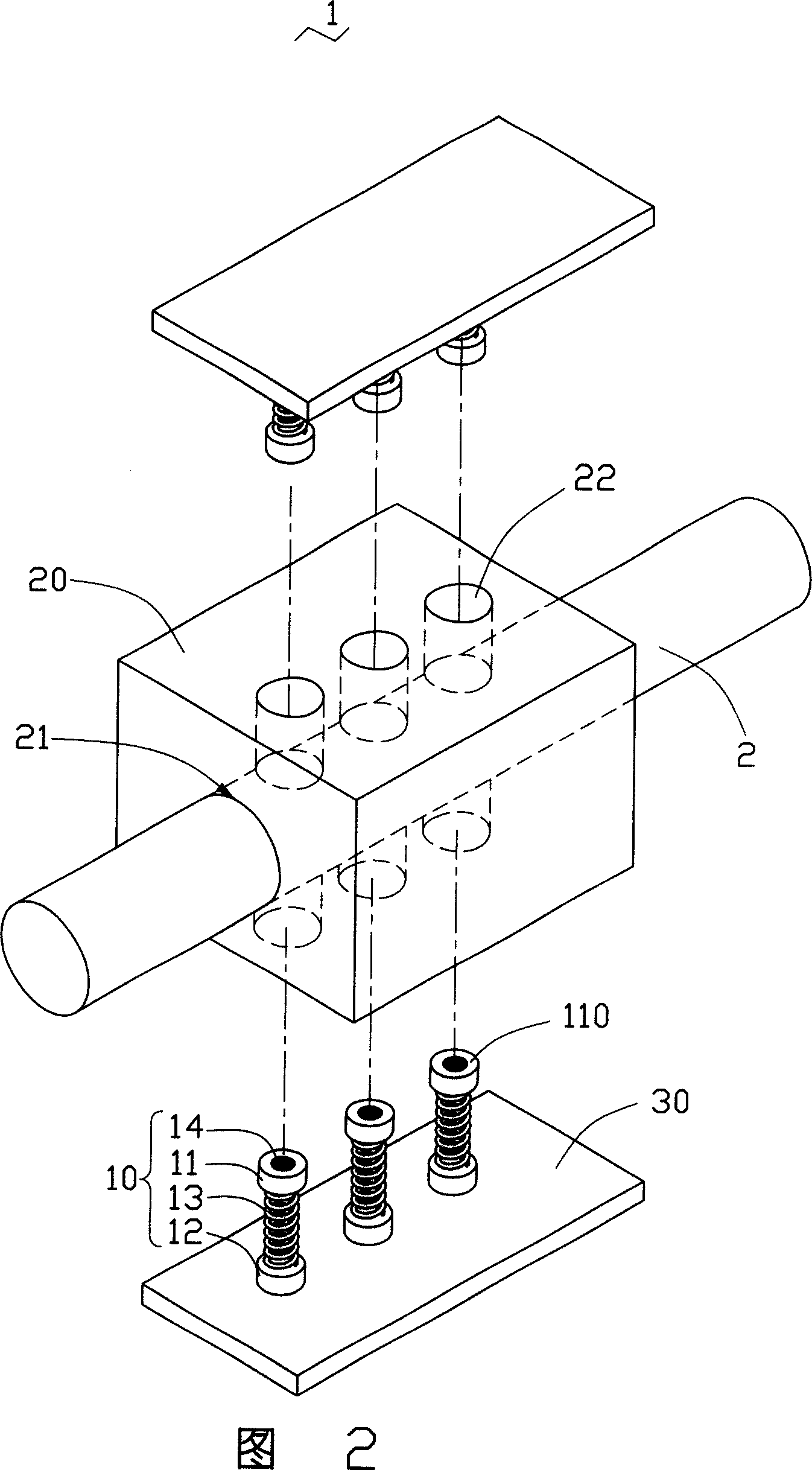

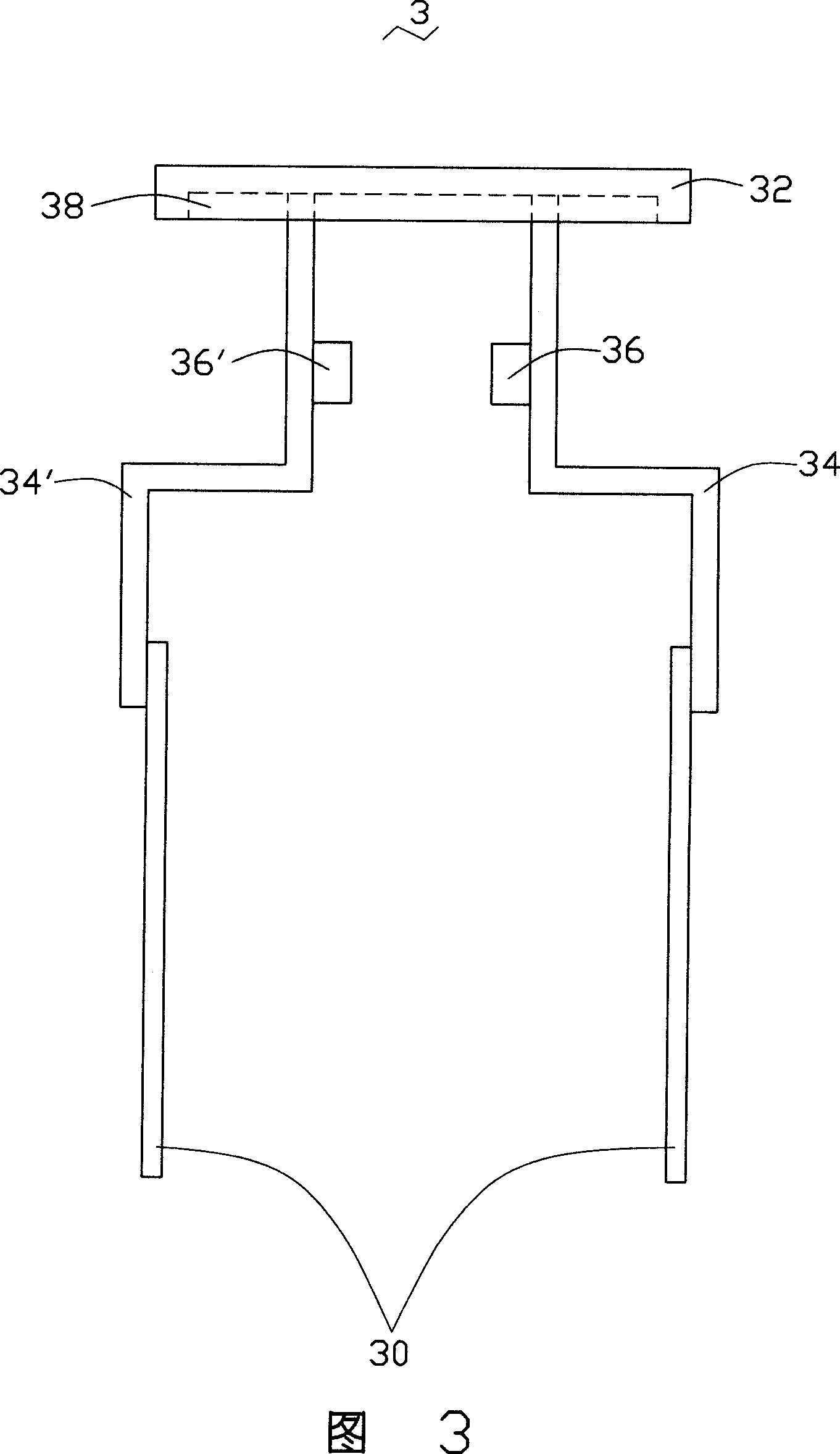

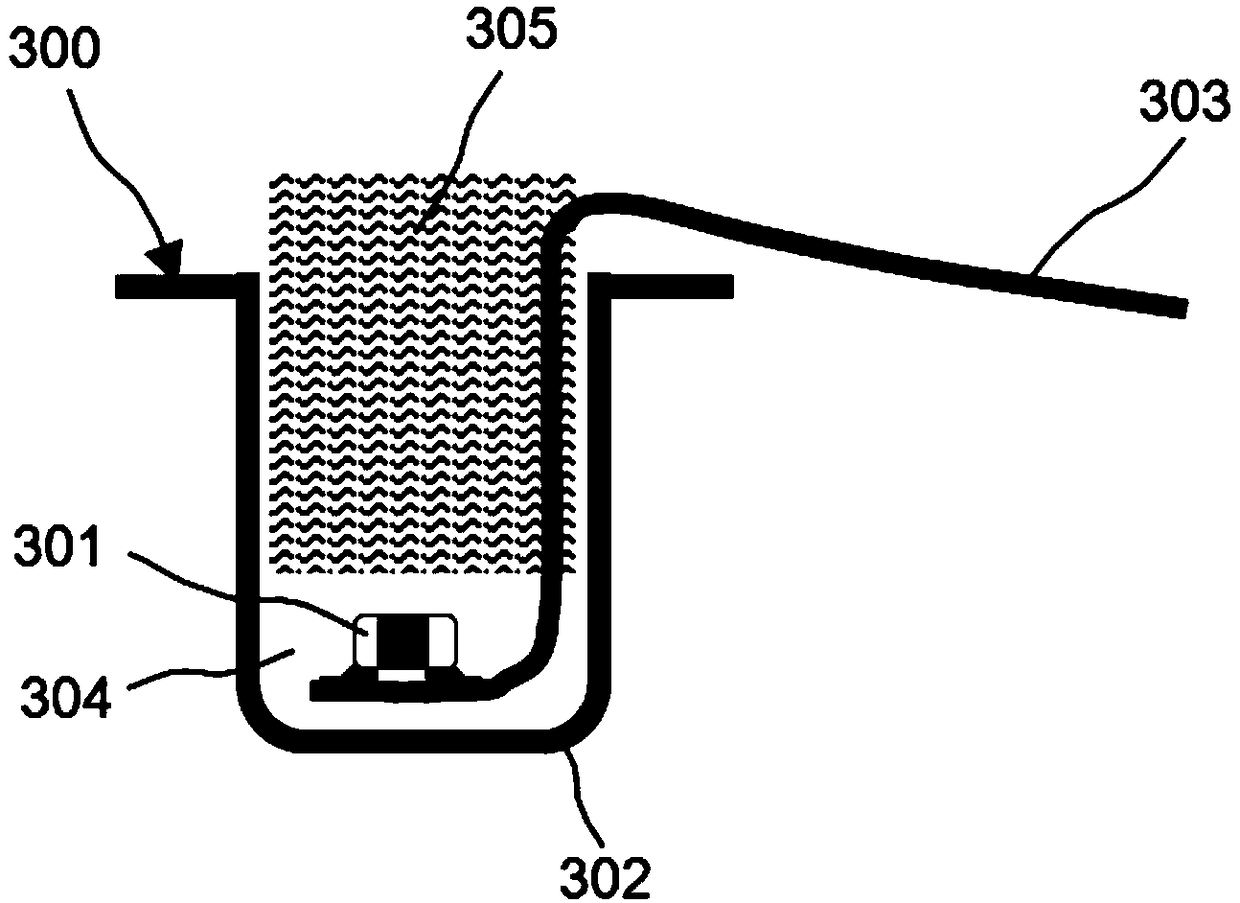

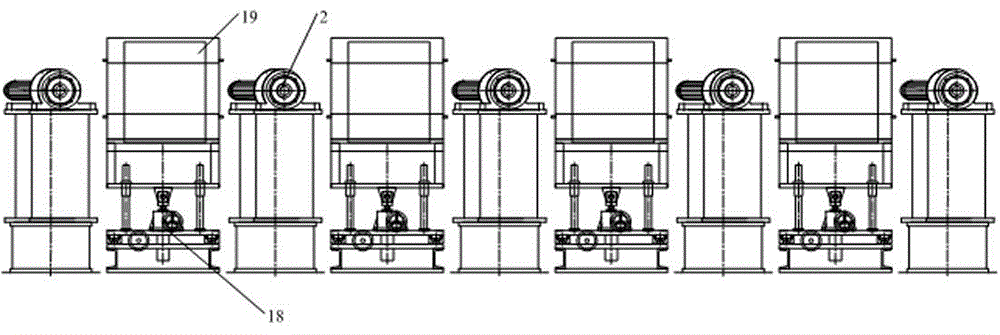

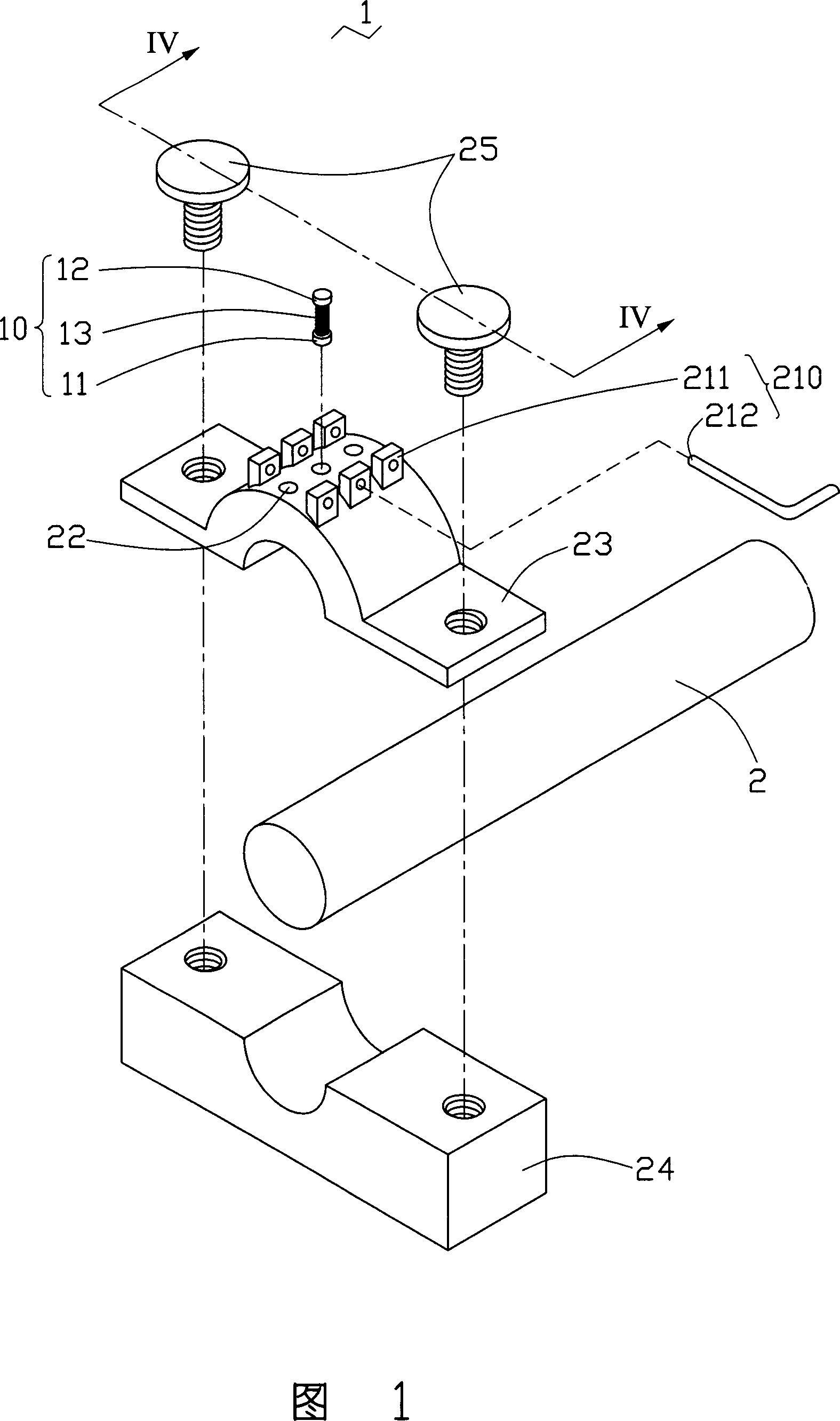

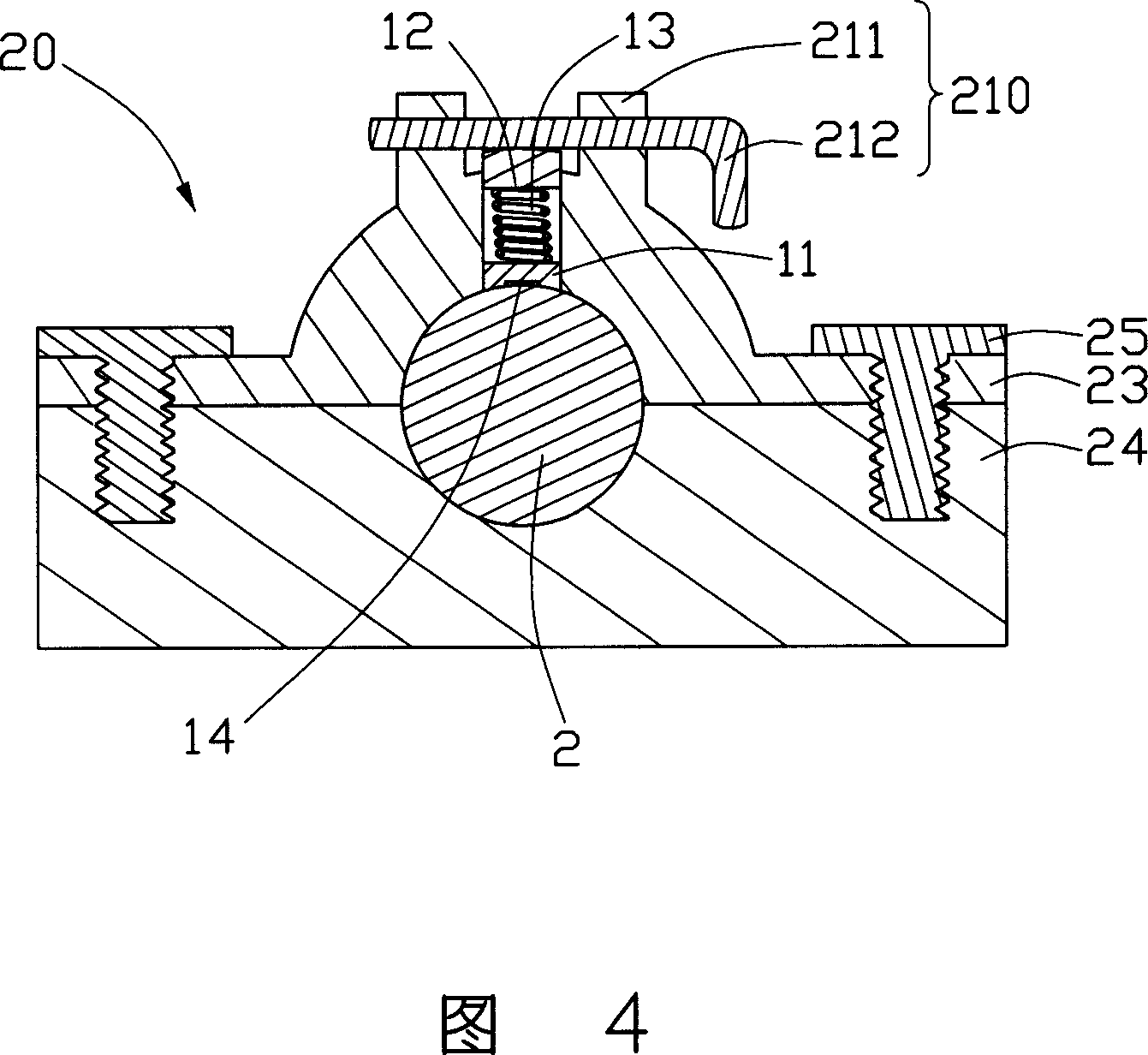

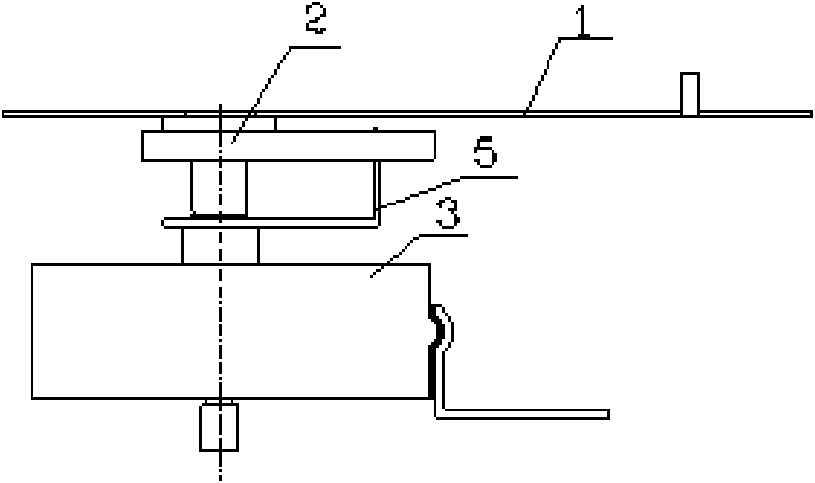

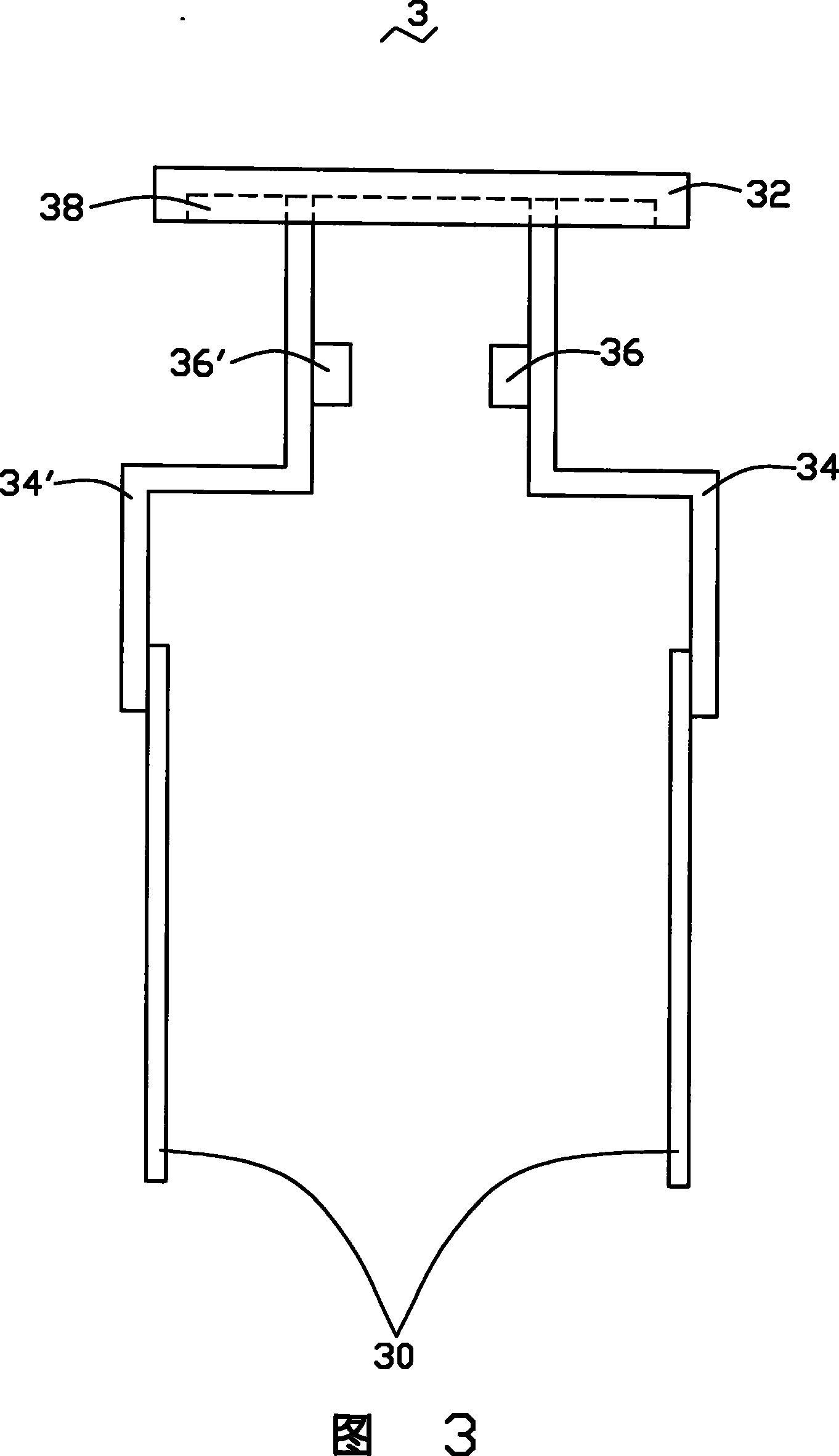

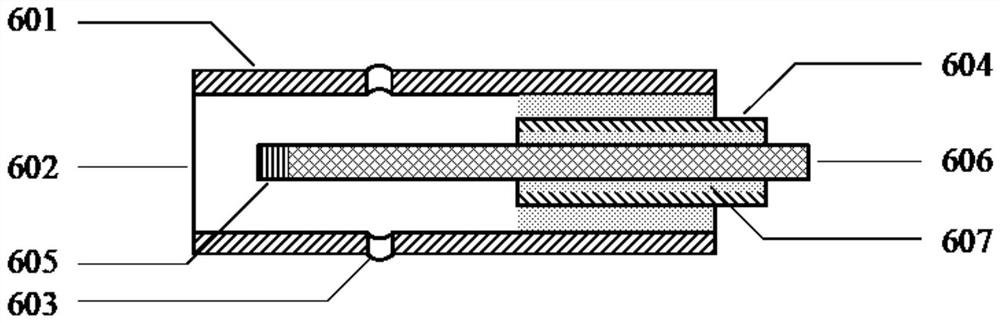

System for measuring temp of heat pipe

InactiveCN101000316AReduce temperature measurement errorImprove measurement accuracyMaterial heat developmentThermometers using electric/magnetic elementsElastic componentEngineering

The invention supplies a heat pipe temperature measuring system. It includes one heat pipe temperature measuring device and one linear displacement control device. The former includes one setting part, at least one measuring component, at least one pressing board. The setting part is set one setting cavity and at least one inserting hole. Each measuring component includes one load-bearing block, one elastic