Hot-pipe temperature measuring device

A heat pipe and measurement technology, applied in the field of heat transfer, can solve the problems of the actual temperature error of the heat pipe surface in the measurement results, the heat-resistant tape is not easy to apply force, the contact is not direct, reliable, etc., to reduce errors, improve accuracy, Effect of reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

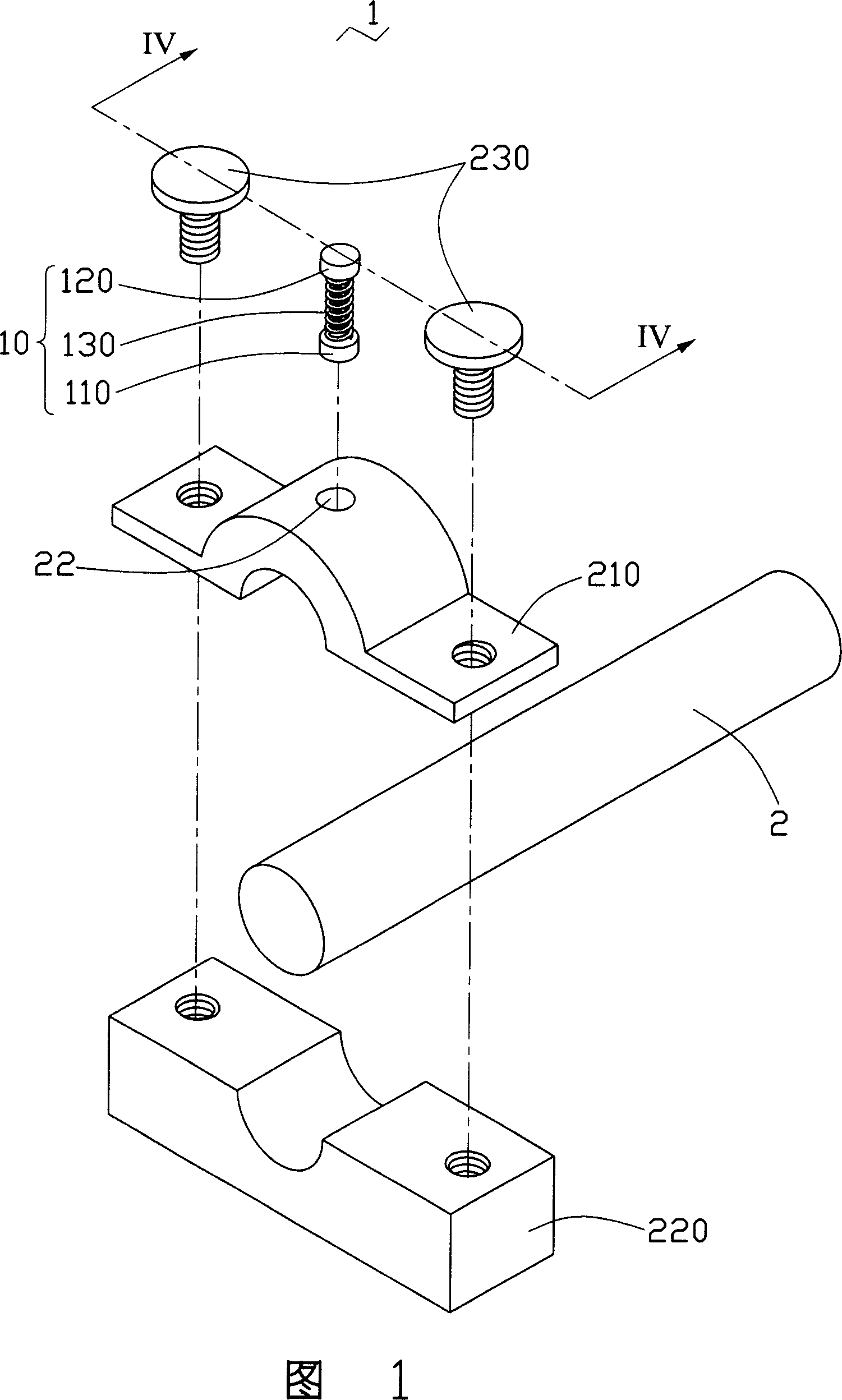

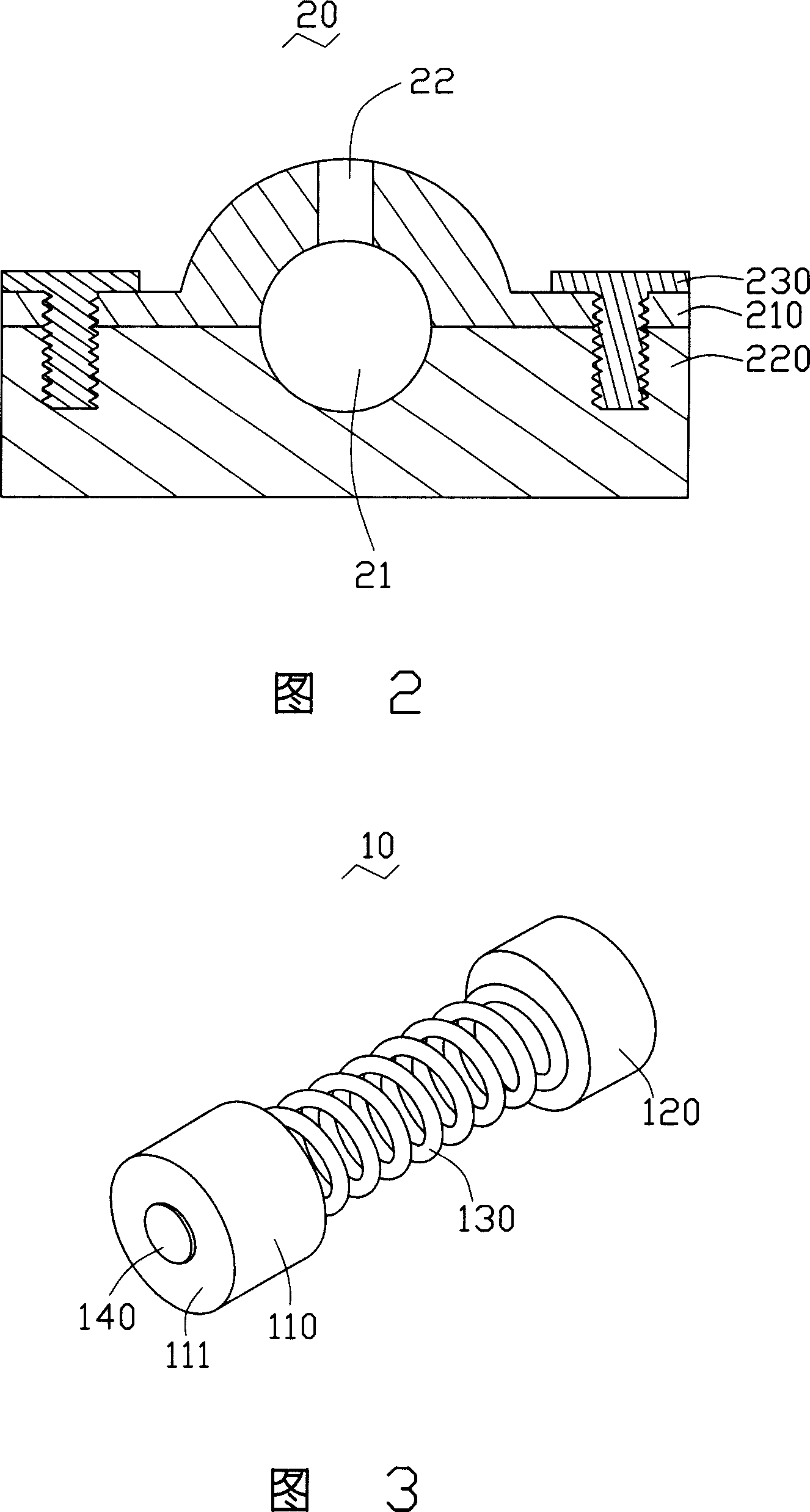

