Low-temperature swing adsorption device

A technology of pressure swing adsorption and low temperature, which is applied to the device of desorption kinetics and thermodynamic parameters, and measures the adsorption field of gas on the adsorbent. It can solve the problems of long time to reach adsorption equilibrium, low nitrogen adsorption rate, and large diffusion resistance. , to achieve the effect of high accuracy, convenient application and small random error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

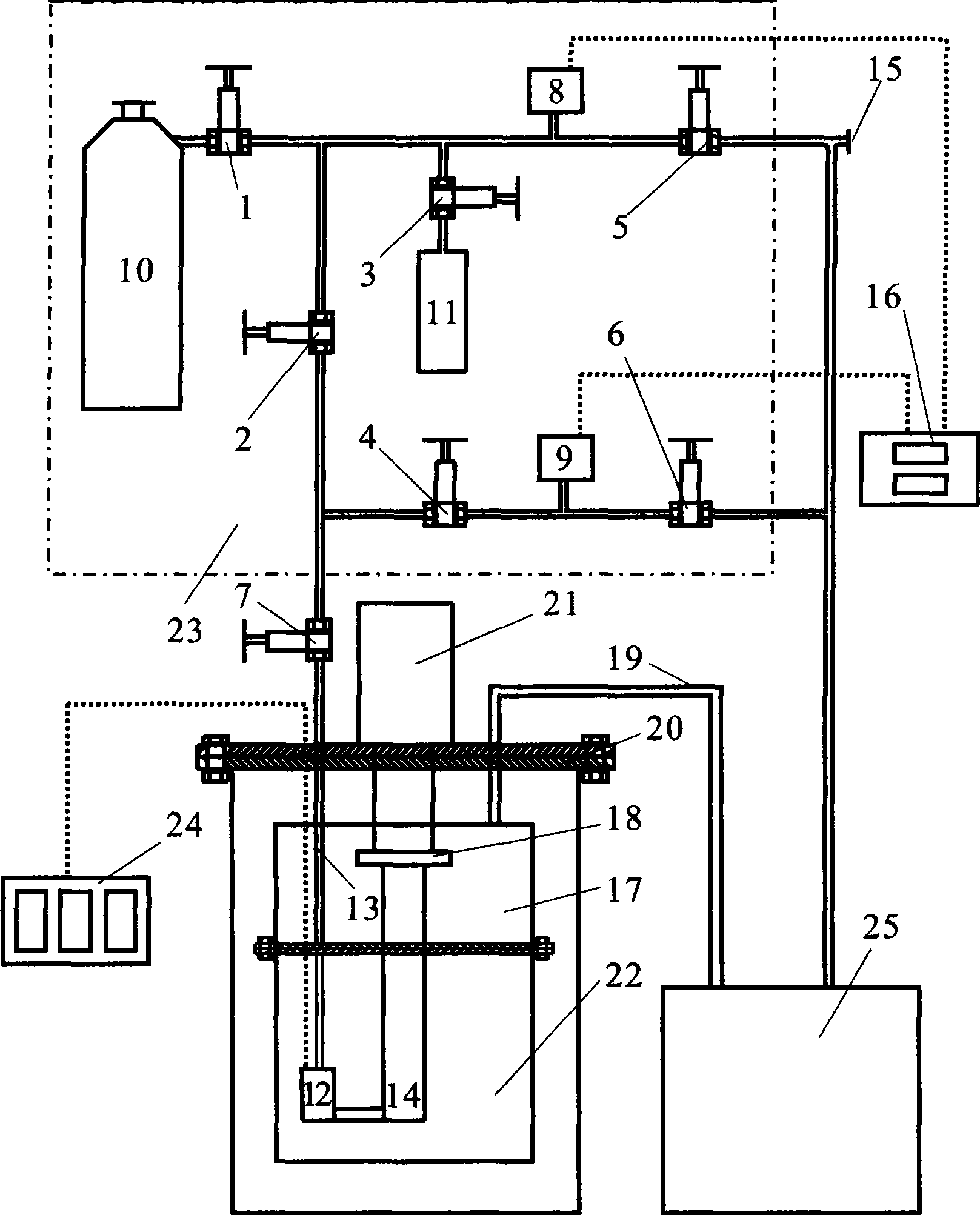

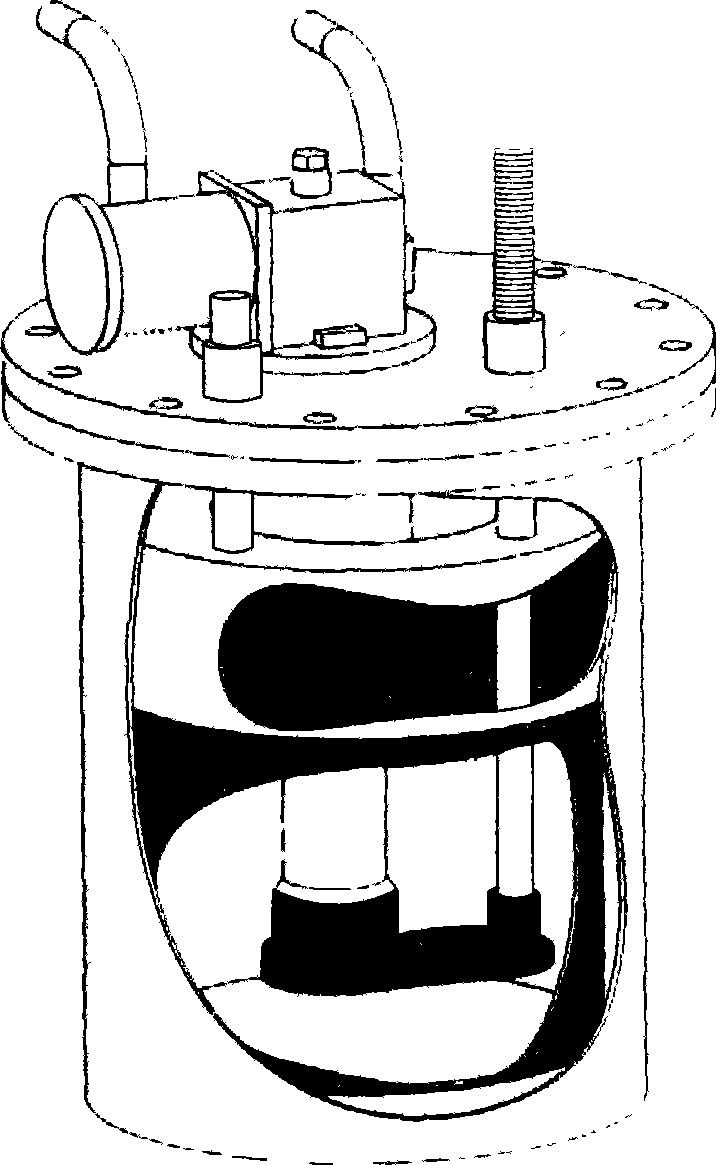

[0022] figure 1 It is a schematic diagram of the structure of the adsorption measurement device of the present invention. The 4.2KG-M low-temperature refrigerator is used as the cold source, and the first-stage cold head 18 and the second-stage cold head 14 that output the cooling capacity are sealed and set in the stainless steel cavity to ensure sufficient low temperature for the gas measurement and control pipeline. figure 2 It is a three-dimensional view of the structure of the vacuum cavity. The cavity is divided into inner and outer layers. The outer cavity is made of non-magnetic stainless steel and polished internally; the inner cavity is divided into upper and lower sections, and the upper section is made of stainless steel. Annular cavity 17, which can Liquid nitrogen is loaded to assist refrigeration; the lower section is made of copper, which becomes a cold screen and conducts the cooling capacity of liquid nitrogen downward. The contact surfaces of the two are c...

Embodiment 2

[0034] The standard volumetric method is used to measure the surface parameters of porous materials, such as figure 1 As shown, the volume of the reference cell (the carrier gas pipeline above the valve 7) is 21.63ml, placed in a room temperature environment, and try to keep the room temperature constant; the volume of the adsorption chamber 12 is 5.34ml, which contains the adsorbent that needs to be detected. In order to overcome the influence of temperature changes on the pressure sensor in the room temperature environment, thereby affecting the entire experimental data, the changes in room temperature are recorded in real time, and the influence of temperature on pressure is corrected through the actual gas state equation. The refrigerator 21 provides cooling capacity to the adsorption chamber 12, and the temperature fluctuation range is less than 0.1K in a steady state.