component, and one thermocouple. One end of the elastic component is connected with load-bearing block. The thermocouple clung to one side of the load-bearing block far from the elastic component to measure heat pipe temperature. Each pressing board is connected with another end of the elastic component. The linear displacement control device is used to control the linear displacement for the pressing board.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

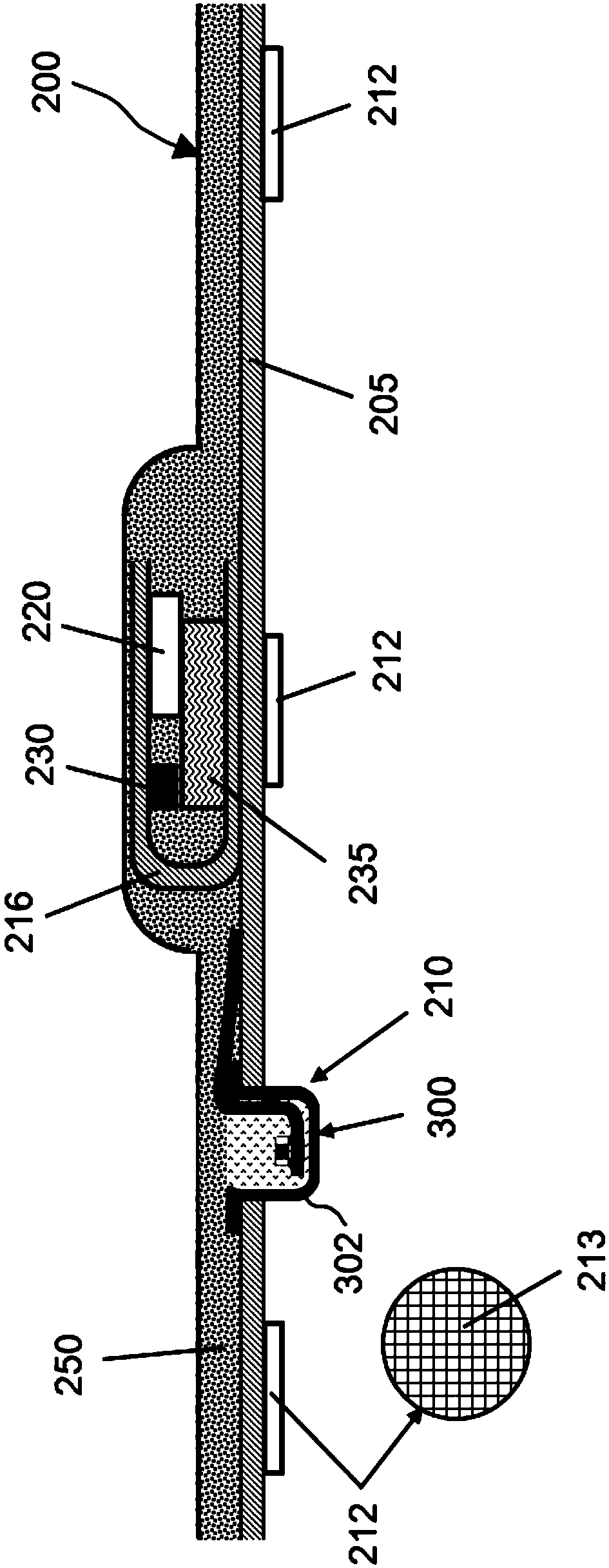

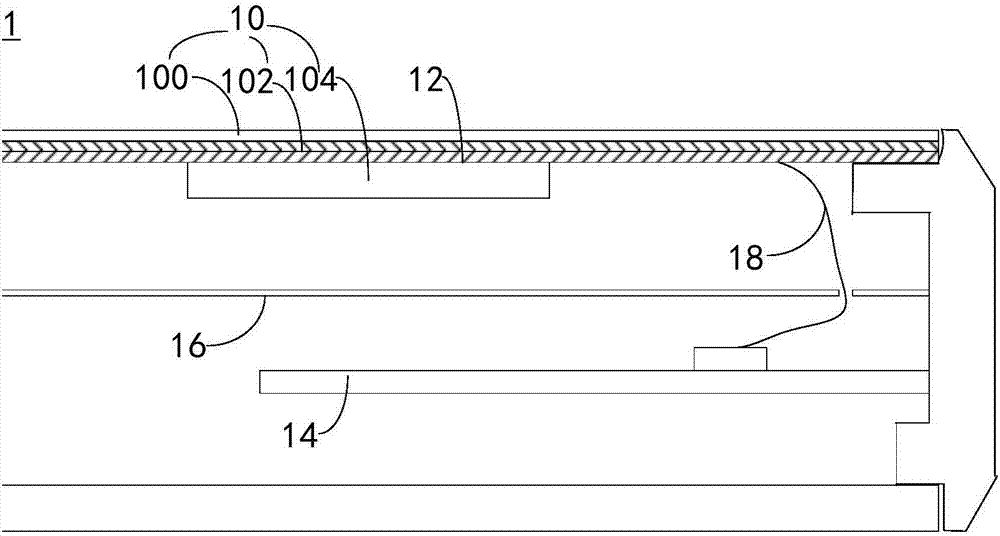

Wearable patch for measuring temperature and electrical signals

ActiveCN108344524AIncreased durabilityReduce cooling effectBody temperature measurementDiagnostic recording/measuringElectricitySemiconductor chip

The invention discloses a wearable patch that includes a stretchable and permeable substrate having a first opening; a temperature sensing unit mounted in the stretchable and permeable substrate, wherein the temperature sensing unit comprises a