Temperature indicator segmentation compensating device

A compensating device and indicator technology, applied to thermometers, thermometer parts, measuring devices, etc., can solve the problems of increasing measurement errors and unable to completely eliminate ambient temperature errors, reduce temperature measurement errors, and facilitate popularization and application , easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

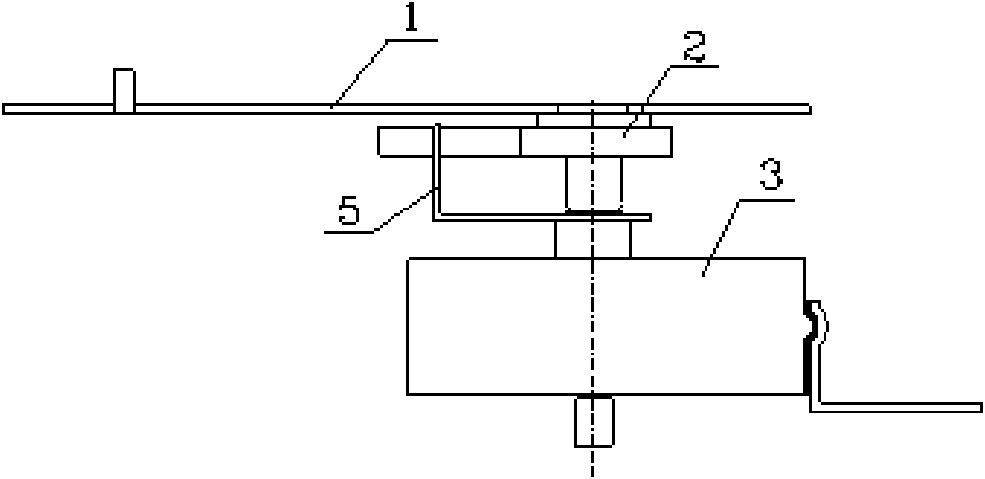

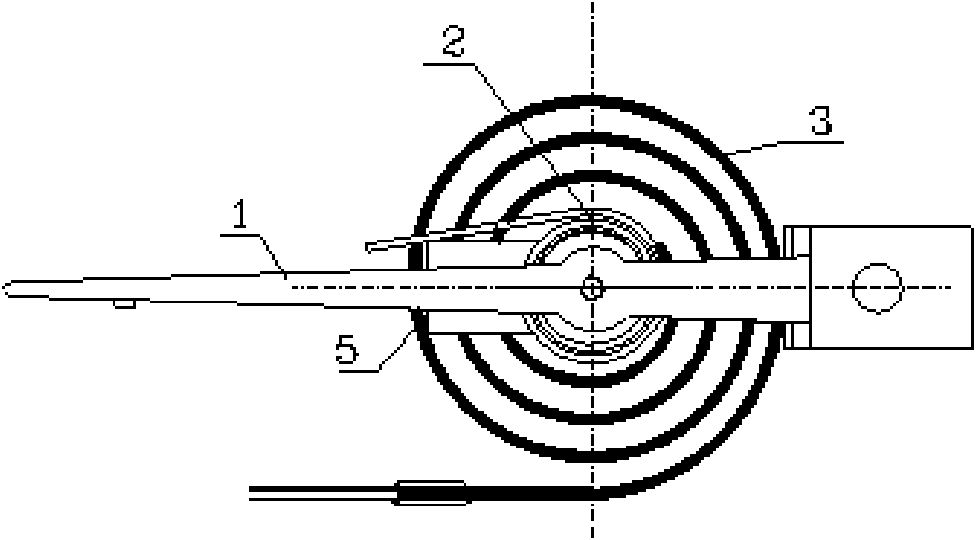

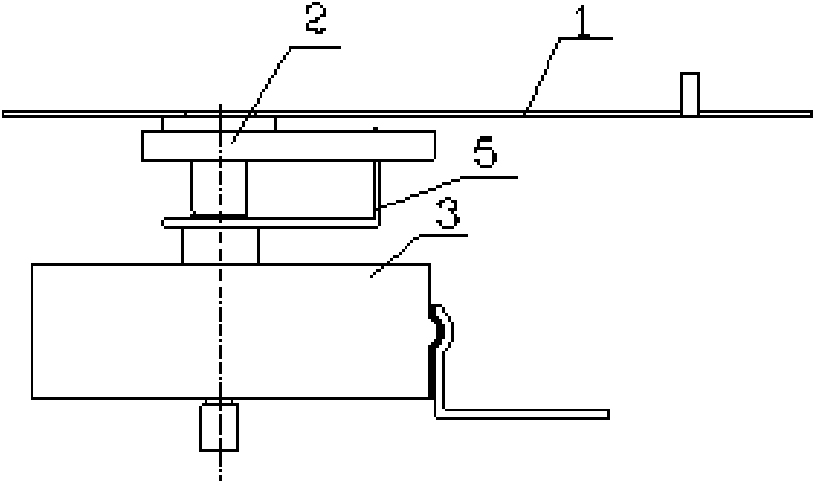

[0037]Embodiment 2 of the present invention: as the second embodiment of the present utility model, as Figure 9-Figure 12 As shown, it also includes a temperature pointer 1, a compensation system, and a Bourdon tube 3. The compensation system is fixedly connected to the rotating shaft of the temperature pointer 1, and the compensation sheet II 4 is coaxially connected to the compensation sheet I 2 , and the compensation sheet II 4 Push rod 5 is housed below, and Bowden tube 3 is housed below push rod 5. Among them, putter 5 is Shape, its transverse section is fixed on the rotating shaft, and the difference is that the hole that push rod 5 cooperates with the rotating shaft is a long hole, and the track groove dish 6 that cooperates push rod 5 to rotate is housed between push rod 5 and Bowden tube 3. A track groove is provided on the track groove disk 6, and the track groove includes a connected inner track 7 and an outer track 8, and the vertical section of the push rod 5 e...

Embodiment 3

[0040] Embodiment 3 of the present invention: as the third embodiment of the present invention, as Figure 13-Figure 16 As shown, compared with embodiment 2, the track groove plate 6 is replaced by the cam plate 10 and the tension spring 11 below it, and the lower end of the vertical section of the push rod 5 is stuck on the outer edge of the cam plate 10, and is held by the tension spring 11 is pulled, and under the pull of extension spring 11, the motion locus of push rod 5 follows the shape of cam disc 10 (see the shape of cam disc 10 Figure 17 ) changes, and the vertical section of the push rod 5 is pushed by the short handle of the compensator II or the long handle of the compensator I2 in different temperature ranges, thereby realizing the segmental compensation of the temperature.

[0041] Other unspecified items are the same as in Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com