Device for measuring heat conductivity coefficient of powder on basis of transient plane heat source method

A transient plane, heat source method technology, applied in the direction of material thermal development, can solve the problem of long thermal conductivity of powder thermal insulation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

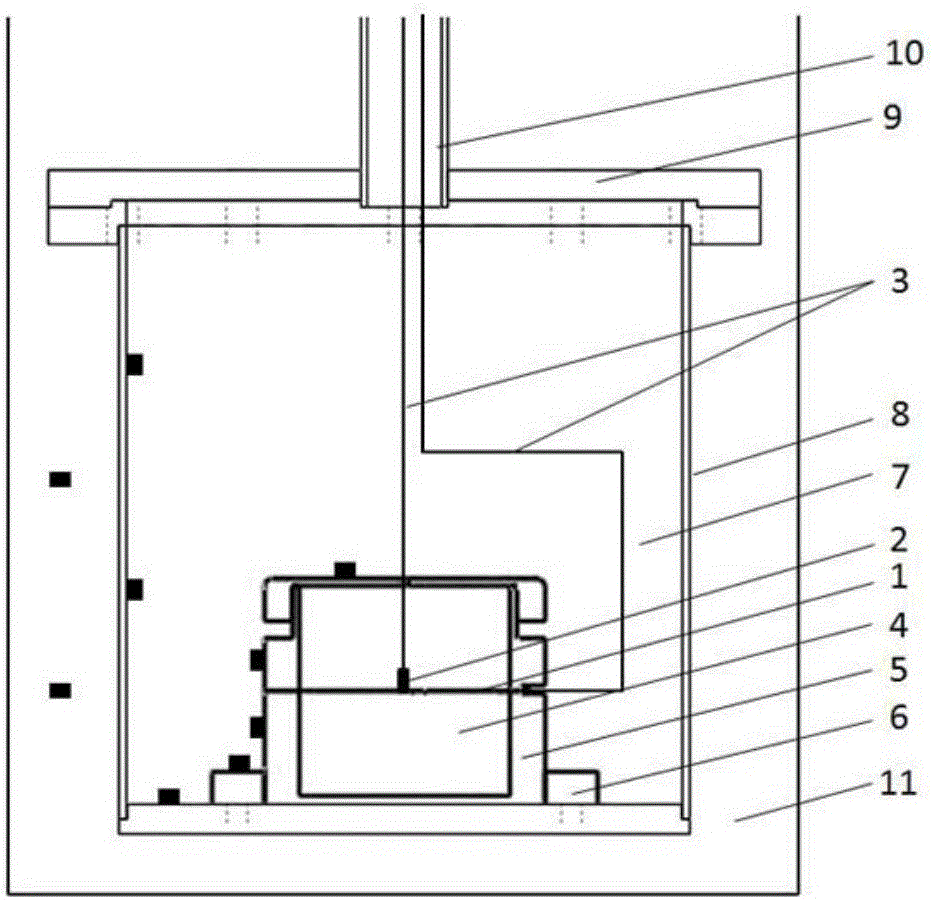

[0051] A device for measuring powder thermal conductivity based on a transient plane heat source method, the device comprising: a vacuum container 7 and a constant temperature system 11; the vacuum container 7 is set in the constant temperature system 11;

[0052] The constant temperature system 11 is an oven (RT-200°C), water bath system (0°C-100°C), oil bath system (100°C-200°C) or other low temperature system (minimum to 30K) (such as: liquid nitrogen (77K ), liquid nitrogen cryogenic box (77K-RT), etc.); the measurable temperature range of this transient plane heat source method thermal conductivity testing device is 30K-473K, and the constant temperature system 11 provides a certain ambient temperature for the sample to be tested;

[0053] Two PT100 platinum resistance thermometers are set in the constant temperature system 11 to monitor constant temperature inside the constant temperature system 11;

[0054] The vacuum container 7 includes a vacuum container cylinder bod...

Embodiment 2

[0085]A device for measuring powder thermal conductivity based on the transient plane heat source method, as described in Example 1.