temperature sensor for measuring a user's skin temperature; electrodes attached to the stretchable and permeable substrate; and a circuit board having a circuit. The electrodes include a bottom surface that can contact with the user's skin and to pick up electric signals from the user's body. A semiconductor chip is mounted on a circuit layer. The semiconductor chip can receive a first electric signal from the temperature sensor in response to a temperature of the user's skin measured by the temperature sensor. The semiconductor chip can receive a second electric signal from the electrodes in response to electric signals picked up from the user's body. The wearable patch can quickly and accurately measure the body temperature and electrical signals of the user.

Owner:维瓦灵克有限公司

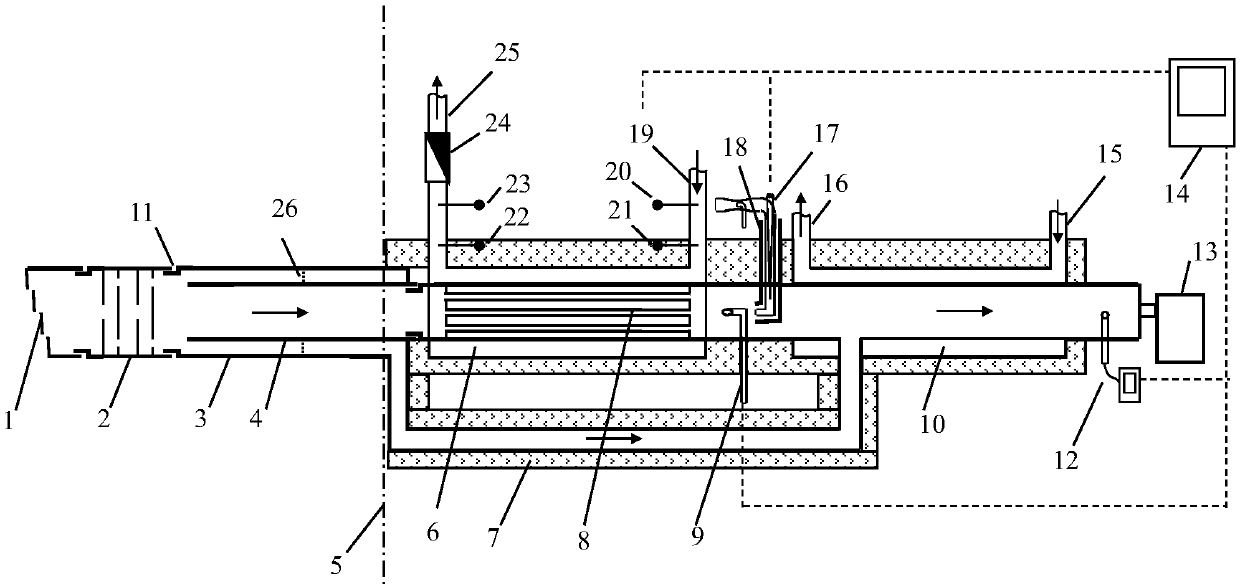

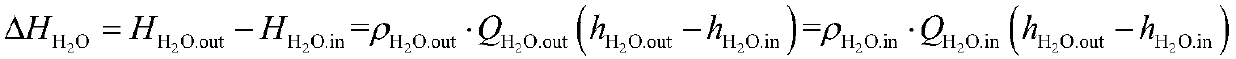

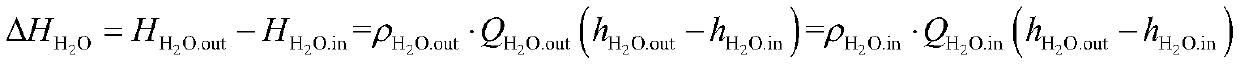

Contact-type temperature measuring device for high-temperature flue gases and measuring method thereof

