Method for measuring temperature of test piece in thermo-electric-force coupling test system

A test system and temperature measurement technology, which is applied to thermometers, thermometers, and measuring devices that use directly heat-sensitive electric/magnetic elements, can solve the problems of inconvenient data recording, high cost of measuring instruments, and large measurement errors. The effect of simple structure, low price and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

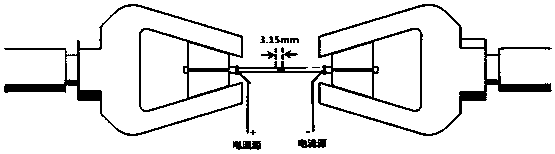

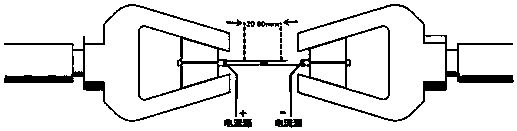

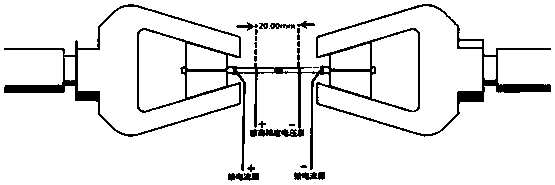

[0021] This embodiment is a method for measuring the temperature of a test piece used in a thermal-electrical-mechanical coupling test system.

[0022] The present invention proposes a method for measuring the temperature of a test piece used in a thermal-electricity-force coupling test system. The basic principle is to measure the resistance of the conductor at a certain temperature according to the change curve of the conductor resistance with temperature, and inversely deduce the temperature of the test piece. temperature. Since the test piece is welded by two oxygen-free copper rods, the resistance of copper changes obviously with temperature. In the manufacturing industry, copper is also used as the probe of the thermal resistance thermometer, and there is a more accurate empirical formula for calibration, so The test method that directly detects the voltage drop of the test piece and calculates the resistance and then deduces the temperature of the test piece has higher ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com