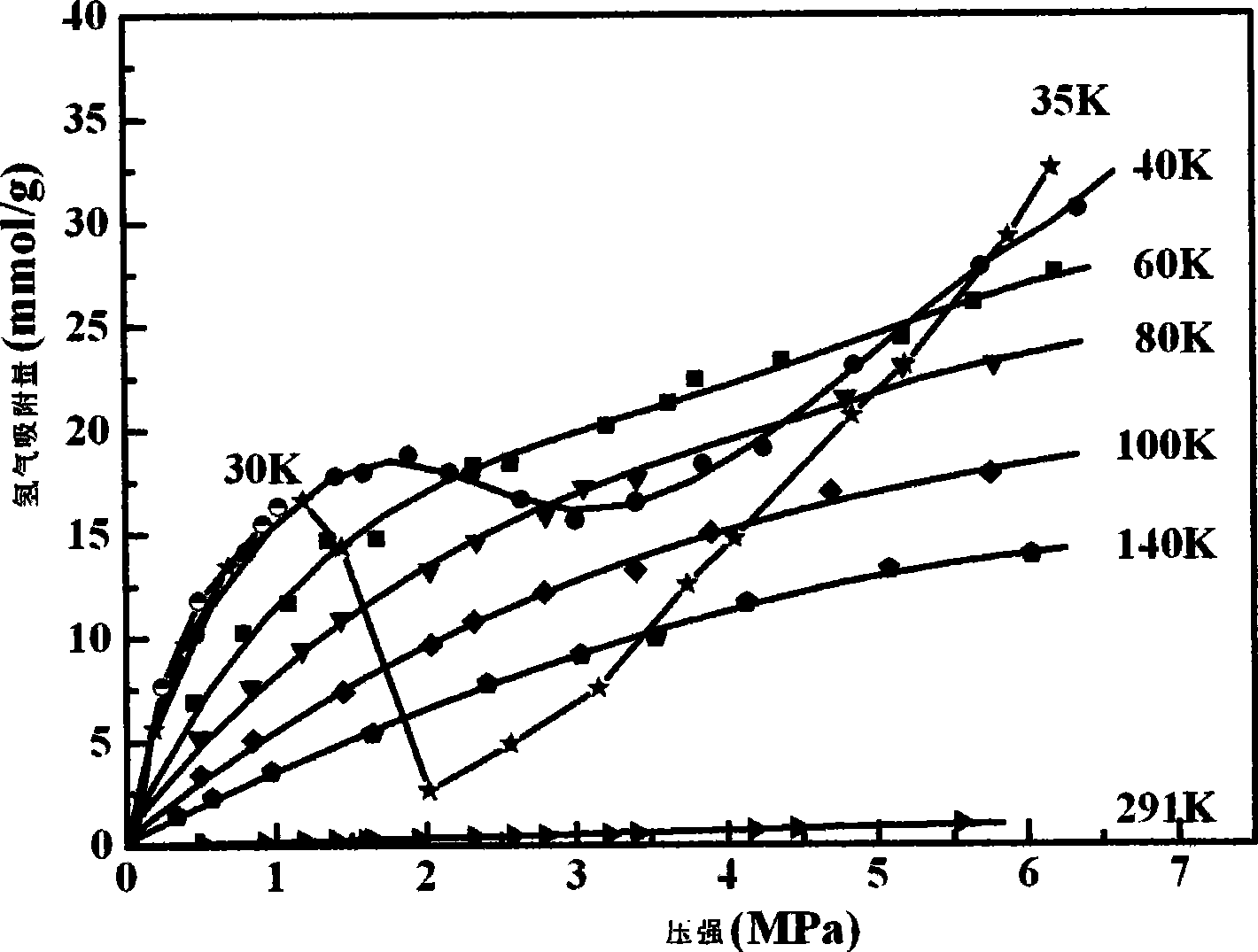

[0035] The adsorption chamber 12 in the present embodiment is equipped with an appropriate amount of u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com