All-directional movable type multifunctional forklift

A mobile, multi-functional technology, applied in the direction of hoisting devices, can solve the problems of steering, inflexible drive, unable to meet the requirements of the operation, etc., to achieve the effect of ensuring high efficiency, improving efficiency, and having broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

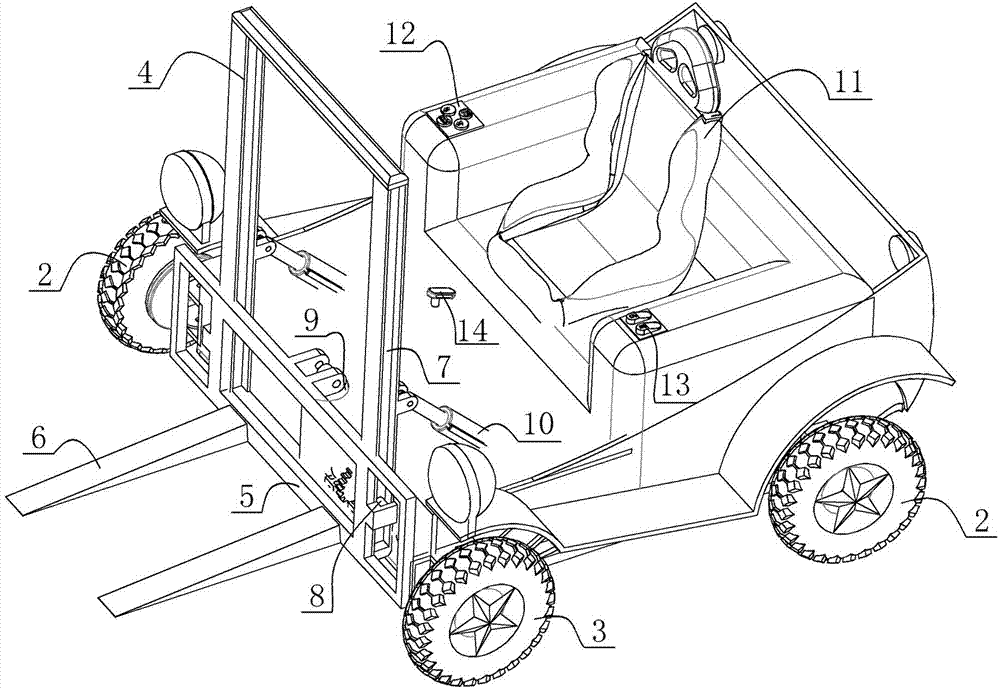

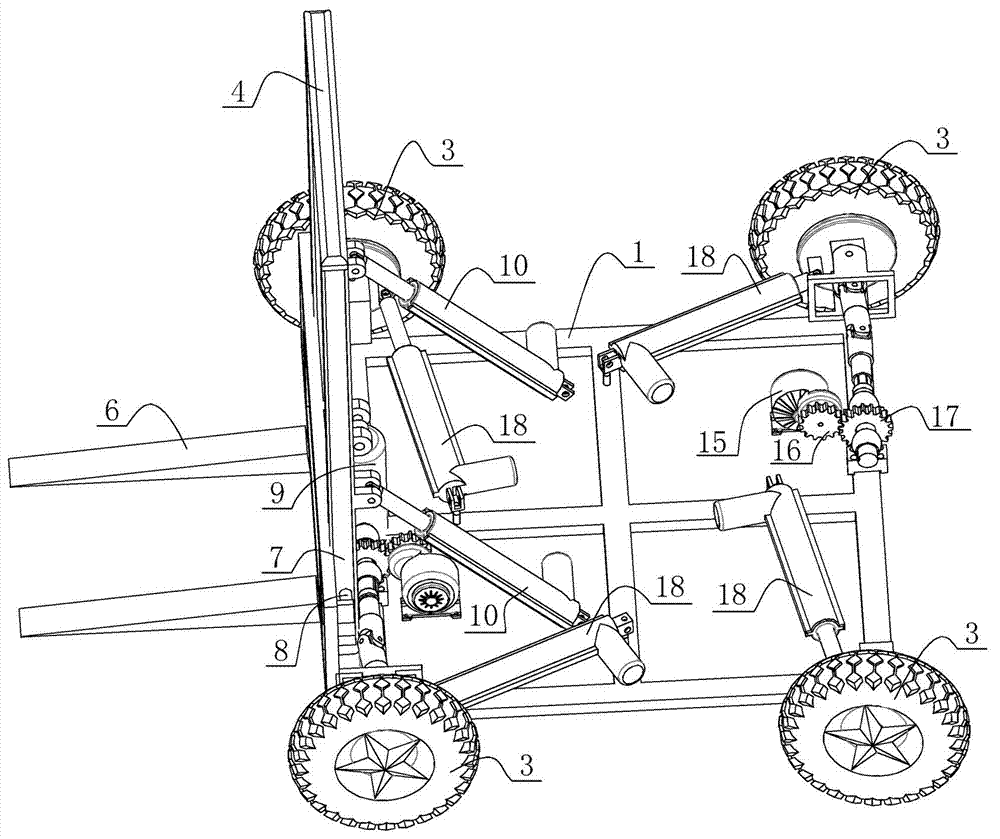

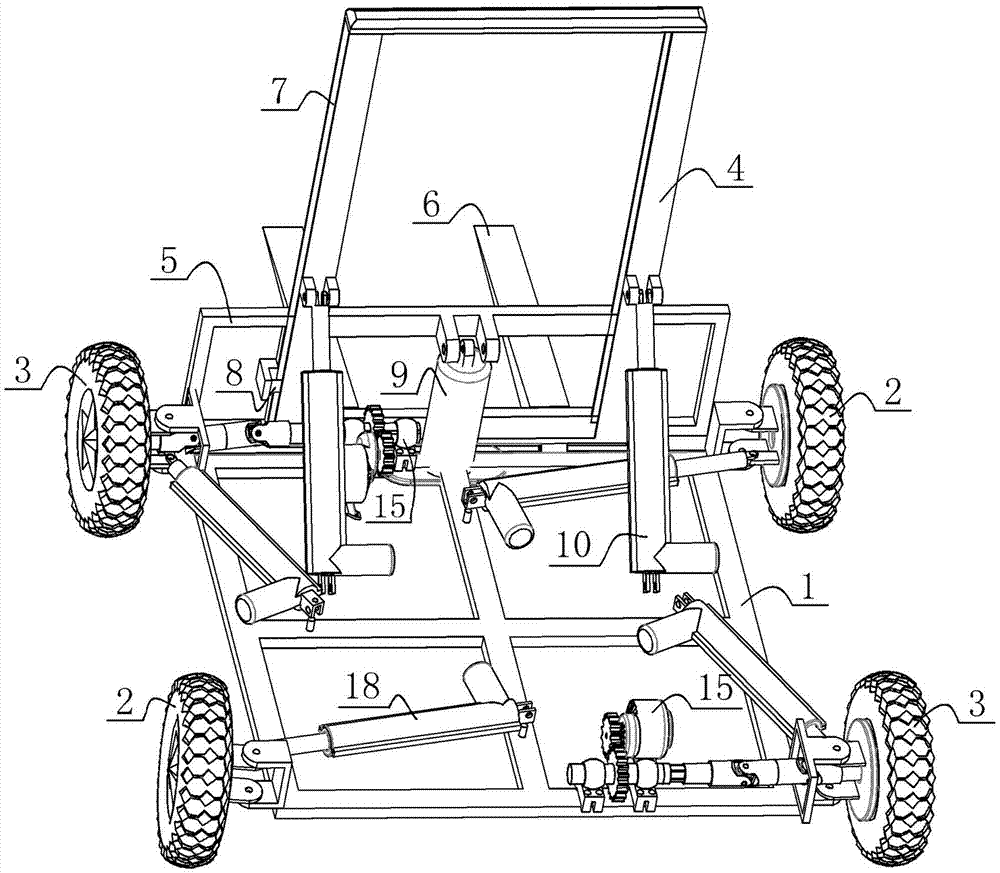

[0023] Such as figure 1 , figure 2 and image 3 As shown, a perspective view of the omnidirectional mobile multifunctional forklift of the present invention is provided, which includes a vehicle frame 1, two driven wheels 2, two driving wheels 3, a support frame 4, a lifting rod 5, fork claws 6, hydraulic pressure Cylinder 9, swing motor 10, seat 11, driving motor 15 and circuit part; the bracket 1 shown plays a role of fixing and supporting, and two driving wheels 3 and two driven wheels 2 are respectively arranged on the opposite corners of the vehicle frame 1 , the driving motor 15 is fixed on the vehicle frame near the driving wheel 3, and the driving motor 15 drives the driving wheel 3 to rotate through the transmission mechanism to realize the forward and backward movement of the forklift. The four corners of the vehicle frame are all provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com