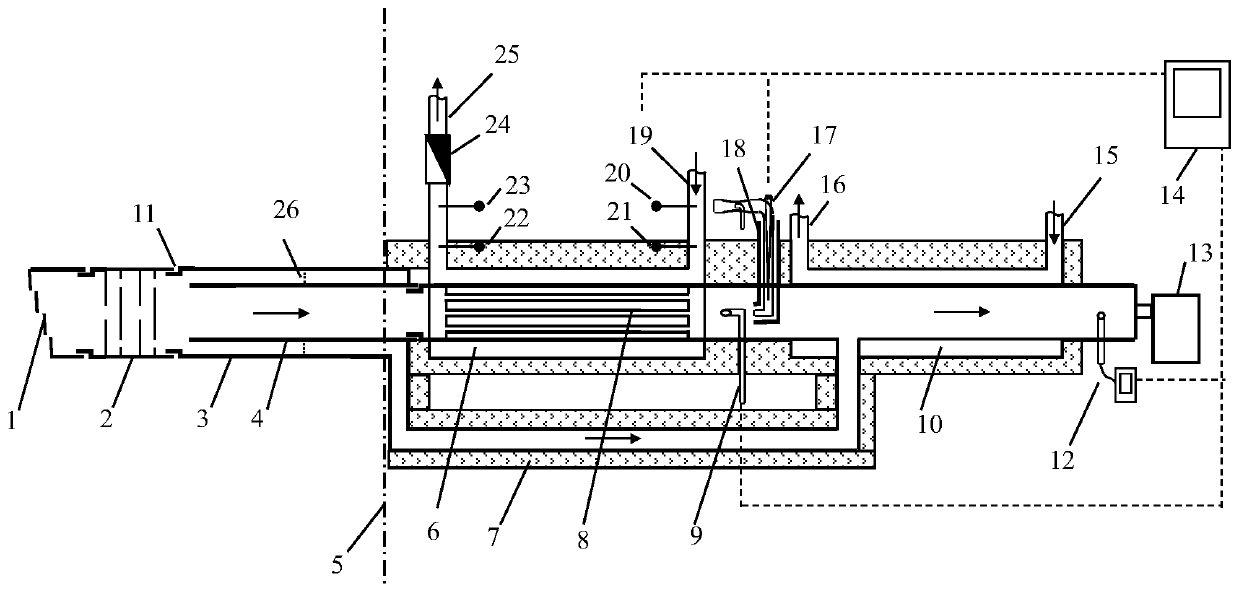

ActiveCN109556749AEfficient separationAvoid wear and tearMaterial heat developmentWithdrawing sample devicesFlue gasData acquisition

The invention discloses a contact-type temperature measuring device for high-temperature flue gases and a measuring method thereof. The device comprises a high-temperature flue gases acquisition system, a water cooled heat exchange system, a flue gases component analysis system, a flue gases extraction device, a measuring element, and a data acquisition and processing system. The measuring element, the flue gases component analysis system are electrically connected with the data acquisition and processing system. The water cooled heat exchange system is arranged behind the high-temperature flue gases acquisition system. The flue gases component analysis system is arranged at the tail end position of a secondary water cooled system, and the flue gases extraction device is connected with thetail end of the secondary water cooled system. The contact-type temperature measuring device for high-temperature flue gases and the measuring method thereof of the invention cool the high-temperature flue gases to below 1200 DEG C through the water cooled heat exchange system, and calculate the temperature of the high-temperature flue gases by measuring the temperature of the high-temperature flue gases and the heat absorption of the cooling medium. Therefore, the high-precision and long-time measuring of the high-temperature flue gases above 1600 DEG C is achieved.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

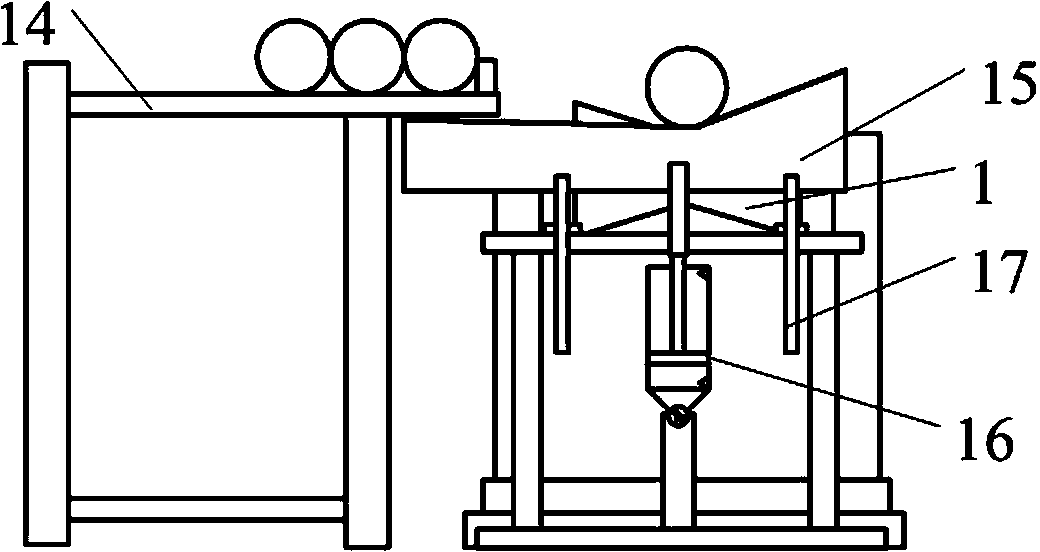

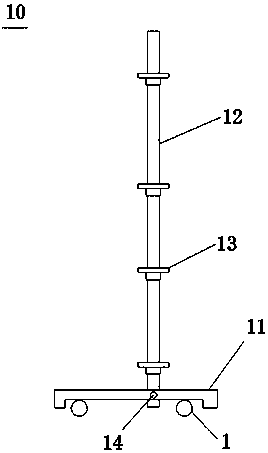

Automatic recognition method for large-volume concrete mold-entering temperature

ActiveCN111174929AImprove work efficiencyImprove accuracyThermometer detailsThermometer applicationsData transportMesh reinforcement

The invention discloses an automatic recognition method for large-volume concrete mold-entering temperature. The method comprises the following steps of: 1, fixing M temperature measuring devices in areinforcing mesh after mass concrete reinforcing steel bar binding and mold erecting are completed; 2, the temperature measuring device is connected to a data collection device, and the data collection device acquires temperature data of the temperature sensor according to a preset frequency and transmits the data to a server; 3, according to a formula I and a formula II, preliminarily judging that fj is the in-mold temperature; and 4, checking and confirming whether fj is the in-mold temperature or not according to a formula 3. According to the method, the concrete mold-entering temperatureand the mold-entering time at each temperature measuring device can be automatically calculated according to a series of temperature data monitored by the temperature measuring devices, so that the working efficiency is greatly improved.

Owner:SHANGHAI CONSTRUCTION GROUP

A multifunctional heat treatment system for steel pipes

ActiveCN104032112BMeet heat treatment process requirementsCompact designFurnace typesHeat treatment furnacesElectrical resistance and conductanceUltra fast

A multifunctional heat treatment system for steel pipes, including six sets of rollers, a medium frequency induction furnace device, a high-temperature resistance furnace device, an ultra-fast cooling device, an external shower and an internal spray device, and a low-temperature resistance furnace device; the six sets of rollers are composed of a feeding roller The intermediate frequency induction heating roller group, the air cooling roller group, the ultra-fast cooling roller group, the external shower internal spray roller group and the blanking roller group are arranged in sequence; the intermediate frequency induction furnace device is set in the intermediate frequency induction heating roller group between two adjacent rollers; the high-temperature resistance furnace device is set on one side of the air-cooling roller set; the ultra-fast cooling roller set is set inside the ultra-fast cooling device; the external shower and inner spray device is set on the outer shower and inner spray roller set One side; the low-temperature resistance furnace device is installed on one side of the unloading roller group. The entire process line of the system of the present invention is compact in design and easy to operate. The required equipment can be combined and selected according to process requirements to meet various heat treatment process requirements for steel pipes.

