Tuned mass damper

A quality tuning and damper technology, applied to building components, earthquake resistance, etc., can solve problems such as poor integrity, complicated maintenance work, complicated technology, etc., and achieve the effect of convenient operation, flexible adjustment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

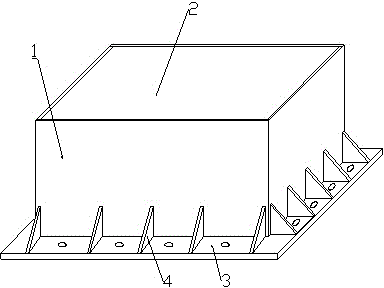

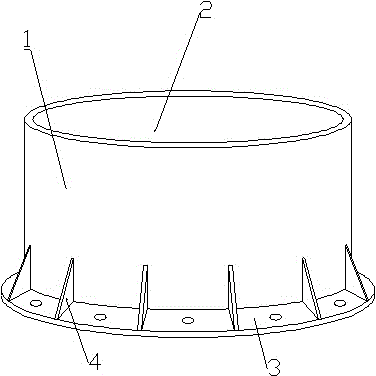

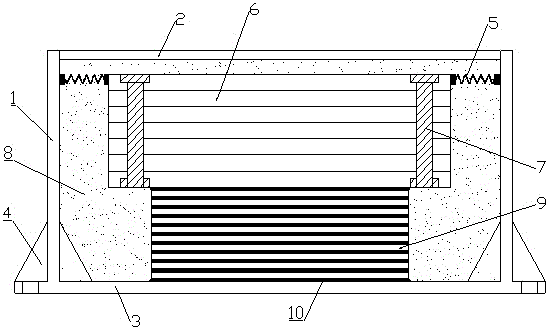

[0021] Such as figure 1 , 2 , 3, 4, and 5, a mass-tuned damper includes a base 3, a steel cylinder 1 fixedly installed on the base 3, an energy-consuming liquid 8 filled in the steel cylinder 1, and a steel cylinder installed on the top of the steel cylinder 1 The sealing plate 2, the bottom of the steel cylinder 1 is fixedly installed with a laminated support assembly, the top of the laminated support assembly is fixedly installed with a mass block assembly, and the upper part of the mass block assembly is connected to the inner wall of the steel cylinder 1 through a spring 5 connect.

[0022] The laminated support assembly includes at least two layers of steel plates 10 and a rubber layer 9 fixedly installed between the steel plates 10, wherein the bottommost steel plate 10 is fixedly connected to the base 3, and the topmost steel plate 10 is fixed to the mass block assembly connect. The mass block assembly includes at least two layers of mass plates 6 and bolts 7 longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com