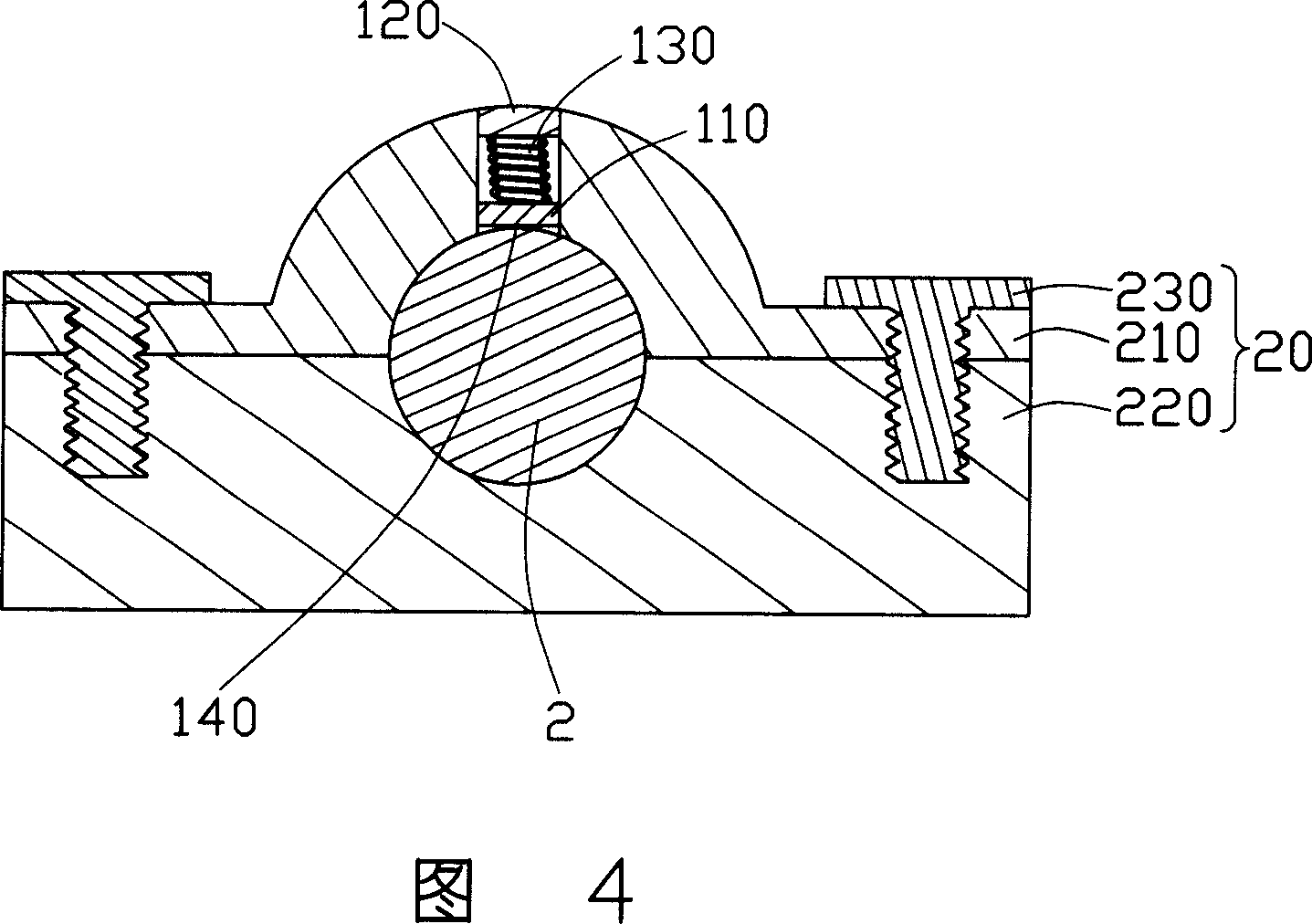

[0015] Please refer to Fig. 1 to Fig. 4 together, the heat pipe temperature measuring device 1 provided by the present invention includes: a clamping part 20 and a measuring assembly 10, and the clamping part 20 is provided with an accommodating cavity 21 and a The accommodating cavity 21 communicates with the insertion hole 22, the accommodating cavity 21 is used to clamp the heat pipe 2, and the insertion hole 22 is used to insert the measurement assembly 10, the measurement assembly 10 includes: a bearing block 110, A pressing block 120, a spring 130 and a thermocouple 140, the spring 130 is supported between the bearing block 110 and the pressing block 120, and the thermocouple 140 is attached to a side of the bearing block 110 away from the spring 130 The surface 111 is used to abut against the heat pipe 2 so as to measure the temperature of the heat pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com