Manufacturing method of micro measuring electrode, measuring method of thermoelectrical potential and related device

A technology for measuring electrodes and manufacturing methods, applied in measuring devices, measuring electrical variables, measuring current/voltage, etc., can solve the problems of sample contamination, failure to reflect the intrinsic properties of samples, and long sample preparation cycle, so as to improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] figure 1 A first embodiment of the present invention is shown.

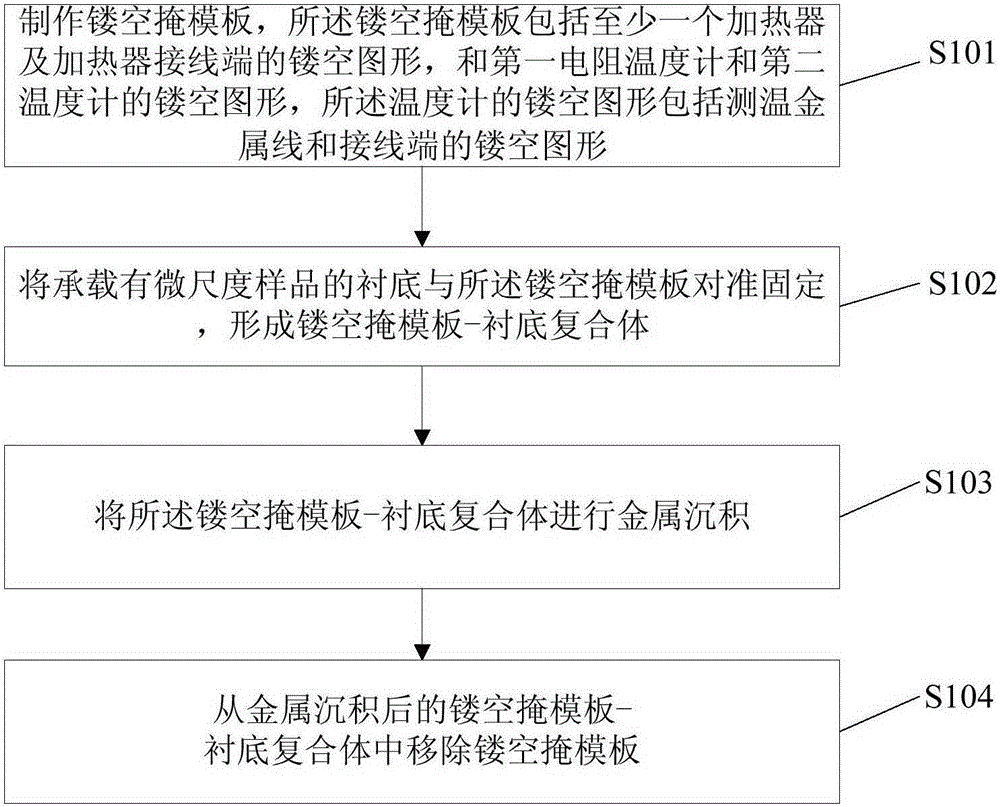

[0040] figure 1 It is a schematic flow chart of the manufacturing method of the micro-measurement electrode provided in this embodiment. refer to figure 1 , 2 , image 3 and Figure 4 , the fabrication method of the micro measuring electrode, comprising:

[0041] Step S101, making a hollowed out mask, the hollowed out mask includes at least one heater and a hollowed out pattern of the heater terminal, and a hollowed out pattern of a first resistance thermometer and a second thermometer, and the hollowed out pattern of the thermometer includes a temperature measuring metal wire And the hollowed-out graphics of the terminals.

[0042] The hollow mask is as image 3 as shown, image 3 is a schematic diagram of the hollowed-out pattern structure of the hollowed-out mask, which is composed of image 3It can be seen that the hollowed out mask includes at least one heater 1 and the hollowed out pattern ...

