Garbage grab crane

A crane and garbage technology, applied in the direction of cranes, walking bridge cranes, load hanging components, etc., can solve the problems of low work efficiency, safety, lack of stability, environmental pollution, etc., and achieve high safety factor and efficiency. Simple operation and improved working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

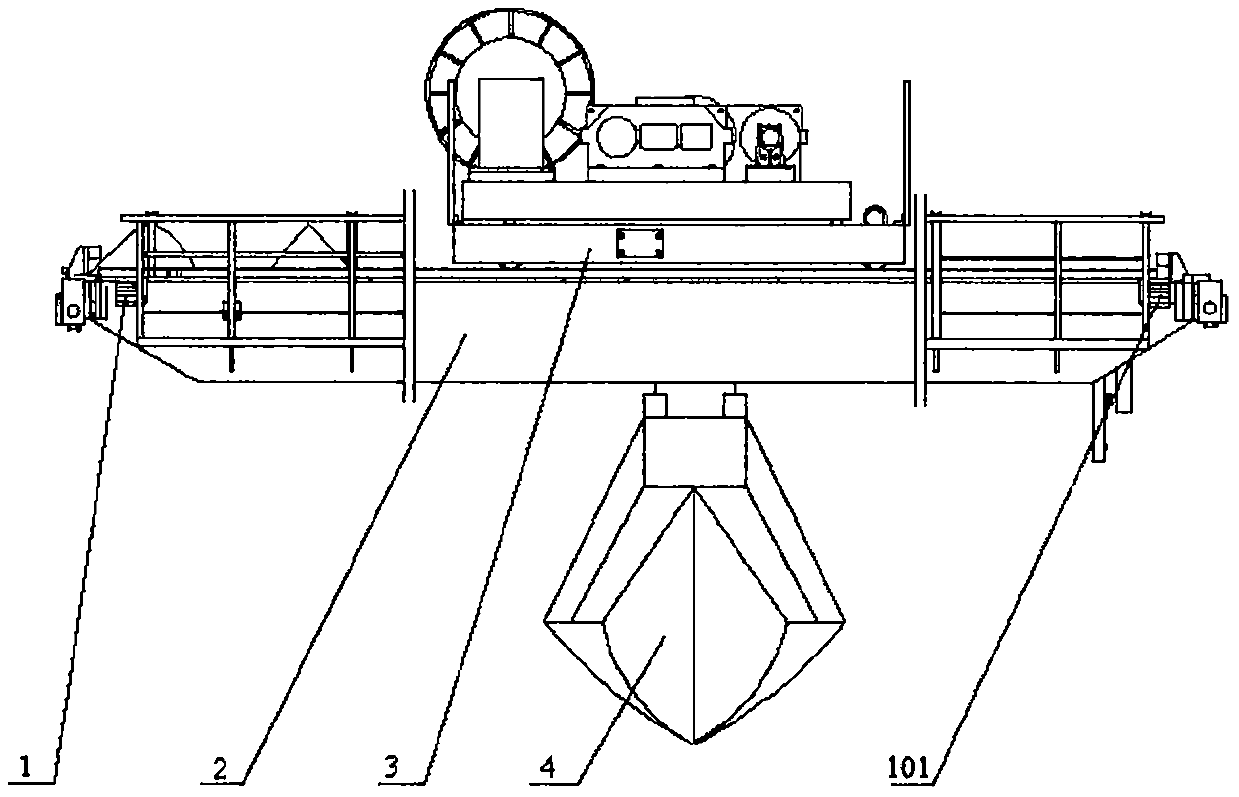

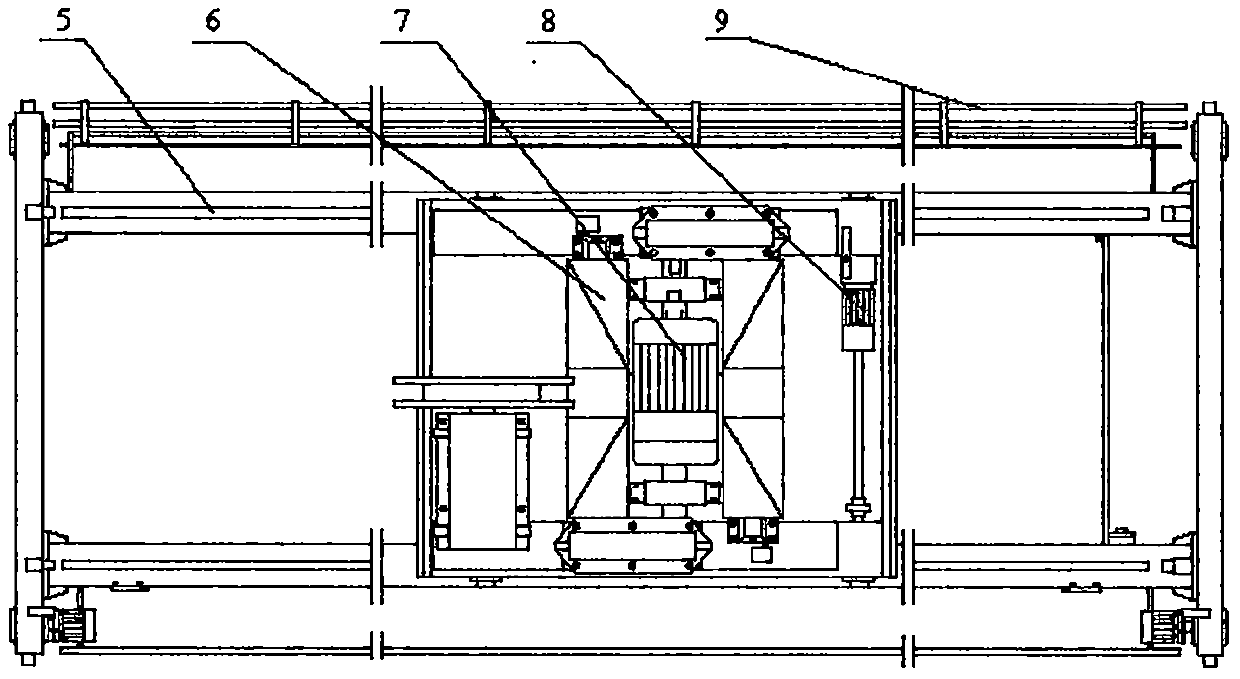

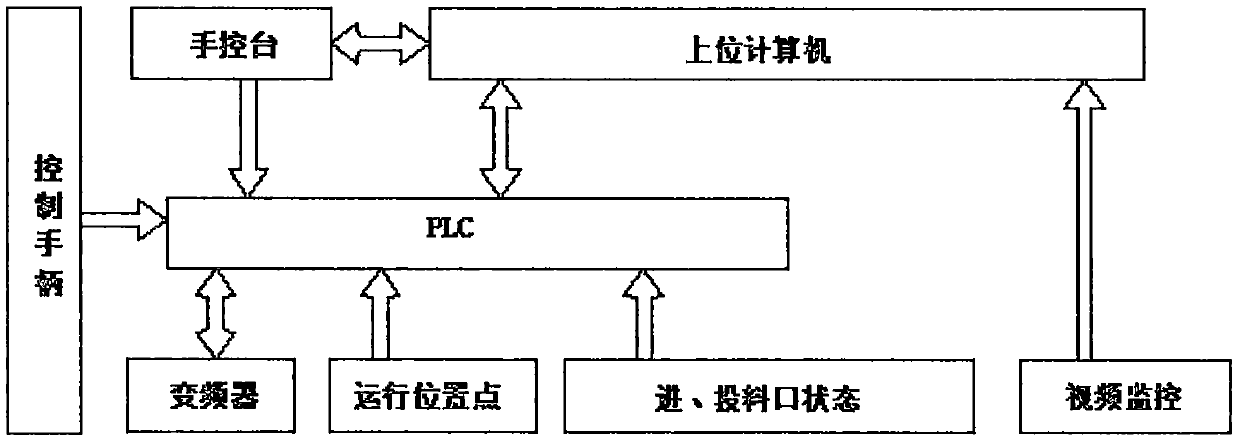

[0018] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a garbage grab crane, which includes a crane, the control system of the crane is composed of a control handle, PLC, hand console, upper computer, frequency converter, operating position point, feeding port status, video monitoring module , the main body of the crane is composed of a cart drive motor 1, a cart 2, a trolley 3, a grab bucket 4, a bridge frame 5, a reel 6, a lifting motor 7, a trolley drive motor 8, and a walking platform railing 9. The motor of the trolley 2 is driven by a frequency converter and its dedicated motor, the motor of the trolley 3 is driven by a frequency converter and its dedicated motor, and the lifting motor 7 is driven by a frequency converter and its dedicated motor. The first motor is provided with a high-precision photoelectric rotary encoder coaxially installed, and the encoder sends out pulses when the motor rotates once a week. The trolley 3 is provided with an ultras...

Embodiment 2

[0023] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a garbage grab crane, which includes a crane, the control system of the crane is composed of a control handle, PLC, hand console, upper computer, frequency converter, operating position point, feeding port status, video monitoring module , the main body of the crane is composed of a cart drive motor 1, a cart 2, a trolley 3, a grab bucket 4, a bridge frame 5, a reel 6, a lifting motor 7, a trolley drive motor 8, and a walking platform railing 9. The motor of the trolley 2 is driven by a frequency converter and its dedicated motor, the motor of the trolley 3 is driven by a frequency converter and its dedicated motor, and the lifting motor 7 is driven by a frequency converter and its dedicated motor. The first motor is provided with a high-precision photoelectric rotary encoder coaxially installed, and the encoder sends out pulses when the motor rotates once a week. The trolley 3 is provided with an ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com