Owner:沈阳科安捷材料技术有限公司

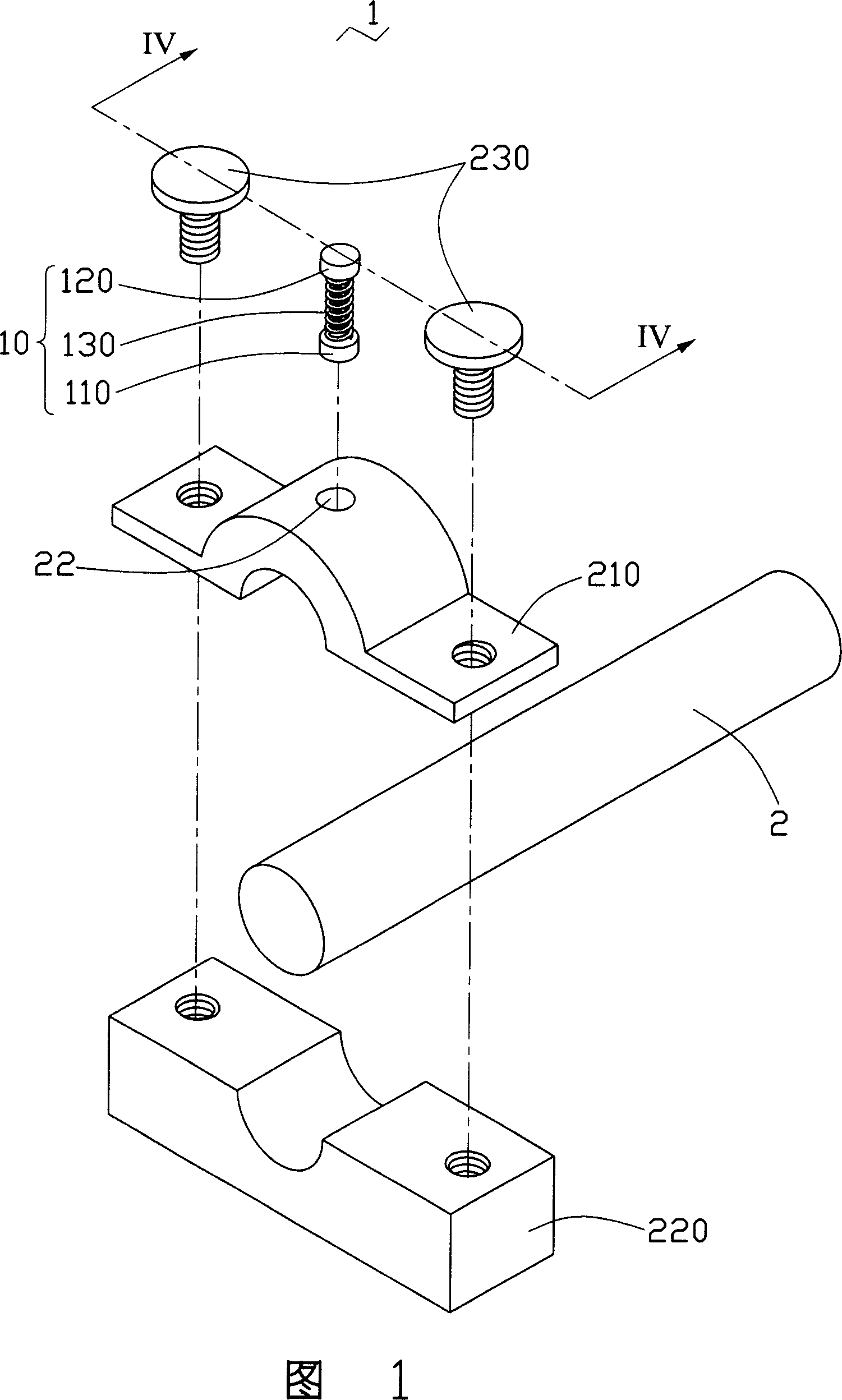

Temperature measuring device and heat tube measuring system

InactiveCN1987382ALower interface thermal resistanceReduce mistakesThermometers using electric/magnetic elementsUsing electrical meansEngineeringThermocouple

The temperature-measuring device includes gripping part, at least a measurement module, accommodation cavity on the gripping part, and at least one insertion hole connected to the accommodation cavity. The accommodation cavity is in use for gripping heat pipe to be measured. The insertion hole is in use for accommodating the measuring module. Being in use for fixing measuring module to be measured, locative structure includes a load bearing block, a pressing block, an elastic cell, and a thermocouple. The elastic cell supports between the load bearing block and the pressing block. Being attached to surface, which is apart from the elastic cell, of load bearing block, the thermocouple is in use for measuring temperature of heat pipe. Through elastic force generated by contraction in length of the elastic cell, the thermocouple contacts heat pipe tightly so as to raise accuracy for measuring temperature of heat pipe.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

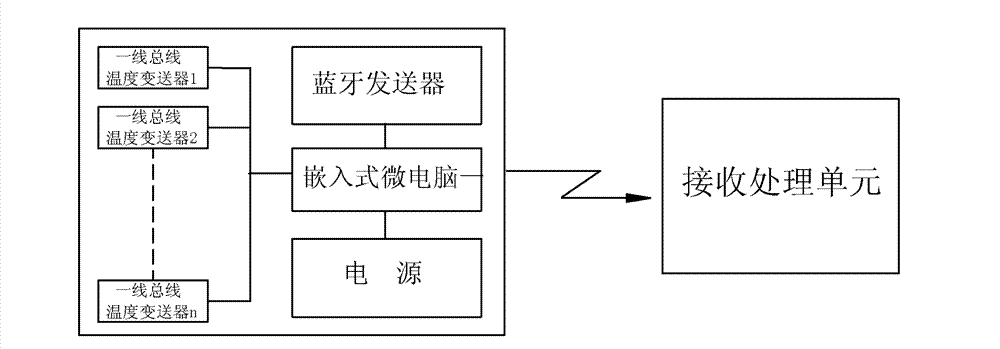

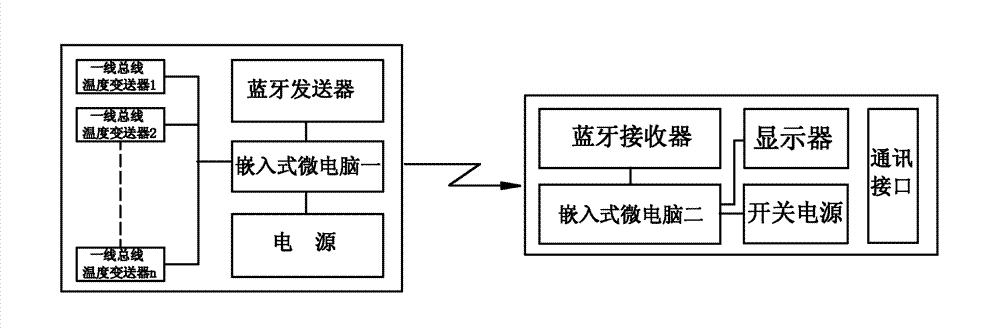

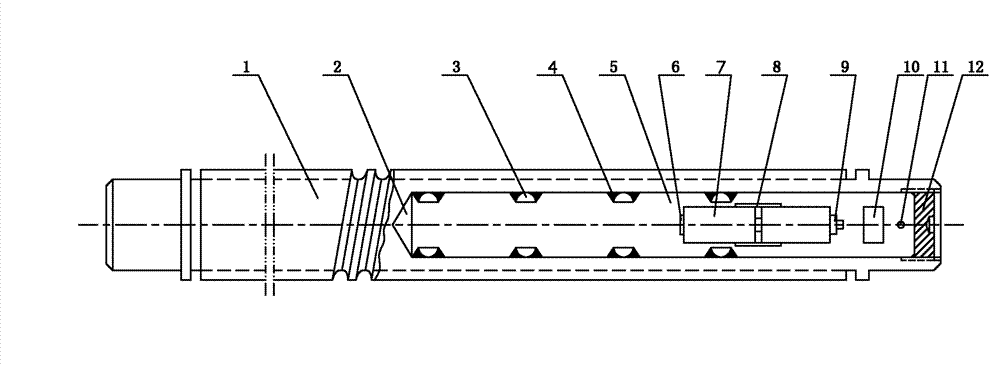

Embedded type multipoint wireless temperature measurement method of guide screw

InactiveCN102109384BImprove machining accuracyReduce temperature measurement errorThermometer detailsTransmission systemsObservational errorEngineering

The invention relates to an embedded type multipoint wireless temperature measurement method of a guide screw, which is characterized in that a wireless temperature measurement device is embedded inside the guide screw; temperature transmitters of the wireless temperature measurement device are distributed in the length direction of the inner wall of the guide screw in a multipoint manner; the peripheries of the temperature transmitters are filled by thermal conduction silicon grease; and the temperature transmitters arranged in a multipoint manner transmit measured temperature data to a Bluetooth receiver of a receiving and processing device through a Bluetooth transmitter. Compared with the prior art, the embedded type multi-point wireless temperature measurement method has the beneficial effects that as the wireless temperature measurement device is embedded inside the guide screw, and the measured temperature data is transmitted to the receiving and processing device through the Bluetooth transmitter, the temperature measurement error is small, the real-time online measurement can be realized, and the remote transmission can be realized; and the measurement error can be controlled within the minimum range, so that the precision of a machine tool is improved, and the product quality is improved.

Owner:辽宁忠大镕冠机器人有限公司

Temperature measuring device and heat tube measuring system

InactiveCN1987382BClose contactReduce temperature measurement errorThermometers using electric/magnetic elementsUsing electrical meansLength contractionEngineering

The temperature-measuring device includes gripping part, at least a measurement module, accommodation cavity on the gripping part, and at least one insertion hole connected to the accommodation cavity. The accommodation cavity is in use for gripping heat pipe to be measured. The insertion hole is in use for accommodating the measuring module. Being in use for fixing measuring module to be measured, locative structure includes a load bearing block, a pressing block, an elastic cell, and a thermocouple. The elastic cell supports between the load bearing block and the pressing block. Being attached to surface, which is apart from the elastic cell, of load bearing block, the thermocouple is in use for measuring temperature of heat pipe. Through elastic force generated by contraction in lengthof the elastic cell, the thermocouple contacts heat pipe tightly so as to raise accuracy for measuring temperature of heat pipe.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

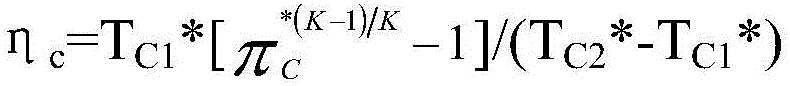

Pressure and flow stabilizing device of pipeline gas

ActiveCN106704832AEliminate swirl effectsLittle effect of temperature differencePipe elementsPipeline systemsCycloneLow speed

The invention provides a pressure and flow stabilizing device of a pipeline gas. The pressure and flow stabilizing device comprises a pressure and flow stabilizing barrel, a gas inlet pipe and an exhaust pipe, wherein the pressure and flow stabilizing barrel comprises a barrel body and a first end plate and a second end plate which are respectively arranged on the two end faces of the barrel body; the gas inlet pipe is arranged on the lower side of the first end plate; the exhaust pipe is arranged on the upper side of the second end plate; the gas inlet pipe and the exhaust pipe communicate with the pressure and flow stabilizing barrel; and a pressure measurement hole and a temperature measurement hole are formed in the surface of the pressure and flow stabilizing barrel. The pressure and flow stabilizing device has the beneficial effects that a gas flow pressure and flow stabilizing unit is composed of the large-diameter and eccentric pressure and flow stabilizing barrel, and gas flow at the high speed from tens of meters per second to hundreds of meters per second is changed to gas flow at the low speed of 15 meters per second or below, so that a dynamic temperature head and a dynamic pressure head are greatly decreased, and the gas cyclone influence is greatly eliminated; and besides, through mixing flow in the pressure and flow stabilizing barrel, the influence of temperature difference of a central layer and an outer layer of a gas pipeline is reduced, and measurement errors of pressure and temperature of the high-speed flow gas are decreased.

Owner:CHINA NORTH ENGINE INST TIANJIN

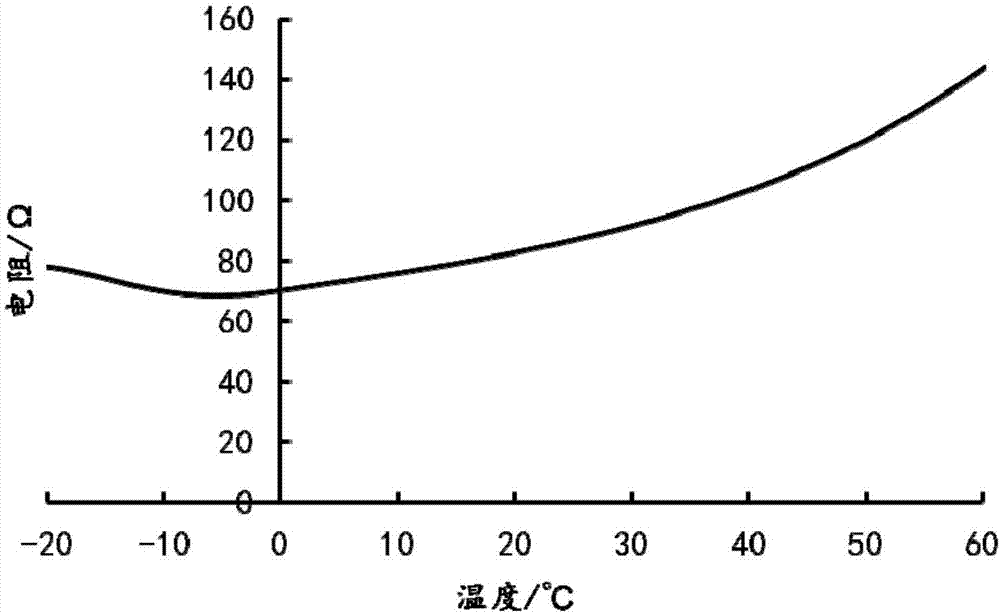

Mobile terminal

InactiveCN107219015AAccurate responseAccurate detectionThermometer detailsThermometers using electric/magnetic elementsComputer terminalMotherboard

The invention discloses a mobile terminal including a screen, a main board, and a transparent temperature sensing film. The temperature sensing film is in contact with the screen and is connected with the main board electrically; and the temperature sensing film senses an external temperature by the screen and then transmits a sensing result to the main board to obtain the external temperature. Therefore, with the mobile terminal, the temperature measurement error can be reduced.