Embodiment 2

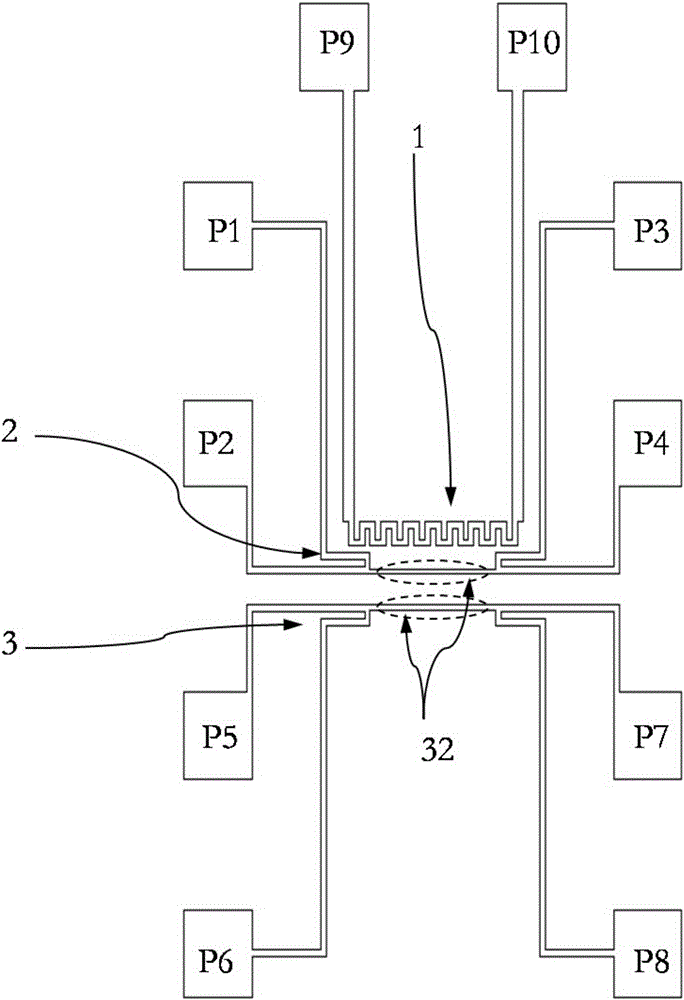

[0052] This embodiment provides a measuring device for thermoelectric potential of a microscale sample. see Figure 5 and Image 6 , Figure 5 is a structural schematic diagram of a measuring device for thermoelectric potential of a microscale sample; Image 6 It is a schematic diagram of the structure of the temperature-changing sample stage in the measuring device of the thermoelectric potential of the micro-scale sample. The device for measuring the thermoelectric potential of a micro-scale sample includes: the micro-measurement electrode and the temperature-variable sample stage 4, the vacuum chamber 5, the measurement circuit, the temperature controller 6, the calibration thermometer 10 and the thermometer head 7 produced by the first embodiment. The variable temperature sample stage 4 is placed in the vacuum chamber 5. The variable temperature sample stage 4 includes a sample holder 12, a sample holder electrical terminal 11, a sample holder thermometer terminal 31, a...

Embodiment 3

[0061] Figure 8 A third embodiment of the present invention is shown.

[0062] Figure 8 It is a schematic flow chart of the method for measuring thermoelectric potential of micro-scale samples provided in the third embodiment of the present invention. This method uses the measuring device for measuring thermoelectric potential of micro-scale samples provided in the second embodiment.

[0063] see Figure 8 , 9 And 10, the measuring method of described micro-scale sample thermoelectric potential comprises:

[0064] In step S301, a calibration thermometer is fixed on the surface of the substrate on which the micro-measurement electrodes are fabricated, and the substrate is placed on the sample seat of the variable temperature sample stage.

[0065] In this embodiment, a group of T-type thermocouples is used as a calibration thermometer, and a group of T-type thermocouples are fixed with silver glue on the surface of the substrate on which micro-measurement electrodes are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com