Fiber bragg grating total temperature measuring device capable of realizing heat conduction error correction

A fiber grating, thermal conductivity error technology, applied in measuring devices, measuring heat, thermometers with physical/chemical changes, etc., can solve the problem that the fiber grating total temperature probe cannot accurately measure the total airflow temperature, reduce the temperature measurement accuracy, and increase the thermal conductivity. Error and other problems, to achieve the effect of improving temperature measurement accuracy, high flexibility and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

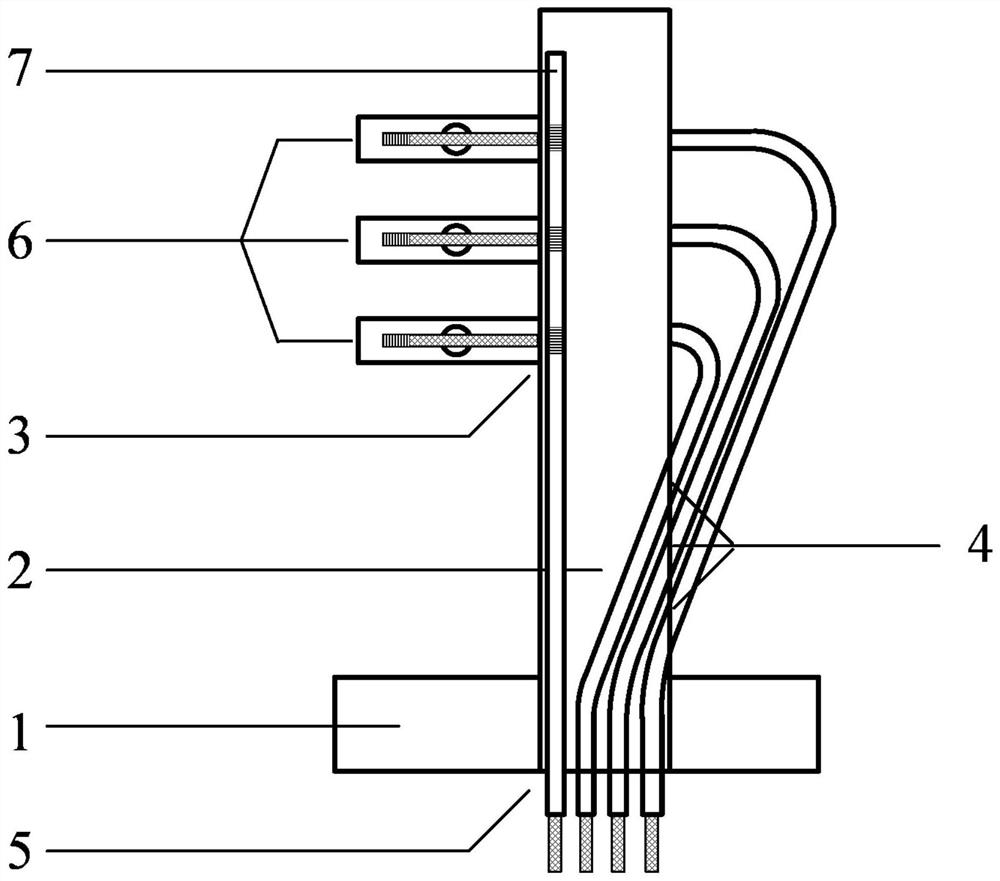

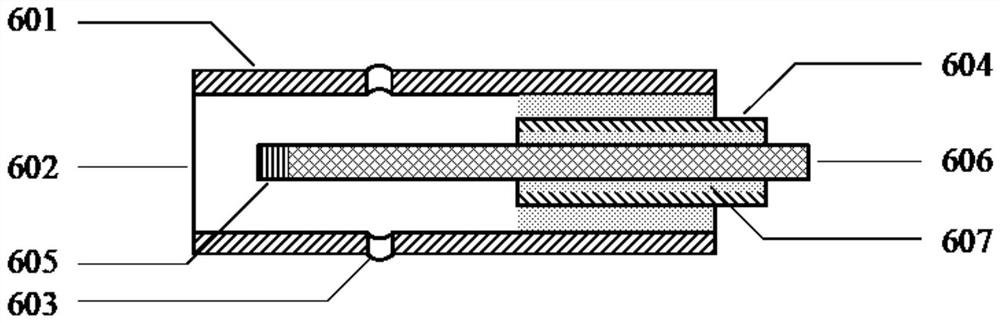

[0053] see Figure 1 to Figure 5 , a fiber grating total temperature measurement device capable of correcting thermal conduction errors, comprising a mounting base 1, a bracket 2, a total temperature probe 6 and a bracket temperature probe 7.

[0054] The installation base 1 is used to support the bracket 2 .

[0055] A plurality of total temperature probe mounting holes 3 are provided on the side facing the airflow of the support 2 .

[0056] The support 2 is a hollow cylinder.

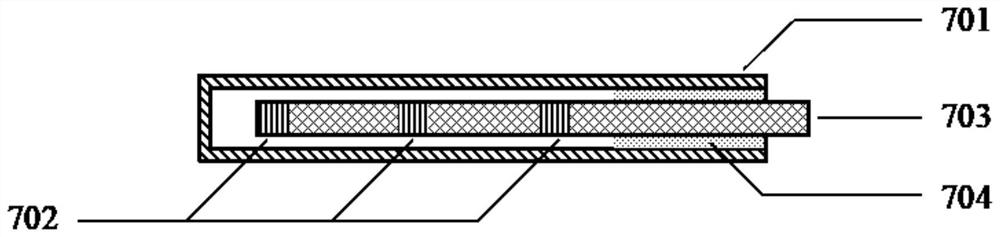

[0057] The bottom end of the bracket 2 is provided with a bracket temperature probe installation hole 5 .

[0058] The back airflow side of the bracket 2 is provided with a plurality of outlet holes 4 for the grating support tube of the total temperature probe.

[0059] The total temperature probe 6 is fixed on the bracket 2 through the total temperature probe installation hole 3 .

[0060] The total temperature probe 6 is used to monitor the total temperature of the high-speed airflow.

[0061]...

Embodiment 2

[0083] A fiber grating total temperature measuring device capable of correcting heat conduction errors, comprising an installation base 1, a bracket 2, a total temperature probe 6 and a bracket temperature probe 7.

[0084] The installation base 1 is used to support the bracket 2 .

[0085] A plurality of total temperature probe mounting holes 3 are provided on the side facing the airflow of the support 2 .

[0086] The support 2 is a hollow cylinder.

[0087] The bottom end of the bracket 2 is provided with a bracket temperature probe installation hole 5 .

[0088] The total temperature probe 6 is fixed on the bracket 2 through the total temperature probe installation hole 3 .

[0089] The total temperature probe 6 is used to monitor the total temperature of the high-speed airflow.

[0090] The bracket temperature probe 7 is fixed in the bracket 2 through the bracket temperature probe mounting hole 5 .

[0091] The bracket temperature probe 7 is used to monitor the temper...

Embodiment 3

[0093] A fiber grating total temperature measurement device capable of correcting thermal conduction errors, the main structure is shown in Example 2, wherein, the back airflow side of the support 2 is provided with a number of lead-out holes 4 for the total temperature probe grating support tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com