Owner:JRD COMM (SHENZHEN) LTD

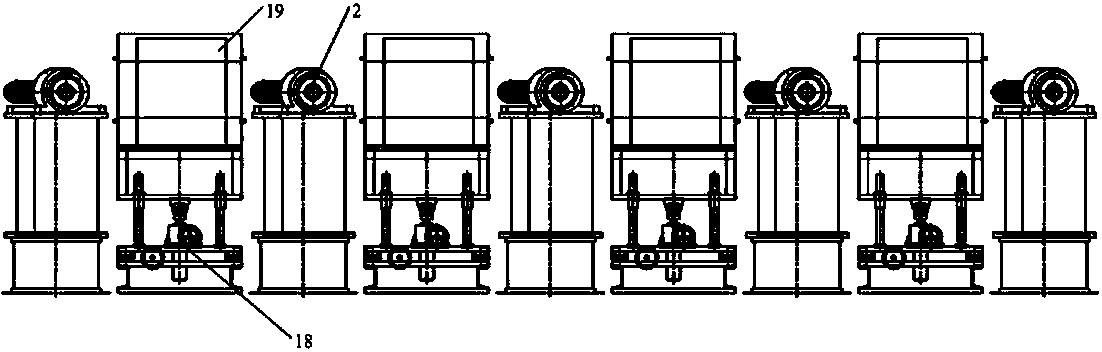

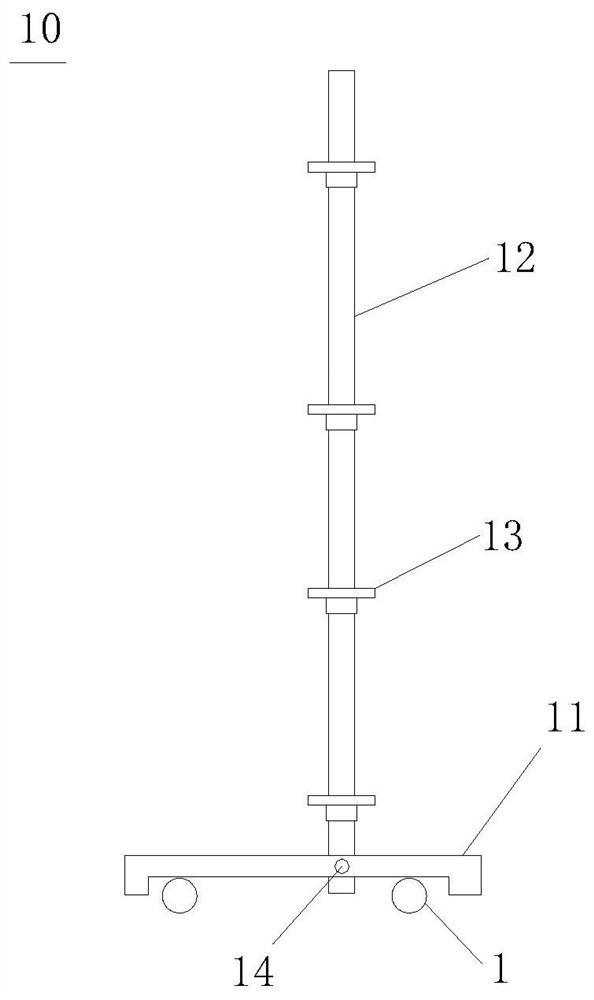

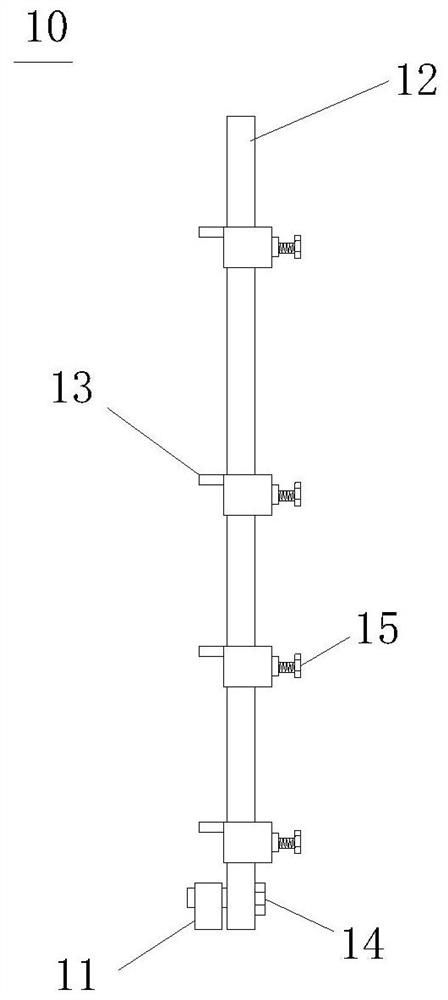

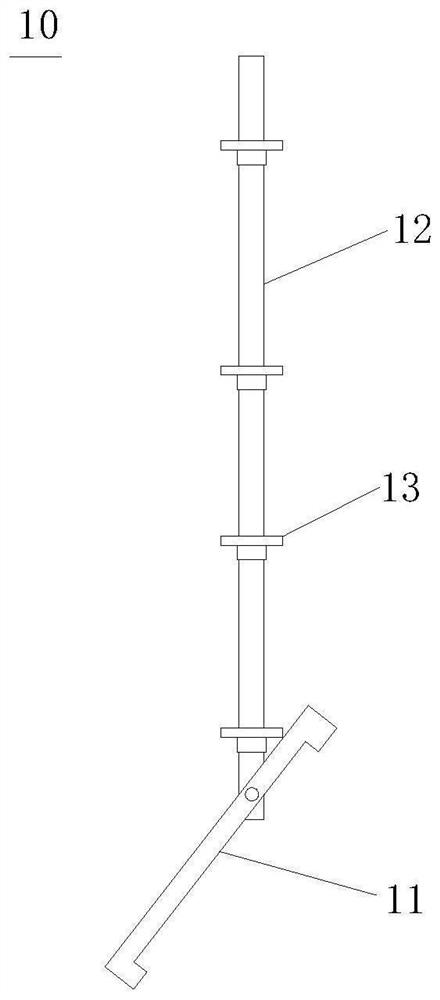

A digital temperature measurement system for mass concrete construction

ActiveCN111413001BReduce workloadHigh temperature resistantThermometer detailsTemperatue controlMeasuring instrumentData acquisition

The invention discloses a digital temperature measurement system for large-volume concrete construction. The temperature measurement system includes a temperature measurement device bracket, several serial temperature measurement devices, a data acquisition device and a server. The temperature measuring device bracket includes a supporting base, a vertical bar arranged on the supporting base, and a short horizontal bar arranged on the vertical bar. The series temperature measuring device includes a data line, and several temperature measuring instruments packaged on the data line, and the temperature measuring instrument includes a temperature sensor, a thin-walled steel sleeve, a filling material, a rubber pad and a heat shrinkable sleeve. The data acquisition device collects the temperature data of the temperature sensor according to the preset frequency, and transmits the data to the server. The series temperature measuring device has the advantages of high temperature resistance, anti-damage, anti-interference, and short-circuit prevention. The temperature measuring device bracket is used to fix the series temperature measuring device. The temperature measuring instrument is changed to a horizontal setting, which can effectively improve the measurement accuracy.

