Hydrophobic lipophilic soft aerogel block and preparation method thereof

A hydrophobic, lipophilic and aerogel technology, which is applied in the field of aerogels, can solve the problems of long preparation time and achieve the effects of simple preparation process, good hydrophobic effect and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

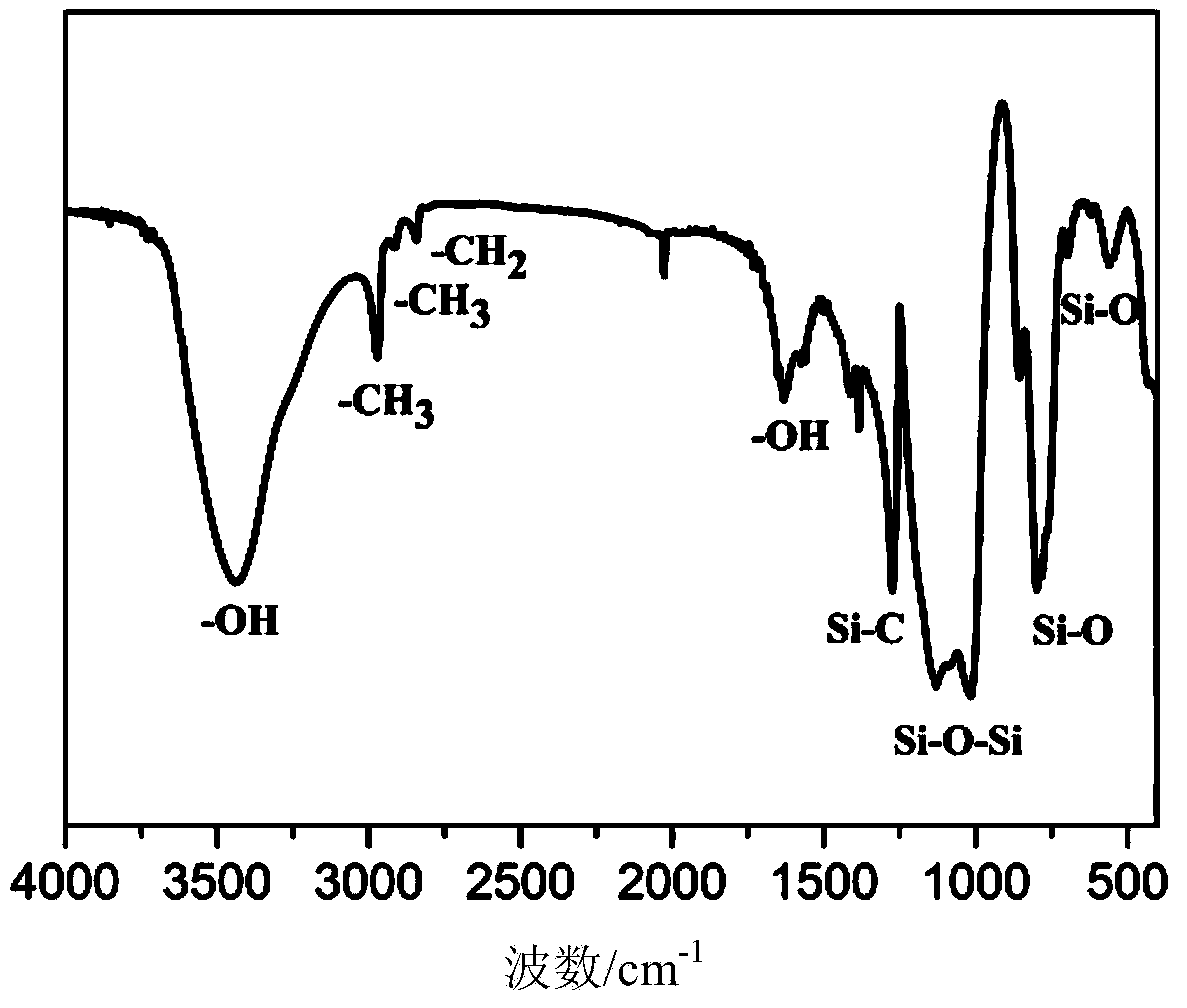

[0027] At room temperature, mix methyltriethoxysilane: dimethyldiethoxysilane: ethanol: deionized water in a molar ratio of 0.6:0.4:2:6 in a container, and add 1.4g of surfactant hexadecane at the same time Base trimethylammonium bromide CTAB, put the mixed solution on a stirrer and stir evenly. Add dropwise 1.12ml of hydrochloric acid with a molar concentration of 0.1mol / L to the mixed solution to promote hydrolysis. After stirring for 2 hours, 12 ml of ammonia water with a molar concentration of 5 mol / L was added dropwise, and after stirring for 10 minutes, the solution was poured into an airtight container and gelled at room temperature. Add ethanol to cover the wet gel, and replace the ethanol every 8h to remove the surfactant in the gel. After aging at room temperature for 2 days, the obtained wet gel was placed in an autoclave for supercritical fluid drying to obtain a co-precursor hydrophobic, lipophilic and soft airgel block.

[0028] The density of the prepared airg...

Embodiment 2

[0030] At room temperature, mix methyltriethoxysilane: dimethyldiethoxysilane: ethanol: deionized water in a molar ratio of 0.5:0.5:2:6 in a container, and add 1.3g of surfactant hexadecane at the same time Base trimethylammonium bromide CTAB, put the mixed solution on a stirrer and stir evenly. Add dropwise 1.4ml of dilute acetic acid with a molar concentration of 0.1mol / L to the mixed solution to promote hydrolysis. After stirring for 8 hours, 11 ml of ammonia water with a molar concentration of 5 mol / L was added dropwise, and after stirring for 10 minutes, the solution was poured into a closed container and gelled at room temperature. Add ethanol to cover the wet gel, and replace the ethanol every 8h to remove the surfactant in the gel. After aging at room temperature for 2 days, the obtained wet gel was placed in an autoclave for supercritical fluid drying to obtain a co-precursor hydrophobic, lipophilic and soft airgel block.

[0031] The density of the prepared airgel ...

Embodiment 3

[0033] At room temperature, mix methyltriethoxysilane: dimethyldiethoxysilane: methanol: deionized water in a molar ratio of 0.6:0.4:2:6 in a container, and add 1g of surfactant hexadecyl at the same time Trimethylammonium chloride CTAC, put the mixed solution on a stirrer and stir evenly. Add 1.5 ml of hydrochloric acid with a molar concentration of 0.1 mol / L dropwise to the mixed solution to promote hydrolysis. After stirring for 24 hours, 10 ml of ammonia water with a molar concentration of 5 mol / L was added dropwise, and after stirring for 10 minutes, the solution was poured into a closed container and gelled at room temperature. Add methanol to cover the wet gel, and replace the methanol every 8h to remove the surfactant in the gel. After aging at room temperature for 2 days, the obtained wet gel was placed in an autoclave for supercritical fluid drying to obtain a co-precursor hydrophobic, lipophilic and soft airgel block.

[0034] The density of the prepared airgel bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com