A method for controlling the atmosphere field of a heating furnace

A heating furnace and atmosphere technology, which is applied in the field of heating furnace atmosphere field regulation, heating furnace combustion detection and optimization control, can solve problems such as model training, achieve operation optimization, reduce temperature measurement errors, and prevent uneven product quality and finished products rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0045] An embodiment of the invention includes:

[0046] (1) Layout steps of testing equipment:

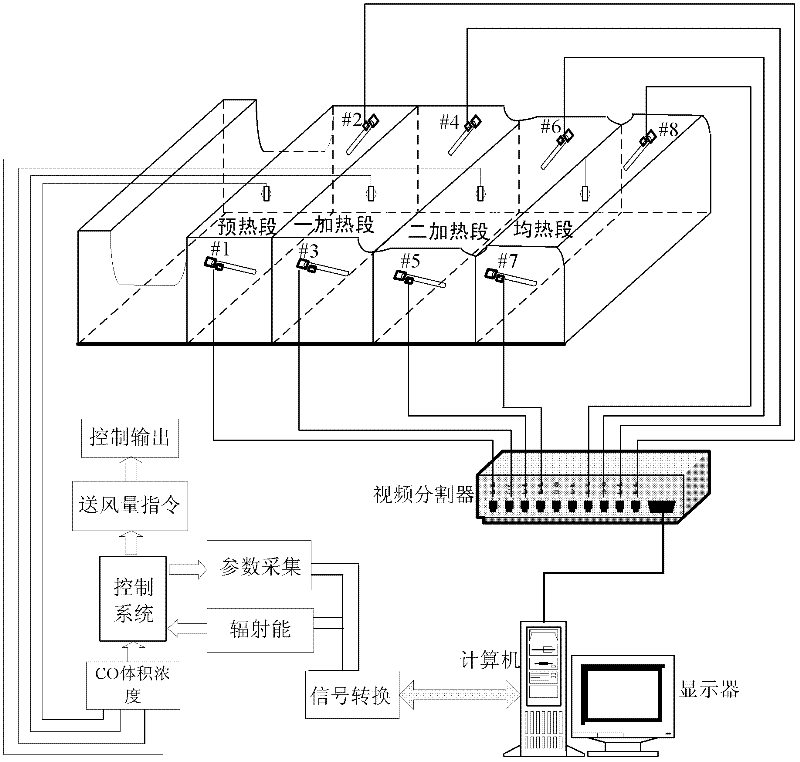

[0047]In a 1580 four-stage industrial heating furnace in a certain company, the preheating section, the first heating section, the second heating section, and the soaking section are all equipped with flame probes, and each section is equipped with 2 flame probes. Each flame probe is composed of Composed of a CCD camera and an optical lens barrel, each flame probe is connected to a video splitter, and the video splitter synthesizes 8 images taken by 8 flame probes into a flame image and outputs it to the computer;

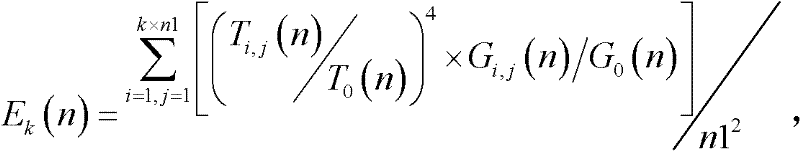

[0048] The actual internal size of the monitored heating furnace is (length×width×height): 32810mm×11700mm×2200mm, and 8 flame detectors detect all grid areas. The pixels of each flame detector are set to 30×30, and the total pixels of 8 flame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com