Owner:SHANGHAI CONSTRUCTION GROUP

Temperature indicator segmentation compensating device

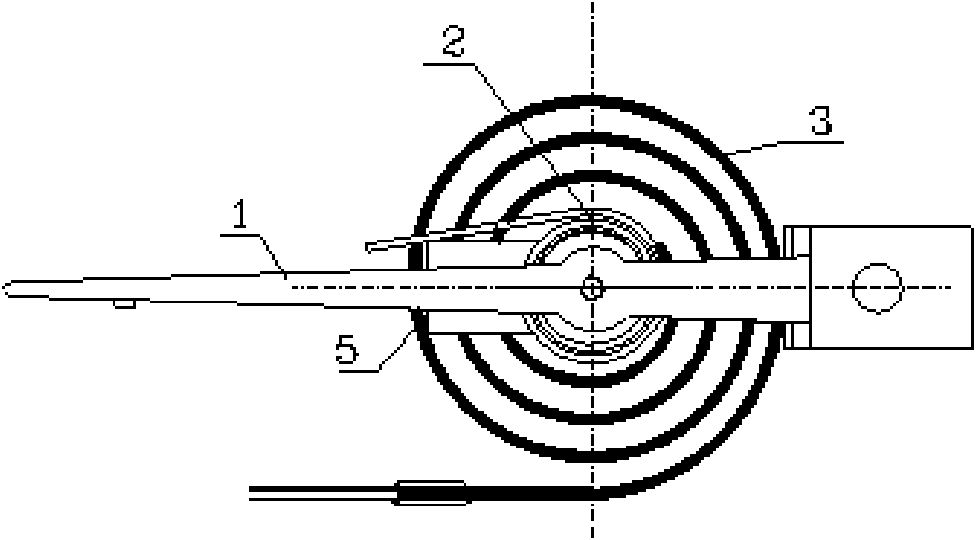

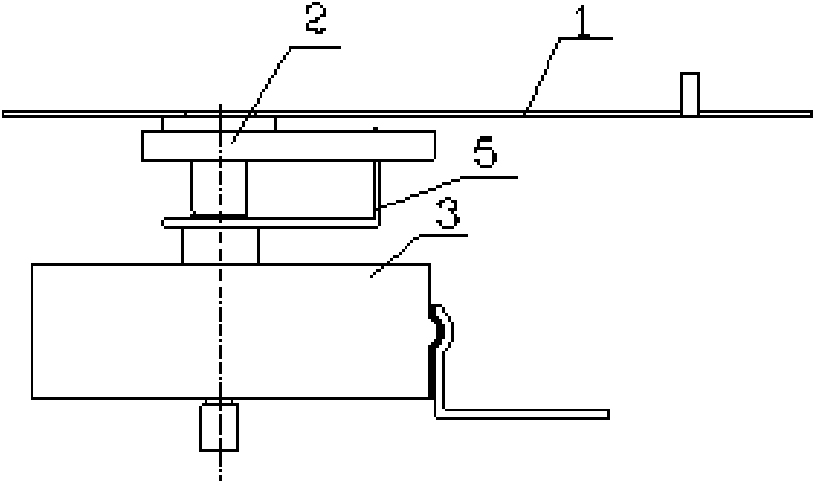

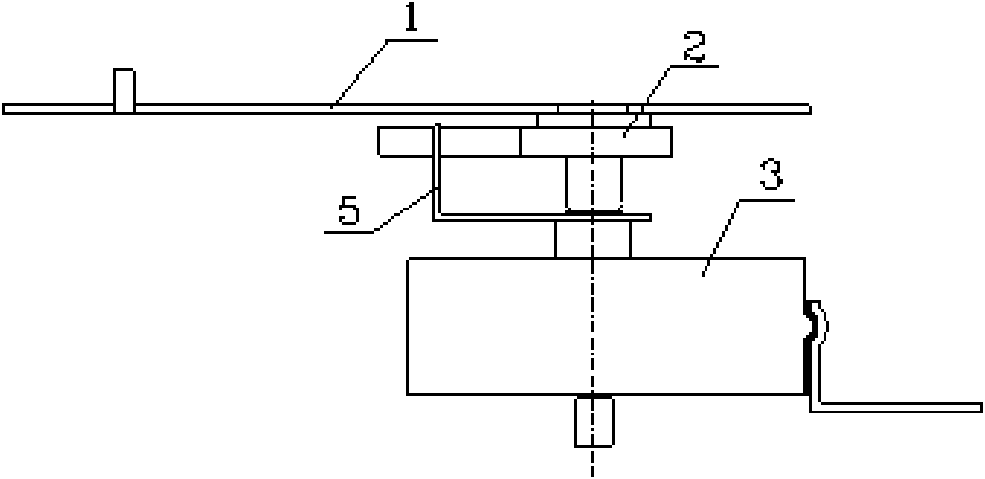

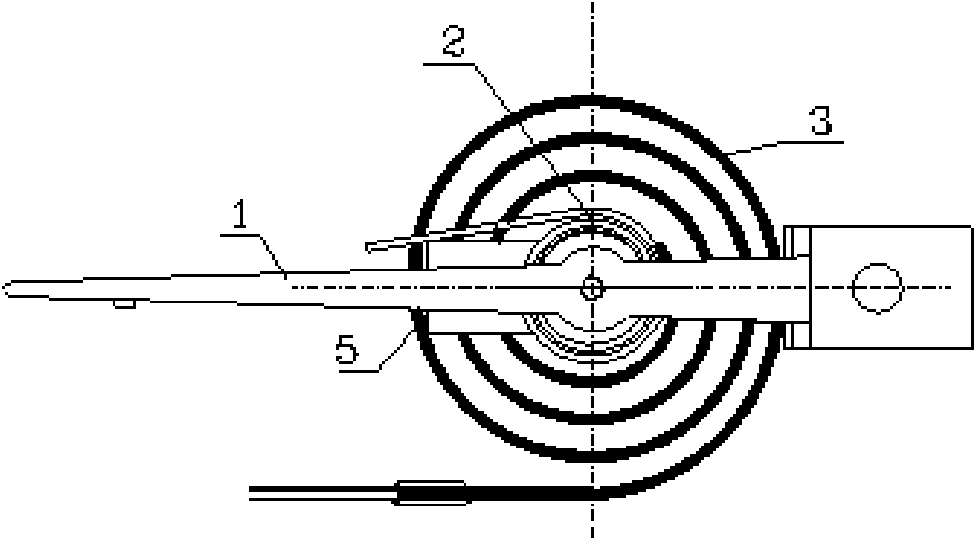

The invention discloses a temperature indicator segmentation compensating device which comprises a temperature pointer (1), a compensation system and a Bourdon tube (3), wherein the compensation system consists a compensation strip i (2) and a compensation strip ii (4); the revolving shaft of the compensation system is fixedly connected with that of the temperature pointer (1); the compensation strip ii (4) is coaxially connected below the compensation strip i (2); a push rod (5) is arranged below the compensation strip ii (4); and the Bourdon tube (3) is arranged below the push rod (5). The compensation strip ii is arranged coaxially to the compensation strip I, and an eccentricity is arranged between the revolving shaft of the push rood and that of the compensation system and the temperature pointer, or a track groove plate or a cam plate is arranged to limit the rotating track of the push rod so as to realize segmentation compensation of temperature. The temperature indicator is effectively compensated by the segmentation compensating device, thus further reducing the temperature detection error; in addition, the compensating device has simple structure, easy manufacture and low cost, and is beneficial to popularization and application.

Owner:杭州科宏仪器仪表有限公司

Temperature indicator segmentation compensating device

Owner:杭州科宏仪器仪表有限公司

An optimized temperature measurement method based on a single-camera colorimetric temperature measurement system

ActiveCN110954222BRealize the calibration of spectroscopic ratio distributionAvoid temperature measurement errorsPyrometry using electric radation detectorsComputational physicsImage matching

The invention discloses an optimized temperature measurement method based on a single-camera colorimetric temperature measurement system, which involves calibrating the proportional distribution of spectral intensity; optimizing the calculation formula of pixel unit temperature; calibrating and optimizing the parameters of the calculation formula of pixel unit temperature; calibrating the proportional distribution of spectral intensity includes Filter selection, fixed position of single camera colorimetric temperature measurement system, first band image and second band position calibration and sub-image matching, first band and second band dual-channel image acquisition, reference target point spectroscopic intensity ratio calculation and Calculation of the spectral intensity ratio distribution of the area to be measured; the optimized pixel unit temperature calculation formula includes the temperature calculation formula that takes the obtained reference target point spectral intensity ratio as an optimization parameter into the temperature measurement system, and the calibration and optimization pixel unit temperature calculation formula parameters include filtering Chip selection, reference temperature point selection, heating up of black body furnace, image acquisition, calibration formula derivation and multi-parameter collaborative optimization. The measured temperature is more accurate by optimizing the temperature measurement method.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A high-temperature flue gas contact temperature measuring device and its measuring method

ActiveCN109556749BImprove separation efficiencyEasy to disassembleMaterial heat developmentWithdrawing sample devicesCollection systemFlue gas

The invention discloses a high-temperature flue gas contact temperature measuring device and a measuring method thereof. The device comprises: a high-temperature flue gas collection system, a water-cooled heat exchange system, a flue gas component analysis system, an air extraction device, a measuring element, and a data acquisition system. and processing system; the measuring element, the flue gas component analysis system are electrically connected to the data acquisition and processing system; the water-cooled heat exchange system is arranged after the high-temperature flue gas collection system, and the flue gas The component analysis system is arranged at the tail end of the secondary water cooling system, and the exhaust device is connected to the tail end of the secondary water cooling system. The invention uses a water-cooled heat exchange system to cool the high-temperature flue gas to below 1200°C, and calculates the temperature of the high-temperature flue gas by measuring its temperature and the heat absorbed by the cooling medium, thereby realizing high-precision and long-term monitoring of the high-temperature flue gas above 1600°C. Measurement.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

System for measuring temperature of heat pipe

InactiveCN101000316BReduce temperature measurement errorImprove measurement accuracyMaterial heat developmentThermometers using electric/magnetic elementsElastic componentEngineering

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Temperature measuring device and temperature measuring method thereof

ActiveCN102539001BReduce temperature measurement errorThermometers using electric/magnetic elementsUsing electrical meansElectrical resistance and conductanceSignal processing circuits

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

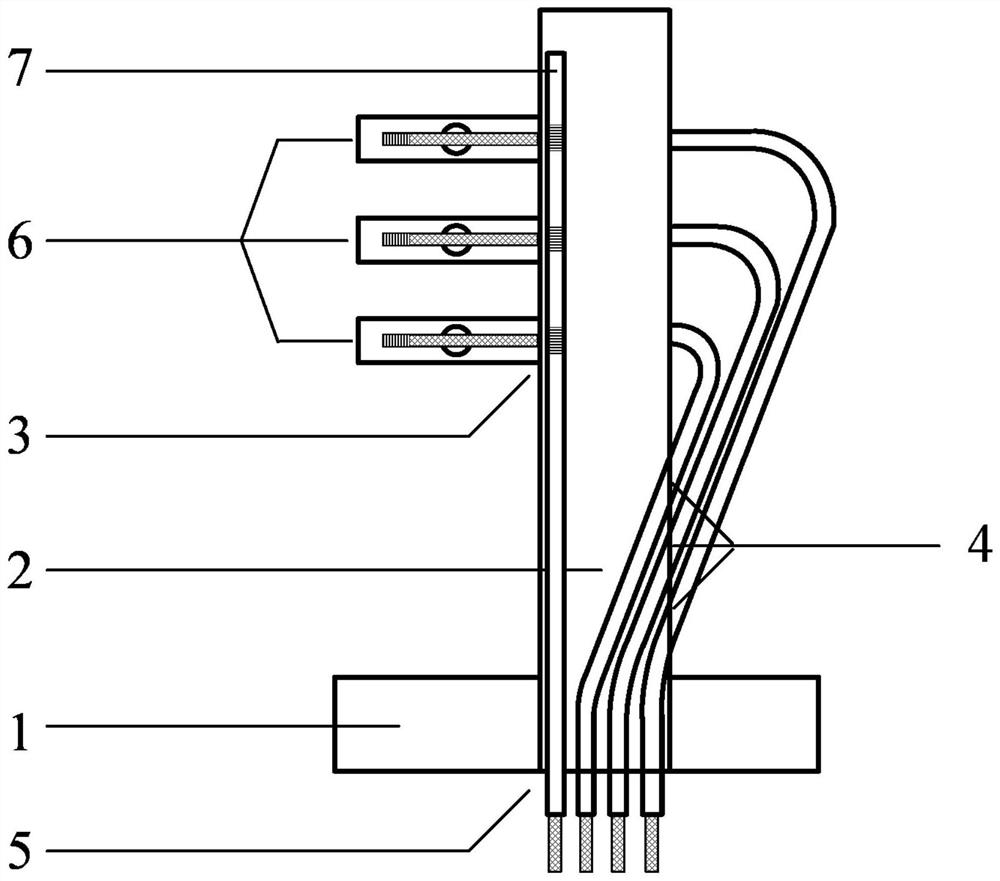

Fiber bragg grating total temperature measuring device capable of realizing heat conduction error correction

PendingCN113758603AImprove accuracyThermal error correctionThermometers using physical/chemical changesThermometer applicationsFiberFiber Bragg grating

The invention discloses a fiber bragg grating total temperature measuring device capable of realizing heat conduction error correction. The fiber bragg grating total temperature measuring device comprises a mounting base (1), a bracket (2), a total temperature probe (6) and a bracket temperature probe (7). The invention provides the fiber bragg grating total temperature measuring device capable of realizing heat conduction error correction. The device can correct heat conduction errors, improve the temperature measurement precision and improve the accuracy of measured data, the overall size of the device is small, the structure is flexible, and the heat conduction errors of a plurality of total temperature probes can be corrected at the same time.

