A multifunctional heat treatment system for steel pipes

A heat treatment system and multifunctional technology, applied in the field of multifunctional heat treatment systems for steel pipes, can solve the problems of long heating time of steel pipes, difficulty in refining the microstructure of steel pipes, and limitations in performance improvement, so as to achieve good comprehensive structure performance and shorten heating and heat preservation Time, effect on improving organization and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

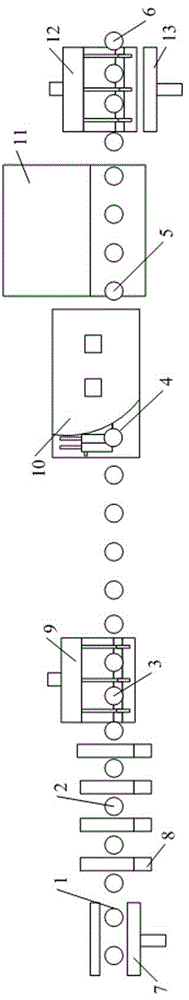

[0077] The size of the steel pipe selected in this embodiment is Φ139.7×7.72×5000mm. The heat treatment process method of the steel pipe is: intermediate frequency diathermy → heat preservation → controlled cooling → quenching → tempering. The process steps are as follows:

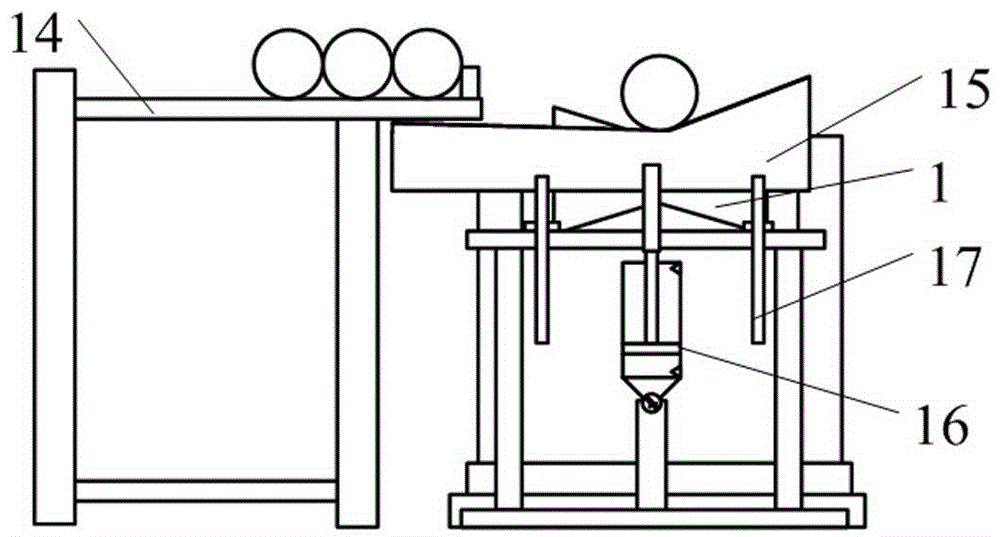

[0078] Lift the steel pipes to the inclined loading platform in advance, and place them in sequence; start the loading device, the loading pallet on the device lifts the steel pipe from the loading platform, and the steel pipe rolls in with a limit baffle The loading pallet of (feeding baffle) will fall onto the loading roller table as the loading pallet is lowered;

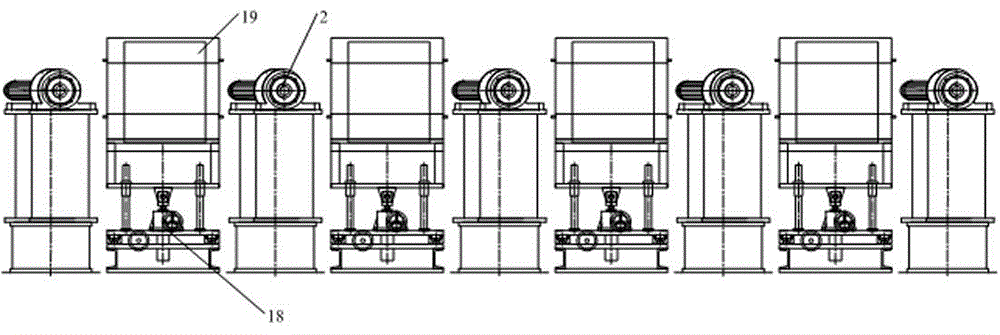

[0079] Intermediate frequency induction heating: start the feeding roller table group and the intermediate frequency induction furnace roller table group to move the steel pipe forward. When the steel pipe moves into the intermediate frequency induction furnace, stop the roller table and adjust the height of the intermediate frequency induction fur...

Embodiment 2

[0086] The size of the steel pipe selected in this embodiment is Φ152.4×14×5000mm, and the heat treatment process method of the steel pipe is: intermediate frequency heat insulation → heat preservation → air cooling → controlled cooling → air cooling. The process steps are as follows:

[0087] Lift the steel pipes to the inclined loading platform in advance, and place them in sequence; start the loading device, the loading pallet on the device lifts the steel pipe from the loading platform, and the steel pipe rolls in with a limit baffle The loading pallet of (feeding baffle) will fall onto the loading roller table as the loading pallet is lowered;

[0088] Intermediate frequency induction heating: start the feeding roller table group and the intermediate frequency induction furnace roller table group to move the steel pipe forward. When the steel pipe moves into the intermediate frequency induction furnace, stop the roller table and adjust the height of the intermediate frequency i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com