[0086] To measure the thermal conductivity of the powder at 100°C and 10Pa, the steps are as follows:

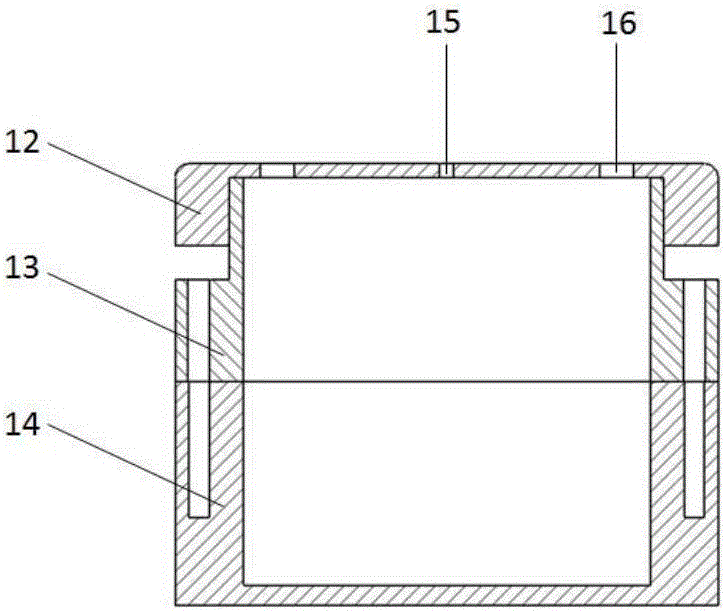

[0087] 1) Install Hot Disk thermal constant analysis software in the computer;

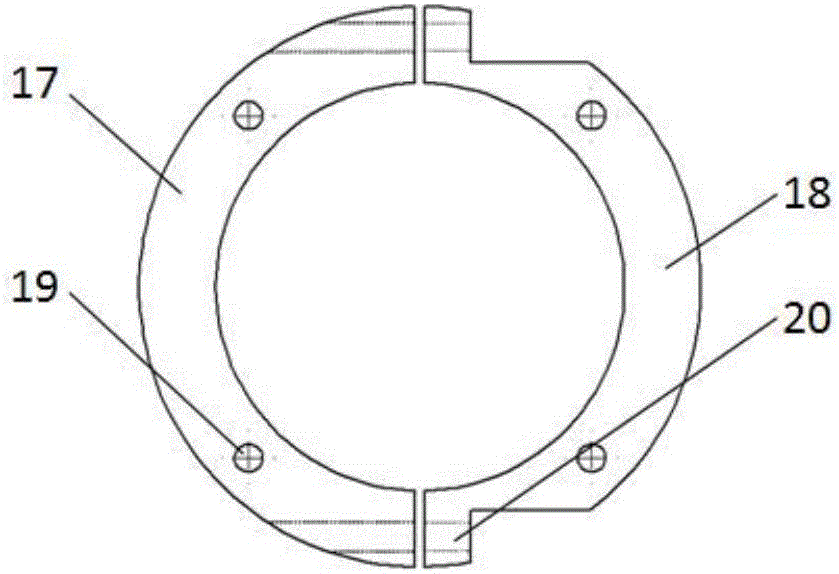

[0088] 2) Installation of the sample to be tested: first fill the sample area 4 to be tested in the lower half 14 of the powder sample rack with powder samples, place the test probe 1, connect the upper half 13 of the powder sample rack and the lower half 14 of the powder sample rack Fix (clamp the test probe with the upper half 13 and the lower half 14 of the powder sample rack); the sample area 4 to be tested in the upper half 13 of the powder sample rack is filled with powder samples; the inner surface of the upper cover 12 of the powder sample rack Glue the 1000-mesh stainless steel mesh, connect and fix the upper half 13 of the powder sample rack with the u...

Embodiment 3

[0097] A device for measuring powder thermal conductivity based on the transient plane heat source method, as described in Example 1.

[0098] Measuring powder at 77K, 10 -3 The thermal conductivity under Pa, the steps are as follows:

[0099] 1) Install Hot Disk thermal constant analysis software in the computer;

[0100] 2) Installation of the sample to be tested: first fill the sample area 4 to be tested in the lower half 14 of the powder sample rack with powder samples, place the test probe 1, connect the upper half 13 of the powder sample rack and the lower half 14 of the powder sample rack Fix (clamp the test probe with the upper half 13 of the powder sample holder and the lower half 14 of the powder sample holder); the sample area 4 to be tested in the upper half 13 of the powder sample holder is filled with powder samples; cover 12 on the powder sample holder The inner surface of the 1000-mesh stainless steel mesh is glued, and the upper half 13 of the powder sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com