Owner:CHONGQING UNIV

Pipeline gas pressure and flow stabilization device

ActiveCN106704832BEliminate swirl effectsLittle effect of temperature differenceFluid dynamicsPipe elementsCycloneLow speed

The invention provides a pressure and flow stabilizing device of a pipeline gas. The pressure and flow stabilizing device comprises a pressure and flow stabilizing barrel, a gas inlet pipe and an exhaust pipe, wherein the pressure and flow stabilizing barrel comprises a barrel body and a first end plate and a second end plate which are respectively arranged on the two end faces of the barrel body; the gas inlet pipe is arranged on the lower side of the first end plate; the exhaust pipe is arranged on the upper side of the second end plate; the gas inlet pipe and the exhaust pipe communicate with the pressure and flow stabilizing barrel; and a pressure measurement hole and a temperature measurement hole are formed in the surface of the pressure and flow stabilizing barrel. The pressure and flow stabilizing device has the beneficial effects that a gas flow pressure and flow stabilizing unit is composed of the large-diameter and eccentric pressure and flow stabilizing barrel, and gas flow at the high speed from tens of meters per second to hundreds of meters per second is changed to gas flow at the low speed of 15 meters per second or below, so that a dynamic temperature head and a dynamic pressure head are greatly decreased, and the gas cyclone influence is greatly eliminated; and besides, through mixing flow in the pressure and flow stabilizing barrel, the influence of temperature difference of a central layer and an outer layer of a gas pipeline is reduced, and measurement errors of pressure and temperature of the high-speed flow gas are decreased.

Owner:CHINA NORTH ENGINE INST TIANJIN

Method for regulating and controlling air-flowing environment of heating furnace

ActiveCN102297451BRealize energy savingReduce oxidation burnFuel supply regulationCombustionOptimal control

The invention discloses a method for regulating and controlling an air-flowing environment of a heating furnace, which belongs to the field of combustion monitoring and controlling, is applicable to detection and optimal control over combustion of a heating furnace and solves the problems that a mode is needed to be retrained when actual operation work conditions are deviated from preset conditions of the model or when parameters for supporting model operation are detected to be abnormal because an empirical mode is applied in the internal combustion monitoring of the traditional furnace. Themethod comprises the steps of equipment arrangement detection, image number processing and control. According to the method disclosed by the invention, a radioactive energy signal is extracted from flame image in different arranged sections of the heating furnace and is combined with air-flowing environments in the different sections for detecting and calculating reasonable air / combustion ratio, thus the oxidation and burn of steel and furnace tubes caused by the improper air-flowing environments in the heating furnace are reduced and the irregularity of quality of products in different batches is prevented. According to the method, proper air-flowing environments in the furnace can be created, temperature measuring errors are reduced and operation optimization, energy saving and emissionreduction of the heating furnace are realized.

Owner:HUAZHONG UNIV OF SCI & TECH

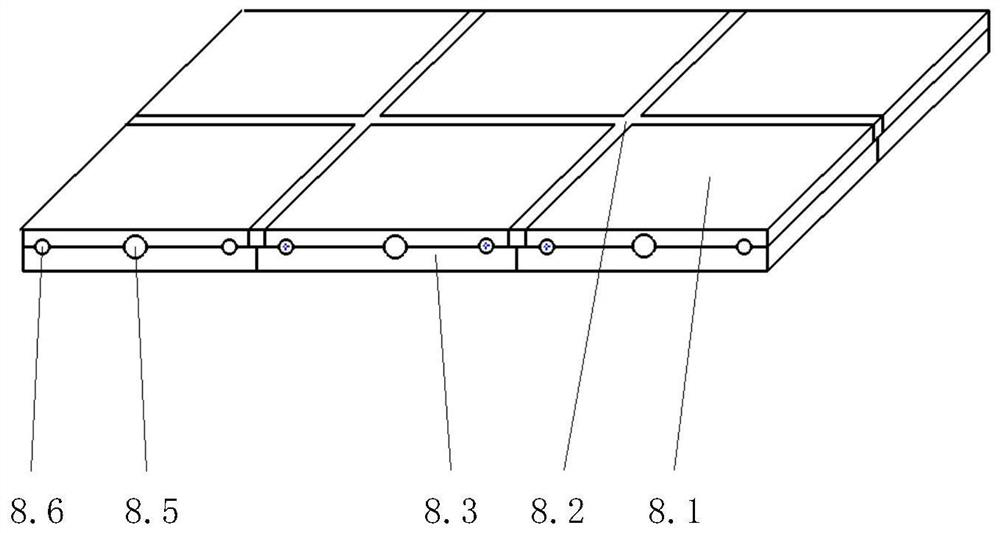

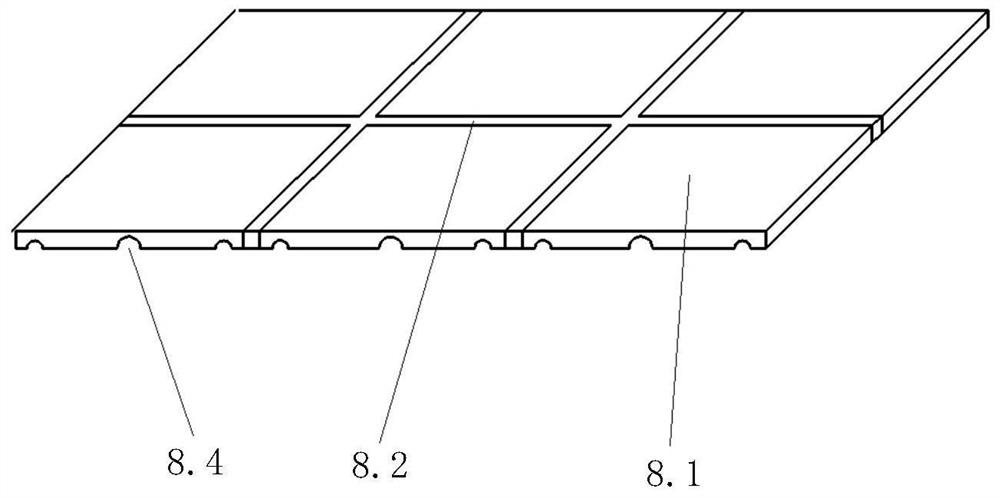

A control method of intelligent sub-regional temperature control composite material laying mold

The invention discloses an intelligent sub-area temperature-controlled composite material laying mold and a control method. The control areas are separated by a heat insulation layer to reduce the heat transfer rate between each temperature control area; the circulating fluid is used to increase or decrease the surface temperature of the mold; the circulating pipeline is used to load the circulating fluid and set In the mold body; a temperature control adjustment component, which is used for splitting or merging of the circulating fluid after the temperature is raised or lowered to input different temperature control areas to adjust the surface temperature of the mold body in different temperature control areas; a temperature sensor, It is used to detect the mold surface temperature. The invention can meet the temperature process curve of the thermoplastic composite material member in the stage of laying and in-situ solidification and molding, and can guarantee the quality and performance of the final product.

Owner:WUHAN UNIV

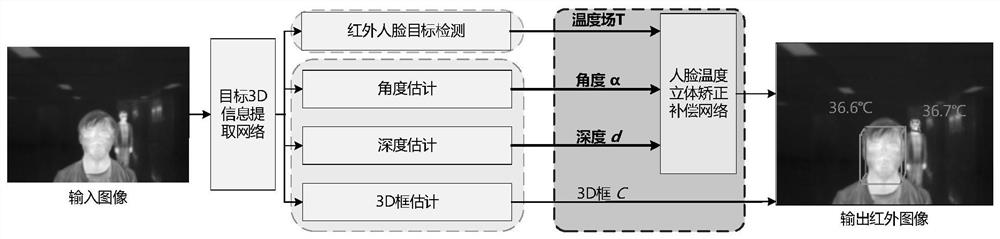

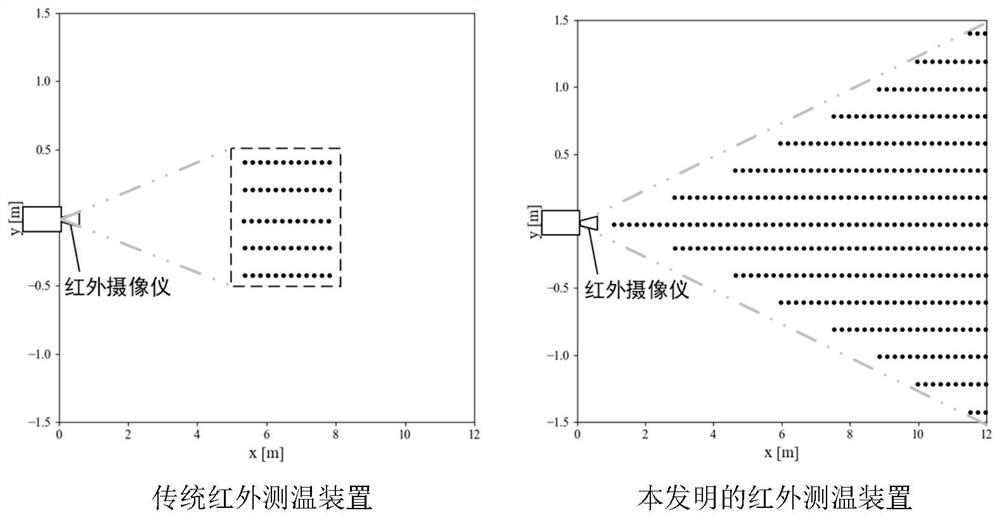

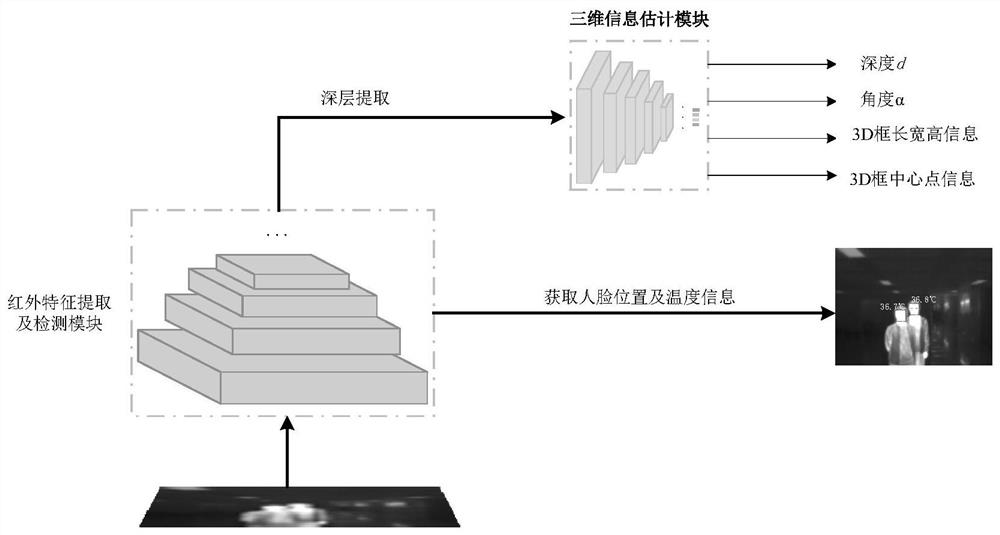

Remote target temperature accurate measurement method based on monocular infrared stereoscopic vision correction

PendingCN114061761AEffective prevention and controlLow costImage enhancementImage analysisFeature extractionRadiology

The invention relates to a remote target temperature accurate measurement method based on monocular infrared stereoscopic vision correction, which belongs to the technical field of infrared image recognition and detection. The method comprises the following steps of acquiring an infrared image containing temperature field information through a monocular infrared camera, inputting the infrared image into a target 3D information extraction network, and performing feature extraction and infrared face target detection so as to obtain target three-dimensional information and temperature field information, and constructing a face temperature three-dimensional correction and compensation network, inputting the obtained three-dimensional information and temperature field information into the face temperature three-dimensional correction and compensation network, carrying out three-dimensional vision temperature correction, and outputting an infrared image with temperature information, a 3D frame and angle information. The detection range can be expanded, the temperature measurement error is reduced, and the cost is reduced.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com