Manufacture method for membrane resistance thermometer

A manufacturing method and technology of thin film resistors, applied in the application of thermometers, thermometers, thermometers with directly sensitive electrical/magnetic components, etc., can solve problems such as inconsistency, increased width, and thin film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

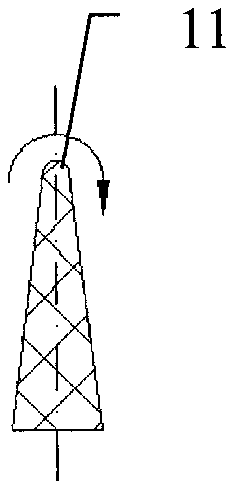

[0032] (1) Use acetone to clean the borosilicate glass substrate with a sharp front edge shape, and clean the glass substrate again by ion bombardment in the coating machine, and the ion bombardment time is 20 minutes. The shape of the glass substrate is shown in Figure 1, including a pointed front edge 11; the radius of the pointed front edge ranges from 1 mm to 5 mm. The length direction of the leading edge is along the cylindrical axis of the tip of the leading edge, such as Figure 1a Arrow direction shown. The circumferential direction of the leading edge is along the circular arc direction of the cylinder, such as Figure 1b Arrow direction shown. The pointed front edge is used to simulate the stagnation point of the pointed front edge of the aircraft.

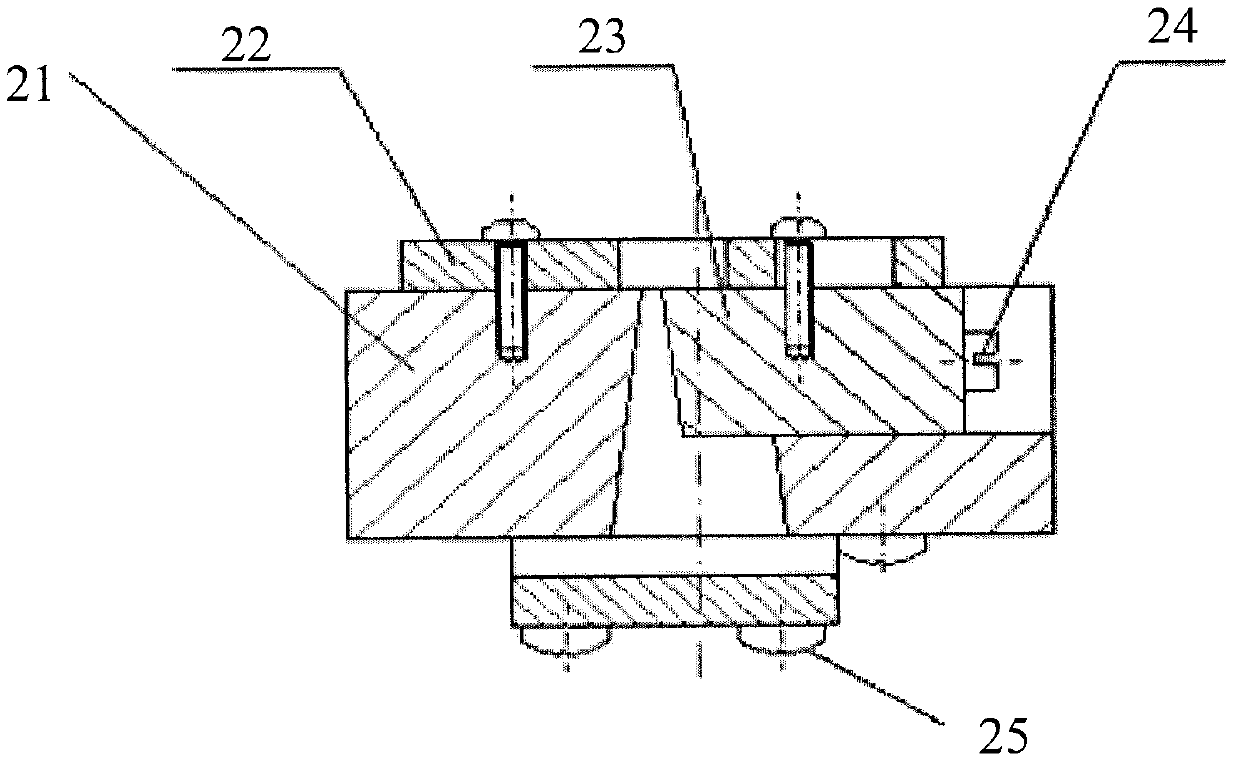

[0033] (2) Mount the glass substrate in the coating fixture. The structure of the coating fixture is shown in FIG. 2, including a base 21, a pressing plate 22, a bayonet 23, a side adjustable screw 24, and a bottom adjusta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com